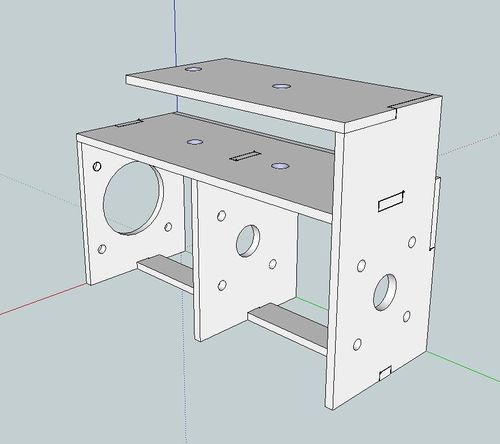

Quick Attach Wheel Module

This is work on redesigning the Quick Connect Wheel module for fabrication with the CNC Torch Table.

Update June 9, 2013

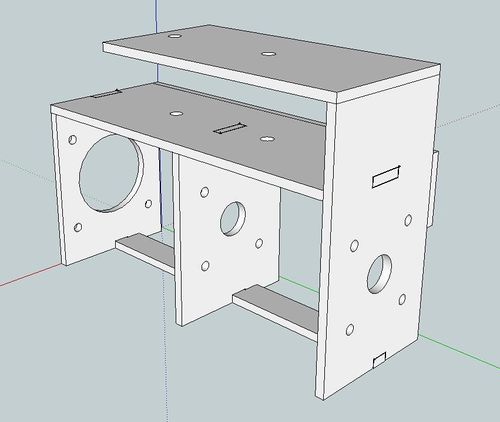

Changes: Added 1/2" extensions to bearing and motor mount plates to aid setup and alignment of rear reinforcement plate. Also created additional slot and tab features to top frame clamping plate to prevent improper orientation during assembly. Vertical bolt hole were increased to 1" diameter, while bearing and motor bolt holes were increased to 5/8" diameter to accommodate 9/16" bolts with adequate tolerance.

Concerns: Top frame clamping plate slot and tab feature adds center seam which will need to be adequately filled with weld material. Voids could result in stress concentration and fracture nucleation site accelerating fatigue failure.

--Justin Burnett (talk) 05:55, 10 June 2013 (CEST)

Update May 27, 2013

Source CAD File(SketchUp):File:Wheelmount - edited 5-26-13.skp

Notes: Added tongue and groove features to previous (February 3, 2012) quick attach wheel module assembly in order to increase manufacturability. Each slot is over sized by 1/32" in all dimensions while the mating tab is maintained at the chosen nominal value.

Concerns: Bolt hole sizes deviate slightly from those discussed during Design Sprint #3 on 5-26-13. These dimensions need to be confirmed.