OSE CircularKnitic v18.03: Difference between revisions

Jump to navigation

Jump to search

(→To Do) |

(→To Do) |

||

| Line 3,342: | Line 3,342: | ||

**maybe position flat bar tangent to machine circle | **maybe position flat bar tangent to machine circle | ||

**or mount angel to corner, print second piece to bolt through and hold in place | **or mount angel to corner, print second piece to bolt through and hold in place | ||

**or combine thread feeder into mountain? one part? snap together? | |||

*add fillet to the angle iron mount on the in inside wall base | *add fillet to the angle iron mount on the in inside wall base | ||

*fabric weight clip holder plates | *fabric weight clip holder plates | ||

Revision as of 02:20, 3 March 2019

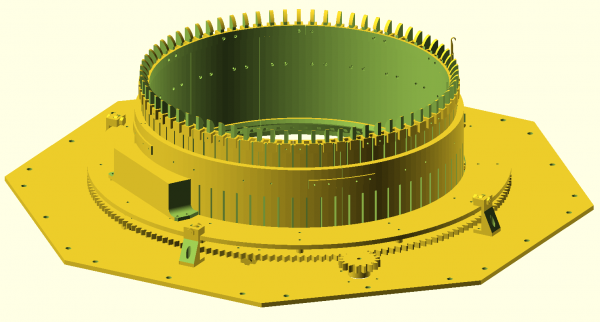

Overview

- OSE's Fork of CircularKnitic, the open source circulate knitting machine

- Code available on GitHub https://github.com/OpenSourceEcology/circular_knitic

- Test build log - User:Dorkmo/Builds/CircularKnitic

Goals

Needle Accomidation

- Long tails

- Bent back tails (postponed)

- Test 3D printed needles (postponed)

Fabric Spool

- Apply constant tension on fabric (postponed)

- Roll onto spool for easy handling and storage (postponed)

Part Code

CKvars.scad

- Variables to be defined for all aspects of the specific machine to be built

- These variables should be set the same for each part that is rendered

- need to define nominal distance between top of needle to top of CKp4.

- need to increase number of p3 and p4 parts.

- calculate printer footprint for each part.

////MAIN SETTINGS////

//select needle size file that will be used

include <CKneedleVars-KH260.scad>;

//number of "p2" parts around circle //Jan2019

p2number=12; //12 //36 ///36 //12

//number of needles mounted on each "p2" part

p2needles=5; //5 //10 ///5 //5

//number of "p3" parts around circle

p3number=4; //4 //18 ///4 //4

//number of "p4" parts around circle

p4number=4; //4 //18 ///4 //4

//distance from the inside face of one needle to the next

needle2needle=13.5334; //default=14.35615 //try 8.414 //13.5334

//calculated diameter from inside edge of needles

p2needlegrooveID=((needle2needle*p2number*p2needles)/PI);

//nnumber of Z bearing mounts

c1zmounts=p3number;

c1steppersnumber=2; //number of stepper motors driving the gear

////MATERIALS////

//thread feeder stand above mountain

TF=1; // 0=none 1=angle iron 2=makerbeamm

TFW=60; //distance between outside edge of makerbream

aaX=12.7; //12.7 = 1/2in

aaT=1.5875; //1.5875 = 1/16in

aaboltD=3;

aaboltHD=5.68;

aaboltHH=3;

aanutH=4;

aasqNutW=5.5;

aasqNutH=1.8;

aasqNutSlop=0.25;

pM2slop=0.25;

pM2H=aaX*3;

pM2mink=4;

pM2fH=10;

tipHole=3; //hole Size

tipOpenX=10;

tipOpenZ=10;

tipcylD=1.75; //1.5

tipcy2D=tipcylD*1.5;

//-(tipOpenX/2)+(tipcylD/2)

upper_surfaceH=3.175; //thickness of upper rotating plate ///5 //6.35= 1/4"inch

bottom_surface_motor_gearsH=3.175; //thickness of geared rotating plate

table_surface=3.175; //thickness of plate of main table

woodbeamW=25.4; //table leg wood beam width

woodbeamScrewOD=6.32; // 1/4" screw hole

////PART SETTINGS////

//plate

pPplate1=bottom_surface_motor_gearsH; //thickness of geared plated

pPplate2=upper_surfaceH;

/*

//"connector0912" connects upper_surface plate to bottom_surface geared plate

connector0912H=12;

connector0912L=25;

connector0912W=8;

connector0912HoleOD=3; //hole diameter

connector0912HoleC2C=17; //center of hole to center of other hole

*/

//p5 BearringSmall1312_x_4.stl

bearingholderSmallB2C=5.5; //from base of bearing holder to center of bearing

bearingholderSmallBOD=10; //Outside Diameter of bearing

bearingholderSmallBID=4.9; //Inside Diameter of bore hole of bearing

bearingholderSmallBW=4; //Width of bearing

bearingholderSmallgaproll=0.25; //extra space to leave below bearing for rolling

bearingholderSmallgapclear=0.5; //extra space to leave above bearing inside holder

//BearringZ

bearingholderZBOD=10; //Outside Diameter of bearing

bearingholderZBID=4.9; //Inside Diameter of bore hole of bearing

bearingholderZBW=4; //Width of bearing //4

//p1 - stepper gear

NEMAshaftOD=5;

NEMAshaftCut=0.5;

NEMAshaftL=20; //length of shaft from motor face

NEMAshaftFL=15; //length of flat side of shaft

NEMAboltOD=3;

NEMAboltHeadH=3;

NEMAboltHeadOD=5.68;

NEMAboltHexOD=2.87;

NEMAfaceCricOD=22;

NEMAboltDis=31;

NEMAmotorW=42;

NEMAsetboltL=8; //length of M3 botl used for set screw

NEMAsetboltOD=3;

NEMAsetHeadOD=5.68;

NEMAsqNutW=5.5;

NEMAsqNutH=1.8;

NEMAsqNutSlop=0.25;

spurgearTn=16; //number of teeth on bull gear

//p2 - inner needle wall holder

needleWidthslop=0.4; //exta thickness

needleWidth=nX+needleWidthslop;

p2needlegroovefromID=2.0;

p2ID=p2needlegrooveID-(p2needlegroovefromID*2);

p2needlegrooveDepthslop=0.4; //exta thickness

p2needlegrooveDepth=nY+p2needlegrooveDepthslop;

//p2H calculated below;

p2W=p2needlegroovefromID+p2needlegrooveDepth;

p2OD=p2ID+(p2W*2);

//p2holeH calculated below

p2holeD=2;

p2holeCSD=4.01726;

p2holeCSL=1.5;

p2endtrim=0.5;

echo("p2ID", p2ID);

//p3 - outer needle wall slide

p3wiggle=0.1;

p3baseH=3; //height of outer base

p3wallW=(nH-nY)/2; //half of needle butt

p3upperwallW=3;

p3baseholeD=3;

p3baseholeScrewHeadD=5.68;

p3baseholefromODID=p3baseholeScrewHeadD/2;

p3baseholenumber=4;

p3ridgeW1=3;

p3ridgeW2=5;

p3ridgeH=5;

p3wallholefromtop=5;

p3wallchamfW=2;

p3wallchamfH=3;

//p3wallH in calculations below

//p3grooveH1 in calculations below

//p3grooveH2 in calculations below

p3grooveHslop=1;

p3grooveWslop=0.8; //extra Width in needle groove

p3grooveW=nX+p3grooveWslop;

p3clear=5; //distance from top of p3 to needle flipper in down position

p3baseID2N=2; //clearance between baseID and needles

p3baseID=p2OD+(p3baseID2N*2);

p3baseOD=p2OD+(p3wiggle*2)+(p3wallW*2)+(p3wallchamfW*2)+(p3baseholeScrewHeadD*2);

centerlineD=p2ID+(p2W+(p3wiggle*2));

p3wallOD=centerlineD+(p3wallW*2)+((p2W+(p3wiggle*2)/2));

p3wallID=centerlineD+((p2W+(p3wiggle*2)/2));

p3base45W=p3ridgeW2+p3wiggle+p2W+p3wiggle+p3baseID2N;

p3base45H=p3base45W; //height of 45 degree overhang

p3needleholefactorW=1.5; //multiply width of needle tail hole in base by this

p3endtrim=0.5;

//p4

p4rampH=14.57;

p4rampfromID=2.5;

p4rampoverhangH=4;

p4rsH=p4rampH-p4rampoverhangH; //height of ramp surface

p4rampfromOD=1.34;

p4rampC1=10;

p4rampC2=40;

p4rampC2transX=10;

p4rampC2transZ=3.82;

p4baseH=13;

p4basegapH=8;

p4baseW=11.2;

p4basegapW=p2W+0.2; //5.09

p4clawW=min((needle2needle-(nX*2)),9);

p4holesnumber=3;

p4holeH=5;

p4rampW=max(min(p4clawW-3,4),2.5);

p4clear=-0.5; //distance above top of p4 from flipper in down position //need to fix -0.5?

p4endtrim=0.5;

echo("rampW", p4rampW);

//space between rotating plates

pPextra=1; //extra room below nC at lowest point

pPspace2=nC+(p4baseH-p4basegapH)+pPextra; //space between geared plate and mountain plate, needle nC? //12

//p5 small bearing holder

p5boltHeadOD=8; //look up sales drawing - used to cut mountain

p5boltHeadH=3.65; //look up sales drawing - used to cut mountain

p5nutH=5;

p5boltD=5;

p5boltL=30; //bolt to hold bearings

p5wingW=7;

p5wingL=p5boltHeadH+p5boltL;

p5wingH=3;

p5bodyW=bearingholderSmallBOD+6;

p5bodyL=p5boltL-p5nutH;

p5bearCl=1.5; //distance from top of body to OD of bearing

p5bodyH=bearingholderSmallgapclear+bearingholderSmallBOD-p5bearCl;

p5wiggleL=0.4; //clearnace around bearing

p5wiggleW=0.25; //clearnace around bearing

p5bearingfromwall=4.25;

p5mountholeOD=3; //mounting bolt OD

p5mountBoltHeadOD=5.68;

pPspace1=bearingholderSmallgapclear+bearingholderSmallBOD+bearingholderSmallgaproll; //? space from main table top to first plate - calc w/ bearing holder height, stepper motor shaft length?

