CEB Press v16.09/SCAD Files/Parametric: Difference between revisions

(→To Do) |

|||

| (131 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

'''work in progress''' | '''work in progress''' moved on to [[CEB Press v17.08/SCAD Files/]] | ||

creating an OpenSCAD replica of v16.09 | creating an OpenSCAD replica of v16.09 | ||

| Line 5: | Line 5: | ||

[[CEB Press v16.09/SCAD Files/Parametric]] | [[CEB Press v16.09/SCAD Files/Parametric]] | ||

Latest files on Google Drive for download: [https://drive.google.com/open?id=0BwxMMqGvwTM-c2NMZ3dHVlpOQWM link] | |||

=Default Variables= | =Default Variables= | ||

| Line 10: | Line 11: | ||

By making a SCAD file with the variables used throughout the CEB press, we can use the "include" command within each individual part's file to pull in the same dimensions. [https://en.wikibooks.org/wiki/OpenSCAD_User_Manual/Include_Statement#Variables Read More] | By making a SCAD file with the variables used throughout the CEB press, we can use the "include" command within each individual part's file to pull in the same dimensions. [https://en.wikibooks.org/wiki/OpenSCAD_User_Manual/Include_Statement#Variables Read More] | ||

vars.scad | :::vars.scad | ||

<nowiki> | <nowiki> | ||

| Line 17: | Line 18: | ||

brickCH=6; | brickCH=6; | ||

$fn= | $fn=8; //defines resolution of circles. 8 is okay for review. 100 or greater should be used for for final dxf export. | ||

dZstandard=0.5; //thickness of steel to be cut for drawer parts | |||

fZstandard=0.5; | |||

aZstandard=0.5; //thickness of steel to be cut for arm parts | |||

fBOLTHOLEstandardD=1; //standard bolts used on frame | |||

sliderodholeOD=1.2; | |||

dGap=0.03125; //gap between a hole cut's edge and the part sitting within the hole. //D3 appears to use 0.3125, is this in error? | dGap=0.03125; //gap between a hole cut's edge and the part sitting within the hole. //D3 appears to use 0.3125, is this in error? | ||

// | //all parts set to standard thickness below | ||

//off standard preferences can be defined below | |||

//drawer | |||

drawergap=0.0283; //extra room for drawer to slide in the space between f1 and f4 | |||

drawerHgap=0.1884; //total extra space from drawer sides to frame walls. sum of both sides. | |||

d1z=dZstandard; | d1z=dZstandard; | ||

d2z=dZstandard; | |||

d3z=dZstandard; | |||

d4z=dZstandard; | |||

d5z=dZstandard; | |||

d6z=dZstandard; | |||

d5z=dZstandard; | |||

d7z=dZstandard; | |||

d8z=dZstandard; | |||

d9z=dZstandard; | |||

//frame | |||

f1x=24.2; | |||

f1y=6; | |||

f1z=0.5; | |||

f2y=3.5; | |||

f2z=fZstandard; | |||

f3x=f1x; | |||

f3y=3.5; | |||

f3z=fZstandard; | |||

f4y=11; | |||

f4z=fZstandard; | |||

f5y=3.5; | |||

f5z=fZstandard; | |||

f6y=8; | |||

f6z=fZstandard; | |||

f8y=brickW; | |||

f8z=fZstandard; | |||

f8boltD=1; | |||

f9y=4.5; | |||

f9x=43.5; //set based on MAINcylinder | |||

f9z=fZstandard; | |||

f8x=f9x; | |||

f11x=1.25; | |||

f11z=fZstandard; | |||

f13z=fZstandard; | |||

//arms | |||

a1x=4; | |||

a1y=72; //calculate based on drawer cylinder | |||

a1z=aZstandard; | |||

a2x=6; | |||

a2y=72; //calculate based on drawer cylinder | |||

a2z=aZstandard; | |||

a4z=aZstandard; | |||

a6z=aZstandard; | |||

// | |||

//Input your main cylinder's dimenions here | |||

// | |||

cylinderMAINminC2E=0; //main hydraulic cylinder's distance from center of mounting hole to the end of the shaft when fully compressed. | cylinderMAINminC2E=0; //main hydraulic cylinder's distance from center of mounting hole to the end of the shaft when fully compressed. | ||

cylinderMAINmaxC2E=0; //main hydraulic cylinder's distance from center of mounting hole to the end of the shaft when fully extended. | cylinderMAINmaxC2E=0; //main hydraulic cylinder's distance from center of mounting hole to the end of the shaft when fully extended. | ||

// | |||

//Input your drawer cylinder's dimenions here | |||

// | |||

cylinderDRAWERbodyH=3; //measured when in position, largest length from top to bottom of cylinder | |||

cylinderDRAWERminC2C=0; //drawer's hydraulic cylinder's distance from the center of one mounting hole to the center of the other when fully compressed. | cylinderDRAWERminC2C=0; //drawer's hydraulic cylinder's distance from the center of one mounting hole to the center of the other when fully compressed. | ||

cylinderDRAWERmaxC2C=0; ///drawer's hydraulic cylinder's distance from the center of one mounting hole to the center of the other when fully extended. | cylinderDRAWERmaxC2C=0; ///drawer's hydraulic cylinder's distance from the center of one mounting hole to the center of the other when fully extended. | ||

cylinderDRAWERrodclevisW=2.5; //width of cylinders' clevis on end of rod | |||

cylinderDRAWERrodclevisID=1; | |||

cylinderDRAWERrodclevisOD=2; | |||

cylinderDRAWERrearclevisW=2.5; //width of mounting clevis cylinder body | |||

cylinderDRAWERrearclevisID=1; | |||

cylinderDRAWERrearclevisOD=2; | |||

cylinderDRAWERrearclevisClearance=3; //usable space around rear clevis pin (in diameter). be aware of hyraulic fittings. | |||

//variables calculated | //the following variables are calculated in order of dependence on preceding variables | ||

d3x=brickL+(d2z*2); | d3x=brickL+(d2z*2); | ||

d3y=brickCH-d1z; | d3y=brickCH-d1z; | ||

d4x=brickW+d3z+d3z; | d4x=brickW+d3z+d3z; | ||

d4y=brickCH-d1z; | d4y=brickCH-d1z; | ||

d5x=brickL+(d2z*2); | |||

d5y=brickW; | |||

d6x=brickL+(d2z*2); | |||

d6y=brickCH; | |||

d7x=cylinderDRAWERrearclevisClearance; | |||

d7y=a4z+d8z+cylinderDRAWERbodyH; | |||

d9x=cylinderDRAWERbodyH+d6z; | |||

d9y=cylinderDRAWERbodyH+d8z; | |||

d8x=brickL+(d2z*2); | |||

d8y=max(5,(d9x-d6z)); //need to review fundamentals, 5 minimun unless d9 gets larger than d8 | |||

d1x=18.5; //need to come up with a formula | |||

d1y=18; //need to come up with a formula | |||

d2x=d8y+d6z+brickW+d3z+d5y+d3z; | |||

d2y=brickCH; | |||

f11y=f8y; | |||

f6x=brickL+(d2z*2)+(f9y*2)+drawerHgap; | |||

f8x=43.5; //need to define based on MAINcylinder inputs | |||

f2x=brickL+(d2z*2)+drawerHgap+(f9y*2)-(1.4*2); //distance between large cut outs in f9 | |||

f5x=brickL+(d2z*2)+drawerHgap+(f9y*2)+(a1x*2); //distance between outer edges of each A1 | |||

f4x=f5x-0.5; //same as f5 but minus 0.25 on each side to give a little overhang | |||

</nowiki> | </nowiki> | ||

| Line 71: | Line 160: | ||

//Corner Joint - allows the sides of two parts to create inlayed corner. Aids with welding. | //Corner Joint - allows the sides of two parts to create inlayed corner. Aids with welding. | ||

//need to verify module math is the same throughout all parts. | //need to verify module math is the same throughout all parts. | ||

module cornerjoint(Z,L,H,EndGap,PadL,PadH){ | |||

module cornerjoint(Z,L,H,EndGap,PadL,PadH,CJangle,CJcenter){ | |||

//change so that H = Z of inlayed part (usually 0.5) | //change so that H = Z of inlayed part (usually 0.5) | ||

//add center and angle in degrees option, orgin far side of cut out area | //add center and angle in degrees option, orgin far side of cut out area | ||

difference(){ | |||

if((CJangle==0)&&(CJcenter==0)) | |||

translate([EndGap,H-PadH,0]) | { | ||

translate([0,0,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | |||

translate([L-EndGap-PadL,H,0]) | |||

cube([PadL,PadH,Z]);} | |||

} | |||

else if((CJangle==90)&&(CJcenter==0)) | |||

{ | |||

translate([H+PadH,0,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | |||

translate([L-EndGap-PadL,H,0]) | |||

cube([PadL,PadH,Z]);} | |||

} | |||

else if((CJangle==180)&&(CJcenter==0)) | |||

{ | |||

translate([L,H+PadH,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | |||

translate([L-EndGap-PadL,H,0]) | |||

cube([PadL,PadH,Z]);} | |||

} | |||

else if((CJangle==270)&&(CJcenter==0)) | |||

{ | |||

translate([0,L,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | |||

translate([L-EndGap-PadL,H,0]) | |||

cube([PadL,PadH,Z]);} | |||

} | |||

//centered | |||

else if((CJangle==0)&&(CJcenter==1)) | |||

{ | |||

translate([-L/2,0,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | |||

translate([L-EndGap-PadL,H,0]) | |||

cube([PadL,PadH,Z]);} | |||

} | |||

else if((CJangle==90)&&(CJcenter==1)) | |||

{ | |||

translate([0,-L/2,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | |||

translate([L-EndGap-PadL,H,0]) | |||

cube([PadL,PadH,Z]);} | |||

} | |||

else if((CJangle==180)&&(CJcenter==1)) | |||

{ | |||

translate([L/2,0,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | cube([PadL,PadH,Z]); | ||

translate([L-EndGap-PadL,H | translate([L-EndGap-PadL,H,0]) | ||

cube([PadL,PadH,Z]);} | |||

} | |||

else if((CJangle==270)&&(CJcenter==1)) | |||

{ | |||

translate([0,L/2,0]) | |||

rotate([0,0,CJangle]) | |||

difference(){ | |||

cube([L,H+PadH,Z]); | |||

translate([EndGap,H,0]) | |||

cube([PadL,PadH,Z]); | cube([PadL,PadH,Z]); | ||

translate([L-EndGap-PadL,H,0]) | |||

cube([PadL,PadH,Z]);} | |||

} | |||

} //end cornerjoint module | } //end cornerjoint module | ||

| Line 109: | Line 284: | ||

} //end center translate | } //end center translate | ||

} //end tabinsert module | } //end tabinsert module | ||

</nowiki> | </nowiki> | ||

| Line 114: | Line 290: | ||

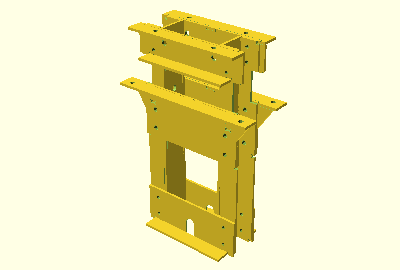

=Frame= | =Frame= | ||

==Assembly== | ==Frame Assembly== | ||

*F4 holes look slightly more narrow than the F9 holes. | |||

*calculate F4 and F5 Z height from the top down. Let f9 length be adjusted by cylinder. try to avoid calculation again. | |||

