Product structure modeling

Introduction

Product structure [modeling] is a hierarchical decomposition of a product, typically known as the Bill of Materials (BOM).—Wikipedia, [1]

Bill of Materials[2]

BOMs are of hierarchical nature, with the top level representing the finished product which may be a sub-assembly or a completed item. BOMs that describe the sub-assemblies are referred to as modular BOMs.

A bill of materials "implosion" links component pieces to a major assembly, while a bill of materials "explosion" breaks apart each assembly or sub-assembly into its component parts.

A modular BOM can be displayed in the following formats:

- A single-level BOM that displays the assembly or sub-assembly with only one level of children. Thus it displays the components directly needed to make the assembly or sub-assembly.

- An indented BOM that displays the highest-level item closest to the left margin and the components used in that item indented more to the right.

- Modular (planning) BOM

Domain Theory

Domain Theory is a systems approach for the analysis and synthesis of products. Its basic idea is to view a product as systems of activities, organs and parts and to define structure, elements, behaviour and function in these domain.

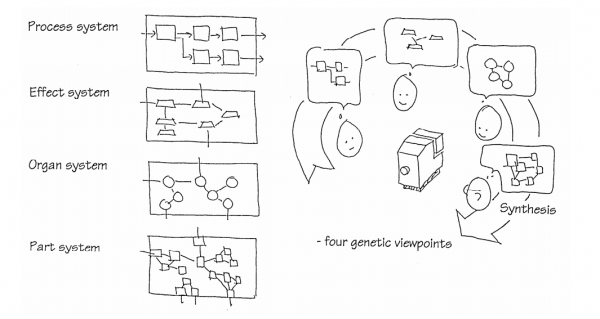

According to Domain Theory, a product is seen from four system point of views:[4]

- A process view, where the transformation of materials, energy, and information of the product related to its use or function is central. This viewpoint lead to description of a process structure.

- An effect view, where the desired functions or effects are in focus. These effects must be able to facilitate the necessary transformations. This viewpoint is related to an effect / function structure.

- An organ view, where the technical principles or means of the product are in focus. These principles or solutions are called organs (or function carriers) and by their functionality they create the desired effects. The result of design considerations is an organ structure.

- A part view (or assembly view), where the machine parts of the products are in focus. By determining material, form, tolerances and surface quality of each part and relations between the parts, the necessary conditions for the organs and their functionality are created.

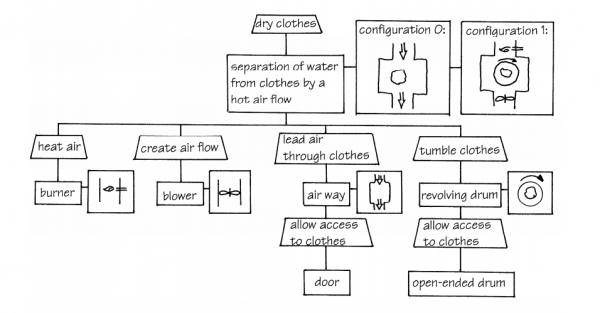

Function-oriented decomposition[4]

Each of the four structural views indicates possible ways of decomposing a product or product assortment. Functional decomposition seems to be the core of decomposition because it can be argued that functionality is the most important property of a product, i.e. if the product does not possesses right functions then other properties are uninteresting. [4]

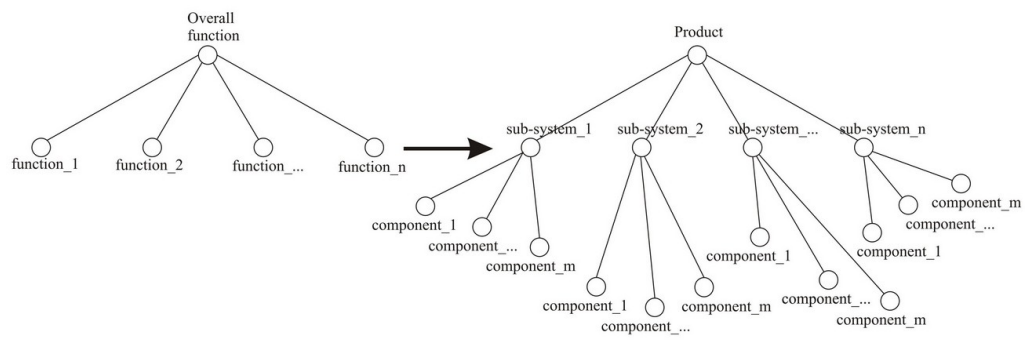

Product-Function-Component tree[5]