//made max of bearing holder, and p3wall45H?

echo("pPspace1",pPspace1);

p1H=pPspace1+pPplate1+1;

//p6 big bearing holder

p6wingW=30;

p6wingL=25;

p6wingH=3;

p6bodyW=16;

p6bodyL=25;

p6bodyH=9.5;

p6wiggleL=0.4;

p6wiggleW=0.6;

p6bearingfromwall=4.25;

p6mountholeOD=3;

p6mountholeHeadOD=5.68; //OD of socket screw head

p6mounthole2front=8;

p6mounthole2side=3;

//p7 Z bearing holder - need to tweak more for different size bearings

//bearing bolt

p7boltHeadOD=8; //look up sales drawing - used to cut mountain

p7boltHeadH=3.65; //look up sales drawing - used to cut mountain

p7nutH=2.7; //jam nut

p7boltD=5;

p7boltL=16; //bolt to hold bearings

p7baseH=4;

p7wallW=3;

p7mountH=bearingholderZBOD-2;

p7mountholeOD=3;

p7mountholeHeadOD=5.68;

p7mounthole2edge=4.5;

p7bearingfromfront=3;

p7wiggleL=0.4;

p7wiggleW=0.25;

p7baseW=bearingholderZBOD+8; //16

p7baseL=max((((p7bearingfromfront+bearingholderZBW+p7bearingfromfront)*2)+p7wallW),(p7mountholeHeadOD*2)+p7wallW,(p7mounthole2edge*2)+p7wallW); //23

p7mountL=(p7baseL-p7wallW)/2; //13

echo("suggested boltL for Z bearing", ceil(((((p7baseL-p7wallW)/2)+p7wallW+p7nutH)/2))*2 );

//p8 plate connector

p8boltHeadOD=5.68; //look up sales drawing - used to cut mountain

p8boltHeadH=3; //look up sales drawing - used to cut mountain

p8nutH=4; //jam nut

p8boltD=3;

p8boltL=30; //bolt to hold bearings ????

p8baseW=8;

p8holeD=p8boltD;

p8H=pPspace2;

echo("suggested boltL for spacer", ceil((upper_surfaceH+pPspace2+bottom_surface_motor_gearsH+p8nutH)/5)*5 ); //20,22,25,30 commonly availabble

//p9 outer connector

p9thickness=2;

p9H=10;

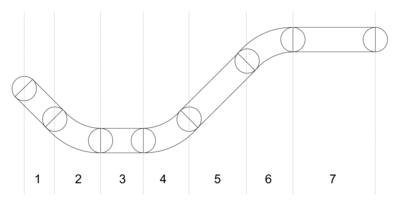

//mountain

pMwallT=9; //min thickness from groove to back wall //7.5 //10

pMgroove=nH-nY-p3wallW+1; //depth of groove

pMgrooveSlop=2; //height slop of groove

pMgrooveD=nC+pMgrooveSlop; //Z plane diamter of groove cut

pMgrooveAngle=45;

pMgrooveC1=pPspace2; //top of groove at position 1 "entrance" pPspace2 ///////////

pMgrooveC2=nC+pPextra; //top of groove at position 2 "push down" nC+2 ////////////

echo("pushdown distance",pPspace2-(nC+pPextra));

threadthickness=0.5; //approx used to leave space above p2

pMgrooveC3=pMgrooveC2+(pMgrooveD-nC)-(nG+threadthickness)+(p4baseH-p4basegapH)+p4rampH+p4clear+nF; //top of groove at position 3 "top center" calc! //44.25

pMwallHextra=5.75; //extra height above groove at heighest point

pMH=pMwallHextra+pMgrooveC3; //total height of mountain

pMshelfH=4; //thickness of shelf resting on top of c3

pMshelfchamfR=6; //radius of chamfer at join shelf/wall

pMshelfBoltD=3;

//c2 geared plate - clean up below, not used to generate gear

c2H=bottom_surface_motor_gearsH;

c2t2t=6.858;

c2width=50; //depricated?

c2gap=0.25; //gap between c2ID and p3wallOD

c2OD=(c2width*2)+(c2gap*2)+p2OD+(p3wiggle*2)+(p3wallW*2);

c2ID=(c2gap*2)+p2OD+(p3wiggle*2)+(p3wallW*2); //should this be p3wallOD+(c2gap*2)

c2teeth=((c2OD*PI)/c2t2t);

c2dipitch=c2teeth/(c2OD*PI);

cWiggle=0.1; //extra height on mountaint cutout for c3 to sit in

/////////////////////

//calculated settings

/////////////////////

bearingholderZB2C=(bearingholderZBOD/2)+pPspace1+pPplate1+pPspace2+pPplate2; //from base of bearing holder to center of bearing

rez=p2number*p2needles*2;

centerlineD=p2ID+(p2W+(p3wiggle*2));

p3grooveH1=pPspace1+pPplate1; //bottom of verticle groove in p3

p3grooveH2=pPspace1+pPplate1+pMgrooveC3; //top of groove in p3

p4baseOD=centerlineD+p4baseW;

p4baseID=centerlineD-p4baseW;

p4basegapOD=centerlineD+p4basegapW;

p4basegapID=centerlineD-p4basegapW;

//firstcenter=(((((360/p2number/p2needles/2)/360*(p2OD*PI))-(needleWidth/2))/((360/p2number/p2needles/2)/360*(p2OD*PI)))*(360/p2number/p2needles/2))/2;

//doesnt work on narrow needle arrangement, moved to second gap

p2H=pPspace1+pPplate1+pMgrooveC2+(nA-nC-nB-nG)-threadthickness-p3base45H;

p3wallH=pPspace1+pPplate1+pMgrooveC2+nA-nB-nC-nF-p3clear;

p2holeH=p3grooveH2+((p3wallH-p3grooveH2)/2); //hight from table top

//c3

c3ID=c2ID;

c3H=upper_surfaceH;

pMID=c2ID;

pMODwall=c2ID+(pMgroove*2)+(pMwallT*2);

/////////////////////////////////

pMgrooveOR=pMgroove+(pMID/2); //center to OD of groove

// is this supposed to be the radius?

/////////////////////////////////

////////////////////////

// MOUNTAIN VARIABLES //

////////////////////////

mult=20; //rough multiplier 5-30

grez=rez*mult; //number of sides of groove path main circle

gdeg=360/grez; //standard fraction of a degree per groove rez

glen=(pMID*PI)/grez; //length of arc of each rez's fraction of a degree

glnd=glen/gdeg; //length of standard fraction of a degree

gcho=2*(pMID/2)*sin(gdeg/2); //chord length of glnd

garc=gdeg*(pMID/2); //arc length... too close to get to smaller digits that are diff?

echo("rez", rez);

echo("grez", grez);

echo("gdeg", gdeg);

echo("glen", glen);

echo("glnd", glnd);

echo("pMgrooveC3", pMgrooveC3);

pMgrooveturnR=14; //radius of upper curved path in groove 15

pMgrooveturnR2=7; //radius of lower curved path in groove 7

pMp3X=3; //length of flat area of section 3

pMcutRez=2; //cuts per degree

pMcutcylRez=36; //number of sides on groove cutting clylinder

pMcutA=45; //angle of cut path

//7

pMp7X=3; //half of length of plateu of groove. preferably whole number

pMd7=pMp7X/glnd; //number of degrees for entire groove7

pMd7s=0; //degree turn to center of groove

pMd7e=pMd7; //highest degree turn for section 7

pMh7s=pMgrooveC3-(pMgrooveD/2); //height of center of groove

pMh7e=pMgrooveC3-(pMgrooveD/2);

//6

pMp6X=cos(90-pMcutA)*pMgrooveturnR;

pMd6=pMp6X/glnd;

pMd6s=pMd7e;

pMd6e=pMd7e+pMd6;

function func6(i) = (pMgrooveturnR*cos(asin(((i-pMd6s)*(pMp6X/pMd6))/pMgrooveturnR))-pMgrooveturnR);

pMh6s=pMh7e;

pMh6e=pMh7e+func6(pMd6e);

//5

pMh5s=pMh6e;

pMh5e=0;

pMp5X=(pMh5s-pMh5e)*tan(90-pMcutA);

pMd5=pMp5X/glnd;

pMd5s=pMd6e;

pMd5e=pMd6e+pMd5;

//4

pMh4e=pMgrooveC2-(pMgrooveD/2);

pMp55X=(pMgrooveturnR2*tan(90-pMcutA))-(pMgrooveturnR2*sin(90-pMcutA))+(pMh4e/tan(90-pMcutA));

pMd55=pMp55X/glnd;

pMp4X=cos(90-pMcutA)*pMgrooveturnR2; /////////problem with non-45 angles, p55X?

pMd4=pMp4X/glnd;

pMd4s=pMd5e-pMd55;

pMd4e=pMd5e-pMd55+pMd4;

function func4(i) = -(pMgrooveturnR2*cos(asin(((pMd4e-i)*(pMp4X/pMd4))/pMgrooveturnR2))-pMgrooveturnR2);

pMh4s=func4(pMd4s);

//3

pMp3X=2.5; //length of lower plateu of groove 2.5

pMd3=pMp3X/glnd; //number of degrees for groove section 3

pMd3s=pMd4e; //degree turn to center of groove

pMd3e=pMd4e+pMd3; //highest degree turn for section 7

pMh3s=pMh4e; //height of center of groove

pMh3e=pMh4e;

//2

pMp2X=cos(pMcutA)*pMgrooveturnR2;

pMd2=pMp2X/glnd;

pMd2s=pMd3e;

pMd2e=pMd3e+pMd2;

function func2(i) = -(pMgrooveturnR2*cos(asin(((i-pMd2s)*(pMp2X/pMd2))/pMgrooveturnR2))-pMgrooveturnR2);

pMh2e=pMh3e+func2(pMd2s);

pMh2s=pMh3e;

//1

pMh1s=pMh2e;

pMh1e=pMgrooveC1-(pMgrooveD/2); //-(pMgrooveD/2)

pMp1X=(pMh1e-pMh1s)*tan(90-pMcutA);

pMd1=pMp1X/glnd;

pMd1s=pMd2e;

pMd1e=pMd2e+pMd1;

//0

pMp0X=pMgrooveD/2; //pMgrooveD

pMd0=pMp0X/glnd; //pMgrooveD/glnd; //define later

//mounting shelf and holes settings

pMshelfX=pMshelfBoltD*3; //length of shelf in mm

pMshelfd=pMshelfX/glnd; //number of degrees of shelf

pMshelfHole1X=pMshelfchamfR+(pMshelfBoltD*1.5); //distance to hole center from main body

pMshelfHole1d=(pMshelfHole1X/glen)*gdeg; //number of degrees from edge to hole center

pMshelfHole2X=pMshelfX-(pMshelfBoltD*1.5); //distance to hole center from main body

pMshelfHole2d=(pMshelfHole2X/glen)*gdeg; //number of degrees from edge to hole center

pMextman=0.0002; //increase size of filler piece to make part manifold correctly

//END MOUNTAIN VARS

///////////////////////

//c3 - redo with extra mountian tab/shelf distance

c3OD=

max(

((pow((pow(((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+pMshelfX),2)+pow((((c2ID+(pMgroove*2)+(pMwallT*2))/2)),2)),1/2))*2)+((p7mountL+p7boltHeadH)*2)

,

((((p3baseOD/2)+1+p5wingL+1+p7bearingfromfront+(p7wiggleL/2)+bearingholderZBW))*2)

);

//removed following, going to shrink p8 as needed

//(((pMID/2)+(pMgroove)+1+(p8baseL/2)+(p8holeC2C/2)+(p8holeD*1.25)+(p7mountL))*2)

//MAX() of distance from mountain, and distance from plate spacers bolts

//need to consider tooth size on plate c2 ??

echo("X", ((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+pMshelfX));

echo("Y", ((c2ID+(pMgroove*2)+(pMwallT*2))/2));

echo("c3OD=", c3OD);

pMODshelf=c3OD;

pMarcL=((PI*c2ID)*((pMd1e-pMd0)*2)/360); //approx arc length of mountain - could get more accurate number

echo("pMarcL",pMarcL);

pMmaxNum=floor((PI*c2ID)/pMarcL); //max number of mountains around circumference

echo("pMmaxNum",pMmaxNum);

pMnum=floor(pMmaxNum/2);

echo("pMnum",pMnum);

//number of sets of bearings mounted to geared plated

c2bmounts=pMnum; //p3number //probably should be higher

echo("c2bmounts",c2bmounts);

p7number=(ceil(max(

c2bmounts*1.3,

4

)/4))*4;

echo("p7number", p7number);