[[Image:CEBscad-frame.png|400px]] | |||

:::Fp.scad | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

use <f1p.scad>; | |||

use <f2p.scad>; | |||

use <f3p.scad>; | |||

use <f4p.scad>; | |||

use <f5p.scad>; | |||

use <f6p.scad>; | |||

//use <f7p.scad>; | |||

use <f8p.scad>; | |||

use <f9p.scad>; | |||

//use <f10p.scad>; | |||

use <f11p.scad>; | |||

//use <f12p.scad>; | |||

translate([0,(f8y/2)+f1z,f9x]) | |||

rotate([90,180,0]) | |||

f1p(); | |||

translate([0,-(f8y/2),f9x]) | |||

rotate([90,180,0]) | |||

f1p(); | |||

translate([-f2x/2,(f8y/2),f9x-f1y]) | |||

rotate([0,0,0]) | |||

f2p(); //connected to F1 | |||

translate([f2x/2,-(f8y/2),f9x-f1y]) | |||

rotate([0,0,180]) | |||

f2p(); | |||

translate([0,(f8y/2),f9x]) | |||

rotate([0,180,0]) | |||

f3p(); //connected to F1 | |||

translate([0,-(f8y/2),f9x]) | |||

rotate([0,180,180]) | |||

f3p(); //connected to F1 | |||

translate([0,(f8y/2)+f6z,(f9x-f1y-brickCH-drawergap-f4y)]) | |||

translate([0,( | |||

rotate([90,0,0]) | rotate([90,0,0]) | ||

f4p(); //?group with f5? | |||

translate([0,-( | |||

translate([0,-(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)]) | |||

rotate([90,0,0]) | rotate([90,0,0]) | ||

F4(); | f4p(); | ||

translate([0,(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+f4y]) | |||

rotate([0,180,0]) | |||

f5p(); //connected to F4 | |||

translate([0,-(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+f4y]) | |||

rotate([0,180,180]) | |||

f5p(); //connected to F4 | |||

translate([-f2x/2,(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+7.5-(f2z/2)]) | |||

rotate([0,0,0]) | |||

f2p(); //connected to F1 | |||

translate([f2x/2,-(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+7.5-(f2z/2)]) | |||

rotate([0,0,180]) | |||

f2p(); | |||

translate([0,( | translate([0,(f8y/2)+f6z,f6y]) | ||

rotate([90, | rotate([90,180,0]) | ||

f6p(); | |||

translate([ | translate([0,-(f8y/2),f6y]) | ||

rotate([90,180,0]) | |||

f6p(); | |||

rotate([ | |||

translate([- | translate([-f2x/2,(f8y/2),0]) | ||

rotate([0,0,0]) | |||

f2p(); //connected to F6 | |||

rotate([0, | |||

/ | translate([f2x/2,-(f8y/2),0]) | ||

rotate([0,0,180]) | |||

f2p(); | |||

translate([f6x/2,0,0]) | |||

rotate([0,0,180]) | |||

f11p(); | |||

translate([ | |||

translate([f6x/2,0,f9x-f1y-d2y-f4y-drawergap-0.5]) | |||

rotate([0,0,180]) | |||

f11p(); | |||

translate([ | translate([f6x/2,0,f9x-0.5]) | ||

rotate([0,0,180]) | |||

f11p(); | |||

translate([-f6x/2,0,0]) | |||

rotate([0,0,0]) | |||

f11p(); | |||

translate([-f6x/2,0,f9x-f1y-d2y-f4y-drawergap-0.5]) | |||

rotate([0,0,0]) | |||

translate([- | f11p(); | ||

translate([-f6x/2,0,f9x-0.5]) | |||

rotate([0,0,0]) | |||

f11p(); | |||

translate([1.9-8.5,0,0]){ //??? | |||

rotate([0,0,90]){ | |||

translate([(f8y/2),f8z,0]) | |||

rotate([90,-90,0]) | |||

f8p(); | |||

translate([(f8y/2)+(f9z/2)-(f8z/2),0,0]) | |||

rotate([0,-90,0]) | |||

f9p(); | |||

translate([-(f8y/2)+(f9z/2)+(f8z/2),0,0]) | |||

rotate([0,-90,0]) | |||

f9p(); | |||

} //end rotate | |||

} //end translate | |||

} | |||

} //end | |||

translate([-1.9+8.5,0,0]){ | |||

rotate([0,0,-90]){ | |||

translate([(f8y/2),f8z,0]) | |||

rotate([90,-90,0]) | |||

f8p(); | |||

translate([(f8y/2)+(f9z/2)-(f8z/2),0,0]) | |||

rotate([0,-90,0]) | |||

f9p(); | |||

translate([-(f8y/2)+(f9z/2)+(f8z/2),0,0]) | |||

rotate([0,-90,0]) | |||

f9p(); | |||

} //end rotate | |||

} //end translate | |||

} //end | |||

</nowiki> | </nowiki> | ||

| Line 348: | Line 448: | ||

Abuts: A2 | Abuts: A2 | ||

*need to tweak bolt translates? | |||

*change to use cornerjoint module instead of insert module on outter ends of F3 connections | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f1p(); | |||

module f1p(){ | |||

difference(){ | difference(){ | ||

translate([-( | translate([-(f1x/2),0,0]) | ||

cube([ | cube([f1x,f1y,f1z]); | ||

translate([-( | translate([-(f1x/2),0,0]) | ||

cuts(); | cuts(); | ||

translate([( | translate([(f1x/2),0,0]) | ||

mirror([1,0,0]) | mirror([1,0,0]) | ||

cuts(); | cuts(); | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

tabinsert(1,f3z,f1z,0.0625,0.125,0,0,0.25,0.25,0.0,0,0,0,0); | |||

translate([0,f1y-0.25,0]) | |||

translate([0, | cube([0.4,0.25,f1z]); //appears to be intended to interface with A2, but not sure why | ||

cube([0.4,0.25, | translate([(f1x-f2x)/2,f1y-f2z,0]) | ||

translate([2 | tabinsert(1,f2z,f1z,0.0625,0.125,0,0,0,0,0.25,0.25,0.25,0.25,0); //f2 | ||

translate([(f1x/2)-1,0,0]) | |||

translate([ | tabinsert(1,f3z,f1z,0.0625,0.125,0.25,0.25,0,0,0.0,0,0,0,0); | ||

translate([((f1x-d3x-drawerHgap)/2)-2,1.5,0]) //bolt center to inner edge of f9=2 | |||

cylinder(h = f1z, r = 0.375); | |||

translate([((f1x-d3x-drawerHgap)/2)-2,4.5,0]) | |||

translate([ | cylinder(h = f1z, r = 0.375); | ||

cylinder(h = | translate([((f1x-d3x-drawerHgap)/2)+(sliderodholeOD/2)+drawerHgap,2.465,0]) //not sure what this is supposed to align with, drawer? | ||

translate([ | cylinder(h = f1z, r = sliderodholeOD/2); | ||

cylinder(h = | } //end cuts module | ||

translate([ | |||

cylinder(h = | } //end f1p module | ||

} //end module | |||

</nowiki> | </nowiki> | ||

| Line 391: | Line 496: | ||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f2p(); | |||

module f2p(){ | |||

difference(){ | difference(){ | ||

cube([f2x,f2y,f2z]); | |||

cube([ | translate([1,0,0]) | ||

translate([ | cornerjoint(f2z,f2x-2,f1z,0.125,f2x-2-0.25,0.125,0,0); | ||

} //end difference | } //end difference | ||

} //end f2p module | |||

} //end module | |||

</nowiki> | </nowiki> | ||

| Line 420: | Line 518: | ||

Bolts to: F12 | Bolts to: F12 | ||

*F3 and F1 should probably be made the same length. | |||

**going to set f3y=f1y. also some tweaks to insert holes | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f3p(); | |||

module f3p(){ | |||

difference(){ | difference(){ | ||

translate([-( | translate([-(f3x/2),0,0]) | ||

cube([ | cube([f3x,f3y,f3z]); | ||

translate([-( | translate([-(f3x/2),0,0]) | ||

cuts(); | cuts(); | ||

translate([( | translate([(f3x/2),0,0]) | ||

mirror([1,0,0]) | mirror([1,0,0]) | ||

cuts(); | cuts(); | ||

| Line 439: | Line 541: | ||

module cuts(){ | module cuts(){ | ||

translate([1,0,0]) | translate([1,0,0]) | ||

cornerjoint(f3z,(f3x-4)/2,f1z,1,1,0.125,0,0); | |||

translate([5.375,f3y/2,0]) | |||

cylinder(h = f3z, r = 0.5); | |||

} //end cuts module | |||

} //end f3p module | |||

translate([5.375, | |||

cylinder(h = | |||

} //end module | |||

</nowiki> | </nowiki> | ||

| Line 458: | Line 554: | ||

Bolts to: F9 | Bolts to: F9 | ||

*use cornerjoint module instead of insert for F5 connection | |||

*bolt holes look like they're maybe slightly miss aligned? | |||

**are they different sized? | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f4p(); | |||

module f4p(){ | |||

difference(){ | difference(){ | ||

translate([-( | translate([-(((brickL+(d2z*2)+drawerHgap+(f9y*2)))/2),0,0]) | ||

cube([ | union(){ | ||

translate([-( | cube([(brickL+(d2z*2)+drawerHgap+(f9y*2)),f4y,f4z]); | ||

translate([-((f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2))))/2,f4y/2,0]) | |||

f4triangle(); | |||

translate([f4x-((f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2),f4y/2,0]) | |||

mirror([1,0,0]) | |||

f4triangle(); | |||

} | |||

translate([-(f4x/2),0,0]) | |||

cuts(); | cuts(); | ||

translate([( | translate([(f4x/2),0,0]) | ||

mirror([1,0,0]) | mirror([1,0,0]) | ||

cuts(); | cuts(); | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([ | //f5 outer | ||

translate([(f4x/2)+((f5x/2)-2),f4y,0]) | |||

cornerjoint(f4z,4,f5z,0.125,1,0.125,180,1); | |||

//tabinsert(4,f5z*2,f4z,0.0625,0.125,0,0,0,0,0,0,0.25,0.25,1); | |||

translate([( | //f5 center | ||

translate([(f4x/2),f4y,0]) | |||

tabinsert(2,f5z*2,f4z,0.0625,0.125,0,0,0,0,0.0,0,0.25,0.25,1); | |||

translate([( | |||

//f2 | |||

translate([(f4x-f2x+1)/2,7.5,0]) | |||

tabinsert(1,f2z,f6z,0.0625,0.125,0.25,0.25,0.25,0.25,0.25,0.25,0.25,0.25,1); | |||

