Power Cube/Manufacturing Instructions/Fabrication June 2011

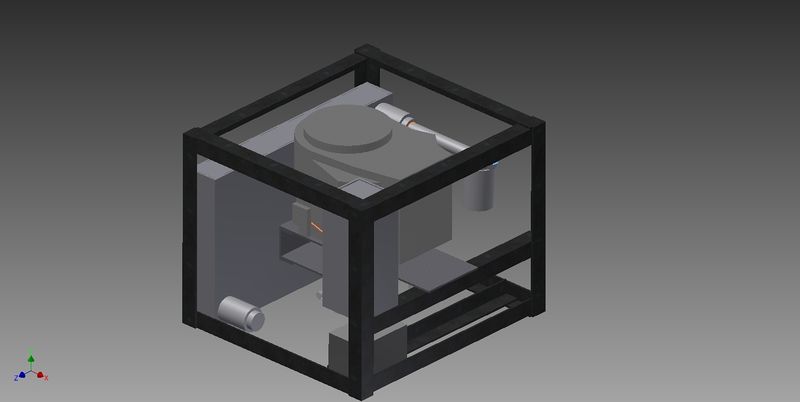

Power Cube 4.0 Construction

Here's how to replicate our Powercube 4.0 design. Keep in mind that this the powercube is still at the prototype stages and designs are likely to change. There's also a few fittings /wires that are not reflected in this design. Aside from that, there should be enough information here to construct your very own OSE PowerCube 4.0!

All designs, CAD drawings, media and documentation are mirrored on OpenPario.

