Steam Cycle Integration

A solar powered turbine is a type of heat engine, and is based upon the thermodynamics of a gas cycling through higher pressures and temperatures to lower pressures and temperatures, doing work in the process. In reality, a physical apparatus is necessary for providing the pathway for our working gas (steam) to increase in temperature and pressure and then do work and return to a less energetic state and back up again.

Although it is possible to exhaust steam directly to the atmosphere, and let the boundless energy absorbing capacities of a vast atmosphere and planet dictate part of the cycle, this leads to large losses of energy, as the water returns as room temperature rather than at its temperature of condensation, and all the energy lost by the steam in reaching room temperature is absorbed by air currents rather than harnessed.

Thus, to harness as much of the solar energy originally absorbed, we look to a Closed loop system. Such a design handles the fluid from exhaust to a reservoir at Tc (the lowest temperature of the thermodynamic cycle) and up through preheating and regeneration to before the absorber, where Th (the highest temperature in the cycle) and working pressure are reached.

Also, in order to preserve energy for reuse in the system, pipe insulation should be used on all pipes outside the absorber.

Pipe Insulation

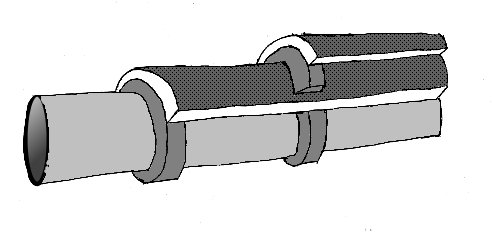

Ceramic cloth is being used for high temperature insulation of pipes in this system. The effectiveness of this cloth can be greatly increased by using airgaps with reflective barriers. here, thin strips of ceramic cloth leave air gaps, and then the pipe is wrapped with a full layer of ceramic cloth with aluminum foil (or a more resilient reflecting film) on the underside. Small tacks hold the layers of cloth to the cloth spacers below them.

In this picture of a two layer insulated pipe, the pipe is light grey, the strips of cloth used for spacers are dark grey, and the sheets of cloth are white and thacthed black/grey. The aluminum foil (not shown) is on the underside of the sheets of cloth inorder to reflect radiated heat back. Here, the layers are cut away so that the structure is more visible.

A similar arrangement (covering only 180 degrees of the pipe) could be used for the absorber tubes.

The step between preheated water ( greater than 100 degrees C but much less than Th) is accomplished by a Valve delivery system.