//f9 bolts | |||

translate([((f4x-brickL-(d2z*2)-drawerHgap)/2)-2,2,0]) | |||

translate([( | cylinder(h = f4z, r = 0.5025); //diameter 1.0? | ||

translate([((f4x-brickL-(d2z*2)-drawerHgap)/2)-2,6,0]) | |||

cylinder(h = f4z, r = 0.5025); | |||

translate([((f4x-brickL-(d2z*2)-drawerHgap)/2)-2,9,0]) | |||

cylinder(h = f4z, r = 0.5025); | |||

cylinder(h = | |||

translate([( | |||

cylinder(h = | |||

translate([( | |||

cylinder(h = | |||

} //end module | } //end module | ||

module f4triangle (){ | |||

difference(){ | |||

cube([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,f4y/2,f4z]); | |||

difference(){ | |||

cube([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,f4y/2,f4z]); | |||

translate([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,0,0]) | |||

rotate([0,0,atan(((f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2)/(f4y/2))]) | |||

cube([10,10,f4z]); | |||

translate([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,0,0]) | |||

cube([10,10,f4z]); | |||

} | |||

} | |||

} //end f4triangle module | |||

} //end f4p module | |||

</nowiki> | </nowiki> | ||

| Line 519: | Line 632: | ||

Bolts to: A1 | Bolts to: A1 | ||

:::f5p.scad | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f5p(); | |||

module f5p(){ | |||

difference(){ | difference(){ | ||

translate([-( | translate([-(f5x/2),0,0]) | ||

cube([ | cube([f5x,f5y,f5z]); | ||

translate([-( | translate([-(f5x/2),0,0]) | ||

cuts(); | cuts(); | ||

translate([( | translate([(f5x/2),0,0]) | ||

mirror([1,0,0]) | mirror([1,0,0]) | ||

cuts(); | cuts(); | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([4, | translate([4,0,0]) | ||

cornerjoint(f5z,(f5x-(4*2)-2)/2,f4z,1,1,0.125,0,0); | |||

//arm bolt hole | |||

translate([(a1x/2),f5y-1.5,0]) //aligns with hole in center of a1x | |||

cylinder(h = f5z, r = 0.5); | |||

//might add an insert for an A6 type of support | |||

} //end cuts module | |||

translate([ | } //end f5p module | ||

cylinder(h = | |||

} | |||

} //end module | |||

</nowiki> | </nowiki> | ||

| Line 563: | Line 675: | ||

Bolts to: F9 | Bolts to: F9 | ||

*changed bolt hole distance to outer edge, the drawerHgap makes it goofy to have a round number from center. | |||

**need to change translate to accomidate for drawerHgap | |||

*need to use insert module for f2 holes | |||

*need to use MAINcylinder specs to make cylinder pin hole | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f6p(); | |||

module f6p(){ | |||

difference(){ | difference(){ | ||

translate([-( | translate([-(f6x/2),0,0]) | ||

cube([ | cube([f6x,f6y,f6z]); | ||

translate([-( | translate([-(f6x/2),0,0]) | ||

cuts(); | cuts(); | ||

translate([( | translate([(f6x/2),0,0]) | ||

mirror([1,0,0]) | mirror([1,0,0]) | ||

cuts(); | cuts(); | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([( | translate([(f6x-f2x)/2,f6y-f2z,0]) | ||

cylinder(h = | tabinsert(1,f2z,f6z,0.0625,0.125,0,0,0,0,0.25,0.25,0.25,0.25,0); //F2 | ||

translate([( | |||

cylinder(h = | //need to change this section to match MAINcylinder specs | ||

translate([(f6x/2)-1.125,f6y-3.22,0]) | |||

cube([2.25,3.22,f6z]); | |||

translate([f6x/2,f6y-3.22,0]) | |||

cylinder(h = f6z, r = 1.125); | |||

// bolt holes to f9 | |||

translate([((f6x-brickL-(d2z*2)-drawerHgap)/2)-2,2,0]) | |||

cylinder(h = f6z, r = 0.38); //diameter 0.76? | |||

translate([((f6x-brickL-(d2z*2)-drawerHgap)/2)-2,6,0]) | |||

cylinder(h = f6z, r = 0.38); | |||

} //end module | } //end cuts module | ||

} //end f6p module | |||

</nowiki> | </nowiki> | ||

| Line 602: | Line 724: | ||

Bolts to: Rub Plate ? | Bolts to: Rub Plate ? | ||

*need to redo cornerjoint module inputs | |||

*need to set standard bolt size | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f8p(); | |||

module f8p(){ | |||

difference(){ | difference(){ | ||

cube([ | cube([f8x,f8y,f8z]); | ||

translate([ | translate([(1/12)*f8x,0,0]) | ||

cornerjoint( | cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,0,1); | ||

translate([ | translate([(5/12)*f8x,0,0]) | ||

cornerjoint( | cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,0,1); | ||

translate([ | translate([(9/12)*f8x,0,0]) | ||

cornerjoint( | cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,0,1); | ||

translate([ | translate([(1/12)*f8x,f8y,0]) | ||

cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,180,1); | |||

cornerjoint( | translate([(5/12)*f8x,f8y,0]) | ||

translate([ | cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,180,1); | ||

translate([(9/12)*f8x,f8y,0]) | |||

cornerjoint( | cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,180,1); | ||

translate([ | |||

cornerjoint( | |||

hull(){ | hull(){ | ||

translate([ | translate([f8x-7-((f1y+d2y+drawergap+1)-(0.26/2)),f8y/2,0]) //?x interfaces with what? need to calculate center of F8 | ||

cylinder(h = | cylinder(h = f8z, r = f8boltD/2); | ||

translate([ | translate([f8x-7-((f1y+d2y+drawergap+1)+(0.26/2)),f8y/2,0]) | ||

cylinder(h = | cylinder(h = f8z, r = f8boltD/2); | ||

} | } | ||

hull(){ | hull(){ | ||

translate([ | translate([f8x-((f1y+d2y+drawergap+1)-(0.26/2)),f8y/2,0]) //?x interfaces with what? | ||

cylinder(h = | cylinder(h = f8z, r = f8boltD/2); | ||

translate([ | translate([f8x-((f1y+d2y+drawergap+1)+(0.26/2)),f8y/2,0]) | ||

cylinder(h = | cylinder(h = f8z, r = f8boltD/2); | ||

} | } | ||

} | } | ||

} //end f8p module | |||

} //end | |||

</nowiki> | </nowiki> | ||

| Line 664: | Line 779: | ||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f9p(); | |||

module f9p(){ | |||

difference(){ | difference(){ | ||

cube([ | cube([f9x,f9y,f9z]); | ||

translate([ | translate([(3/12)*f9x,0,0]) | ||

cornerjoint( | cornerjoint(f9z,(f8x/6),f8z,0.25,0.5,0.125,0,1); | ||

translate([ | translate([(7/12)*f9x,0,0]) | ||

cornerjoint( | cornerjoint(f9z,(f8x/6),f8z,0.25,0.5,0.125,0,1); | ||

translate([ | translate([(11/12)*f9x,0,0]) | ||

cornerjoint(f9z,(f8x/6),f8z,0.25,0.5,0.125,0,1); | |||

translate([0,f9y-0.5,0]) | |||

tabinsert(0.5,0.5,f9z,0.03125,0.125,0,0,0,0,0.25,0.25,0,0,0); | |||

translate([f9x-f1y-d2y-f4y-drawergap-0.5,f9y-0.5,0]) | |||

tabinsert(0.5,0.5,f9z,0.03125,0.125,0,0,0,0,0.25,0.25,0.25,0.25,0); | |||

translate([f9x-0.5,f9y-0.5,0]) | |||

tabinsert(0.5,0.5,f9z,0.03125,0.125,0,0,0,0,0,0,0.25,0.25,0); | |||

translate([2,1. | //big cutout | ||

cylinder(h = | translate([f9x-(f1y-0.2)-(a2x+0.4),f9y-1.4,0]) | ||

translate([6, | cube([a2x+0.4,1.4,f9z]); //?interfaces with a2? | ||

cylinder(h = | |||

//bolt holes | |||

//f6 | |||

translate([2,2,0]) //?x interfaces with f6? | |||

//replacing translate y=1.9 with y=f9y-2.5 | |||

cylinder(h = f9z, r = 0.38); | |||

translate([6,2,0]) //?x interfaces with f6? | |||

cylinder(h = f9z, r = 0.38); | |||

//distance from center to edge of part is 1.5 | |||

//distance between center to center is 9.5283 | |||

//distance from center to edge of part is 2 | |||

//gap between parts is 6.0283 | |||

//drawer is 6.0 tall | |||

//leaves 0.0283 space | |||

//should this be 0.03125? (1/32) | |||

translate([ | //should f4 be attached with 4 smaller bolts instead of 3 big ones. would prevent all movement? | ||

cylinder(h = | //f4 | ||

translate([ | translate([f9x-f1y-d2y-drawergap-2,2,0]) //replacing translate y=1.9 with f9y-2.5 | ||

cylinder(h = | cylinder(h = f9z, r = 0.5025); | ||

translate([ | translate([f9x-f1y-d2y-drawergap-5,2,0]) | ||

cylinder(h = | cylinder(h = f9z, r = 0.5025); | ||

translate([f9x-f1y-d2y-drawergap-9,2,0]) | |||

cylinder(h = f9z, r = 0.5025); | |||

//f1 | |||

translate([ | translate([f9x-4.5,2,0]) //?x interfaces with f1? | ||

cylinder(h = | cylinder(h = f9z, r = 0.38); | ||

translate([ | translate([f9x-1.5,2,0]) //?x interfaces with f1? | ||

cylinder(h = | cylinder(h = f9z, r = 0.38); | ||

} | } | ||

} | |||

</nowiki> | </nowiki> | ||

| Line 736: | Line 865: | ||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

f11p(); | |||

module f11p(){ | |||

difference(){ | difference(){ | ||

translate([0,-( | translate([0,-(f11y/2),0]) | ||

cube([ | cube([f11x,f11y,f11z]); | ||

translate([0,-( | translate([0,-(f11y/2),0]) | ||

cuts(); | cuts(); | ||

translate([0,( | translate([0,(f11y/2),0]) | ||

mirror([0,1,0]) | mirror([0,1,0]) | ||

cuts(); | cuts(); | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([0.5,0,0]) | translate([0.5,0,0]) | ||

cube([0.125,0. | cube([0.125,0.125+f9z,f11z]); | ||

translate([0.625,0,0]) | translate([0.625,0,0]) | ||

cube([0. | cube([f11x-0.5-0.125,f9z,f11z]); | ||

} //end module | } //end cuts module | ||

} //end f11p module | |||

</nowiki> | |||

==F12== | |||

Bolts to Hopper Seat | |||

==F13== | |||

Spacer betwwen F6 and F9 used to accomidate MAINcylinder with larger diameter than brickW | |||