//number of plate connectors

c2connectors=c2bmounts*3; // need to tweak so does not overlap mountain footprint

/////gear calcs/////

//solve for # of teeth and circ_pitch that gives proper tooth whole depth

Td=5; //tooth depth-ish? - used to calculate # teeth large gear and pitch

Tn=floor(((-2*c3OD)/((c3OD-Td)-c3OD))-2); //number of teeth? - for big gear

pCir=180*(c3OD-(Td))/Tn; //circular pitch - use for both big and small gear

CKp1_circular_pitch=pCir;

CKp1_number_of_teeth=spurgearTn;

CKp1_pitch_diameter = CKp1_number_of_teeth * CKp1_circular_pitch / 180;

CKp1_pitch_radius = CKp1_pitch_diameter/2;

CKc2_circular_pitch=pCir;

CKc2_number_of_teeth=Tn;

CKc2_pitch_diameter = CKc2_number_of_teeth * CKc2_circular_pitch / 180;

CKc2_pitch_radius = CKc2_pitch_diameter/2;

echo("c3OD",c3OD);

echo("Tn",Tn);

echo("pitch",180*(c3OD-(Td))/Tn);

echo("pCir",pCir);

p5mounthole2front=(p5mountBoltHeadOD/2)+Td;

p5mounthole2back=

max(

(p5mountBoltHeadOD/2)+(((pMID+(pMgroove*2))-(p3baseOD+2))/2)

,

(p5mountBoltHeadOD/2)+4

);

//p8

p8holeend2C=4;

p8innerboltO2C=(c2ID/2)+pMgroove+1+p8holeend2C; //radius of origin to center of inner bolt

p8outerboltO2C=min(

(c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW-p7boltHeadH-1-(p8boltHeadOD/2)

,

CKc2_pitch_radius-(Td/2)-1-p8holeend2C

); //radius of origin to center of outer bolt

p8holeC2C=p8outerboltO2C-p8innerboltO2C; //p8baseL-(p8holeend2C*2)

p8baseL=p8holeC2C+(p8holeend2C*2); //25

//c1

c1H=table_surface;

c1width=c2width+91.36; //depricated?

c1OD=(CKp1_pitch_radius+CKc2_pitch_radius+(NEMAmotorW/2)+woodbeamW+2)*2; // c2OD + (c1width-c2width);

c1zOD=(((c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW+(p7baseL-p7mounthole2edge))+woodbeamW+2)*2; //outside diameter of plate at Z mounts

c1W=max(

c1OD*(-ceil(1/(floor( (2-c1steppersnumber)*(c1steppersnumber/(2/c1steppersnumber)) )+1))+1)

,

c3OD

);

test=1;

echo("floor",

(-ceil(1/(floor( (2-c1steppersnumber)*(c1steppersnumber/(2/c1steppersnumber)) )+1))+1)

); //if there are more than 2 steppers = 1

echo("c3OD",c3OD);

echo("c1W",c1W);

//thread feeder

M2tipY=tipOpenX/2; //pM2mink

M2tipZ=(((tipOpenX/2)-(nE/2))*2)+tipHole+(tipcylD/2);

M2tiptopC=(((tipOpenX/2)-(nE/2))*2)+tipHole+(tipcylD/2)-(pM2mink/4);

M2inX=((((sin(pMd4s)*(pMID/2))-(aaX/2)-(0)))*2);

M2inY=(((c2ID+(pMgroove*2)+(pMwallT*2))/2))-((p3wallID/2)-(p2needlegrooveDepthslop/2))-(nD-nY)-nD; //(M2tipY) //(nD-nY) //tipcylD/2

M2inZ=pM2H-pM2mink;

M2backwallOD=((c2ID+(pMgroove*2)+(pMwallT*2))/2)+aaT;

////SETTINGS OUTPUT ECHOS///

echo("Total Needles:", p2number*p2needles);

echo("Millimeters Between Needles:", PI*p2needlegrooveID/(p2number*p2needles));

echo("OD of p3:", p3baseOD);

echo("OD of c1:", c2OD+(c1width-c2width));

/////BOM COUNT///////

if(TF==1){

echo("Thread Feeder Mount Bolt: (2)", (ceil(((((pMID/2)-(cos(pMd4s)*(pMID/2)))+pMwallT+pMgroove)-(sin(pMd4s)*(aaboltHD))-2-aaboltHH+aaT+aanutH)/2)*2) );

}

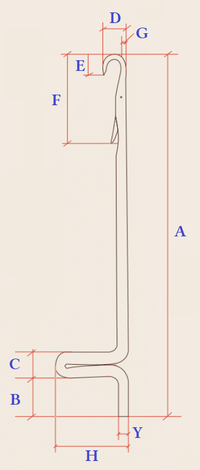

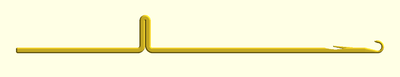

Needles

CKneedleVars-KH260.scad

- purchased here: http://shop.sckmcl.com.hk/product_info.php?products_id=136

//NEEDLE for Brother KH260 //measurements by dorkmo nX=1.4; //typical thickness from side to side nY=2.44; //typical thickness from front to back nA=157.9; //total length of needle nB=53; //distance from bottom of needle to bottom of bent tab. nC=4.82; //thickness of bent tab. top to bottom. nD=5.48; //hook front to back nE=4.10; //from top of loop to bottom of hook nF=22.0; //from top of loop to bottom of flipper in down position nG=1.10; //minimum thickness of hook. front to back. nH=17.03; //max distance from front to back nT=0; //0=straight tail 1=bent tail aka folded back. Y of tail = C if T=1.

CKneedleVars-SK120.scad

- difficult to find these exact needles for sale

//NEEDLE for SK120 //measured by original CircularKnitic team nX=1.4; //typical thickness from side to side nY=2.44; //typical thickness from front to back nA=97.73; //total length of needle nB=7.72; //distance from bottom of needle to bottom of bent tab. nC=4.92; //thickness of bent tab. top to bottom. nD=5.09; //hook front to back nE=4.62; //from top top loop to bottom of hook nF=19.94; //top to bottom of flipper in down position nG=1.04; //minimum thickness of hook. front to back. nH=16.4; //max distance from front to back nT=0; //0=straight tail 1=bent tail aka folded back. Y of tail = C of T=1.

3D Prints

- Parts to be printed on the 3D printer

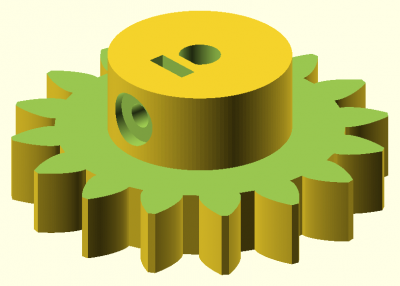

CKp1.scad "motor gear"

- Uses 2 parts

- M3 Square Nut

- M3x8 Bolt, 6 or 10 might work

- need to fix "child()" OpenScad error

include <CKvars.scad>;

use <CKc3--topplate.scad>

//////

//=BOM=

//M3 Square Nut https://www.fastenal.com/products/details/0161907

//M3x8 Bolt https://www.fastenal.com/products/details/86002

//////

rez=p2number*p2needles*2; //calculate desired rezolution

$fn=rez; //defines resolution of circles.

pi=3.1415926535897932384626433832795;

mirror([0,0,1])

CKp1();

module CKp1(){

difference(){

union(){

difference(){

gear (circular_pitch=pCir,

gear_thickness = p1H,

rim_thickness = p1H,

hub_thickness = p1H,

circles=0);

cylinder(h=p1H+2,d=NEMAshaftOD); // donut hole

difference(){

cylinder(d=c3OD,h=pPspace1-1);

cylinder(d=NEMAfaceCricOD+2,h=pPspace1-1);

}

}//end difference

//flat shaft face

rotate([0,0,360/spurgearTn/2])

translate([(NEMAshaftOD/2)-NEMAshaftCut,-NEMAshaftOD/2,0])

cube([NEMAshaftOD,NEMAshaftOD,p1H]);

}//end union

//square nut hole

rotate([0,0,360/spurgearTn/2])

translate([(NEMAshaftOD/2)-NEMAshaftCut+1.5-(NEMAsqNutSlop/2),-((NEMAsqNutW+NEMAsqNutSlop)/2),0])

cube([NEMAsqNutH+NEMAsqNutSlop,NEMAsqNutW+NEMAsqNutSlop,pPspace1-1]);

rotate([0,0,360/spurgearTn/2])

translate([0,0,(pPspace1-1)/2])

rotate([0,90,0])

cylinder(d=NEMAsetboltOD,h=NEMAfaceCricOD/2);

rotate([0,0,360/spurgearTn/2])

translate([(NEMAshaftOD/2)-NEMAshaftCut+NEMAsetboltL-0.5,0,(pPspace1-1)/2])

rotate([0,90,0])

cylinder(d=NEMAsetHeadOD+1,h=NEMAfaceCricOD/2);

}//end difference

}//end module

// Parametric Involute Bevel and Spur Gears by GregFrost

// It is licensed under the Creative Commons - GNU LGPL 2.1 license.

// © 2010 by GregFrost, thingiverse.com/Amp

// http://www.thingiverse.com/thing:3575 and http://www.thingiverse.com/thing:3752

//==================================================

// Bevel Gears:

// Two gears with the same cone distance, circular pitch (measured at the cone distance)

// and pressure angle will mesh.

module gear (

number_of_teeth=spurgearTn,

circular_pitch=false, diametral_pitch=false,

pressure_angle=28,

clearance = 0.2,

gear_thickness=5,

rim_thickness=8,

rim_width=5,

hub_thickness=10,

hub_diameter=15,

bore_diameter=5,

circles=0,

backlash=0,

twist=0,

involute_facets=0,

flat=false)

{

if (circular_pitch==false && diametral_pitch==false)

echo("MCAD ERROR: gear module needs either a diametral_pitch or circular_pitch");

//Convert diametrial pitch to our native circular pitch

circular_pitch = (circular_pitch!=false?circular_pitch:180/diametral_pitch);

// Pitch diameter: Diameter of pitch circle.

pitch_diameter = number_of_teeth * circular_pitch / 180;

pitch_radius = pitch_diameter/2;

echo ("Teeth:", number_of_teeth, " Pitch radius:", pitch_radius);

// Base Circle

base_radius = pitch_radius*cos(pressure_angle);

// Diametrial pitch: Number of teeth per unit length.

pitch_diametrial = number_of_teeth / pitch_diameter;

// Addendum: Radial distance from pitch circle to outside circle.

addendum = 1/pitch_diametrial;

//Outer Circle

outer_radius = pitch_radius+addendum;

//Use if statement and mix/max to select tooth count and circular pitch that creates a radius that is smaller than the OD of the CKp3

//circular pitch defined bt ckp3OD. number of teeth calculated for target addendum.

echo("radius",outer_radius);

// Dedendum: Radial distance from pitch circle to root diameter

dedendum = addendum + clearance;

// Root diameter: Diameter of bottom of tooth spaces.

root_radius = pitch_radius-dedendum;

backlash_angle = backlash / pitch_radius * 180 / pi;

half_thick_angle = (360 / number_of_teeth - backlash_angle) / 4;

// Variables controlling the rim.

rim_radius = root_radius - rim_width;

// Variables controlling the circular holes in the gear.

circle_orbit_diameter=hub_diameter/2+rim_radius;

circle_orbit_curcumference=pi*circle_orbit_diameter;

