Power Cube v15.6: Difference between revisions

(→Files) |

Tom Griffing (talk | contribs) (→Files) |

||

| (27 intermediate revisions by 2 users not shown) | |||

| Line 10: | Line 10: | ||

=Instructional= | =Instructional= | ||

==Frame Assembly== | |||

<html><iframe width="560" height="315" src="https://www.youtube.com/embed/AgxTk7EZtNc" frameborder="0" allowfullscreen></iframe></html> | |||

=Other Modules= | |||

All the modules are linked on Page 1 of this document: | |||

<html><iframe src="https://docs.google.com/presentation/d/1KJWzIyvMWcBeTGwfwGl9oNQn1V3dKXnyISVlqUzCwXE/embed?start=false&loop=false&delayms=3000" frameborder="0" width="960" height="569" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | <html><iframe src="https://docs.google.com/presentation/d/1KJWzIyvMWcBeTGwfwGl9oNQn1V3dKXnyISVlqUzCwXE/embed?start=false&loop=false&delayms=3000" frameborder="0" width="960" height="569" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | ||

==Sample 3D Print== | ==Sample 3D Print== | ||

| Line 18: | Line 25: | ||

=Introduction= | =Introduction= | ||

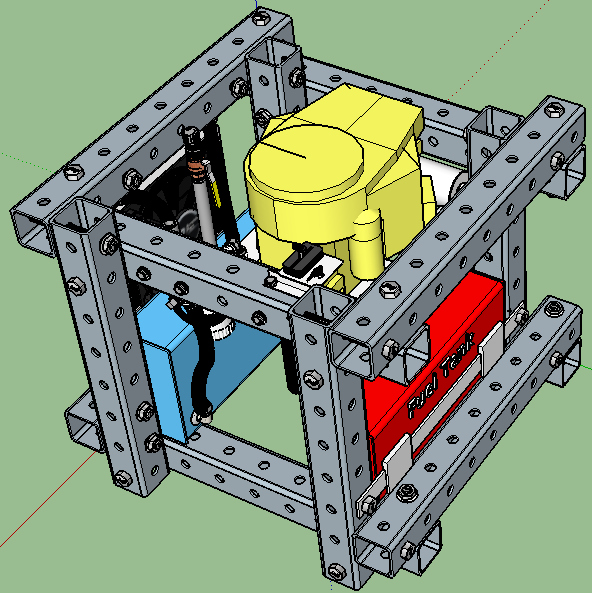

The Power Cube, Version | The Power Cube, Version 15.6 is a powerful, portable hydraulic power supply that operates efficiently and with minimal noise. The design combines a 28 HP Briggs & Stratton engine and a fixed-displacement hydraulic pump that has proven to work well with OSE machines and for other compatible hydraulic machines. This version includes a frame of 4" x 4" tubular steel that provides a strong structural frame for mounting other power cubes or attachments. | ||

The Power Cube | The Power Cube marks the next level of quick connect modularity, making it easy to assemble, use and maintain and is standard for all hydraulic equipment in the Global Village Construction Set. | ||

NOTE: This document is still under development and is not ready yet for "Prime Time" fabrication. This note will be removed when it has reached a "comfortable" level of completion. | NOTE: This document is still under development and is not ready yet for "Prime Time" fabrication. This note will be removed when it has reached a "comfortable" level of completion. | ||

| Line 56: | Line 63: | ||

Oct 2014: Changed sight gauge to shorter model and moved above the suction strainer for greater visibility - TLG. | Oct 2014: Changed sight gauge to shorter model and moved above the suction strainer for greater visibility - TLG. | ||

Apr 2015: Added a pressure gauge - TLG. | Apr 2015: Added a pressure gauge - TLG. | ||

May 2015: Moved the filler neck near the center of the tank to prevent fuel leaks due to side-to-side "sloshing". | |||

Jun 2015: Changed fuel filler to use extended neck (from coyote-gear.com) to reduce leaks due to "sloshing": | |||

[[Image:ExtendedFuelFillerNeck.png Extended Fuel Filler Neck]] | |||

=Files= | =Files= | ||

These is the | These is the 15.6 release. See file revision history for other versions. | ||

'''Bill Of Materials''' (BOM): [ | '''Bill Of Materials''' (BOM): [https://docs.google.com/spreadsheets/d/1ncYW6sCtBuj71nHp1o_hJvjoZYJWA-tSDTGV05P44kY/edit#gid=606109794 Power Cube BOM] | ||