<nowiki> | |||

include <vars.scad>; | |||

use <modus.scad>; | |||

f13p(); | |||

module f13p(){ | |||

difference(){ | |||

cube([f6y,f9y,f13z]); | |||

translate([2,f9y-2.5,0]) //?x interfaces with f6? | |||

//replacing translate y=1.9 with y=f9y-2.5 | |||

cylinder(h = f9z, r = 0.38); | |||

translate([6,f9y-2.5,0]) //?x interfaces with f6? | |||

cylinder(h = f9z, r = 0.38); | |||

} | |||

} //end f13p module | |||

</nowiki> | </nowiki> | ||

| Line 934: | Line 1,095: | ||

Bolts to: A1 | Bolts to: A1 | ||

*add insert holes for drawer part D7 | |||

**location will be determined by cylinder specifications. | |||

**length of A1 and holes to attach to A4 will need to be go along with this. | |||

<nowiki> | <nowiki> | ||

| Line 1,044: | Line 1,209: | ||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

a6p(); | |||

module a6p(){ | |||

X=a2x; | |||

Y=a1x; | |||

Zx=a2z; | |||

Zy=a1z; | |||

W=min(((1)/cos((atan((Y-1)/(X-1))))),((1)/sin((atan((Y-1)/(X-1)))))); | |||

//trying to make some overhang for insert to butt up against. not perfect but working | |||

//trying for 0.5, but not getting there exactly | |||

difference(){ | |||

union(){ | |||

translate([-1/tan(atan((Y-1)/(X-1))),0,0]) | |||

rotate([0,0,atan((Y-1)/(X-1))]) | |||

translate([0,-W,0]) | |||

#cube([50,W,a6z]); | |||

cube([0.625,Zx,a6z]); | |||

translate([X-Zy,Y-0.625,0]) | |||

cube([Zy,0.625,a6z]); | |||

} //end union - start difference | |||

translate([0.625,0,0]) | |||

cube([100,Zx,a6z]); | |||

translate([-100,-99,0]) | |||

cube([100,100,a6z]); | |||

translate([0,-100,0]) | |||

cube([100,100,a6z]); | |||

translate([0,Y,0]) | |||

cube([100,100,a6z]); | |||

translate([X,0,0]) | |||

cube([100,100,a6z]); | |||

translate([X-Zy,Y-0.625-100,0]) | |||

cube([Zy,100,a6z]); | |||

} //end difference | |||

} //end a6p module | |||

</nowiki> | </nowiki> | ||

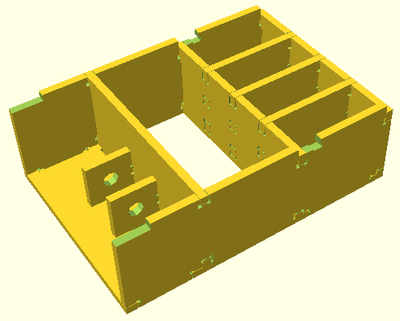

=Drawer= | =Drawer= | ||

==Drawer Assembly== | |||

*origin located at center of bottom of compression chamber | |||

*X-axis oriented along movement of drawer | |||

[[Image:CEB-scad-drawer.png|400px]] | |||

:::Dp.scad | |||

<nowiki> | |||

include <vars.scad>; | |||

use <modus.scad>; | |||

use<d1p.scad>; | |||

use<d2p.scad>; | |||

use<d3p.scad>; | |||

use<d4p.scad>; | |||

use<d5p.scad>; | |||

use<d6p.scad>; | |||

use<d8p.scad>; | |||

use<d9p.scad>; | |||

//main translate | |||

translate([-d8y-d6z-(brickW/2),-d2z-(brickL/2),0]){ | |||

translate([0,d2z,0]) | |||

rotate([90,0,0]) | |||

d2p(); | |||

translate([0,d2z+d2z+brickL,0]) | |||

rotate([90,0,0]) | |||

d2p(); | |||

translate([0,d8x/2,0]) | |||

rotate([0,0,270]) | |||

d8p(); | |||

translate([d8y+d6z,d6x/2,0]) | |||

rotate([90,0,270]) | |||

d6p(); | |||

translate([d8y+d6z+brickW,d3x/2,d3y]) | |||

rotate([270,0,270]) | |||

d3p(); | |||

translate([d8y+d6z+brickW+d3z,d5x/2,0]) | |||

rotate([0,0,270]) | |||

d5p(); | |||

translate([d8y+d6z+brickW+d3z+(d5y/2),((d5x/2)+(d5z/2))-(brickL/4),0]) | |||

rotate([90,0,0]) | |||

d4p(); | |||

translate([d8y+d6z+brickW+d3z+(d5y/2),(d5x/2)+(d5z/2),0]) | |||

rotate([90,0,0]) | |||

d4p(); | |||

translate([d8y+d6z+brickW+d3z+(d5y/2),((d5x/2)+(d5z/2))+(brickL/4),0]) | |||

rotate([90,0,0]) | |||

d4p(); | |||

translate([d8y+d6z+brickW+d5y+d3z,d3x/2,d3y]) | |||

rotate([270,0,270]) | |||

d3p(); | |||

translate([d8y+d6z,(((d6x-cylinderDRAWERrodclevisW)/2)-(d9z)),0]) | |||

rotate([90,0,180]) | |||

d9p(); | |||

translate([d8y+d6z,(cylinderDRAWERrodclevisW+d9z)+((((d6x-cylinderDRAWERrodclevisW)/2)-(d9z))),0]) | |||

rotate([90,0,180]) | |||

d9p(); | |||

translate([(d8y+d6z+brickW),(brickL/2)+d2z,d3y]) | |||

rotate([0,0,270]) | |||

d1p(); | |||

// | |||

//add drawer cylinger rod half and rod clevis | |||

// | |||

} //end main translate | |||

</nowiki> | |||

==D1== | ==D1== | ||

| Line 1,054: | Line 1,359: | ||

**need to review | **need to review | ||

:::d1p.scad | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | include <vars.scad>; | ||

use <modus.scad>; | use <modus.scad>; | ||

d1p(); | |||

module d1p(){ | |||

difference(){ | difference(){ | ||

| Line 1,073: | Line 1,380: | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

cube([2 | cube([(d1x-brickL-d2z-d2z)/2,16,d1z]); | ||

translate([2 | translate([(d1x-brickL-d2z-d2z)/2,1.5,0]) //1.5 could be better defined, but needs to match D2's cut out | ||

cube([0.6,5,d1z]); | cube([0.6,5,d1z]); //June freecad model has larger cut out | ||

} //end module | } //end module | ||

} //end d1p module | |||

</nowiki> | </nowiki> | ||

| Line 1,092: | Line 1,400: | ||

echo(d8y+d6z+brickW+d3z+d5y+d3z); //total length of part | echo(d8y+d6z+brickW+d3z+d5y+d3z); //total length of part | ||

d2p(); | |||

module d2p(){ | |||

difference(){ | difference(){ | ||

cube([d2x,d2y,d2z]); | cube([d2x,d2y,d2z]); | ||

| Line 1,145: | Line 1,457: | ||

} //end difference | } //end difference | ||

} //end d2p module | |||

| Line 1,158: | Line 1,472: | ||

//this part is rendered upside down from placement | //this part is rendered upside down from placement | ||

d3p(); | |||

module d3p(){ | |||

difference(){ | difference(){ | ||

| Line 1,170: | Line 1,488: | ||

module cuts(){ | module cuts(){ | ||

translate([0, | translate([0,d3y/2,0]) | ||

cornerjoint(d3z,d3y-(0.75*2),d2z,0.125,0.25,0.125,270,1); | |||

cornerjoint(d3z,d3y-(0.75*2), | |||

//outer columns tab inserts | //outer columns tab inserts | ||

| Line 1,192: | Line 1,509: | ||

tabinsert(d4z,(0.75*2),d3z,dGap,0.09375,0.625,0.25,0.25,0.625,0,0,0,0,1); | tabinsert(d4z,(0.75*2),d3z,dGap,0.09375,0.625,0.25,0.25,0.625,0,0,0,0,1); | ||

} //end cuts | } //end cuts module | ||

} //end d3p module | |||

</nowiki> | </nowiki> | ||

| Line 1,198: | Line 1,517: | ||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

d4p(); | |||

module d4p(){ | |||

difference(){ | difference(){ | ||

| Line 1,213: | Line 1,534: | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([0, | translate([0,d5z+0.75,0]) | ||

cornerjoint(d4z,(d4y-(0.75*2)-0.5-d5z)/2,d3z,0.125,((d4y-(0.75*2)-0.5-d5z)/2)-(0.125*2),0.125,270,0); | |||

translate([0,d4y-0.75-((d4y-(0.75*2)-0.5-d5z)/2),0]) | |||

cornerjoint(d4z,(d4y-(0.75*2)-0.5-d5z)/2,d3z,0.125,((d4y-(0.75*2)-0.5-d5z)/2)-(0.125*2),0.125,270,0); | |||

translate([-0.125,0,0]) | |||

cornerjoint(d4z,((d4x-0.5)/2)+(0.125),d5z,0.125,((d4x-0.5)/2)-0.125,0.125,0,0); | |||

} //end cut module | |||

} //end d4p module | |||

} //end | |||

</nowiki> | </nowiki> | ||

==D5== | ==D5== | ||

::d5p.scad | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

d5p(); | |||

module d5p(){ | |||

difference(){ | difference(){ | ||

| Line 1,259: | Line 1,569: | ||

cuts(); | cuts(); | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([0, | translate([0,d5y/2,0]) | ||

cornerjoint(d5z,d5y-(0.5*2),d2z,0.125,0.25,0.125,270,1); | |||

translate([1,0,0]) | translate([1,0,0]) | ||

cube([ | cube([(d5x-(1*3))/2,0.125,d5z]); | ||

translate([1,d5y-0.125,0]) | translate([1,d5y-0.125,0]) | ||

cube([ | cube([(d5x-(1*3))/2,0.125,d5z]); | ||

translate([ | translate([(brickL/4)+d2z,d5y/2,0]) | ||

tabinsert(0.5,0.5,d5z,0.03125,0.09375,0.25,0.25,0.25,0.25,0.25,0.25,0.25,0.25,1); | |||

translate([d5x/2,3,0]) | translate([d5x/2,3,0]) | ||

tabinsert(0.5,0.5,d5z,0.03125,0.09375,0.25,0.25,0.25,0.25,0.25,0.25,0.25,0.25,1); | |||

} //end cuts module | |||

} //end module | } //end d5p module | ||

</nowiki> | </nowiki> | ||

==D6== | ==D6== | ||

<nowiki> | |||

include <vars.scad>; | |||

use <modus.scad>; | |||

d6p(); | |||

module d6p(){ | |||

difference(){ | difference(){ | ||

| Line 1,321: | Line 1,609: | ||

cuts(); | cuts(); | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([0, | translate([0,1,0]) | ||

cornerjoint(d6z,d6y-1-0.5,d2z,0.125,0.25,0.125,270,0); | |||

translate([(((d6x-cylinderDRAWERrodclevisW)/2)-(d9z/2)),((d9y-d8z)/2)+d8z,0]) | |||

tabinsert(d9z,0.5,d5z,0.03125,0.09375,0.25,0.25,0.25,0.25,0.25,0.25,0.25,0.25,1); | |||