// Limit the circle size to 90% of the gear face.

circle_diameter=

min (

0.70*circle_orbit_curcumference/circles,

(rim_radius-hub_diameter/2)*0.9);

difference()

{

union ()

{

difference ()

{

linear_exturde_flat_option(flat=flat, height=rim_thickness, convexity=10, twist=twist)

gear_shape (

number_of_teeth,

pitch_radius = pitch_radius,

root_radius = root_radius,

base_radius = base_radius,

outer_radius = outer_radius,

half_thick_angle = half_thick_angle,

involute_facets=involute_facets);

if (gear_thickness < rim_thickness)

translate ([0,0,gear_thickness])

cylinder (r=rim_radius,h=rim_thickness-gear_thickness+1);

}

if (gear_thickness > rim_thickness)

linear_exturde_flat_option(flat=flat, height=gear_thickness)

circle (r=rim_radius);

if (flat == false && hub_thickness > gear_thickness)

translate ([0,0,gear_thickness])

linear_exturde_flat_option(flat=flat, height=hub_thickness-gear_thickness)

circle (r=hub_diameter/2);

}

translate ([0,0,-1])

linear_exturde_flat_option(flat =flat, height=2+max(rim_thickness,hub_thickness,gear_thickness))

circle (r=bore_diameter/2);

if (circles>0)

{

for(i=[0:circles-1])

rotate([0,0,i*360/circles])

translate([circle_orbit_diameter/2,0,-1])

linear_exturde_flat_option(flat =flat, height=max(gear_thickness,rim_thickness)+3)

circle(r=circle_diameter/2);

}

}

}

module linear_exturde_flat_option(flat =false, height = 10, center = false, convexity = 2, twist = 0)

{

if(flat==false)

{

linear_extrude(height = height, center = center, convexity = convexity, twist= twist) child(0);

}

else

{

child(0);

}

}

module gear_shape (

number_of_teeth,

pitch_radius,

root_radius,

base_radius,

outer_radius,

half_thick_angle,

involute_facets)

{

union()

{

rotate (half_thick_angle) circle ($fn=number_of_teeth*2, r=root_radius);

for (i = [1:number_of_teeth])

{

rotate ([0,0,i*360/number_of_teeth])

{

involute_gear_tooth (

pitch_radius = pitch_radius,

root_radius = root_radius,

base_radius = base_radius,

outer_radius = outer_radius,

half_thick_angle = half_thick_angle,

involute_facets=involute_facets);

}

}

}

}

module involute_gear_tooth (

pitch_radius,

root_radius,

base_radius,

outer_radius,

half_thick_angle,

involute_facets)

{

min_radius = max (base_radius,root_radius);

pitch_point = involute (base_radius, involute_intersect_angle (base_radius, pitch_radius));

pitch_angle = atan2 (pitch_point[1], pitch_point[0]);

centre_angle = pitch_angle + half_thick_angle;

start_angle = involute_intersect_angle (base_radius, min_radius);

stop_angle = involute_intersect_angle (base_radius, outer_radius);

res=(involute_facets!=0)?involute_facets:($fn==0)?5:$fn/4;

union ()

{

for (i=[1:res])

assign (

point1=involute (base_radius,start_angle+(stop_angle - start_angle)*(i-1)/res),

point2=involute (base_radius,start_angle+(stop_angle - start_angle)*i/res))

{

assign (

side1_point1=rotate_point (centre_angle, point1),

side1_point2=rotate_point (centre_angle, point2),

side2_point1=mirror_point (rotate_point (centre_angle, point1)),

side2_point2=mirror_point (rotate_point (centre_angle, point2)))

{

polygon (

points=[[0,0],side1_point1,side1_point2,side2_point2,side2_point1],

paths=[[0,1,2,3,4,0]]);

}

}

}

}

// Mathematical Functions

//===============

// Finds the angle of the involute about the base radius at the given distance (radius) from it's center.

//source: http://www.mathhelpforum.com/math-help/geometry/136011-circle-involute-solving-y-any-given-x.html

function involute_intersect_angle (base_radius, radius) = sqrt (pow (radius/base_radius, 2) - 1) * 180 / pi;

// Calculate the involute position for a given base radius and involute angle.

function rotated_involute (rotate, base_radius, involute_angle) =

[

cos (rotate) * involute (base_radius, involute_angle)[0] + sin (rotate) * involute (base_radius, involute_angle)[1],

cos (rotate) * involute (base_radius, involute_angle)[1] - sin (rotate) * involute (base_radius, involute_angle)[0]

];

function mirror_point (coord) =

[

coord[0],

-coord[1]

];

function rotate_point (rotate, coord) =

[

cos (rotate) * coord[0] + sin (rotate) * coord[1],

cos (rotate) * coord[1] - sin (rotate) * coord[0]

];

function involute (base_radius, involute_angle) =

[

base_radius*(cos (involute_angle) + involute_angle*pi/180*sin (involute_angle)),

base_radius*(sin (involute_angle) - involute_angle*pi/180*cos (involute_angle))

];

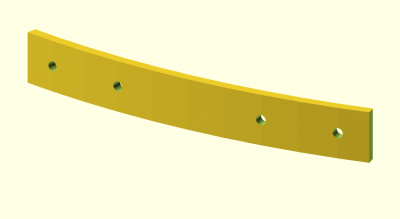

CKp2.scad "inner"

- need to fix hole matching with p4

include <CKvars.scad>;

CKp2();

module CKp2(){

rez=p2number*p2needles*2;

$fn=rez; //defines resolution of circles.

translate([p2OD/2,0,0]){

difference(){

cylinder(h=p2H,d=p2OD);

cylinder(h=p2H,d=p2ID);

translate([-p2OD/2,-p2OD/2,0]){

cube([p2OD,p2OD/2,p2H]);

}

rotate([0,0,-360/p2number]){

translate([-p2OD/2,0,0])

cube([p2OD,p2OD/2,p2H]);

}

for(i=[1:p2needles]){

rotate([0,0,(360/p2number/p2needles/2)-(360/p2number/p2needles*i)]){

translate([-p2OD/2-0.2,-needleWidth/2,0])

cube([p2needlegrooveDepth+0.2,needleWidth,p2H]);

}

}

rotate([0,0,-360/p2number/p2needles]){

translate([-p2OD/2-0.2,0,p2holeH-p3base45H])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

}

rotate([0,0,-360/p2number/p2needles*(p2needles-1)]){

translate([-p2OD/2-0.2,0,p2holeH-p3base45H])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

}

echo(((((360/p2number/p2needles/2)/360*(p2OD*PI))-(needleWidth/2))/((360/p2number/p2needles/2)/360*(p2OD*PI)))*(360/p2number/p2needles/2));

//firstcenter=(((((360/p2number/p2needles/2)/360*(p2OD*PI))-(needleWidth/2))/((360/p2number/p2needles/2)/360*(p2OD*PI)))*(360/p2number/p2needles/2))/2; not using

// 2nd hole

rotate([0,0,-(360/p2number/p2needles)*2]){

translate([-p2OD/2-0.2,0,p2holeH-p3base45H])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

}

//3rd hole

rotate([0,0,-360/p2number+((360/p2number/p2needles)*2)]){

translate([-p2OD/2-0.2,0,p2holeH-p3base45H])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

} //end rotate

//end hole

//p4 mount holes

// 1st p4 mount hole

rotate([0,0,-(360/p2number/p2needles)*2]){

translate([-p2OD/2-0.2,0,p2H-(p4basegapH-p4holeH)])

rotate([0,90,0]){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

}

}

//2nd p4 mount hole

// 2nd hole

rotate([0,0,-(360/p2number/p2needles)*3]){

translate([-p2OD/2-0.2,0,p2H-(p4basegapH-p4holeH)])

rotate([0,90,0]){

#cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

}

}

//end p4 mount holes

//trim end of part

if(p2number>1){

rotate([0,0,-(360/(p2OD*PI/p2endtrim))])

mirror([1,1,0])

#cube([p2OD/2,p2OD/2,p2H]);

}

} //end main difference

} //end main translate

} //end module

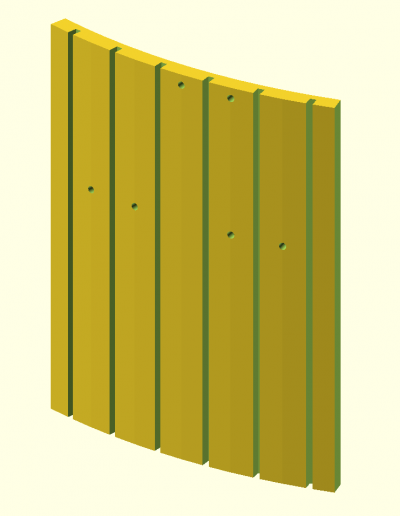

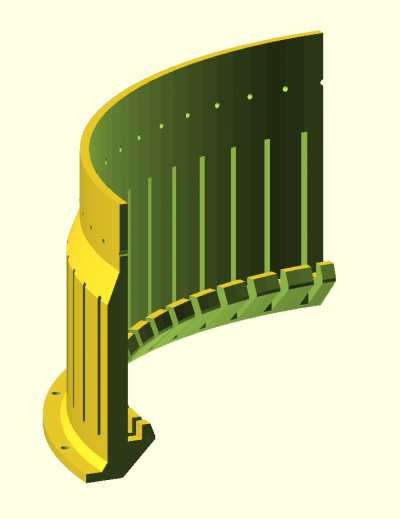

CKp3.scad "outer"

- could make base bolt similar to p7 with bolt in sloped wall.

- coul move closer to p3wallOD

- what to do if needle has bent back tail?

include <CKvars.scad>;

/*

///////////////////

use <CKneedle.scad>;

rotate([0,0,(360/p2number*p2needles/2)]){

translate([0,0,-nB+(pPspace1+pPplate1)])

rotate([0,0,(360/(p2number*p2needles))*1])

translate([(p2needlegrooveDepthslop/2),0,0])

translate([0,nX/2,0])

rotate([90,0,0])

needle();

translate([0,0,-nB+(pPspace1+pPplate1+pMgrooveC1-nC)])

rotate([0,0,(360/(p2number*p2needles))*2])

translate([(p2needlegrooveDepthslop/2),0,0])

translate([0,nX/2,0])

rotate([90,0,0])

needle();

translate([0,0,-nB+(pPspace1+pPplate1+pMgrooveC2-nC)])

rotate([0,0,(360/(p2number*p2needles))*3])

translate([(p2needlegrooveDepthslop/2),0,0])

translate([0,nX/2,0])

rotate([90,0,0])

needle();

translate([0,0,-nB+(pPspace1+pPplate1+pMgrooveC3-nC)])

rotate([0,0,(360/(p2number*p2needles))*4])

translate([(p2needlegrooveDepthslop/2),0,0])

translate([0,nX/2,0])

rotate([90,0,0])

needle();

}

///////////////////

*/

translate([-p3baseOD/2,0,0])

CKp3();

echo("p3wallH",p3wallH);

module CKp3(){

rez=p2number*p2needles*2;

//p2number*p2needles*2

//p2number*2*2;

$fn=rez; //defines resolution of circles.

centerlineD=p2ID+(p2W+(p3wiggle*2));

echo(centerlineD);

translate([p3baseOD/2,0,0]){

difference(){

union(){

cylinder(h=p3baseH,d=p3baseOD);

cylinder(h=p3base45H,d=p3baseID);