Product-Function-Component tree is rooted with product on the top of the tree, and then a merge of functions to next tree-level is made. Since in this stage we know nothing about product sub-systems or subassemblies, i.e. we know nothing about product’s component structure we assign functions to the second-tree level so they will substitute product’s subsystems. Assumption made here is that a product can be broken down into subassemblies corresponding to the functions of the technical system. According to this, Product-Function-Component tree is created by merging two dependant tree structures.

Functional Decomposition Diagrams[6]

Typically, functional decomposition is used during the project analysis phase to create functional decomposition diagrams (FDDs), as part of requirements specification documents. However, it can also be used for smaller projects, to document the deliverables and to clarify whether the project is on the right track.

When dealing with functional decomposition, it pays off to have a good knowledge of some basic terms associated with it:

- Function – A function is a task expressed as a verb-noun phrase. Some examples of the functions of ATM machines are verb-noun phrases such as “reads cards,” “prints recipes,” or “allows for touch input.”

- Sub-function – Functions often have a hierarchical relationship. This means that certain functions require other functions to work in order to be executed. The required functions are sub-functions of a higher function.

- Decomposition – Decomposition is the process of breaking down something complex into smaller parts.

- FDD (functional decomposition diagram) – The individual functions and sub-functions of a process or system can be graphically displayed in a hierarchical order as a functional decomposition diagram, which shows how the various functions are organized.

How To Perform Functional Decomposition

When designing a system using the functional decomposition approach, start by identifying a single general function that best encapsulates the major objective. Try to avoid accidentally including secondary functions in the definition of the general function to keep the functional decomposition process as unrestricted as possible.

Keeping the general function in mind, proceed to find the closest sub-functions that must happen in order for the general function to take place. Think about how the sub-functions connect to the main function and note it down in a functional decomposition diagram.

Continue like this sub-function by sub-function, trying to find other required sub-functions. Repeat this until you’ve identified all required sub-functions. Finally, carefully check the resulting functional decomposition diagram for errors and inaccuracies.

Pros and Cons of Functional Decomposition

Like all business analysis techniques, even functional decomposition has its pros and cons. It’s necessary to be aware of them in order to accurately determine when it’s suitable to use functional decomposition and when another technique may be better.

Pros

- The simplicity of functional decomposition diagrams makes it very easy to understand complex systems.

- Knowing the exact functions and sub-functions that make up a system allows for more efficient organization and better planning.

- Each function can be treated as an individual unit, making it possible to localize problems at the atomic level.

- Makes it apparent which areas are more complex than other areas.

Cons

When performed correctly, functional decomposition doesn’t really have any downsides. However, there are numerous pitfalls that BAs tend to fall into when performing a functional decomposition analysis for the first time. These include:

- Either not going deep enough or going too deep when breaking down a system.

- Doing an unnecessary amount of work by creating everything from scratch instead of relying on templates.

- Excluding clients from the discussion.

See Also

- Wikipedia - Function–means tree

- Depth of Modularity

- Modular Breakdown

- Zachman Ontology

- How to Make a BOM

- Visual Bill of Materials

References

- ↑ Wikipedia - Product structure modeling

- ↑ Wikipedia - Bill of materials

- ↑ Andreasen, Mogens & Howard, Thomas & Bruun, Hans. (2014). Domain Theory, Its Models and Concepts. 10.1007/978-1-4471-6338-1_9.

- ↑ 4.0 4.1 4.2 Structuring as a basis for Product Modelling: Niels Henrik Mortensen, Claus Thorp Hansen

- ↑ Midžić, Ida et al. “CONTEXT-FREE GRAMMAR BASED RULES FOR COMPONENT-LEVEL PRODUCT STRUCTURE MODELLING.” (2010).

- ↑ The Relevance Of Functional Decomposition Diagrams