BOM

| Name | Quantity | Dimensions |

| ENGINE ASSEMBLY | 1 | |

| Engine | 1 | |

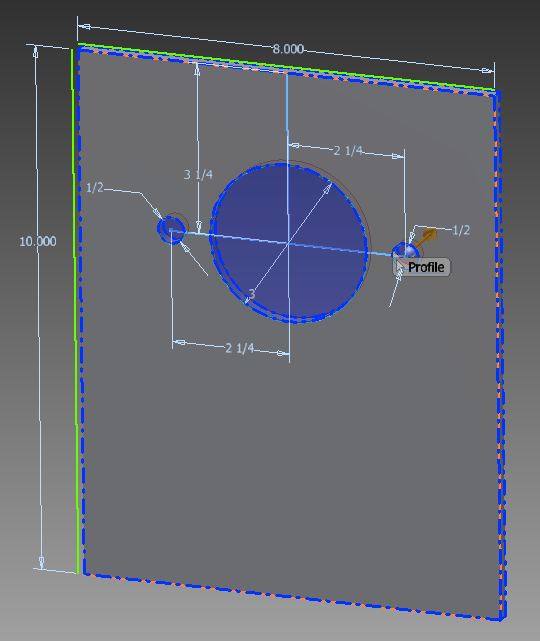

| Mounting Plate - Hydraulic Motor | 1 | 8"x10"x1/4" |

| Connector Plate | 1 | 8"x3.75"x1/4" |

| Mounting Angle | 2 | 8"x(2"x1/4") |

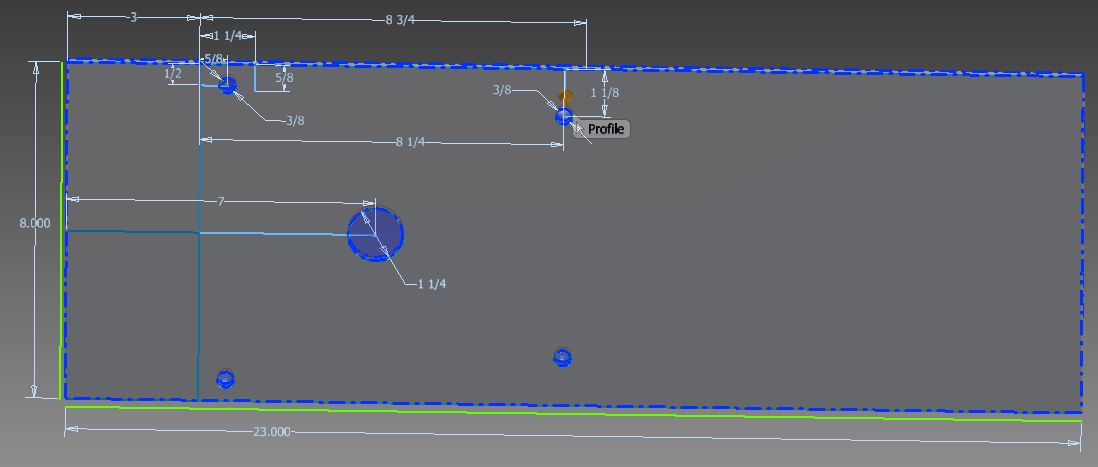

| Engine Mount Plate | 1 | 8"x23"x1/4" |

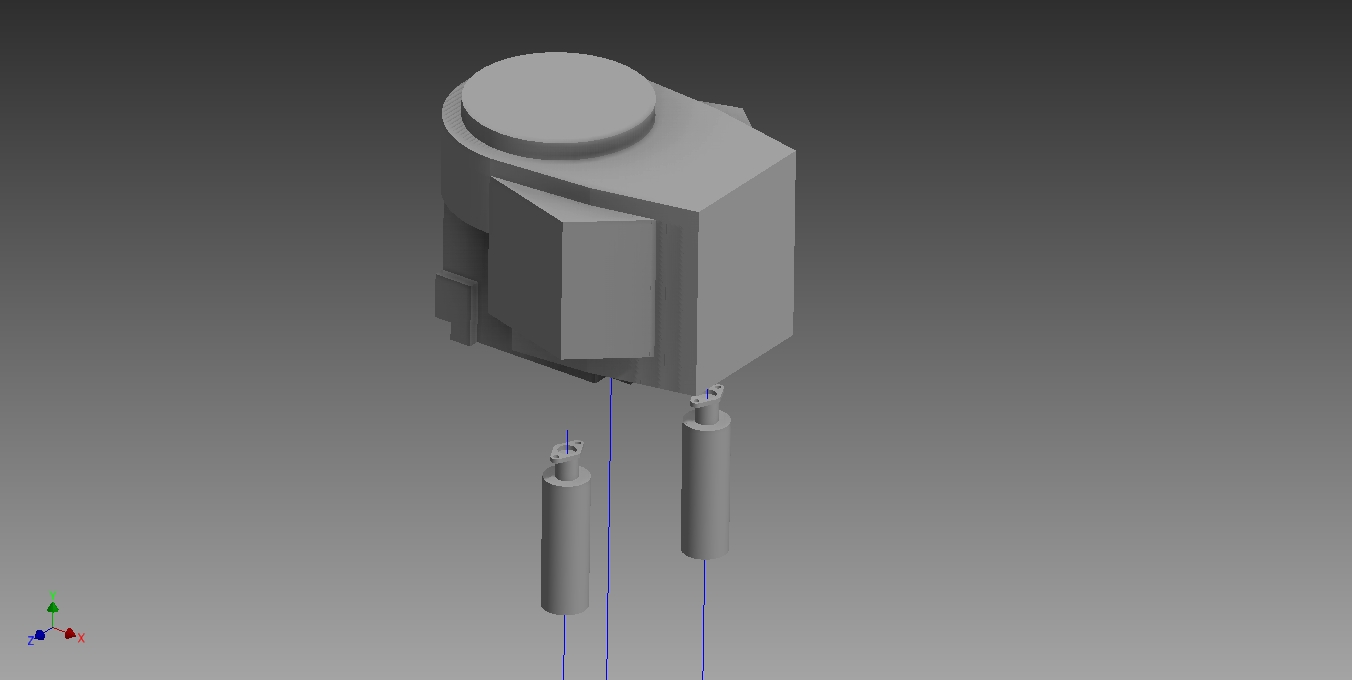

| Lovejoy Coupler | 1 | 2.5"x2.25" |

| Hydraulic Motor | 1 | |

| Gas Tank | 1 | 14"x6"x6" |

| FUEL FILTER ASSEMBLY | 1 | |

| Fuel Filter Fitting | 1 | |

| Fuel Filter | 1 | 3.5"x5" |

| FRAME ASSEMBLY | 1 | 24"x27.5"x30" |

| 24" Angle | 4 | 24"x(2"x1/4") |

| 27" Angle | 4 | 27"x(2"x1/4") |

| 29" Angle | 6 | 29"x(2"x1/4") |

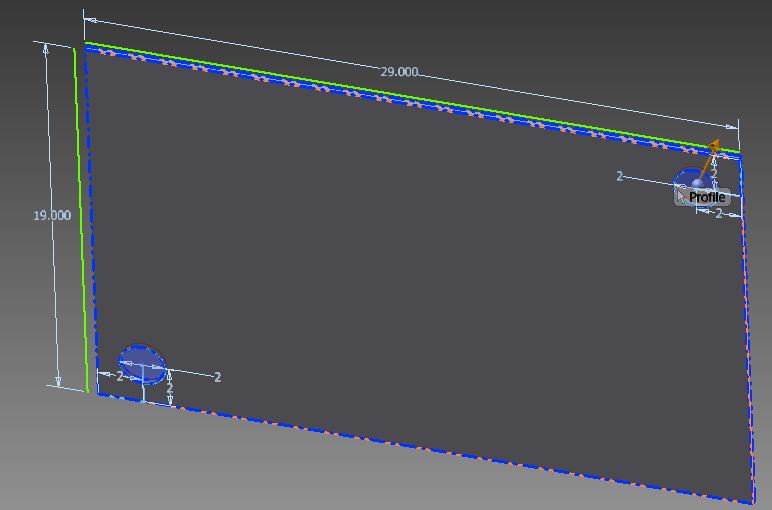

| HYDRAULIC TANK ASSEMBLY | 1 | 19"x29"x4" |