//ridge

translate([0,0,p3base45H])

difference(){

cylinder(h=p3ridgeH,d=centerlineD-((p2W+(p3wiggle*2)/2)));

translate([0,0,0])

cylinder(h=p3ridgeH,d1=centerlineD-(p3ridgeW2*2)-((p2W+(p3wiggle*2)/2)),d2=centerlineD-(p3ridgeW1*2)-((p2W+(p3wiggle*2)/2)));

} //end diff

difference(){

translate([0,0,p3baseH])

cylinder(h=p3wallchamfH,d1=centerlineD+((p3wallchamfW+p3wallW)*2)+((p2W+(p3wiggle*2)/2)),d2=centerlineD+(p3wallW*2)+((p2W+(p3wiggle*2)/2)));

cylinder(h=p3wallchamfH+p3baseH,d=centerlineD+((p2W+(p3wiggle*2)/2)));

}

difference(){

cylinder(h=p3wallH,d=centerlineD+(p3wallW*2)+((p2W+(p3wiggle*2)/2)));

cylinder(h=p3wallH,d=centerlineD+((p2W+(p3wiggle*2)/2)));

}

} //end main union

cylinder(h=p3wallH,d=p3baseID-(p3base45W*2)+1);

cylinder(h=p3base45H,d1=p3baseID,d2=p3baseID-(p3base45W*2));

translate([-p3baseOD/2,-p3baseOD/2,0]){

cube([p3baseOD,p3baseOD/2,p3wallH]);

}

rotate([0,0,-360/p3number]){

translate([-p3baseOD/2,0,0])

cube([p3baseOD,p3baseOD/2,p3wallH]);

}

//thin wall

translate([0,0,p3grooveH2])

difference(){

cylinder(d=p3wallOD,h=p3wallH);

cylinder(d=p3wallID+(p3upperwallW*2),h=p3wallH);

cylinder(d1=p3wallOD,d2=p3wallID+(p3upperwallW*2),h=p2holeH-(p9H/2)-p3grooveH2-1);

}

//slots

for(i=[1:p2needles*(p2number/p3number)]){

rotate([0,0,(360/p2number/p2needles/2)-(360/p2number/p2needles*i)]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,-p3grooveW/2,p3grooveH1-p3grooveHslop])

cube([p3wallW+0.2,p3grooveW,p3grooveH2-p3grooveH1+(p3grooveHslop*2)]);

}

}

//base mounting holes

for(i=[1:p3baseholenumber]){

rotate([0,0,(((360/p3number/p3baseholenumber))/2)-((360/p3number/p3baseholenumber)*i)]){

translate([-(p3baseOD/2)+p3baseholefromODID,0,0])

cylinder(h=p3baseH,d=p3baseholeD,$fn=18);

}

}

//p2 mounting holes

for(i=[0:(p2number*p2needles)]){

rotate([0,0,(i*-360/(p2number*p2needles))]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,0,p2holeH])

rotate([0,90,0]){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD,$fn=18);

} //end rotate

} //end rotate

} //end for

for(i=[0:(p2number/p3number)-1]){

rotate([0,0,(-360/p2number/p2needles*(p2needles-1))+(i*-360/p2number)]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,0,p2holeH])

rotate([0,90,0]){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD, $fn=18);

}

}

}//end for

//end middle holes

//trim end of part

if(p3number>1){

rotate([0,0,-(360/(p3baseOD*PI/p3endtrim))])

mirror([1,1,0])

cube([p3baseOD/2,p3baseOD/2,p3wallH]);

}

//base needle holes

difference(){

for(i=[1:p2needles*(p2number/p3number)]){

rotate([0,0,(360/p2number/p2needles/2)-(360/p2number/p2needles*i)]){

translate([-(p3wallID/2),-p3grooveW*p3needleholefactorW/2,0])

#cube([(p3wallID/2),p3grooveW*p3needleholefactorW,p3base45H+p3ridgeH+1]); //Z = p3base45H

}

}

difference(){

cylinder(d=p3wallOD,h=p3base45H+p3ridgeH+1);

cylinder(d=p3wallID,h=p3base45H+p3ridgeH+1);

}

//cylinder(d=centerlineD-((p2W+(p3wiggle*2)/2)),h=p3base45H+p3ridgeH+1);

}

} //end main difference

} //end main translate

} //end module

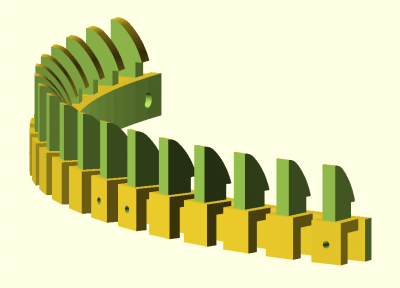

CKp4.scad "yard holder"

include <CKvars.scad>;

CKp4();

module CKp4(){

rez=p2number*p2needles*2;

$fn=rez; //defines resolution of circles.

translate([p4baseOD/2,0,0]){

difference(){

union(){

cylinder(h=p4baseH,d=p4baseOD-(p4basegapW*2)-((p4baseW-p4basegapW)/2*2));

//ramps

for(i=[1:p2needles*(p2number/p4number)]){

rotate([0,0,(360/p2number/p2needles)-(360/p2number/p2needles*i)-(((360/p2number/p2needles))/2)]){

difference(){

union(){

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4rampH+p4baseH-(p4rampC1/2)])

rotate([90,0,0])

cylinder(h=p4rampW,d=p4rampC1);

intersection(){

translate([-10,0,3.82])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4rampH+p4baseH-(p4rampC2/2)])

rotate([90,0,0])

cylinder(h=p4rampW,d=p4rampC2);

translate([-7,0,-2.86/2])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

}

}//end union

translate([-p4rampC2/2,0,0])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

translate([0,0,0])

translate([-p4baseOD/2+p4rampfromOD,p4rampW/2,p4baseH-(p4rampC2/2)-0.1])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

translate([0,-p4clawW/2,0])

translate([-(p4baseID/2)-p4rampfromID,0,p4baseH])

cube([(p4baseID/2)+p4rampfromID,p4clawW,p4rampoverhangH]);

translate([-7,0,0])

translate([-p4baseOD/2+p4rampfromOD,(p4rampW/2)+(p4rampC2/2)-0.01,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

translate([-7,0,0])

translate([-p4baseOD/2+p4rampfromOD,-(p4rampW/2)-(p4rampC2/2)+0.01,p4rampH+p4baseH-(p4rampC2/2)])

cube([p4rampC2,p4rampC2,p4rampC2],center=true);

}//end ramps difference

} //end for rotate

}//end for

//claws

for(i=[1:p2needles*(p2number/p4number)]){

rotate([0,0,(360/p2number/p2needles)-(360/p2number/p2needles*i)-(((360/p2number/p2needles))/2)]){

translate([-p4baseOD/2,-p4clawW/2,0])

cube([(p4baseOD-p4baseID)/2,p4clawW,p4baseH]);

}

}//end for

} //end main union

cylinder(h=p4baseH,d=p4baseID);

translate([-p4baseOD/2,-p4baseOD/2,0]){

cube([p4baseOD,p4baseOD/2,p4baseH]);

}

rotate([0,0,-360/p4number]){

translate([-p4baseOD/2,0,0])

cube([p4baseOD,p4baseOD/2,p4baseH]);

}

difference(){

cylinder(h=p4basegapH,d=p4basegapOD);

cylinder(h=p4basegapH,d=p4basegapID);

}

//holes

//middle holes

for(i=[0:(p2number/p4number)-1]){

rotate([0,0,(-360/p2number/p2needles*0.5)+(i*-360/p2number)]){

translate([-p4baseOD/2-0.2,0,p4holeH])

rotate([0,90,0]){

union(){

cylinder(h=p4baseOD-p4baseID+0.2, d=p2holeD);

translate([0,0,((p4baseOD-p4baseID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

} //end translate

} //end union

} //end rotate

} // end rotate

} //end for

//second set

for(i=[0:(p2number/p3number)-1]){

rotate([0,0,-(360/p2number/p2needles*0.5)+(360/p2number/p2needles)+(i*-360/p2number)+(-360/p2number)]){

translate([-p4baseOD/2-0.2,0,p4holeH])

rotate([0,90,0]){

union(){

cylinder(h=p4baseOD-p4baseID+0.2, d=p2holeD);

translate([0,0,((p4baseOD-p4baseID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

} //end translate

} //end union

} //end rotate

} // end rotate

} //end for

//end middle holes

//trim end

if(p4number>1){

rotate([0,0,-(360/(p4baseOD*PI/p4endtrim))])

mirror([1,1,0])

#cube([p4baseOD/2,p4baseOD/2,p4rampH+p4baseH]);

}

} //end main difference

} //end main translate

} //end module

CKp5.scad "small bearing holder"

include <CKvars.scad>;

CKp5(1); //small bearing holder

module CKp5(B){

mirror([0,1,0]){

translate([-(p5wingW+p5bodyW+p5wingW)/2,-p5wingL,0]){

//bearing

if(B==1){

translate([(p5wingW+p5bodyW+p5wingW)/2,p5bearingfromwall+(p5wiggleL/2)+p5boltHeadH,bearingholderSmallB2C])

rotate([270,0,0])

difference(){

cylinder(d=bearingholderSmallBOD,h=bearingholderSmallBW, $fn=36);

cylinder(d=bearingholderSmallBID,h=bearingholderSmallBW, $fn=36);

}

translate([(p5wingW+p5bodyW+p5wingW)/2,p5bodyL-p5bearingfromwall-bearingholderSmallBW-(p5wiggleL/2)+p5boltHeadH,bearingholderSmallB2C])

rotate([270,0,0])

difference(){

cylinder(d=bearingholderSmallBOD,h=bearingholderSmallBW, $fn=36);

cylinder(d=bearingholderSmallBID,h=bearingholderSmallBW, $fn=36);

}

//bolt

translate([(p5wingW+p5bodyW+p5wingW)/2,p5boltHeadH,bearingholderSmallB2C])

rotate([-90,0,0])

rotate([0,0,360/6/2])

CKbolt(p5boltD,p5boltL,p5boltHeadH,p5boltHeadOD);

//nut

translate([(p5wingW+p5bodyW+p5wingW)/2,p5bodyL+p5boltHeadH,bearingholderSmallB2C])

rotate([-90,0,0])

rotate([0,0,360/6/2])

CKnut(p5boltD,p5nutH,p5boltHeadOD);

} //end if

difference(){

union(){

//wing left

difference(){

cube([p5wingW,p5wingL,p5wingH]);

//wing left holes

translate([p5wingW/2,p5mounthole2front,0])

cylinder(d=p5mountholeOD,h=p5wingH+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2back,0])

cylinder(d=p5mountholeOD,h=p5wingH+0.1,$fn=36);

} //end wing left difference

//body

translate([p5wingW,p5boltHeadH,0]){

difference(){

cube([p5bodyW,p5bodyL,p5bodyH]);

// bearing cutout 1

translate([((p5bodyW)/2)-((bearingholderSmallBOD+p5wiggleW)/2),p5bearingfromwall,0])

cube([bearingholderSmallBOD+p5wiggleW,bearingholderSmallBW+p5wiggleL,p5bodyH+0.1]);

// bearing cutout 2

translate([((p5bodyW)/2)-((bearingholderSmallBOD+p5wiggleW)/2),p5bodyL-p5bearingfromwall-(bearingholderSmallBW+p5wiggleL),0])

cube([bearingholderSmallBOD+p5wiggleW,bearingholderSmallBW+p5wiggleL,p5bodyH+0.1]);

