Biochar-Lime Co-production System: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

m (fixed internal links) |

||

| Line 1: | Line 1: | ||

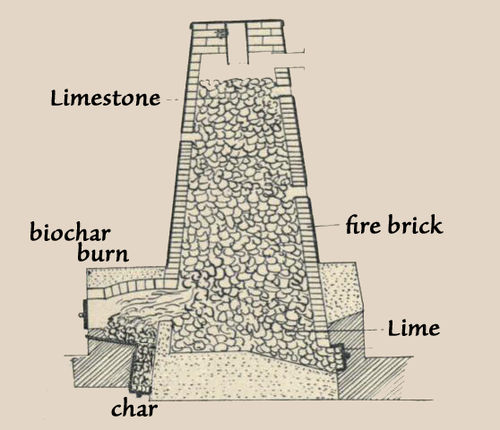

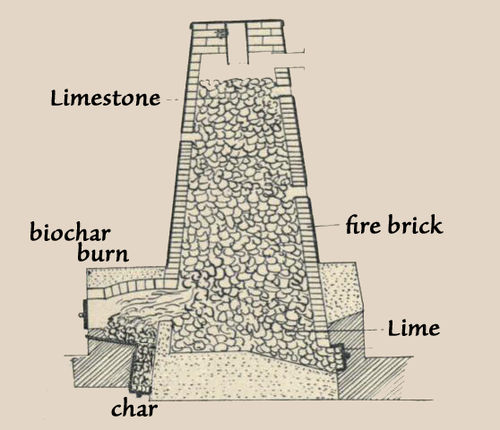

[[File:Biochar_Lime_kiln_drawing.jpg|500px|thumb|right|Model of (continuous) biochar/lime co-production system. Limestone is added at the top. Wood or other biomass is charred at the bottom. The combusion of pyrolysis gas ("wood gas") from [biochar] production provides the heat that turns limestone into quicklime.]] | [[File:Biochar_Lime_kiln_drawing.jpg|500px|thumb|right|Model of (continuous) biochar/lime co-production system. Limestone is added at the top. Wood or other biomass is charred at the bottom. The combusion of pyrolysis gas ("wood gas") from [[biochar]] production provides the heat that turns limestone into quicklime.]] | ||

Idea to couple the production of [biochar] with [lime] burning. The pyrolysis gas generated during char production is not flared off but used to make quicklime, which has many uses in construction and other areas. The process is carbon-negative. This type of production needs relatively close ('round the clock) monitoring but there is potential for automation. | Idea to couple the production of [[biochar]] with [[lime]] burning. The pyrolysis gas generated during char production is not flared off but used to make quicklime, which has many uses in construction and other areas. The process is carbon-negative. This type of production needs relatively close ('round the clock) monitoring but there is potential for automation. | ||

Revision as of 14:57, 25 February 2016

Model of (continuous) biochar/lime co-production system. Limestone is added at the top. Wood or other biomass is charred at the bottom. The combusion of pyrolysis gas ("wood gas") from biochar production provides the heat that turns limestone into quicklime.

Idea to couple the production of biochar with lime burning. The pyrolysis gas generated during char production is not flared off but used to make quicklime, which has many uses in construction and other areas. The process is carbon-negative. This type of production needs relatively close ('round the clock) monitoring but there is potential for automation.