| Hydraulic Tank Plates | 2 | 19"x29"x1/4" |

| Flat - Hydraulic Sides | 2 | 19"x3.5"x1/4" |

| Flat - Hydraulic Bottom/Top | 2 | 3.5"x28.5"x1/4" |

| Battery | 1 | 5"x6"x7.5" |

| Hydraulic Mount | 2 | 4.75"x3" |

Total Metal to Purchase (summary)

| Type | Width | Thickness | Total Length (rounded up) |

| Angle | 2" | 1/4" | 400" |

| Plate | 19" | 1/4" | 60" |

| Plate | 8" | 1/4" | 40" |

| Plate | 6" | 1/4" | 12" |

| Plate | 3.5" | 1/4" | 100" |

| Tube | 6" | 1/4" | 14" |

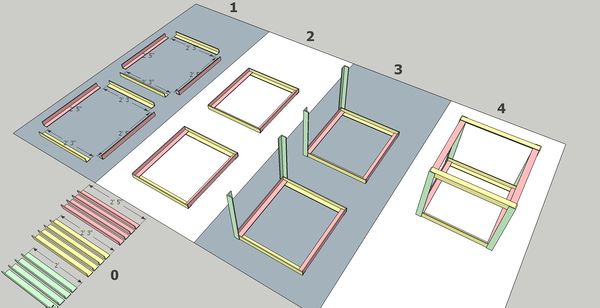

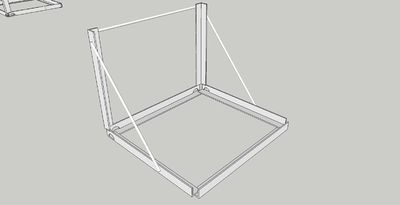

Frame

The Power Cube 4.0 (as of this prototype at least) is not actually a strict cube. But more of a lopsided box.) The longest dimensions are on the side (left to right), while the shortest dimension is up/down. See below.