// bore hole cutout

translate([(p5bodyW)/2,-0.1,bearingholderSmallB2C])

rotate([270,0,0])

cylinder(d=bearingholderSmallBID,h=p5bodyL+0.2,$fn=36);

} //end body difference

} //end body translate

//wing right

translate([p5wingW+p5bodyW,0,0]){

difference(){

cube([p5wingW,p5wingL,p5wingH]);

//wing right holes

translate([p5wingW/2,p5mounthole2front,0])

cylinder(d=p5mountholeOD,h=p5wingH+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2back,0])

cylinder(d=p5mountholeOD,h=p5wingH+0.1,$fn=36);

} //end wing right difference

} //end wing right translate

}

difference(){

translate([(-(((c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW))/2)+((p5wingW+p5bodyW+p5wingW)/2),0,0])

cube([((c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW),((c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW),p5bodyH]);

translate([(p5wingW+p5bodyW+p5wingW)/2,((c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW)/2,0])

cylinder(d=((c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW),h=p5bodyH,$fn=360);

}

}//end body translate

} //end main translate

} //end mirror

} //end main module

module CKbolt(D,BL,HH,HSD){

cylinder(d=D,h=BL,$fn=32);

fudge = 1/cos(180/(6));

translate([0,0,-HH])

rotate([0,0,360/6/2])

cylinder(h=HH,r=HSD/2*fudge,$fn=(6));

}

module CKnut(BD,H,SD){

fudge = 1/cos(180/(6));

difference(){

translate([0,0,0])

rotate([0,0,360/6/2])

cylinder(h=H,r=SD/2*fudge,$fn=(6));

cylinder(d=BD,h=H,$fn=32);

}

}

CKp6.scad "big bearing holder"

- Depricated

- Replaced with p5

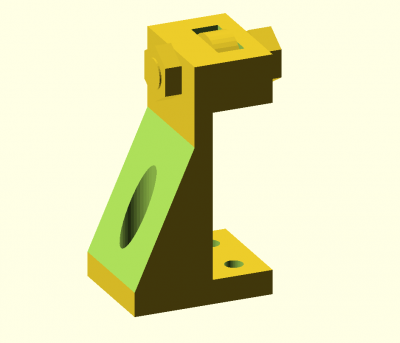

CKp7.scad "Z bearing holder"

- should a horizontal bearing be added to help keep plates aligned?

include <CKvars.scad>;

rotate([0,90,0])

CKp7(0); //small bearing holder

module CKp7(B){

translate([-p7baseW/2,0,0]){

difference(){

union(){

cube([p7baseW,p7baseL,p7baseH]);

cube([p7baseW,p7baseL/2,p7baseH+p7mountnutH]);

translate([0,(p7baseL/2)-(p7wallW/2),0])

cube([p7baseW,p7wallW,bearingholderZB2C+(p7mountH/2)]);

translate([0,(p7baseL/2)-(p7wallW/2)-p7mountL,bearingholderZB2C-(p7mountH/2)])

cube([p7baseW,p7mountL,p7mountH]);

//diagnal brace

translate([0,((p7baseL-p7wallW)/2)+p7wallW,p7baseH]){

difference(){

cube([p7baseW,(p7baseL-p7wallW)/2,bearingholderZB2C*2/3]);

translate([0,(p7baseL-p7wallW)/2,0])

rotate([1/tan(((bearingholderZB2C*2/3))/((p7baseL-p7wallW)/2)),0,0])

cube([p7baseW,bearingholderZB2C*2,bearingholderZB2C*2]);

} //end brace translate

} //end brace difference

} //end main union

//bore hole

translate([(p7baseW)/2,((p7baseL/2)-(p7wallW/2)-p7mountL)-0.1,bearingholderZB2C])

rotate([270,0,0])

cylinder(d=bearingholderZBID,h=p7mountL+p7wallW+0.2,$fn=36);

//bearing cutout

translate([((p7baseW)/2)-((bearingholderZBOD+p7wiggleW)/2),(p7baseL/2)-(p7wallW/2)-p7mountL+p7bearingfromfront,bearingholderZB2C-(p7mountH/2)-0.1])

cube([bearingholderZBOD+p7wiggleW,bearingholderZBW+p7wiggleL,p7mountH+0.2]);

////mount holes

// hole 1

translate([p7mounthole2edge,p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=p7baseH+0.1,$fn=36);

// hole 2

translate([p7baseW-p7mounthole2edge,p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=p7baseH+0.1,$fn=36);

// hole 3

translate([p7baseW/2,p7baseL-p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=p7baseH+0.1,$fn=36);

translate([p7baseW/2,p7baseL-p7mounthole2edge,p7baseH])

cylinder(d=p7mountholeHeadOD,h=bearingholderZB2C+(p7mountH/2),$fn=36);

// hole 1 hex head

translate([p7mounthole2edge,p7mounthole2edge,p7baseH])

cylinder(d=p7mountnutOD,h=p7mountnutH+0.1,$fn=6);

// hole 2 hex head

translate([p7baseW-p7mounthole2edge,p7mounthole2edge,p7baseH])

cylinder(d=p7mountnutOD,h=p7mountnutH+0.1,$fn=6);

} //end main difference

//bearing

if(B==1){

translate([p7baseW/2,p7bearingfromfront+(p7wiggleL/2),bearingholderZB2C])

rotate([270,0,0])

difference(){

cylinder(d=bearingholderSmallBOD,h=bearingholderSmallBW, $fn=36);

cylinder(d=bearingholderSmallBID,h=bearingholderSmallBW, $fn=36);

}

//bolt

translate([p7baseW/2,0,bearingholderZB2C])

rotate([-90,0,0])

rotate([0,0,360/6])

CKbolt(p7boltD,p7boltL,p7boltHeadH,p7boltHeadOD);

//nut

translate([p7baseW/2,((p7baseL-p7wallW)/2)+p7wallW,bearingholderZB2C])

rotate([-90,0,0])

rotate([0,0,360/6])

CKnut(p7boltD,p7nutH,p7boltHeadOD);

} //end if

} //end main translate

} //end main module

module CKbolt(D,BL,HH,HSD){

cylinder(d=D,h=BL,$fn=32);

fudge = 1/cos(180/(6));

translate([0,0,-HH])

rotate([0,0,360/6/2])

cylinder(h=HH,r=HSD/2*fudge,$fn=(6));

}

module CKnut(BD,H,SD){

fudge = 1/cos(180/(6));

difference(){

translate([0,0,0])

rotate([0,0,360/6/2])

cylinder(h=H,r=SD/2*fudge,$fn=(6));

cylinder(d=BD,h=H,$fn=32);

}

}

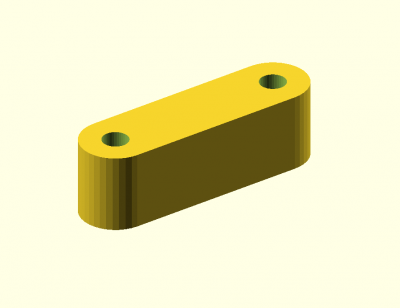

CKp8.scad "plate connector"

include <CKvars.scad>;

CKp8(); //small bearing holder

module CKp8(){

translate([0,0,0]){

difference(){

// cube([p8baseW,p8baseL,pPspace2]);

hull(){

translate([0,p8baseW/2,0])

cylinder(d=p8baseW,h=p8H,$fn=36);

translate([0,p8baseL-(p8baseW/2),0])

cylinder(d=p8baseW,h=p8H,$fn=36);

}

translate([0,p8holeend2C,-0.1])

cylinder(d=p8holeD,h=p8H+0.2,$fn=36);

translate([0,p8baseL-p8holeend2C,-0.1])

cylinder(d=p8holeD,h=p8H+0.2,$fn=36);

} //end main difference

} //end translate

} //end main module

CKp9.scad "outer connector"

include <CKvars.scad>;

CKp9(); //small bearing holder

module CKp9(){

rez=p2number*p2needles*2;

$fn=rez;

translate([-p3wallOD/2,0,0]){

difference(){

cylinder(h=p9H,d=p3wallOD+p9thickness);

cylinder(h=p9H,d=p3wallOD);

//first and last holes

rotate([0,0,-(360/p2number/p2needles)*2]){

translate([(p3wallOD/2)-0.1,0,p9H/2])

rotate([0,90,0]){

#cylinder(h=p9thickness+0.2, d=p2holeD, $fn=18);

}

}

rotate([0,0,((360/p2number/p2needles)*2)]){

translate([(p3wallOD/2)-0.1,0,p9H/2])

rotate([0,90,0]){

cylinder(h=p9thickness+0.2, d=p2holeD, $fn=18);

}

}

//end first and last holes

//outer holes

rotate([0,0,(-360/p2number/p2needles)]){

translate([(p3wallOD/2)-0.1,0,p9H/2])

rotate([0,90,0]){

cylinder(h=p9thickness+0.2, d=p2holeD, $fn=18);

}

}

rotate([0,0,(360/p2number/p2needles)]){

translate([(p3wallOD/2)-0.1,0,p9H/2])

rotate([0,90,0]){

cylinder(h=p9thickness+0.2, d=p2holeD, $fn=18);

}

}

//end outer holes

// cut off ends

rotate([0,0,-((-360/p2number/p2needles)+(1.4*-360/p2number/p2needles))]){

cube([(p3wallOD+p9thickness)*2,(p3wallOD+p9thickness)*2,(p3wallOD+p9thickness)*2]);

}

rotate([0,0,((-360/p2number/p2needles)+(1.4*-360/p2number/p2needles))]){

translate([0,-((p3wallOD+p9thickness)*2),0])

cube([(p3wallOD+p9thickness)*2,(p3wallOD+p9thickness)*2,(p3wallOD+p9thickness)*2]);

}

translate([-((p3wallOD+p9thickness)*2),-((p3wallOD+p9thickness)*2)/2,0])

#cube([(p3wallOD+p9thickness)*2,(p3wallOD+p9thickness)*2,(p3wallOD+p9thickness)*2]);

} //end main difference

} //end translate

} //end main module

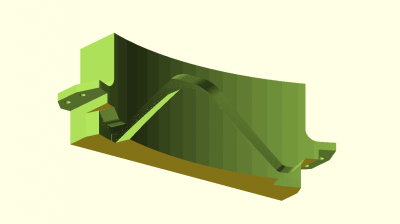

CKpM.scad "mountain"

- takes a long time to render, have to be patient

- need to set a minimum thickness of the mountain based on distance between bolt holes

- add center inlay groove for middle plate to sit in. hold mountain in place.

