Soil Preparation for CEB

It appears that Auroville Earth Institute is the only well-documented producer of stabilized CEBs - with a proven track record. They use a soil crusher, followed by a soil mixer.

Powell and Sons also have a soil mixer, but it is not clear what grade of soil is required for it. The missing step in the Powell and Sons route appears to be how you prepare soil that goes into the soil mixer in the first place. The result of the Powell and Sons soil mixer is cloddy in the video shown, so that by definition cannot have a good mixing of cement - unless they are not showing their best results.

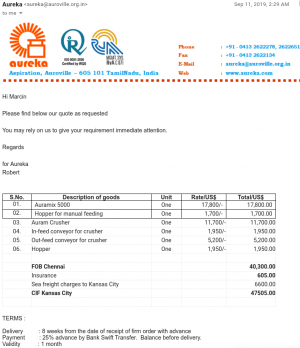

The OSE route is to use a hammermill to get a perfect mix. See design at Soil Mixer 2019. This actually combines 3 functions in one, in the usual style of OSE simplicity. The Auroville mixer only was $24k FOB Kansas City in 2019, so the combined soil prep equipment is $48k without tractor:

The OSE soil mixer costs about $3k in materials, and is fully automated for integration with the OSE CEB press. The 3 functions that the OSE Soil Mixer performs are:

- Soil crushing - Vigorous hammermill action breaks not only clods but also stones using a 3000 RPM rotor. The mix turns into a uniform powder.

- Cement dosing, mixing, and watering. Automated system takes care of this using a small electric auger timed by the microcontroller. This is the typical soil mixer/conditioner function.

- Soil Loading - by opening up a gate, contents of the hammer mill empty by inertia into the brick press by using a discharge chute or funnel. This is typically done by a conveyor, or by a tractor loader - which are eliminated by design in our process.

The OSE soil mixer has a large hopper and is loaded by a tractor. The CEB itself then doesn't need a large hopper. See Soil Mixer 2019 for more detail on the simplified OSE route.

Communication with Michael Altfield

Visiting Auroville. Questions to ask:

- What particle size of clay soil is considered finely enough pulverized for CEB stabilization? 6 mm? 1 mm? 0.1 mm? We plan on beginning to produce our soil mixer ilnext year, and to sell stabilized block.

- See Soil Mixer 2019 article and ask them for tech review.

- Connect me to any designers there who have open culture

- Document the practical side of their block production. Do they sell their block? What does their business.model look like for selling block?

- Ask them if they are open to collaboration on a workshop where we take the two machine sets (OSE + Auroville) and compare them side by side for workflow, cost, performance. This could be the greatest CEB workshop in the world.

- Document the labor requirements for a full stabilized CEB pressing operation. I'm counting from their 2 videos on the Auram Soil Crusher and Mixer/Brick Press - that there are 15 people involved in the overall operation if soil crushing and mixing/pressing is happening, and capital cost of $48k for crushign/mixing, not counting tractor . For OSE, we need 3 people for the overall brick pressing operation, and $3k in materials for the OSE Soil Mixer crushing/mixing machine - so 24x cheaper if you build it yourself. Next step is to build and test our full CEB pressing operation at Summer X 2020.

- What is the cost of their semiautomatic brick press? Auram CEB Press

Links

- Earth blender from Powell and Sons - http://www.adobemachine.com/peb/home.htm

- Soil mixer from Auroville - http://www.aureka.com/earth-construction-equipment/auramix-5000

- Before the soil is mixed, it is crushed with the Soil Crusher - http://www.aureka.com/earth-construction-equipment/auram-crusher

- Auroville Earth Institute website - [1]