Troy Martz Gasifier

Basics

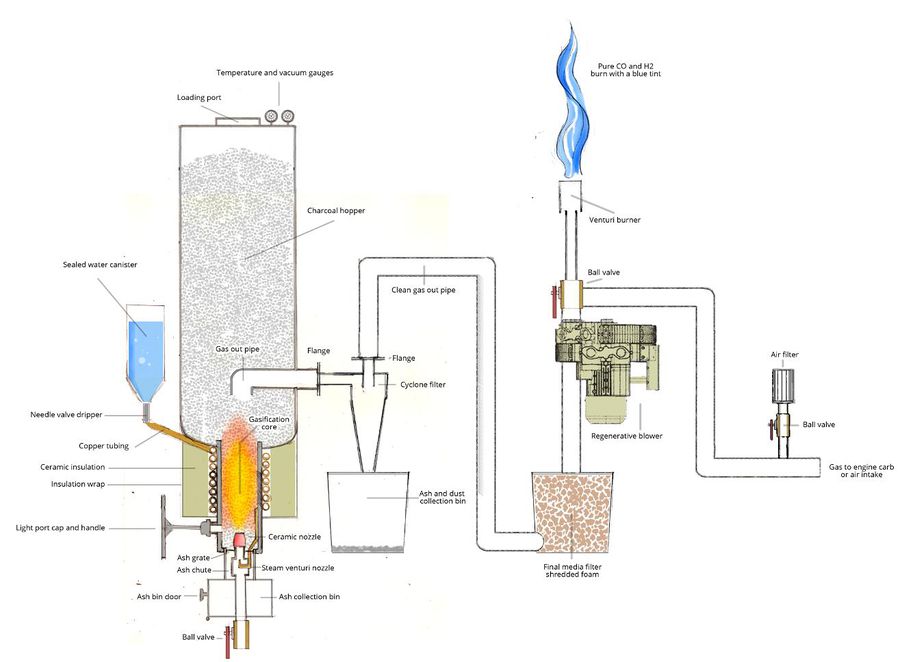

- An Updraft Gasifier designed to run on Charcoal

- Cyclonic and Packed Media Syngas Filtration

Concept

Images

Open Source Carburetor

Communications

Marcin,

My name is Troy Martz, and I am a long-time gasifier enthusiast, permaculturist, and natural farmer. I’ve built several gasifiers over the years, and recently started a new company, Off Grid Pro, to capitalize on all things “alternative energy” for the small guy.

I’ve been following OSE for several years now, and I wanted to reach out to you about a possible collaboration with us. I want to see if you have any interest in adopting our brand new charcoal gasifier… But first, let me give you a little background…

In the gasifier world, 95% of gasification enthusiasts consist of “biomass” guys – people who put wood chunks into a hopper, and press the “go” button. The other 5% are the charcoal guys – pure carbon. I started out as a biomass guy, spent a few year tinkering around, and then switch to charcoal after many problems. I’ll never go back…

There really isn’t a flame war here. It’s not like Mac vs. PC, or Internet Explorer vs. Netscape… Both camps exist peacefully, and exchange information. However, there are some arguments on which is better. Here are a few:

The biomass guys say:

· Charcoal has less BTU’s than biomass

· We don’t have to deal with breathing in charcoal dust/powder

· We don’t have to make charcoal to run our systems

The charcoal guys say (including me now):

· Sufficiently drying wood/biomass to an appropriate water content % takes days. Charcoal can be made and used in mere hours.

· The byproduct of charcoal sizing (anything under 1/16th of an inch) just happens to be perfectly sized for biochar… what a great byproduct to have J

· We don’t have to worry about tar! Thus, filtration in the down line is relegated to ash and dust… easily done.

· Pure carbon is a perfect catalyst for the reduction process… You never really get 100% there with biomass.

· We eliminated “pyrolysis” from the problem we’re trying to solve, so the gasifier design becomes infinitely more flexible than the “imbert” design

· We can scale gas production with the same system by merely swapping out a single nozzle size – we can go from 2kW to 50kW with the same machine!

· Yes, charcoal has less BTU’s, but we can also utilize those BTU’s by capturing and using that heat with a smart charcoal retort design

· Charcoal gasifiers have the potential to produce far more powerful gas flow than biomass gasifiers... Cracking steam is the key.

I can’t seem to grasp why more people aren’t moving toward charcoal… The case seems clear to me. At any rate, I intend on capitalizing on this market niche by releasing our brand new OpenFire gasifier. We will follow All Power Labs business model by releasing the CAD files as “open source,” but will also manufacture them for those that want to buy it pre-made… my partner is a master fabricator, and served as an underwater welder for the US Navy.