- possibly move/change mounting wings from above c2 to sandwich between c2 and c3 with same height as p8

- would this cause collission with p3 base bolts and pM mount bolts?

include <CKvars.scad>;

//TO DO//

//*add integrated yarn feeder based on needle height

//*function func6 not right? working with 45 angle but not others

//*pMd4 not placing groove properly when not at 45 degrees

///////

CKpM(1); //render mountain 1=w/ grove 0=w/o groove

module CKpM(G){

translate([0,-p3wallOD/2,0]){ //main translate

union(){

difference(){

translate([0,0,pMH/2])

//main cube

translate([0,(c2ID+(pMgroove*2)+(pMwallT*2))/4,0])

cube([c2ID+(pMgroove*2)+(pMwallT*2),(c2ID+(pMgroove*2)+(pMwallT*2))/2,pMH], center=true);

//main ID cut

cylinder(d=pMID,h=pMH+1,$fn=rez);

//////

//angled cut ends

rotate([0,0,atan((((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)))/((cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove))))]) /////////////

translate([-((pMshelfX)/2),0,0])

mirror([1,0,0])

cube([pMID*4,pMID*4,pMH]);

mirror([1,0,0])

rotate([0,0,atan((((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)))/((cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove))))])

translate([-((pMshelfX)/2),0,0])

mirror([1,0,0])

cube([pMID*4,pMID*4,pMH]);

//

//////

//////

//ends' angled cut with shelf

rotate([0,0,(pMd1e-pMd0)])

mirror([1,0,0])

cube([pMID*4,pMID*4,pPspace2+pPplate2]);

mirror([1,0,0])

rotate([0,0,(pMd1e-pMd0)])

mirror([1,0,0])

cube([pMID*4,pMID*4,pPspace2+pPplate2]);

//

//////

//////

//shelf cuts

translate([((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)),0,0])

cube([pMID*4,pMID*4,pPspace2+pPplate2]); //below shelf

mirror([1,0,0])

translate([((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)),0,0])

cube([pMID*4,pMID*4,pPspace2+pPplate2]); //below shelf

translate([(((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+pMshelfX,0,pPspace2+pPplate2])

cube([pMID*4,pMID*4,pMH]); //of shelf

mirror([1,0,0])

translate([(((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+pMshelfX,0,pPspace2+pPplate2])

cube([pMID*4,pMID*4,pMH]); //of shelf

//chamfered cut

mirror([1,0,0])

translate([(((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))-pMshelfchamfR,0,pPspace2+pPplate2+pMshelfH])

minkowski(){

translate([pMshelfchamfR,0,pMshelfchamfR])

cube([pMID*4,pMID*4,pMH]);

sphere(r=pMshelfchamfR,$fn=100);

} //end minkowski

//chamfered cut

mirror([0,0,0])

translate([(((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))-pMshelfchamfR,0,pPspace2+pPplate2+pMshelfH])

minkowski(){

translate([pMshelfchamfR,0,pMshelfchamfR])

cube([pMID*4,pMID*4,pMH]);

sphere(r=pMshelfchamfR,$fn=100);

} //end minkowski

translate([-(cos(45)*((pMshelfX)/2)),sin(45)*((pMshelfX)/2),0])

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

translate([0,(((((c2ID+(pMgroove*2)+(pMwallT*2))/2)/cos(pMd1e-pMd0))-((pMID/2)+(pMshelfBoltD)+pMgroove))/1.5),0])

rotate([0,0,-45])

translate([-pMID/2,0,0])

cube([pMID,pMID,pMH],center=true);

mirror([1,0,0])

translate([-(cos(45)*((pMshelfX)/2)),sin(45)*((pMshelfX)/2),0])

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

translate([0,(((((c2ID+(pMgroove*2)+(pMwallT*2))/2)/cos(pMd1e-pMd0))-((pMID/2)+(pMshelfBoltD)+pMgroove))/1.5),0])

rotate([0,0,-45])

translate([-pMID/2,0,0])

cube([pMID,pMID,pMH],center=true);

//shelf cuts

///////

//////

//mounting bolt holes

//1

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

//2

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

translate([0,(((((c2ID+(pMgroove*2)+(pMwallT*2))/2)/cos(pMd1e-pMd0))-((pMID/2)+(pMshelfBoltD)+pMgroove))/1.5),0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

mirror([1,0,0]){

//1

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

//2

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

translate([0,(((((c2ID+(pMgroove*2)+(pMwallT*2))/2)/cos(pMd1e-pMd0))-((pMID/2)+(pMshelfBoltD)+pMgroove))/1.5),0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

} //end mirror

//end of bolt holes

//////////////

///////////////////GROOVE PATH/////////

if(G==1){

//left needle path cut

needlepathLEFT();

//right needle path cut

mirror([1,0,0])

needlepathLEFT();

}

////////

//space for smallbearingholder bolt heads

translate([0,(pMID/2)+(pMgroove)+1,0]){ //close enough?

//smallbearingholder holes

translate([-(p5wingW+p5bodyW+p5wingW)/2,0,0]){

translate([p5wingW+p5bodyW,0,0]){

//wing right holes

translate([p5wingW/2,p5mounthole2front,0])

cylinder(d=p5boltHeadOD,h=p5boltHeadH+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2back,0])

cylinder(d=p5boltHeadOD,h=p5boltHeadH+0.1,$fn=36);

} //end wing right translate

//wing left holes

translate([p5wingW/2,p5mounthole2front,0])

cylinder(d=p5boltHeadOD,h=p5boltHeadH+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2back,0])

cylinder(d=p5boltHeadOD,h=p5boltHeadH+0.1,$fn=36);

}//end translate - center X of holes

}//end translate to ring

//end bearing bolts

////////

} //end main body diffference

/////////////////////////////

//////extra piece to square up shape

translate([0,0,pPspace2]){

difference(){

translate([0,(c2ID+(pMgroove*2)+(pMwallT*2))/4,((pPplate2+pMextman)/2)])

cube([c2ID+(pMgroove*2)+(pMwallT*2),(c2ID+(pMgroove*2)+(pMwallT*2))/2,pPplate2+pMextman], center=true);

cylinder(d=pMID,h=pMH,$fn=rez);

//90 degree cut

translate([((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)),0,0])

cube([pMID*4,pMID*4,pPplate2+pMextman]); //below shelf

mirror([1,0,0])

translate([((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)),0,0])

cube([pMID*4,pMID*4,pPplate2+pMextman]); //below shelf

//cut to end of groove

difference(){

rotate([0,0,(pMd1e-pMd0)-pMextman])

mirror([0,0,0])

cube([pMID*4,pMID*4,pPplate2+pMextman]);

cube([pMID*4,pMID*4,pPplate2+pMextman]);

}

difference(){

mirror([1,0,0])

rotate([0,0,(pMd1e-pMd0)-pMextman])

mirror([0,0,0])

cube([pMID*4,pMID*4,pPplate2+pMextman]);

mirror([1,0,0])

cube([pMID*4,pMID*4,pPplate2+pMextman]);

}

}//end diff

} //end translate

////////end extra piece

} //end main union

} //end main translate

} //end CKpM module

module needlepathLEFT(){

/////START GROOVE CUTS/////

//7

for(i=[pMd7s:gdeg:pMd7e]){

translate([0,0,pMh7s])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

}//end 7 for

//6

for(i=[pMd6s:gdeg:pMd6e]){

translate([0,0,pMh7s+func6(i)])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

}//end 6 for

//5

for(i=[pMd5s:gdeg:pMd5e]){

translate([0,0,pMh7s+func6(pMd6e)-(tan(pMcutA)*(i-pMd5s)*glnd)]) /////needs work

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

}//end 5 for

//4

for(i=[pMd4s:gdeg:pMd4e]){

hull(){

translate([0,0,func4(i)+pMh4e])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

if(i<=pMd5e){

translate([0,0,pMh7s+func6(pMd6e)-(tan(pMcutA)*(i-pMd5s)*glnd)])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

}

else{

translate([0,0,0])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

}

} //end hull

}//end 4 for

//3

for(i=[pMd3s:gdeg:pMd3e]){

hull(){

translate([0,0,pMh4e])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

if(i<=pMd5e){

translate([0,0,pMh7s+func6(pMd6e)-(tan(pMcutA)*(i-pMd5s)*glnd)])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

}

else{

translate([0,0,0])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

}

} //end hull

}//end 3 for

//2

for(i=[pMd2s:gdeg:pMd2e]){

hull(){

translate([0,0,func2(i)+pMh2s])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

if(i<=pMd5e){

translate([0,0,pMh7s+func6(pMd6e)-(tan(pMcutA)*(i-pMd5s)*glnd)])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

} //end if

else{

translate([0,0,0])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

} //end else

} //end hull

}//end 2 for

//1

for(i=[pMd1s:gdeg:pMd1e]){

hull(){

translate([0,0,pMh2s+func2(pMd2e)+(tan(pMcutA)*(i-pMd1s)*glnd)]) /////needs work

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

if(i<=pMd5e){

translate([0,0,pMh7s+func6(pMd6e)-(tan(pMcutA)*(i-pMd5s)*glnd)])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

} //end if

else{

translate([0,0,0])

rotate([270,0,i])

cylinder($fn=pMcutcylRez,d=pMgrooveD,h=pMgrooveOR);

} //end else

}//end hull

}//end 1 for

} //end left needle groove module

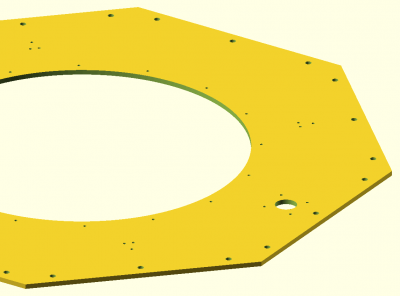

2D Cuts

- Parts to be cut out using a CNC machine

CKc1.scad

include <CKvars.scad>;

use <CKc2--bottom_surface_motor_gears.scad>;

use <CKp1--motor_gear.scad>;

////TODO

//move Z mounts to corners

//place a Z next to stepper, or on either side

//need to reduce to 380 OD width side to side

//need to reduce wasted space around the edges

projection(cut = false)

translate([c1W/2,0,0])

CKc1();

/*

translate([(c1OD/2),0,c1H+1])

rotate([0,0,0])

translate([-(CKp1_pitch_radius+CKc2_pitch_radius),0,0])

CKp1();

*/

//need to make first Z mount less than 45 if there is room

//make sure to update full assembly

//((p3baseOD/2)+1+((p5wingL)-(p5bearingfromwall+(p5wiggleL/2)+p5boltHeadH)))*2; //length to outside of outter bearing

module CKc1(){

echo("c2c of gears",CKp1_pitch_radius+CKc2_pitch_radius);

rez=p2number*p2needles*2; //calculate desired rezolution

$fn=rez; //defines resolution of circles.

translate([0,0,0]){

difference(){

translate([-c1W/2,-c1OD/2,0])

cube([c1W,c1OD,c1H]);

/*

// union(){

//octogon

difference(){

translate([-c1zOD/2,-c1zOD/2,0])

cube([c1zOD,c1zOD,c1H]); //use C1OD stepper side, use new number for Z side

for(i=[2:8]){

rotate([0,0,(45*i)+90])

translate([c1zOD/2,-c1zOD/2,0])

#cube([c1zOD,c1zOD,c1H]);

}

for(i=[1]){

rotate([0,0,(45*i)+90])

translate([c1OD/2,-c1OD/2,0])

#cube([c1OD,c1OD,c1H]);

}

} //end diff

*/

// fudge = 1/cos(180/(8));

// rotate([0,0,360/8/2])

// cylinder(h=c1H,r=(c1OD/2)*fudge,$fn=(8));

// cylinder(h=c1H,d=c1OD);

// } //end main union

cylinder(h=c1H+2,d=p3baseID); // donut hole

//base needle holes

////should these be circles instead? easier to cut? slot with rounded ends?

for(i=[1:p2needles*p2number]){

rotate([0,0,(360/p2number/p2needles/2)-(360/p2number/p2needles*i)]){

translate([-p2OD/2,-needleWidth/2,-0.01])