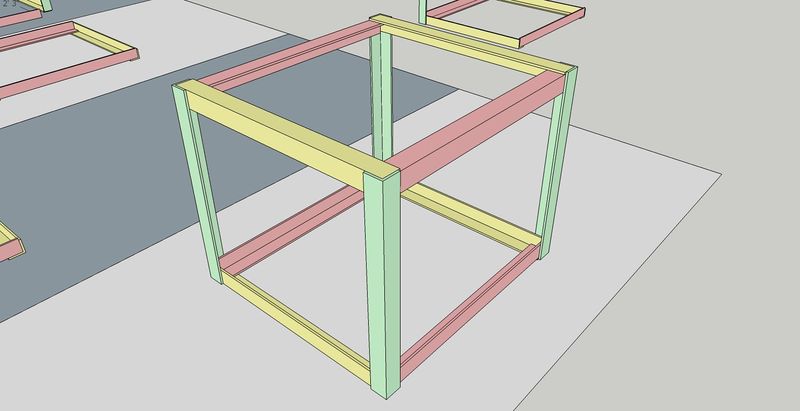

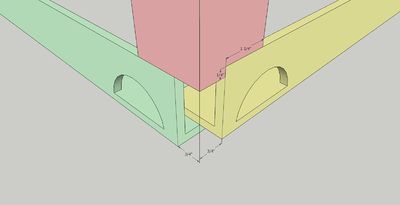

The frame is assembled in halves, and tack/welded in place. A completed frame should look like like this.

Note the overlap order. Short angles (green) on the outside.

Assuming everything goes well on the welding, you should have your very own OSE PowerCube 4.0 Frame!

