Steam Engine Build/Crank

Main > Energy > Steam Engine

Steam Engine Build Instructions

Description

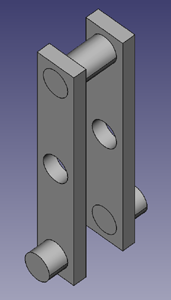

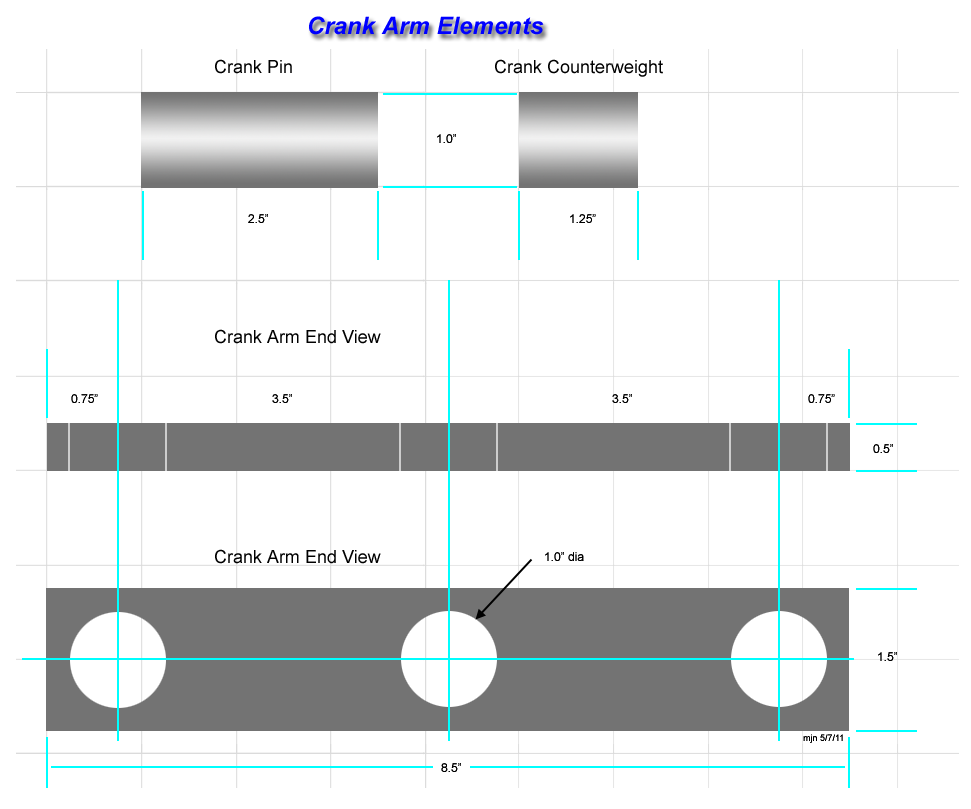

The Steam Engine Crank is part of the crankshaft assembly (see Steam Engine Design/Crankshaft. It provides an offset from the crankshaft center line to covert linear motion from the piston and piston connector rod to rotational motion. Because it is offset from the main drive shaft, the crank arm needs to be carefully balanced to avoid excessive vibration during operation. The design used here is a simple way to guarantee balanced weight on both sides of the shaft. The crank arm is completely symmetric with respect to the shaft. The weight of the crank pin is balanced by creating two pins and cutting it in half to form two counterweights.

The crank pin is designed to slip inside a hole in the crank arm and welded on the outside. It's length allows a half inch to be inserted into the crank arms, one inch for the piston connector rod bearing case, and two, 0.25 inch nylon bushings.

CAD

Drawings

Instructions

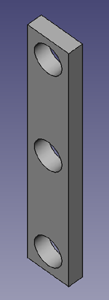

Crank Arms

- Cut two rectangles from half inch steel plate

- Drill three, one inch holes: one in the center, one at both ends 0.75" from the ends in each piece.

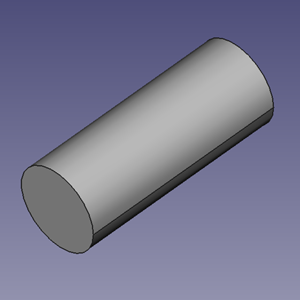

Crank Pin

- Cut a 2.5" length from a 1.0" OD steel shaft.

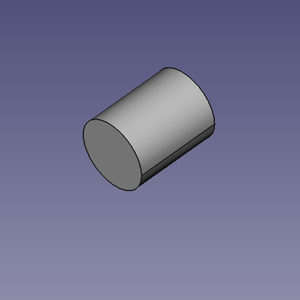

Crank Arm Counterweights

- Cut a 1.25" length from a 1.0" OD steel shaft.

- Cut it exactly in two pieces.

Crank Arm Assembly

- Slip a nylon bushing, the connector rod bearings, and a second nylon bushing onto the crank pin

- Slip the pin assembly into one side of the crank arm and weld ON THE OUTSIDE.

- Slip the other side of the crank arm and weld ON THE OUTSIDE taking care to make the second side exactly parallel to the first.

- Insert one counterweight into a crank arm side and weld.

- Insert the second counterweight on the other side and weld.