{

cube([p2needlegrooveDepth,needleWidth,p3wallH+0.02]);

translate([0,needleWidth/2,0])

cylinder(h=c1H+2,d=needleWidth,$fn=36);

translate([p2needlegrooveDepth,needleWidth/2,0])

cylinder(h=c1H+2,d=needleWidth,$fn=36);

}

} //end rotate

} //end for

//base mounting holes

//p3 - "outer" holes

for(i=[1:p3baseholenumber*p3number]){

rotate([0,0,(((360/p3number/p3baseholenumber))/2)-((360/p3number/p3baseholenumber)*i)]){

translate([-(p3baseOD/2)+p3baseholefromODID,0,0])

cylinder(h=c1H+2,d=p3baseholeD,$fn=18);

} //end rotate

} //end outer hole set for

//Z bearing mount holes

for(i=[0:(p7number/2)-1]){

rotate([0,0,45-((90/((p7number/2)-1))*i)]){

translate([0,(c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW,0]){

translate([-p7baseW/2,0,0]){

// hole 1

translate([p7mounthole2edge,p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=c1H+0.1,$fn=36);

// hole 2

translate([p7baseW-p7mounthole2edge,p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=c1H+0.1,$fn=36);

// hole 3

translate([p7baseW/2,p7baseL-p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=c1H+0.1,$fn=36);

}//end translate

}//end translate

}//end rotate

}//end for

mirror([0,1,0])

for(i=[0:(p7number/2)-1]){

rotate([0,0,45-((90/((p7number/2)-1))*i)]){

translate([0,(c3OD/2)-p7bearingfromfront-(p7wiggleL/2)-bearingholderZBW,0]){ //close enough?

translate([-p7baseW/2,0,0]){

// hole 1

translate([p7mounthole2edge,p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=c1H+0.1,$fn=36);

// hole 2

translate([p7baseW-p7mounthole2edge,p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=c1H+0.1,$fn=36);

// hole 3

translate([p7baseW/2,p7baseL-p7mounthole2edge,0])

cylinder(d=p7mountholeOD,h=c1H+0.1,$fn=36);

}//end translate

}//end translate

}//end rotate

}//end for

//Stepper Mount

for(i=[1:c1steppersnumber]){

rotate([0,0,((360/c1steppersnumber)*i)-(90)])

translate([-(CKp1_pitch_radius+CKc2_pitch_radius),0,0]){

cylinder(d=NEMAfaceCricOD+0.25,h=c1H);

translate([NEMAboltDis/2,NEMAboltDis/2,0])

cylinder(d=NEMAboltOD,h=c1H);

translate([-NEMAboltDis/2,NEMAboltDis/2,0])

cylinder(d=NEMAboltOD,h=c1H);

translate([NEMAboltDis/2,-NEMAboltDis/2,0])

cylinder(d=NEMAboltOD,h=c1H);

translate([-NEMAboltDis/2,-NEMAboltDis/2,0])

cylinder(d=NEMAboltOD,h=c1H);

}

}

//mounting wood beams

for(i=[1:4]){

translate([(((c1W+(c1W/5))/5)*i)-((c1W+(c1W/5))/2),-(c1OD/2)+(woodbeamW/2),0])

cylinder(d=woodbeamScrewOD,h=c1H);

}

mirror([0,1,0])

for(i=[1:4]){

translate([(((c1W+(c1W/5))/5)*i)-((c1W+(c1W/5))/2),-(c1OD/2)+(woodbeamW/2),0])

cylinder(d=woodbeamScrewOD,h=c1H);

}

for(i=[1:2]){

translate([(c1W/2)-(woodbeamW/2),-(((c1W+(c1W/5))/5)*i)+((c1OD+(c1W/5))/2),0])

cylinder(d=woodbeamScrewOD,h=c1H);

}

mirror([1,0,0])

for(i=[1:2]){

translate([(c1W/2)-(woodbeamW/2),-(((c1W+(c1W/5))/5)*i)+((c1OD+(c1W/5))/2),0])

cylinder(d=woodbeamScrewOD,h=c1H);

}

mirror([0,1,0]){

for(i=[1:2]){

translate([(c1W/2)-(woodbeamW/2),-(((c1W+(c1W/5))/5)*i)+((c1OD+(c1W/5))/2),0])

cylinder(d=woodbeamScrewOD,h=c1H);

}

mirror([1,0,0])

for(i=[1:2]){

translate([(c1W/2)-(woodbeamW/2),-(((c1W+(c1W/5))/5)*i)+((c1OD+(c1W/5))/2),0])

cylinder(d=woodbeamScrewOD,h=c1H);

}

}

/*

for(i=[1:7]){

rotate([0,0,(360/8*i)-45]){

translate([-(c1zOD/2)+(woodbeamW/2),0,0])

cylinder(d=woodbeamScrewOD,h=c1H);

translate([-(c1zOD/2)+(woodbeamW/2),tan(360/8/2)*(-(c1zOD/2)+(woodbeamW/2))+(woodbeamW),0])

cylinder(d=woodbeamScrewOD,h=c1H);

translate([-(c1zOD/2)+(woodbeamW/2),tan(360/8/2)*((c1zOD/2)-(woodbeamW/2))-(woodbeamW),0])

cylinder(d=woodbeamScrewOD,h=c1H);

} //end rotate

} //end for

*/

} //end main difference

} //end main translate

} //end CKc1 module

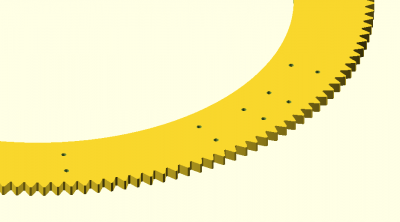

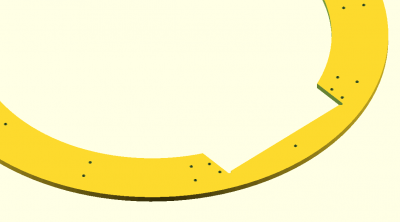

CKc2.scad "geared plate"

- Need to update depricated commands:

- DEPRECATED: child() will be removed in future releases. Use children() instead.

- DEPRECATED: The assign() module will be removed in future releases. Use a regular assignment instead.

Number of Teeth = Floor( ((-2*OutsideDiameter)/(PitchDiameter-OutsideDiameter)) -2 )

Circular Pitch = 180 * PitchDiameter / Number of Teether

include <CKvars.scad>;

use <CKpM--mountain.scad>

use <CKc3--topplate.scad>

rez=p2number*p2needles*2; //calculate desired rezolution

$fn=rez; //defines resolution of circles.

pi=3.1415926535897932384626433832795;

//c3 for review

//translate([0,0,10])

//CKc3();

/*

translate([0,-c3OD/2,0])

translate([0,p3wallOD/2,c2H])

CKpM(0);

*/

projection(cut = false)

CKc2();

module CKc2(){

translate([0,-c3OD/2,0]){

rotate([0,0,-((360/c2connectors))])

difference(){

gear (circular_pitch=pCir,

gear_thickness = c2H,

rim_thickness = c2H,

hub_thickness = c2H,

circles=0);

cylinder(h=c2H+2,d=c3ID); // donut hole

//calculate number of holes to skip in for() using arc of mountain?

//plate connector holes

for(i=[2:c2connectors]){

rotate([0,0,((360/c2connectors)*i)]){

translate([0,p8innerboltO2C,-0.1])

cylinder(d=p8holeD,h=c2H+0.2,$fn=36);

translate([0,p8outerboltO2C,-0.1])

cylinder(d=p8holeD,h=c2H+0.2,$fn=36);

} //end rotate i

} //end for

//small bearing holder

for(i=[1:c2bmounts]){

rotate([0,0,-((360/c2connectors)/2)+((360/c2bmounts)*i)]){

translate([0,((p3baseOD/2)+1),0]){

//smallbearingholder holes

translate([-(p5wingW+p5bodyW+p5wingW)/2,0,0]){

translate([p5wingW+p5bodyW,0,0]){

//wing right holes

translate([p5wingW/2,p5mounthole2back,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2front,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

} //end wing right translate

//wing left holes

translate([p5wingW/2,p5mounthole2back,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2front,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

}//end translate - center X of holes

}//end translate to ring

}//end for rotate

}//end small bearing holder for

//small bearing holder - under mountain

rotate([0,0,((360/c2connectors))]){

translate([0,(p3baseOD/2)+1,0]){ //close enough?

//smallbearingholder holes

translate([-(p5wingW+p5bodyW+p5wingW)/2,0,0]){

translate([p5wingW+p5bodyW,0,0]){

//wing right holes

translate([p5wingW/2,p5mounthole2back,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2front,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

} //end wing right translate

//wing left holes

translate([p5wingW/2,p5mounthole2back,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

translate([p5wingW/2,p5wingL-p5mounthole2front,0])

cylinder(d=p5mountholeOD,h=c2H+0.1,$fn=36);

}//end translate - center X of holes

}//end translate to ring

}//end rotate mountain bearing

//////

//mounting bolt holes

rotate([0,0,((360/c2connectors))]){

//1

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

//2

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

translate([0,(((((c2ID+(pMgroove*2)+(pMwallT*2))/2)/cos(pMd1e-pMd0))-((pMID/2)+(pMshelfBoltD)+pMgroove))/1.5),0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

mirror([1,0,0]){

//1

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

//2

translate([0,(cos(pMd1e-pMd0)*((pMID/2)+(pMshelfBoltD)+pMgroove)),0])

translate([-((((c2ID+(pMgroove*2)+(pMwallT*2))/2)*cos(90-(pMd1e-pMd0)))+(pMshelfX/2)),0,0])

translate([0,(((((c2ID+(pMgroove*2)+(pMwallT*2))/2)/cos(pMd1e-pMd0))-((pMID/2)+(pMshelfBoltD)+pMgroove))/1.5),0])

cylinder(d=pMshelfBoltD, h=pMH, $fn=36);

} //end mirror

} //end rotate

//end of bolt holes

//////////////

}//end main difference

}//end main translate

}//end module

// Parametric Involute Bevel and Spur Gears by GregFrost

// It is licensed under the Creative Commons - GNU LGPL 2.1 license.

// © 2010 by GregFrost, thingiverse.com/Amp

// http://www.thingiverse.com/thing:3575 and http://www.thingiverse.com/thing:3752

//==================================================

// Bevel Gears:

// Two gears with the same cone distance, circular pitch (measured at the cone distance)

// and pressure angle will mesh.

module gear (

number_of_teeth=Tn,

circular_pitch=false, diametral_pitch=false,

pressure_angle=28,

clearance = 0.2,

gear_thickness=5,

rim_thickness=8,

rim_width=5,

hub_thickness=10,

hub_diameter=15,

bore_diameter=5,

circles=0,

backlash=0,

twist=0,

involute_facets=0,

flat=false)

{

if (circular_pitch==false && diametral_pitch==false)

echo("MCAD ERROR: gear module needs either a diametral_pitch or circular_pitch");

//Convert diametrial pitch to our native circular pitch

circular_pitch = (circular_pitch!=false?circular_pitch:180/diametral_pitch);

// Pitch diameter: Diameter of pitch circle.

pitch_diameter = number_of_teeth * circular_pitch / 180;

pitch_radius = pitch_diameter/2;

echo ("Teeth:", number_of_teeth, " Pitch radius:", pitch_radius);

CKc2_pitch_radius=pitch_radius;

// Base Circle

base_radius = pitch_radius*cos(pressure_angle);

// Diametrial pitch: Number of teeth per unit length.

pitch_diametrial = number_of_teeth / pitch_diameter;