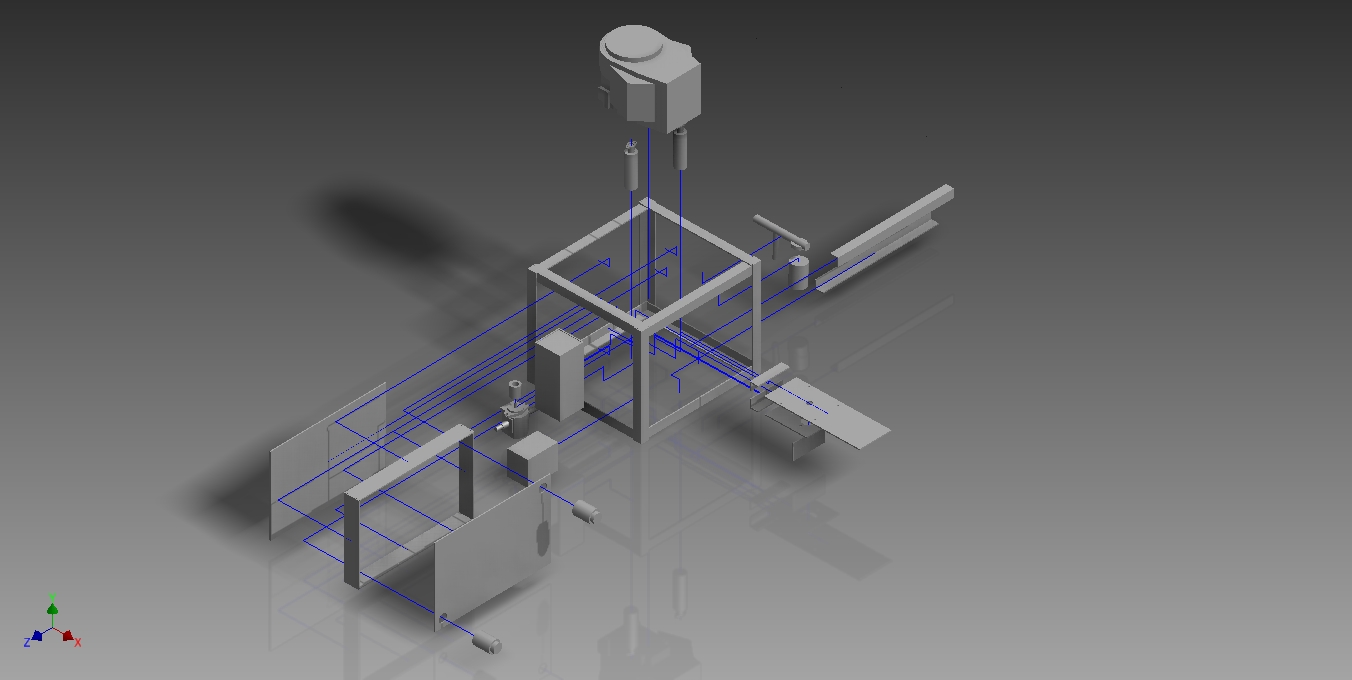

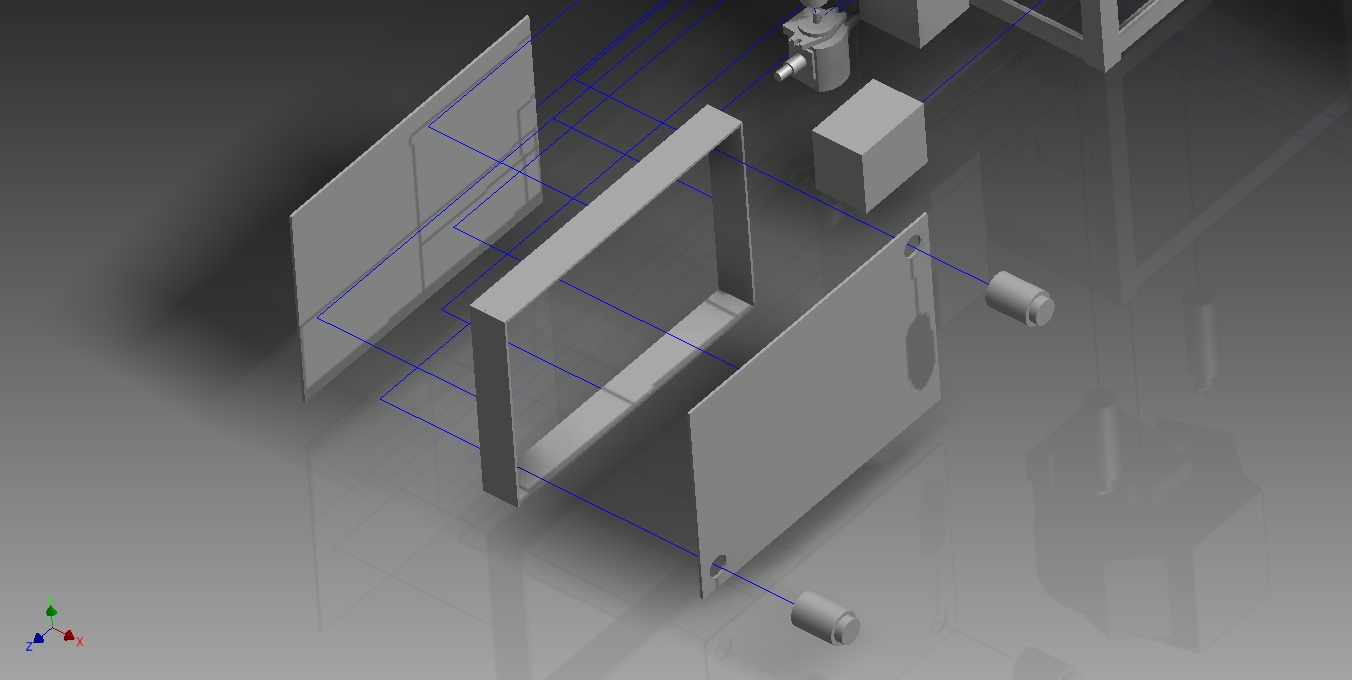

Assembly

The open frame of the power cube makes assembly a snap. Just slide pieces into place, tack and weld away. Later designs will likely feature a little less intensive welding, but for now, it is a solid construction technique.