* Briggs & Stratton Engine Specs (with line drawings) [[File:BriggsStrattonEngineSpecs.pdf]] | * Briggs & Stratton Engine Specs (with line drawings) [[File:BriggsStrattonEngineSpecs.pdf]] | ||

'''Power Cube Working Document''': ["https://docs.google.com/presentation/d/1oJbd8zQPIdDcFlyZn8Gj6_swQh8RWOkQLQ6hae8pHZ0/embed?start=false&loop=false&delayms=3000"] | '''Power Cube Working Document''': ["https://docs.google.com/presentation/d/1oJbd8zQPIdDcFlyZn8Gj6_swQh8RWOkQLQ6hae8pHZ0/embed?start=false&loop=false&delayms=3000"] | ||

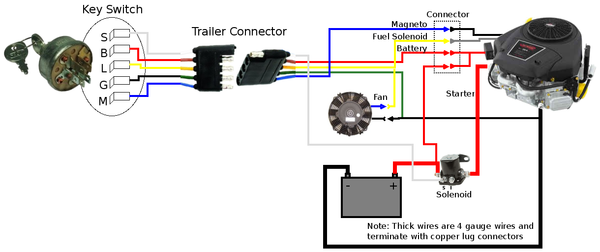

'''Wiring Diagram''': [[File:PC15.6WiringDiagram.dia Wiring Diagram]] | |||

=Fabrication Steps= | =Fabrication Steps= | ||

| Line 78: | Line 82: | ||

The Power Cube is a modular design. The modules are built separately, then combined for the complete Power Cube. The order of module fabrication is not important, but they are all necessary to complete a Power Cube. | The Power Cube is a modular design. The modules are built separately, then combined for the complete Power Cube. The order of module fabrication is not important, but they are all necessary to complete a Power Cube. | ||

Module fabrication procedures are detailed | Module fabrication procedures are detailed in the following document: | ||

[https://docs.google.com/presentation/d/1KJWzIyvMWcBeTGwfwGl9oNQn1V3dKXnyISVlqUzCwXE Module Assembly] | |||

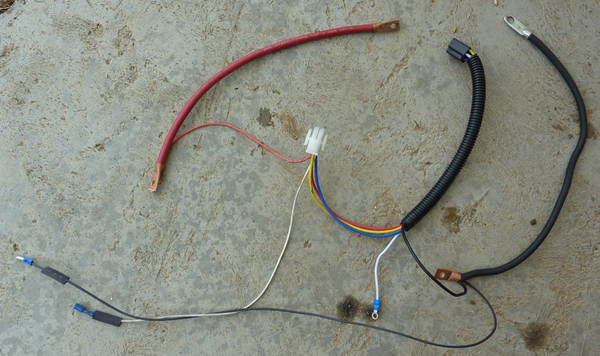

==Wiring Harness== | |||

The Wiring Harness now includes a plug to allow the keyswitch to be repositioned outside the Power Cube. | |||

* '''Drawing''' (click for larger view) | |||

[[File:wiringharness.png|600px]] | |||

* | * '''Photo''' | ||

[[File:wiringharnessphoto.png|600px]] | |||

[[File: | |||

<html><iframe width="420" height="315" src="https://www.youtube.com/embed//eLLylgc73sI" frameborder="0" allowfullscreen></iframe></html> | |||

* '''Battery Terminals''' | |||

<html><iframe width="420" height="315" src="https://www.youtube.com/embed// | <html><iframe width="420" height="315" src="https://www.youtube.com/embed//pn9nxd9DBr0" frameborder="0" allowfullscreen></iframe></html> | ||

* | * '''Engine Connections''' | ||

== | <html><iframe width="420" height="315" src="https://www.youtube.com/embed//v8aDXRBKHKw" frameborder="0" allowfullscreen></iframe></html> | ||

= | |||

===Wiring Harness Extension=== | |||

This version of the wiring harness is designed with a connector allowing the switch to be replaced with a switch with longer wires so it can be used remotely - say from the cab of a tractor. | |||

The assembly for this extension is the same as for the original switch wiring, except with longer wires: | |||

[[File:wiringharnessextension.png|400px]] | |||

The parts for this extended switch are: | |||

* Stens Switch 430-538 http://www.amazon.com/Stens-Starter-Switch-AM102551-430-538/dp/B000VYNG7E/ref=sr_1_1?ie=UTF8&qid=1434834238&sr=8-1&keywords=430-538 | |||

== | * Stens Wiring Harness 430-223 http://www.amazon.com/Stens-UNIVERSAL-WIRING-HARNESS-430-223/dp/B001OK9ZDI/ref=sr_1_1?ie=UTF8&qid=1434833949&sr=8-1&keywords=430-223 | ||