} //end cuts module | |||

} //end d6p module | |||

</nowiki> | |||

==D7== | |||

*Should this part be re-categorized as an Arm part? | |||

*Welds to A4 | |||

**tweaking to add inserts to aid weld | |||

:::d7p.scad | |||

<nowiki> | <nowiki> | ||

include <vars.scad>; | |||

use <modus.scad>; | |||

//need to add holes to A4 for cornerjoint | |||

d7p(); | |||

module d7p(){ | |||

difference(){ | difference(){ | ||

cube([d7x,d7y,d7z]); | cube([d7x,d7y,d7z]); | ||

translate([d7x/2, | |||

//joint | |||

} | translate([d7x/2,0,0]) | ||

cornerjoint(d7z,(d7x-1),a4z,0.125,0.25,0.125,0,1); | |||

//pin hole | |||

translate([d7x/2,a4z+d8z+(cylinderDRAWERbodyH/2),0]) | |||

cylinder(h = d7z,r = (cylinderDRAWERrearclevisID/2)); | |||

} //end difference | |||

} //end d7p module | |||

</nowiki> | </nowiki> | ||

==D8== | ==D8== | ||

*insert holes' position is wrong | |||

<nowiki> | |||

include <vars.scad>; | |||

use <modus.scad>; | |||

d8p(); | |||

module d8p(){ | |||

difference(){ | difference(){ | ||

| Line 1,408: | Line 1,677: | ||

} //end difference | } //end difference | ||

module cuts(){ | module cuts(){ | ||

translate([0, | translate([0,d8y/2,0]) | ||

cornerjoint(d8z,d8y-(0.75*2),d2z,0.125,0.25,0.125,270,1); | |||

translate([1,d8y-0.125,0]) | |||

cube([(d8x-(1*3))/2,0.125,d8z]); | |||

translate([(((d6x-cylinderDRAWERrodclevisW)/2)-(d9z/2)),d8y-((d9x-d6z)/2),0]) | |||

tabinsert(d9z,0.5,d5z,0.03125,0.09375,0.25,0.25,0.25,0.25,0.25,0.25,0.25,0.25,1); | |||

} //end module | } //end module | ||

} //end d8p module | |||

</nowiki> | |||

==D9== | |||

Welds to: D6, D8 | |||

*uses drawer cylinder height to determine clevis pin location | |||

<nowiki> | |||

include <vars.scad>; | |||

use <modus.scad>; | |||

d9p(); | |||

module d9p(){ | |||

difference(){ | difference(){ | ||

cube([d9x,d9y,d9z]); | cube([d9x,d9y,d9z]); | ||

translate([2,2,0]) | //x | ||

translate([-0.125,0,0]) | |||

cornerjoint(d9z,0.125+(d6z+((d9x-d6z-0.5)/2)),d8z,0.125,(d6z+((d9x-d6z-0.5)/2))-0.125,0.125,0,0); | |||

translate([0.5+(d6z+((d9x-d6z-0.5)/2)),0,0]) | |||

cornerjoint(d9z,((d9x-d6z-0.5)/2)+0.125,d8z,0.125,((d9x-d6z-0.5)/2)-0.125,0.125,0,0); | |||

//y | |||

translate([0,-0.125,0]) | |||

cornerjoint(d9z,0.125+(d8z+((d9y-d8z-0.5)/2)),d6z,0.125,(d8z+((d9y-d8z-0.5)/2))-0.125,0.125,270,0); | |||

translate([0,0.5+(d8z+((d9y-d8z-0.5)/2)),0]) | |||

cornerjoint(d9z,((d9y-d8z-0.5)/2)+0.125,d6z,0.125,((d9y-d8z-0.5)/2)-0.125,0.125,270,0); | |||

//pin hole | |||

translate([(0.5/2)+(d6z+((d9x-d6z-0.5)/2)),(0.5/2)+(d8z+((d9y-d8z-0.5)/2)),0]) | |||

cylinder(h = d9z,r = (cylinderDRAWERrodclevisID/2)); | |||

} | |||

} //end d9p module | |||

</nowiki> | </nowiki> | ||

| Line 1,593: | Line 1,849: | ||

</nowiki> | </nowiki> | ||

=Part Review Layout= | |||

*All parts layed out in sequence for review in DXF format | |||

**might find a way to label parts below X axis | |||

:::review.scad | |||

<nowiki> | |||

include <vars.scad>; | |||

use <modus.scad>; | |||

use<d1p.scad>; | |||

use<d2p.scad>; | |||

use<d3p.scad>; | |||

use<d4p.scad>; | |||

use<d5p.scad>; | |||

use<d6p.scad>; | |||

use<d8p.scad>; | |||

use<d9p.scad>; | |||

partspacing=1; //common distance between parts | |||

//d1 | |||

projection(cut = true) //use projection to create 2D DXF files | |||

translate([d1y,d1x/2,0]) | |||

rotate([0,0,90]) | |||

d1p(); | |||

projection(cut = true) | |||

translate([d1y+partspacing+d2y,0,0]) | |||

rotate([0,0,90]) | |||

d2p(); | |||

projection(cut = true) | |||

translate([d1y+partspacing+d2y+partspacing+d2y,0,0]) | |||

rotate([0,0,90]) | |||

d2p(); | |||

projection(cut = true) | |||

translate([d1y+partspacing+d2y+partspacing+d2y+partspacing+d3y,d3x/2,0]) | |||

rotate([0,0,90]) | |||

d3p(); | |||

projection(cut = true) | |||

translate([d1y+partspacing+d2y+partspacing+d2y+partspacing+d3y+partspacing+d3y,d3x/2,0]) | |||

rotate([0,0,90]) | |||

d3p(); | |||

</nowiki> | |||

=To Do= | |||

*get [[Nesting_Software|SVnest]] to work for torch table layout | |||

Latest revision as of 17:56, 3 June 2018

work in progress moved on to CEB Press v17.08/SCAD Files/

creating an OpenSCAD replica of v16.09

CEB Press v16.09/SCAD Files/Parametric

Latest files on Google Drive for download: link

Default Variables

By making a SCAD file with the variables used throughout the CEB press, we can use the "include" command within each individual part's file to pull in the same dimensions. Read More

- vars.scad

brickW=6; brickL=12; brickCH=6; $fn=8; //defines resolution of circles. 8 is okay for review. 100 or greater should be used for for final dxf export. dZstandard=0.5; //thickness of steel to be cut for drawer parts fZstandard=0.5; aZstandard=0.5; //thickness of steel to be cut for arm parts fBOLTHOLEstandardD=1; //standard bolts used on frame sliderodholeOD=1.2; dGap=0.03125; //gap between a hole cut's edge and the part sitting within the hole. //D3 appears to use 0.3125, is this in error? //all parts set to standard thickness below //off standard preferences can be defined below //drawer drawergap=0.0283; //extra room for drawer to slide in the space between f1 and f4 drawerHgap=0.1884; //total extra space from drawer sides to frame walls. sum of both sides. d1z=dZstandard; d2z=dZstandard; d3z=dZstandard; d4z=dZstandard; d5z=dZstandard; d6z=dZstandard; d5z=dZstandard; d7z=dZstandard; d8z=dZstandard; d9z=dZstandard; //frame f1x=24.2; f1y=6; f1z=0.5; f2y=3.5; f2z=fZstandard; f3x=f1x; f3y=3.5; f3z=fZstandard; f4y=11; f4z=fZstandard; f5y=3.5; f5z=fZstandard; f6y=8; f6z=fZstandard; f8y=brickW; f8z=fZstandard; f8boltD=1; f9y=4.5; f9x=43.5; //set based on MAINcylinder f9z=fZstandard; f8x=f9x; f11x=1.25; f11z=fZstandard; f13z=fZstandard; //arms a1x=4; a1y=72; //calculate based on drawer cylinder a1z=aZstandard; a2x=6; a2y=72; //calculate based on drawer cylinder a2z=aZstandard; a4z=aZstandard; a6z=aZstandard; // //Input your main cylinder's dimenions here // cylinderMAINminC2E=0; //main hydraulic cylinder's distance from center of mounting hole to the end of the shaft when fully compressed. cylinderMAINmaxC2E=0; //main hydraulic cylinder's distance from center of mounting hole to the end of the shaft when fully extended. // //Input your drawer cylinder's dimenions here // cylinderDRAWERbodyH=3; //measured when in position, largest length from top to bottom of cylinder cylinderDRAWERminC2C=0; //drawer's hydraulic cylinder's distance from the center of one mounting hole to the center of the other when fully compressed. cylinderDRAWERmaxC2C=0; ///drawer's hydraulic cylinder's distance from the center of one mounting hole to the center of the other when fully extended. cylinderDRAWERrodclevisW=2.5; //width of cylinders' clevis on end of rod cylinderDRAWERrodclevisID=1; cylinderDRAWERrodclevisOD=2; cylinderDRAWERrearclevisW=2.5; //width of mounting clevis cylinder body cylinderDRAWERrearclevisID=1; cylinderDRAWERrearclevisOD=2; cylinderDRAWERrearclevisClearance=3; //usable space around rear clevis pin (in diameter). be aware of hyraulic fittings. //the following variables are calculated in order of dependence on preceding variables d3x=brickL+(d2z*2); d3y=brickCH-d1z; d4x=brickW+d3z+d3z; d4y=brickCH-d1z; d5x=brickL+(d2z*2); d5y=brickW; d6x=brickL+(d2z*2); d6y=brickCH; d7x=cylinderDRAWERrearclevisClearance; d7y=a4z+d8z+cylinderDRAWERbodyH; d9x=cylinderDRAWERbodyH+d6z; d9y=cylinderDRAWERbodyH+d8z; d8x=brickL+(d2z*2); d8y=max(5,(d9x-d6z)); //need to review fundamentals, 5 minimun unless d9 gets larger than d8 d1x=18.5; //need to come up with a formula d1y=18; //need to come up with a formula d2x=d8y+d6z+brickW+d3z+d5y+d3z; d2y=brickCH; f11y=f8y; f6x=brickL+(d2z*2)+(f9y*2)+drawerHgap; f8x=43.5; //need to define based on MAINcylinder inputs f2x=brickL+(d2z*2)+drawerHgap+(f9y*2)-(1.4*2); //distance between large cut outs in f9 f5x=brickL+(d2z*2)+drawerHgap+(f9y*2)+(a1x*2); //distance between outer edges of each A1 f4x=f5x-0.5; //same as f5 but minus 0.25 on each side to give a little overhang

Common Modules

Creating a file of modules will allow for them to be utilized in other files with the "use" command.

modus.scad

//Corner Joint - allows the sides of two parts to create inlayed corner. Aids with welding.