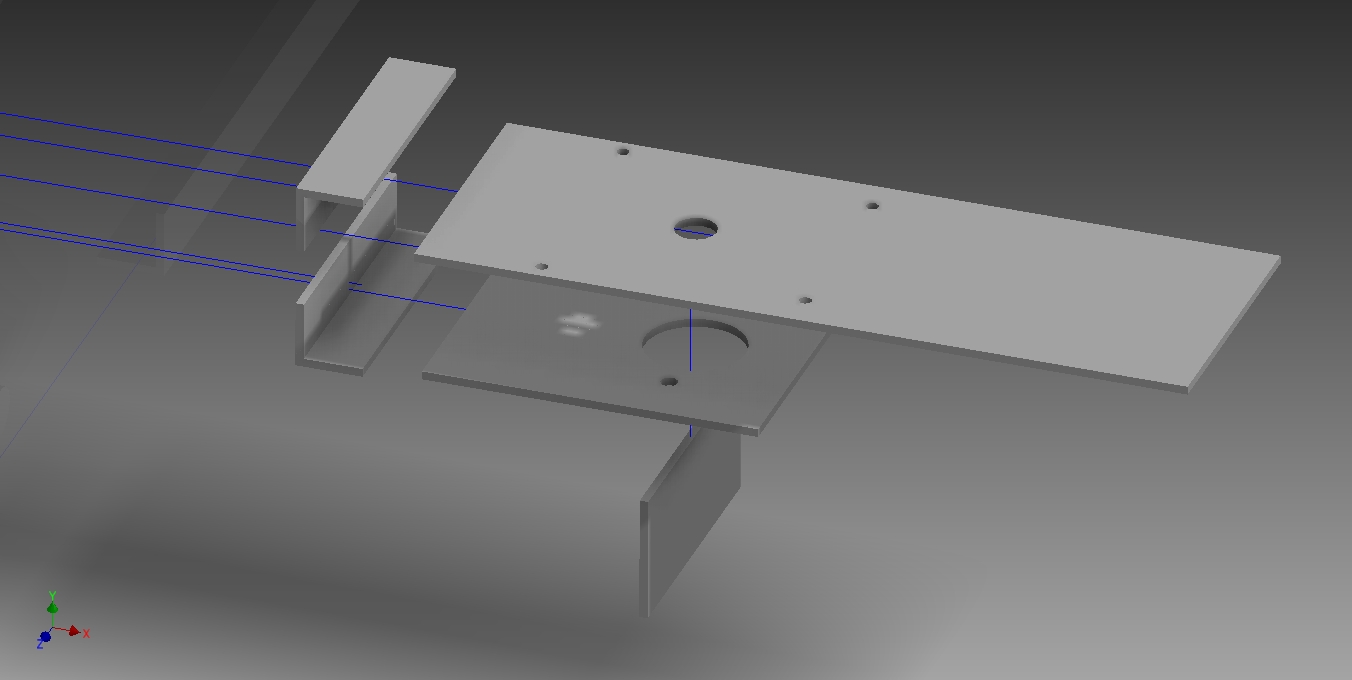

Mounting Assembly

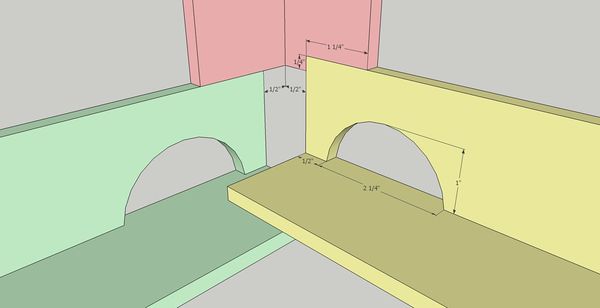

Hydraulic Tank Assembly

Lay out a plate, tack and weld the 3.5" wide pieces vertically in a box shape atop it. Then lay the top plate atop and weld it in place.