* | * 5-Way Trailer Connector: | ||

** 4 ft: http://www.amazon.com/Wesbar-Trailer-Connector-Wishbone-Harness/dp/B0009TNRS4/ref=sr_1_3?ie=UTF8&qid=1439331487&sr=8-3&keywords=5-way+trailer+connector | |||

* 30 ft: http://www.amazon.com/Trailer-Wishbone-Wire-Harness-Flat/dp/B007NU2Z7G/ref=pd_sim_sbs_263_5?ie=UTF8&refRID=06CNS4DVVD5EXT4D2J6F | |||

== | |||

* | * Switch Mounting Bracket, nuts and bolts to secure the bracket | ||

* Flexible Conduit: http://www.amazon.com/BLACK-SPLIT-TUBING-Cover-Polyethylene/dp/B00KDN9IGQ | |||

* | |||

==Final Assembly== | ==Final Assembly== | ||

| Line 247: | Line 141: | ||

* Install hoses to connect hydraulics and tighten appropriately | * Install hoses to connect hydraulics and tighten appropriately | ||

* Install Wiring Harness to key switch, connect to fan and solenoid (do not connect "+" battery connection yet) | * Install Wiring Harness to key switch, connect to fan and solenoid (do not connect "+" battery connection yet) | ||

* Install Engine module: | * Install Engine module: | ||

** Lower Engine Module gently until shaft coupling contacts pump shaft, rock/turn engine until shaft engages pump | ** Lower Engine Module gently until shaft coupling contacts pump shaft, rock/turn engine until shaft engages pump | ||

| Line 256: | Line 152: | ||

** Connect cable from solenoid to starter and tighten carefully | ** Connect cable from solenoid to starter and tighten carefully | ||

* Install battery in battery box | * Install battery in battery box | ||

** Connect | ** Connect battery cables to battery | ||

Overview: [[File:PC7s_Fabrication.pdf]] | Overview: [[File:PC7s_Fabrication.pdf]] | ||

Latest revision as of 02:53, 7 September 2016

Latest version: (download here - you can also download STL for printing)

Development Spreadsheet

Instructional

Frame Assembly

Other Modules

All the modules are linked on Page 1 of this document:

Sample 3D Print

Does not come out well if it's a monolithic small print of about 1 cubic inch size.

Introduction

The Power Cube, Version 15.6 is a powerful, portable hydraulic power supply that operates efficiently and with minimal noise. The design combines a 28 HP Briggs & Stratton engine and a fixed-displacement hydraulic pump that has proven to work well with OSE machines and for other compatible hydraulic machines. This version includes a frame of 4" x 4" tubular steel that provides a strong structural frame for mounting other power cubes or attachments.

The Power Cube marks the next level of quick connect modularity, making it easy to assemble, use and maintain and is standard for all hydraulic equipment in the Global Village Construction Set.

NOTE: This document is still under development and is not ready yet for "Prime Time" fabrication. This note will be removed when it has reached a "comfortable" level of completion.

Features

- Compact hydraulic power source for OSE and other compatible hydraulic tools

- Electric start, 28 horsepower air-cooled engine

- Briggs & Stratton muffler for low noise level

- Controls easily accessible for safety and comfort

- Standard quick connect hydraulic couplers

- Modular design simplifies maintenance and parts replacement

- Removable 7 gallon oil reservoir and fuel tank

- Heavy duty 6-tube oil cooler with fan cool the hydraulic fluid

- Sturdy tubular frame protects unit from damage and provides a simple means for adding attachments

- Pressure relief valve limits the output pressure for safety

- Pressure gauge

Specifications

- Model: OSE Power Cube, Version 7s

- Engine: Briggs & Stratton Professional Series, 28 HP

- Fuel Capacity: 7 Gallons

- Pressure (maximum): 3000 PSI

- Flow (maximum): 15.2 GPM

- Weight (approximate): 400 lbs

Development

The Power Cube has gone through a series of updates and this page reflects the current designs of Version 7s of the Power Cube.

This design has proven to work well and has had few updates lately. Here are the latest updates:

Oct 2014: Added a pressure relief valve and associated plumbing - TLG. Oct 2014: Changed sight gauge to shorter model and moved above the suction strainer for greater visibility - TLG. Apr 2015: Added a pressure gauge - TLG. May 2015: Moved the filler neck near the center of the tank to prevent fuel leaks due to side-to-side "sloshing". Jun 2015: Changed fuel filler to use extended neck (from coyote-gear.com) to reduce leaks due to "sloshing":

Files

These is the 15.6 release. See file revision history for other versions.