//need to verify module math is the same throughout all parts.

module cornerjoint(Z,L,H,EndGap,PadL,PadH,CJangle,CJcenter){

//change so that H = Z of inlayed part (usually 0.5)

//add center and angle in degrees option, orgin far side of cut out area

if((CJangle==0)&&(CJcenter==0))

{

translate([0,0,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

else if((CJangle==90)&&(CJcenter==0))

{

translate([H+PadH,0,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

else if((CJangle==180)&&(CJcenter==0))

{

translate([L,H+PadH,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

else if((CJangle==270)&&(CJcenter==0))

{

translate([0,L,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

//centered

else if((CJangle==0)&&(CJcenter==1))

{

translate([-L/2,0,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

else if((CJangle==90)&&(CJcenter==1))

{

translate([0,-L/2,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

else if((CJangle==180)&&(CJcenter==1))

{

translate([L/2,0,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

else if((CJangle==270)&&(CJcenter==1))

{

translate([0,L/2,0])

rotate([0,0,CJangle])

difference(){

cube([L,H+PadH,Z]);

translate([EndGap,H,0])

cube([PadL,PadH,Z]);

translate([L-EndGap-PadL,H,0])

cube([PadL,PadH,Z]);}

}

} //end cornerjoint module

//Tab Insert - used to cut a hole for an abutting part to insert into. Typically aids with welding the two parts.

module tabinsert(X,Y,Z,dGap,cGap,c1,c2,c3,c4,c5,c6,c7,c8,center){

translate([-dGap-(center*(X/2)),-dGap-(center*(Y/2)),0]){

//main cut

cube([X+(dGap*2),Y+(dGap*2),Z]);

//corner c1c2

translate([-cGap,(Y+(dGap*2))-c1+cGap,0])

{

cube([c2,c1,Z]);}

//corner c3c4

translate([(X+(dGap*2))-c3+cGap,(Y+(dGap*2))-c4+cGap,0]){

cube([c3,c4,Z]);

}

//corner c5c6

translate([(X+(dGap*2))-c6+cGap,-cGap,0])

{

cube([c6,c5,Z]);

}

//corner c7c8

translate([-cGap,-cGap,0]){

cube([c7,c8,Z]);

}

} //end center translate

} //end tabinsert module

Frame

Frame Assembly

- F4 holes look slightly more narrow than the F9 holes.

- calculate F4 and F5 Z height from the top down. Let f9 length be adjusted by cylinder. try to avoid calculation again.

- Fp.scad

include <vars.scad>;

use <modus.scad>;

use <f1p.scad>;

use <f2p.scad>;

use <f3p.scad>;

use <f4p.scad>;

use <f5p.scad>;

use <f6p.scad>;

//use <f7p.scad>;

use <f8p.scad>;

use <f9p.scad>;

//use <f10p.scad>;

use <f11p.scad>;

//use <f12p.scad>;

translate([0,(f8y/2)+f1z,f9x])

rotate([90,180,0])

f1p();

translate([0,-(f8y/2),f9x])

rotate([90,180,0])

f1p();

translate([-f2x/2,(f8y/2),f9x-f1y])

rotate([0,0,0])

f2p(); //connected to F1

translate([f2x/2,-(f8y/2),f9x-f1y])

rotate([0,0,180])

f2p();

translate([0,(f8y/2),f9x])

rotate([0,180,0])

f3p(); //connected to F1

translate([0,-(f8y/2),f9x])

rotate([0,180,180])

f3p(); //connected to F1

translate([0,(f8y/2)+f6z,(f9x-f1y-brickCH-drawergap-f4y)])

rotate([90,0,0])

f4p(); //?group with f5?

translate([0,-(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)])

rotate([90,0,0])

f4p();

translate([0,(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+f4y])

rotate([0,180,0])

f5p(); //connected to F4

translate([0,-(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+f4y])

rotate([0,180,180])

f5p(); //connected to F4

translate([-f2x/2,(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+7.5-(f2z/2)])

rotate([0,0,0])

f2p(); //connected to F1

translate([f2x/2,-(f8y/2),(f9x-f1y-brickCH-drawergap-f4y)+7.5-(f2z/2)])

rotate([0,0,180])

f2p();

translate([0,(f8y/2)+f6z,f6y])

rotate([90,180,0])

f6p();

translate([0,-(f8y/2),f6y])

rotate([90,180,0])

f6p();

translate([-f2x/2,(f8y/2),0])

rotate([0,0,0])

f2p(); //connected to F6

translate([f2x/2,-(f8y/2),0])

rotate([0,0,180])

f2p();

translate([f6x/2,0,0])

rotate([0,0,180])

f11p();

translate([f6x/2,0,f9x-f1y-d2y-f4y-drawergap-0.5])

rotate([0,0,180])

f11p();

translate([f6x/2,0,f9x-0.5])

rotate([0,0,180])

f11p();

translate([-f6x/2,0,0])

rotate([0,0,0])

f11p();

translate([-f6x/2,0,f9x-f1y-d2y-f4y-drawergap-0.5])

rotate([0,0,0])

f11p();

translate([-f6x/2,0,f9x-0.5])

rotate([0,0,0])

f11p();

translate([1.9-8.5,0,0]){ //???

rotate([0,0,90]){

translate([(f8y/2),f8z,0])

rotate([90,-90,0])

f8p();

translate([(f8y/2)+(f9z/2)-(f8z/2),0,0])

rotate([0,-90,0])

f9p();

translate([-(f8y/2)+(f9z/2)+(f8z/2),0,0])

rotate([0,-90,0])

f9p();

} //end rotate

} //end translate

translate([-1.9+8.5,0,0]){

rotate([0,0,-90]){

translate([(f8y/2),f8z,0])

rotate([90,-90,0])

f8p();

translate([(f8y/2)+(f9z/2)-(f8z/2),0,0])

rotate([0,-90,0])

f9p();

translate([-(f8y/2)+(f9z/2)+(f8z/2),0,0])

rotate([0,-90,0])

f9p();

} //end rotate

} //end translate

F1

Welds to: F2, F3

Bolts to: F9

Abuts: A2

- need to tweak bolt translates?

- change to use cornerjoint module instead of insert module on outter ends of F3 connections

include <vars.scad>;

use <modus.scad>;

f1p();

module f1p(){

difference(){

translate([-(f1x/2),0,0])

cube([f1x,f1y,f1z]);

translate([-(f1x/2),0,0])

cuts();

translate([(f1x/2),0,0])

mirror([1,0,0])

cuts();

} //end difference

module cuts(){

tabinsert(1,f3z,f1z,0.0625,0.125,0,0,0.25,0.25,0.0,0,0,0,0);

translate([0,f1y-0.25,0])

cube([0.4,0.25,f1z]); //appears to be intended to interface with A2, but not sure why

translate([(f1x-f2x)/2,f1y-f2z,0])

tabinsert(1,f2z,f1z,0.0625,0.125,0,0,0,0,0.25,0.25,0.25,0.25,0); //f2

translate([(f1x/2)-1,0,0])

tabinsert(1,f3z,f1z,0.0625,0.125,0.25,0.25,0,0,0.0,0,0,0,0);

translate([((f1x-d3x-drawerHgap)/2)-2,1.5,0]) //bolt center to inner edge of f9=2

cylinder(h = f1z, r = 0.375);

translate([((f1x-d3x-drawerHgap)/2)-2,4.5,0])

cylinder(h = f1z, r = 0.375);

translate([((f1x-d3x-drawerHgap)/2)+(sliderodholeOD/2)+drawerHgap,2.465,0]) //not sure what this is supposed to align with, drawer?

cylinder(h = f1z, r = sliderodholeOD/2);

} //end cuts module

} //end f1p module

F2

Welds to: F1, F4, F6

include <vars.scad>;

use <modus.scad>;

f2p();

module f2p(){

difference(){

cube([f2x,f2y,f2z]);

translate([1,0,0])

cornerjoint(f2z,f2x-2,f1z,0.125,f2x-2-0.25,0.125,0,0);

} //end difference

} //end f2p module

F3

Welds to: F1

Bolts to: F12

- F3 and F1 should probably be made the same length.

- going to set f3y=f1y. also some tweaks to insert holes

include <vars.scad>;

use <modus.scad>;

f3p();

module f3p(){

difference(){

translate([-(f3x/2),0,0])

cube([f3x,f3y,f3z]);

translate([-(f3x/2),0,0])

cuts();

translate([(f3x/2),0,0])

mirror([1,0,0])

cuts();

} //end difference

module cuts(){

translate([1,0,0])

cornerjoint(f3z,(f3x-4)/2,f1z,1,1,0.125,0,0);

translate([5.375,f3y/2,0])

cylinder(h = f3z, r = 0.5);

} //end cuts module

} //end f3p module

F4

Welds to: F2, F5

Bolts to: F9

- use cornerjoint module instead of insert for F5 connection

- bolt holes look like they're maybe slightly miss aligned?

- are they different sized?

include <vars.scad>;

use <modus.scad>;

f4p();

module f4p(){

difference(){

translate([-(((brickL+(d2z*2)+drawerHgap+(f9y*2)))/2),0,0])

union(){

cube([(brickL+(d2z*2)+drawerHgap+(f9y*2)),f4y,f4z]);

translate([-((f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2))))/2,f4y/2,0])

f4triangle();

translate([f4x-((f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2),f4y/2,0])

mirror([1,0,0])

f4triangle();

}

translate([-(f4x/2),0,0])

cuts();

translate([(f4x/2),0,0])

mirror([1,0,0])

cuts();

} //end difference

module cuts(){

//f5 outer

translate([(f4x/2)+((f5x/2)-2),f4y,0])

cornerjoint(f4z,4,f5z,0.125,1,0.125,180,1);

//tabinsert(4,f5z*2,f4z,0.0625,0.125,0,0,0,0,0,0,0.25,0.25,1);

//f5 center

translate([(f4x/2),f4y,0])

tabinsert(2,f5z*2,f4z,0.0625,0.125,0,0,0,0,0.0,0,0.25,0.25,1);

//f2

translate([(f4x-f2x+1)/2,7.5,0])

tabinsert(1,f2z,f6z,0.0625,0.125,0.25,0.25,0.25,0.25,0.25,0.25,0.25,0.25,1);

//f9 bolts

translate([((f4x-brickL-(d2z*2)-drawerHgap)/2)-2,2,0])

cylinder(h = f4z, r = 0.5025); //diameter 1.0?

translate([((f4x-brickL-(d2z*2)-drawerHgap)/2)-2,6,0])

cylinder(h = f4z, r = 0.5025);

translate([((f4x-brickL-(d2z*2)-drawerHgap)/2)-2,9,0])

cylinder(h = f4z, r = 0.5025);

} //end module

module f4triangle (){

difference(){

cube([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,f4y/2,f4z]);

difference(){

cube([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,f4y/2,f4z]);

translate([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,0,0])

rotate([0,0,atan(((f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2)/(f4y/2))])

cube([10,10,f4z]);

translate([(f4x-(brickL+(d2z*2)+drawerHgap+(f9y*2)))/2,0,0])

cube([10,10,f4z]);

}

}

} //end f4triangle module

} //end f4p module

F5

Welds to: F4

Bolts to: A1

- f5p.scad

include <vars.scad>;

use <modus.scad>;

f5p();

module f5p(){

difference(){

translate([-(f5x/2),0,0])

cube([f5x,f5y,f5z]);

translate([-(f5x/2),0,0])

cuts();

translate([(f5x/2),0,0])

mirror([1,0,0])

cuts();

} //end difference

module cuts(){

translate([4,0,0])

cornerjoint(f5z,(f5x-(4*2)-2)/2,f4z,1,1,0.125,0,0);

//arm bolt hole

translate([(a1x/2),f5y-1.5,0]) //aligns with hole in center of a1x

cylinder(h = f5z, r = 0.5);

//might add an insert for an A6 type of support

} //end cuts module

} //end f5p module

F6

some errors of symmetry in source dxf drawing. made some assumptions. need to check fit with interfacing parts.