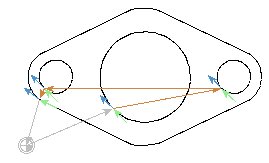

Torch out holes in the top plate in the corners. 2" holes with the center 2"x2" offset from the sides

This would be a good time to break out the soap bubbles and test for leaks on the weld. Assuming the tank is tight, go ahead and move it on into the frame and weld it in place. Spacers may be needed on the sides near the top to keep everything snug.

Final

Mount the hydraulic fittings, hydraulic motor, gas tank, battery and wires. Finish it up to complete your very own OSE Powercube 4.0!

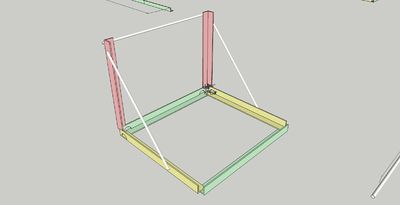

Jig (optional)

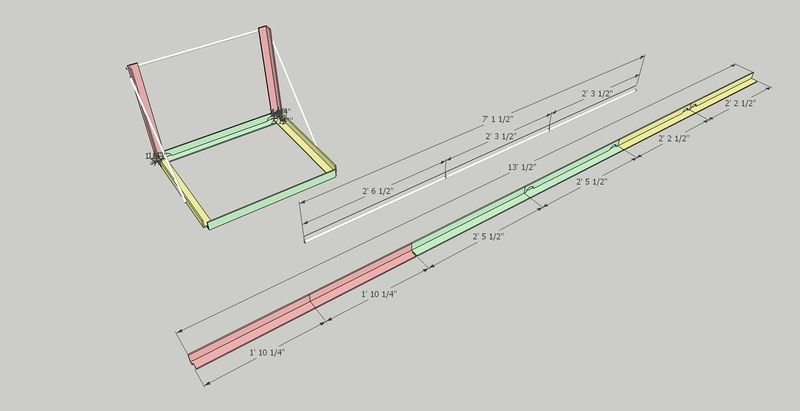

The jig is an optional piece of fabrication equipment that can be very useful to have should you be creating several power cubes concurrently. The materials for the cube are assembled in the jig in half sections and tacked and welded in place.

Materials List

Total Length 14' Angle (2"x1/4") 7'2" Rebar (1/2")

Cut List

| Type | Length | Dimensions | Quantity | Color |

| Angle | 22" | (2"x1/4") | 2 | (red) |

| Angle | 26" | (2"x1/4") | 2 | (yellow) |

| Angle | 29" | (2"x1/4") | 2 | (green) |

| Rebar | 30.5" | (1/2") | 1 | |

| Rebar | 27" | (1/2") | 2 |

Assembly of the Jig is fairly straight forward. Tack and weld the pieces in place.

Be sure to note the overlapping order and the notch made at the bottom of the 1'10 1/4" piece (red). Torch holes in the corners below the frame as seen above. This allows room for the welding torch to get to the PowerCube while welding.

Also note that the corners are offset 3/4" (1/2" measured on the interior), to give room for the cube to sit snugly in the frame (and a convenient gap for welding the corners.)

Tack weld the two shorter rebar sections at roughly a 45 degree angle on the sides. Add a long rebar section to span the gap. Precision is not as important with these, they are more there for stability.

With any luck, you'll have your jig, ready to crank out Power Cubes with!

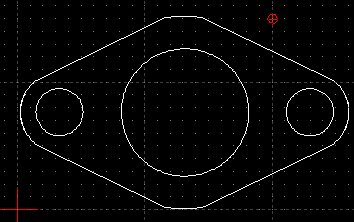

Muffler

Muffler Mound CAD

In QCad:

Uploaded to Open Pario - [1]

CAM file from DXF to G-code Converter:

Uploaded to Open Pario - [2]