Build it, or buy it.

We’re in the final phases of fabrication, and should have it running in 2-3 weeks. Our prototype was a smash hit at the Baja Permaculture Convergence, which was the catalyst to take it mainstream. It all sits on a 4 x 4’ metal pallet (for easy shipping), and contains the following components:

· Charcoal hopper

· Regenerative blower

· Filtration and flare system

· Quad-fuel Honda generator (propane, gasoline, natural gas, wood gas)

· Small propane tank back-up

· Deep-cycle gold cart battery

· Battery charger

· Inverter

I am very interested in seeing what we might be able to do with the power cube. In fact, the assembly above is merely the fabricated units we’ll build and offer for sale. Other people may decide to build it differently. Perhaps you and the OSE team might consider adding our product to your ensemble.

If you’d like to discuss a collaboration, please call me at your convenience. I look forward to a future discussion. Thanks Marcin!

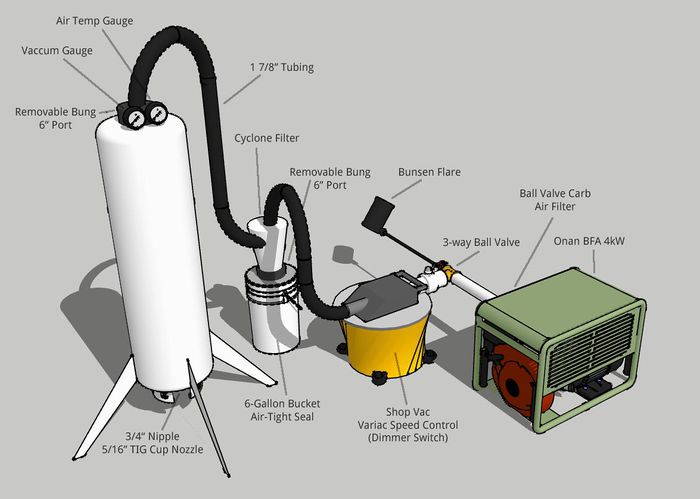

P.S. I’ve attached a photo of our very first prototype, which worked brilliantly, but was made of plastic and other materials that would degrade if left out in the elements… The new version is a true fabricated beauty (very industrial).

619.365.9109

Regards, Troy Martz

Performance Discussion

Q:This is great. So you have the water injector in your existing system as part of the existing design - and you have shown that you are using water effectively as fuel?

A: No… We have “played” with water by sticking a boiling tea kettle under the nozzle. The performance in RPM’s was noticeable, instantaneously.

Q: What is the max percentage of water that you can use here and what is the limiting factor for how much water you can burn in the process? Can you get to 20% water burn by mass?

A: We feel we can approach a 1:1 ration by weight (water to charcoal). A fellow gasser has had success with these ranges in ideal conditions… Certainly we will see a 0.5:1 ratio. I have many charts from old gasifier books from the early 1900’s. This was how they made H2 before steam reformation became the most cost-efficient.

But the really cool thing is that we can almost have an extra 50-100% in gas --- for the cost of water (free?).

Q:Can you pipe your output gas in PVC?

A:Yes. This is no problem at all... There are no high temps past the core. My proof-of-concept has a lot of PVC and ABS pipe… No problems.

Q: Why do you flare the gas off? Is that just a takeoff for other applications?

A:You need to bring the temperature of the core up to optimal temperatures. Ideally, temps over 1,100 C. It takes a couple minutes to achieve this. 3-5 mins.

Q: What is the difference between the prototype that you are building now and the concept drawing above?

A: Not much… The layout is not linear (like the drawing). We are trying to fit this into a 3-dimensional puzzle. Other than that, no real difference.

Q: What is your schedule for prototype finish?

A:I think we are still two weeks out – realistically.

Q: Any new thoughts on Power Cube adaptation? Can you begin fitting the components in a 32x32x32 inch cube of our 4x4 inch structural metal grid beam, even if the tank sticks out a lot?

A:The Power Cube is on the map… for sure. However, we need to complete the Non-OSE platform build first. We need to finish what we started due to a couple of commitments with interested buyers, one big project in Indonesia, and for testing purposes. I would anticipate that as soon as we get this stuff done, and make any necessary modifications, we’ll shift gears and retro-fit to the Power cube.

Video by Troy Martz: "The OpenFire Charcoal Gasifier"