Bill Of Materials (BOM): Power Cube BOM

- Briggs & Stratton Engine Specs (with line drawings) File:BriggsStrattonEngineSpecs.pdf

Power Cube Working Document: ["https://docs.google.com/presentation/d/1oJbd8zQPIdDcFlyZn8Gj6_swQh8RWOkQLQ6hae8pHZ0/embed?start=false&loop=false&delayms=3000"]

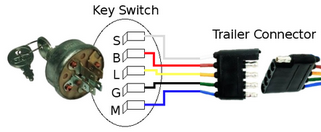

Wiring Diagram: File:PC15.6WiringDiagram.dia Wiring Diagram

Fabrication Steps

The Power Cube is a modular design. The modules are built separately, then combined for the complete Power Cube. The order of module fabrication is not important, but they are all necessary to complete a Power Cube.

Module fabrication procedures are detailed in the following document:

Wiring Harness

The Wiring Harness now includes a plug to allow the keyswitch to be repositioned outside the Power Cube.

- Drawing (click for larger view)

- Photo

- Battery Terminals

- Engine Connections

Wiring Harness Extension

This version of the wiring harness is designed with a connector allowing the switch to be replaced with a switch with longer wires so it can be used remotely - say from the cab of a tractor.

The assembly for this extension is the same as for the original switch wiring, except with longer wires:

The parts for this extended switch are:

- Stens Switch 430-538 http://www.amazon.com/Stens-Starter-Switch-AM102551-430-538/dp/B000VYNG7E/ref=sr_1_1?ie=UTF8&qid=1434834238&sr=8-1&keywords=430-538

- Stens Wiring Harness 430-223 http://www.amazon.com/Stens-UNIVERSAL-WIRING-HARNESS-430-223/dp/B001OK9ZDI/ref=sr_1_1?ie=UTF8&qid=1434833949&sr=8-1&keywords=430-223

- 5-Way Trailer Connector:

- Switch Mounting Bracket, nuts and bolts to secure the bracket

Final Assembly

- Install Fuel Tank module in frame (fuel tank goes beside battery box)

- Install Hydraulic Reservoir module in frame

- Install Pump module and Solenoid module

- Install oil cooler and fan to expanded steel

- Install hoses to connect hydraulics and tighten appropriately

- Install Wiring Harness to key switch, connect to fan and solenoid (do not connect "+" battery connection yet)

- Install Engine module:

- Lower Engine Module gently until shaft coupling contacts pump shaft, rock/turn engine until shaft engages pump

- Install 3/4" bolts / washers / nuts, securing engine plate to pump plate

- Remove nut from right rear engine bolt, place black battery on bolt, replace nut and tighten

- Connect electrical connector from wiring harness to engine

- Connect fuel hose from fuel tank to engine

- Connect cable from solenoid to starter and tighten carefully

- Install battery in battery box

- Connect battery cables to battery

Overview: File:PC7s Fabrication.pdf

Note: Welding Hydraulic Reservoir and Fuel Tank

Note on welding from Ben Horton: "The three "C's" of welding are clean, clean, clean. Tack the entire tank together, then after you clean the work pieces leave a gap between them about 1/6" and fixture the joints so that it is very uniform then weld down hill with minimal torch manipulation (mig). The next thing is to listen you will be able to hear the arc in side the tank as it penetrates. Remember watch the puddle not the arc. With 1/4" material you shouldn't have to stitch weld it but move from joint to joint opposite the one prior. Call me if you have questions." Results: Using above procedure, Marcin welded the fuel tank (1/4" steel, so easy on High-4, 70 wire speed, Millermatic 200) on first pass (except for filler cap, which is sheet metal)! That's a first, as I always had at least one pinhole leak, and about 8-10 at worst in prior production runs. For the end caps - grind edge + top and bottom around edge to 3/8" away from edge, with no factory scale on metal - just clean shiny metal. Grind edges of 6"x12" tube also 3/8" from edge. If cut by bandsaw (our case).

Fabrication

Hydraulic Sight Gauge

Power Cube Assembly Video Script

Steps for Instructional Assembly Video Script

Research

- Mechanical shaft quick coupling patent - [1]

July 2014 - Structural Power Cube

The frame of the Structural Power Cube is designed for stacking of multiple power cubes. This documents is about the angle iron frame Power Cube for applications where only one or two Power Cubes are required. Here is the link to the Structural Power Cube:

Link: Structural Power Cube