Welds to: F2, F7

Bolts to: F9

- changed bolt hole distance to outer edge, the drawerHgap makes it goofy to have a round number from center.

- need to change translate to accomidate for drawerHgap

- need to use insert module for f2 holes

- need to use MAINcylinder specs to make cylinder pin hole

include <vars.scad>;

use <modus.scad>;

f6p();

module f6p(){

difference(){

translate([-(f6x/2),0,0])

cube([f6x,f6y,f6z]);

translate([-(f6x/2),0,0])

cuts();

translate([(f6x/2),0,0])

mirror([1,0,0])

cuts();

} //end difference

module cuts(){

translate([(f6x-f2x)/2,f6y-f2z,0])

tabinsert(1,f2z,f6z,0.0625,0.125,0,0,0,0,0.25,0.25,0.25,0.25,0); //F2

//need to change this section to match MAINcylinder specs

translate([(f6x/2)-1.125,f6y-3.22,0])

cube([2.25,3.22,f6z]);

translate([f6x/2,f6y-3.22,0])

cylinder(h = f6z, r = 1.125);

// bolt holes to f9

translate([((f6x-brickL-(d2z*2)-drawerHgap)/2)-2,2,0])

cylinder(h = f6z, r = 0.38); //diameter 0.76?

translate([((f6x-brickL-(d2z*2)-drawerHgap)/2)-2,6,0])

cylinder(h = f6z, r = 0.38);

} //end cuts module

} //end f6p module

F8

Welds to: F9, F10

Bolts to: Rub Plate ?

- need to redo cornerjoint module inputs

- need to set standard bolt size

include <vars.scad>;

use <modus.scad>;

f8p();

module f8p(){

difference(){

cube([f8x,f8y,f8z]);

translate([(1/12)*f8x,0,0])

cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,0,1);

translate([(5/12)*f8x,0,0])

cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,0,1);

translate([(9/12)*f8x,0,0])

cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,0,1);

translate([(1/12)*f8x,f8y,0])

cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,180,1);

translate([(5/12)*f8x,f8y,0])

cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,180,1);

translate([(9/12)*f8x,f8y,0])

cornerjoint(f8z,(f8x/6),f9z,0.25,0.5,0.125,180,1);

hull(){

translate([f8x-7-((f1y+d2y+drawergap+1)-(0.26/2)),f8y/2,0]) //?x interfaces with what? need to calculate center of F8

cylinder(h = f8z, r = f8boltD/2);

translate([f8x-7-((f1y+d2y+drawergap+1)+(0.26/2)),f8y/2,0])

cylinder(h = f8z, r = f8boltD/2);

}

hull(){

translate([f8x-((f1y+d2y+drawergap+1)-(0.26/2)),f8y/2,0]) //?x interfaces with what?

cylinder(h = f8z, r = f8boltD/2);

translate([f8x-((f1y+d2y+drawergap+1)+(0.26/2)),f8y/2,0])

cylinder(h = f8z, r = f8boltD/2);

}

}

} //end f8p module

F9

Welds to: F8, F11

Bolts to: F1, F4, F6

Abuts: A1 ?, A2 ?, F12

include <vars.scad>;

use <modus.scad>;

f9p();

module f9p(){

difference(){

cube([f9x,f9y,f9z]);

translate([(3/12)*f9x,0,0])

cornerjoint(f9z,(f8x/6),f8z,0.25,0.5,0.125,0,1);

translate([(7/12)*f9x,0,0])

cornerjoint(f9z,(f8x/6),f8z,0.25,0.5,0.125,0,1);

translate([(11/12)*f9x,0,0])

cornerjoint(f9z,(f8x/6),f8z,0.25,0.5,0.125,0,1);

translate([0,f9y-0.5,0])

tabinsert(0.5,0.5,f9z,0.03125,0.125,0,0,0,0,0.25,0.25,0,0,0);

translate([f9x-f1y-d2y-f4y-drawergap-0.5,f9y-0.5,0])

tabinsert(0.5,0.5,f9z,0.03125,0.125,0,0,0,0,0.25,0.25,0.25,0.25,0);

translate([f9x-0.5,f9y-0.5,0])

tabinsert(0.5,0.5,f9z,0.03125,0.125,0,0,0,0,0,0,0.25,0.25,0);

//big cutout

translate([f9x-(f1y-0.2)-(a2x+0.4),f9y-1.4,0])

cube([a2x+0.4,1.4,f9z]); //?interfaces with a2?

//bolt holes

//f6

translate([2,2,0]) //?x interfaces with f6?

//replacing translate y=1.9 with y=f9y-2.5

cylinder(h = f9z, r = 0.38);

translate([6,2,0]) //?x interfaces with f6?

cylinder(h = f9z, r = 0.38);

//distance from center to edge of part is 1.5

//distance between center to center is 9.5283

//distance from center to edge of part is 2

//gap between parts is 6.0283

//drawer is 6.0 tall

//leaves 0.0283 space

//should this be 0.03125? (1/32)

//should f4 be attached with 4 smaller bolts instead of 3 big ones. would prevent all movement?

//f4

translate([f9x-f1y-d2y-drawergap-2,2,0]) //replacing translate y=1.9 with f9y-2.5

cylinder(h = f9z, r = 0.5025);

translate([f9x-f1y-d2y-drawergap-5,2,0])

cylinder(h = f9z, r = 0.5025);

translate([f9x-f1y-d2y-drawergap-9,2,0])

cylinder(h = f9z, r = 0.5025);

//f1

translate([f9x-4.5,2,0]) //?x interfaces with f1?

cylinder(h = f9z, r = 0.38);

translate([f9x-1.5,2,0]) //?x interfaces with f1?

cylinder(h = f9z, r = 0.38);

}

}

F10

Welds to: F8?

F10x=5.9; F10y=2; F10z=0.5; cube([F10x,F10y,F10y]);

F11

Welds to: F9

include <vars.scad>;

use <modus.scad>;

f11p();

module f11p(){

difference(){

translate([0,-(f11y/2),0])

cube([f11x,f11y,f11z]);

translate([0,-(f11y/2),0])

cuts();

translate([0,(f11y/2),0])

mirror([0,1,0])

cuts();

} //end difference

module cuts(){

translate([0.5,0,0])

cube([0.125,0.125+f9z,f11z]);

translate([0.625,0,0])

cube([f11x-0.5-0.125,f9z,f11z]);

} //end cuts module

} //end f11p module

F12

Bolts to Hopper Seat

F13

Spacer betwwen F6 and F9 used to accomidate MAINcylinder with larger diameter than brickW

include <vars.scad>;

use <modus.scad>;

f13p();

module f13p(){

difference(){

cube([f6y,f9y,f13z]);

translate([2,f9y-2.5,0]) //?x interfaces with f6?

//replacing translate y=1.9 with y=f9y-2.5

cylinder(h = f9z, r = 0.38);

translate([6,f9y-2.5,0]) //?x interfaces with f6?

cylinder(h = f9z, r = 0.38);

}

} //end f13p module

Arms

A1

Welds to: A2, A6

Bolts to: A4, A5, F1, H7, H8

Abuts: F9

A1x=4;

A1y=72;

A1z=0.5;

$fn=20;

difference(){

cube([A1x,A1y,A1z]);

translate([0,0.71875,0])

cube([0.6875,0.5625,A1z]);

translate([0,44.8501,0]) //?y.8501?

cube([0.6875,0.5625,A1z]);

translate([0,70.9688,0]) //y 0.46875 from top

cube([0.6875,0.5625,A1z]);

translate([2,2,0])

cylinder(h = A1z, r = 0.4);

translate([2,4,0])

cylinder(h = A1z, r = 0.4);

translate([2,27,0])

cylinder(h = A1z, r = 0.4);

translate([2,37,0])

cylinder(h = A1z, r = 0.4);

hull(){

translate([2,39.67,0]) //small error on drawing

cylinder(h = A1z, r = 0.4);

translate([2,40.25,0]) //small error on drawing

cylinder(h = A1z, r = 0.4);

}

hull(){

translate([2,50.25,0]) //small error

cylinder(h = A1z, r = 0.4);

translate([2,50.85,0]) //small error

cylinder(h = A1z, r = 0.4);

}

translate([2,53.75,0])

cylinder(h = A1z, r = 0.4); translate([2,56.75,0])

cylinder(h = A1z, r = 0.4);

translate([2,63.75,0])

cylinder(h = A1z, r = 0.4);

translate([2,69,0])

cylinder(h = A1z, r = 0.4);

//corner joints

for(i=[0:5])

translate([4,i*11.9375,0])

rotate([0,0,90])

cornerjoint(6.0625,0.625,0.125,0.5,0.125);

}

module cornerjoint(L,H,EndGap,PadL,PadH){

difference(){

cube([L,H,A1z]);

translate([EndGap,H-PadH,0])

cube([PadL,PadH,A1z]);

translate([L-EndGap-PadL,H-PadH,0])

cube([PadL,PadH,A1z]);

}

} //end cornerjoint module

A2

Welds to: A1, A6

Bolts to: Guards, Hopper mounts

Abuts: F1 (?), F9

A2x=5.96603; //?just 6?

A2y=72;

A2z=0.5;

$fn=20;

difference(){

cube([A2x,A2y,A2z]);

translate([A2x-0.6875,0.46875,0])

cube([0.6875,0.5625,A2z]);

translate([A2x-0.6875,26.5874,0]) //?y.8501?

cube([0.6875,0.5625,A2z]);

translate([A2x-0.6875,A2y-0.71875,0]) //y 0.46875 from top

cube([0.6875,0.5625,A2z]);

hull(){

translate([A2x-1.75,21.2,0]) //?y?

cylinder(h = A2z, r = 0.4);

translate([A2x-1.75,22.765,0]) //?y?

cylinder(h = A2z, r = 0.4);

}

hull(){

translate([A2x-1.75,47.56,0]) //?y?

cylinder(h = A2z, r = 0.4);

translate([A2x-1.75,49.0785,0]) //?y?

cylinder(h = A2z, r = 0.4);

}

//corner joints

for(i=[0:5])

translate([0,(i*12)+6,0])

rotate([0,0,270])

cornerjoint(6,0.625,0.125,0.5,0.125);

}

module cornerjoint(L,H,EndGap,PadL,PadH){

difference(){

cube([L,H,A2z]);

translate([EndGap,H-PadH,0])

cube([PadL,PadH,A2z]);

translate([L-EndGap-PadL,H-PadH,0])

cube([PadL,PadH,A2z]);

}

} //end cornerjoint module

A3

Welds to: A4, A5

a3x=4;

a3y=72;

a3z=0.5;

$fn=20;

difference(){

cube([a3x,a3y,a3z]);

//corner joints

for(i=[0:5])

translate([0,(i*12)+6,0])

rotate([0,0,270])

cornerjoint(6,0.625,0.125,0.5,0.125);

}

module cornerjoint(L,H,EndGap,PadL,PadH){

difference(){

cube([L,H,a3z]);

translate([EndGap,H-PadH,0])

cube([PadL,PadH,a3z]);

translate([L-EndGap-PadL,H-PadH,0])

cube([PadL,PadH,a3z]);

}

} //end cornerjoint module

A4

Welds to: A3

Bolts to: A1

- add insert holes for drawer part D7

- location will be determined by cylinder specifications.

- length of A1 and holes to attach to A4 will need to be go along with this.

a4x=6;

a4y=72;

a4z=0.5;

$fn=20;

difference(){

cube([a4x,a4y,a4z]);

hull(){

translate([a4x-2,23.725,0]) //?y?

cylinder(h = a4z, r = 0.4);

translate([a4x-2,24.835,0]) //?y?

cylinder(h = a4z, r = 0.4);

}

hull(){

translate([a4x-4,23.725,0]) //?y?

cylinder(h = a4z, r = 0.4);

translate([a4x-4,24.835,0]) //?y?

cylinder(h = a4z, r = 0.4);

}

hull(){

translate([a4x-2,47.135,0])

cylinder(h = a4z, r = 0.4);

translate([a4x-2,48.265,0])

cylinder(h = a4z, r = 0.4);

}

hull(){

translate([a4x-4,47.135,0])

cylinder(h = a4z, r = 0.4);

translate([a4x-4,48.265,0])

cylinder(h = a4z, r = 0.4);

}

//corner joints

for(i=[0:5])

translate([0,(i*11.9375)+6.0625,0])

rotate([0,0,270])

cornerjoint(6.0625,0.625,0.125,0.5,0.125);

}

module cornerjoint(L,H,EndGap,PadL,PadH){

difference(){

cube([L,H,a4z]);

translate([EndGap,H-PadH,0])

cube([PadL,PadH,a4z]);

translate([L-EndGap-PadL,H-PadH,0])

cube([PadL,PadH,a4z]);

}

} //end cornerjoint module

A5

Welds to: A3

Bolts to: A1

a5x=6;

a5y=72;

a5z=0.5;

$fn=20;

difference(){

cube([a5x,a5y,a5z]);

hull(){

translate([3,23.795,0])

cylinder(h = a5z, r = 0.405);

translate([3,24.805,0])

cylinder(h = a5z, r = 0.405);

}

hull(){

translate([3,47.2,0])

cylinder(h = a5z, r = 0.405);

translate([3,48.2,0])

cylinder(h = a5z, r = 0.405);

}

//corner joints

for(i=[0:5])

translate([6,(i*12)+5.9375,0])

rotate([0,0,90])

cornerjoint(6.125,0.625,0.125,0.5,0.125);

}

module cornerjoint(L,H,EndGap,PadL,PadH){

difference(){

cube([L,H,a5z]);

translate([EndGap,H-PadH,0])

cube([PadL,PadH,a5z]);

translate([L-EndGap-PadL,H-PadH,0])

cube([PadL,PadH,a5z]);

}

} //end cornerjoint module

A6

Welds to: A1, A2

include <vars.scad>;

use <modus.scad>;

a6p();

module a6p(){

X=a2x;

Y=a1x;

Zx=a2z;

Zy=a1z;

W=min(((1)/cos((atan((Y-1)/(X-1))))),((1)/sin((atan((Y-1)/(X-1))))));

//trying to make some overhang for insert to butt up against. not perfect but working

//trying for 0.5, but not getting there exactly

difference(){

union(){

translate([-1/tan(atan((Y-1)/(X-1))),0,0])

rotate([0,0,atan((Y-1)/(X-1))])

translate([0,-W,0])

#cube([50,W,a6z]);

cube([0.625,Zx,a6z]);

translate([X-Zy,Y-0.625,0])

cube([Zy,0.625,a6z]);

} //end union - start difference

translate([0.625,0,0])

cube([100,Zx,a6z]);

translate([-100,-99,0])

cube([100,100,a6z]);

translate([0,-100,0])

cube([100,100,a6z]);

translate([0,Y,0])

cube([100,100,a6z]);

translate([X,0,0])

cube([100,100,a6z]);

translate([X-Zy,Y-0.625-100,0])

cube([Zy,100,a6z]);

} //end difference

} //end a6p module

Drawer

Drawer Assembly

- origin located at center of bottom of compression chamber

- X-axis oriented along movement of drawer

- Dp.scad

include <vars.scad>;

use <modus.scad>;

use<d1p.scad>;

use<d2p.scad>;

use<d3p.scad>;

use<d4p.scad>;

use<d5p.scad>;

use<d6p.scad>;

use<d8p.scad>;

use<d9p.scad>;

//main translate

translate([-d8y-d6z-(brickW/2),-d2z-(brickL/2),0]){

translate([0,d2z,0])

rotate([90,0,0])

d2p();

translate([0,d2z+d2z+brickL,0])

rotate([90,0,0])

d2p();

translate([0,d8x/2,0])

rotate([0,0,270])

d8p();

translate([d8y+d6z,d6x/2,0])

rotate([90,0,270])

d6p();

translate([d8y+d6z+brickW,d3x/2,d3y])

rotate([270,0,270])

d3p();

translate([d8y+d6z+brickW+d3z,d5x/2,0])

rotate([0,0,270])

d5p();

translate([d8y+d6z+brickW+d3z+(d5y/2),((d5x/2)+(d5z/2))-(brickL/4),0])

rotate([90,0,0])

d4p();

translate([d8y+d6z+brickW+d3z+(d5y/2),(d5x/2)+(d5z/2),0])

rotate([90,0,0])

d4p();

translate([d8y+d6z+brickW+d3z+(d5y/2),((d5x/2)+(d5z/2))+(brickL/4),0])

rotate([90,0,0])

d4p();

translate([d8y+d6z+brickW+d5y+d3z,d3x/2,d3y])

rotate([270,0,270])

d3p();

translate([d8y+d6z,(((d6x-cylinderDRAWERrodclevisW)/2)-(d9z)),0])

rotate([90,0,180])

d9p();

translate([d8y+d6z,(cylinderDRAWERrodclevisW+d9z)+((((d6x-cylinderDRAWERrodclevisW)/2)-(d9z))),0])

rotate([90,0,180])

d9p();

translate([(d8y+d6z+brickW),(brickL/2)+d2z,d3y])

rotate([0,0,270])

d1p();

//

//add drawer cylinger rod half and rod clevis

//

} //end main translate

D1

- does not match freecad drawing from JuneGroup file

- need to review

- d1p.scad

include <vars.scad>;

use <modus.scad>;

d1p();

module d1p(){

difference(){

translate([-(d1x/2),0,0])

cube([d1x,d1y,d1z]);

translate([-(d1x/2),0,0])

cuts();

translate([(d1x/2),0,0])

mirror([1,0,0])

cuts();

} //end difference

module cuts(){

cube([(d1x-brickL-d2z-d2z)/2,16,d1z]);

translate([(d1x-brickL-d2z-d2z)/2,1.5,0]) //1.5 could be better defined, but needs to match D2's cut out

cube([0.6,5,d1z]); //June freecad model has larger cut out

} //end module

} //end d1p module

D2

- need to switch to "tabinsert" module

Welds to: D1, D3 (2), D5, D6, D8

include <vars.scad>;

use <modus.scad>;

echo(d8y+d6z+brickW+d3z+d5y+d3z); //total length of part

d2p();

module d2p(){

difference(){

cube([d2x,d2y,d2z]);

//cuts numbered clockwise from top left

//1 - Not on FreeCad Model??

translate([0,d2y-0.43,0])

cube([2,0.43,d2z]);

//2 - D6

translate([d8y,d2y-0.5,0])

tabinsert(d6z,0.5,d2z,dGap,0.125,0,0,0,0,0.25,0.25,0.25,0.25,0);

//3 - D3, D1

translate([d8y+d6z+brickW,d2y-d1z-0.75,0])

tabinsert(d3z,d1z+0.75,d2z,dGap,0.125,0,0,0,0,0.375,0.25,0.25,0.375,0);

translate([d8y+d6z+brickW+d3z,d2y-d1z,0])

tabinsert(1.5-d3z,d1z,d2z,dGap,0.125,0,0,0,0,0.25,0.625,0,0,0);

//4 - D3, D1

translate([d2x-d3z,d2y-0.75-d1z,0]) //put in far corner

tabinsert(d3z,d1z+0.75,d2z,dGap,0.125,0,0,0,0,0,0,0.25,0.5,0);

//5 - D3, D5

translate([d8y+d6z+brickW+d3z+(d5y-0.5),0,0])

tabinsert(0.5,d5z,d2z,dGap,0.125,0.25,0.25,0,0,0,0,0,0,0);

translate([d8y+d6z+brickW+d3z+d5y,0,0])

tabinsert(d3z,0.75,d2z,dGap,0.125,0.25,0.25,0,0,0,0,0,0,0);

//6 - D3, D5

translate([d8y+d6z+brickW,0,0])

tabinsert(d3z,0.75,d2z,dGap,0.125,0.5,0.25,0.25,0.25,0,0,0,0,0);

translate([d8y+d6z+brickW+d3z,0,0])

tabinsert(0.5,d5z,d2z,dGap,0.125,0,0,0.25,0.375,0,0,0,0,0);

//7 - D6, D8

translate([d8y-0.75,0,0])

tabinsert(0.75,d8z,d2z,dGap,0.125,0.25,0.25,0,0,0,0,0,0,0);

translate([d8y,0,0])

tabinsert(d6z,1,d2z,dGap,0.125,0.25,0.25,0.25,0.625,0,0,0,0,0);

//8 - D8

tabinsert(0.75,d8z,d2z,dGap,0.125,0,0,0.25,0.25,0,0,0,0,0);

} //end difference

} //end d2p module

D3

- need to fix corner joint module, then double check its use here

include <vars.scad>;

use <modus.scad>;

//this part is rendered upside down from placement

d3p();

module d3p(){

difference(){

translate([-(d3x/2),0,0])

cube([d3x,d3y,d3z]);

translate([-(d3x/2),0,0])

cuts();

translate([(d3x/2),0,0])

mirror([1,0,0])

cuts();

} //end difference

module cuts(){

translate([0,d3y/2,0])

cornerjoint(d3z,d3y-(0.75*2),d2z,0.125,0.25,0.125,270,1);

//outer columns tab inserts

translate([(brickL/4)+d2z,d3y-d5z-(0.75/2),0])

tabinsert(d4z,0.75,d3z,dGap,0.09375,0.375,0.25,0.25,0.375,0.375,0.25,0.25,0.375,1);

translate([(brickL/4)+d2z,((d4y-d5z)/2),0])

tabinsert(d4z,0.5,d3z,dGap,0.09375,0.25,0.25,0.25,0.25,0.25,0.25,0.25,0.25,1);

translate([(brickL/4)+d2z,0,0])

tabinsert(d4z,(0.75*2),d3z,dGap,0.09375,0.625,0.25,0.25,0.625,0,0,0,0,1);

//center column tab inserts

translate([d3x/2,d3y-d5z-(0.75/2),0])