Rubber Extruder: Difference between revisions

Jump to navigation

Jump to search

(Asked for some clarification on some questions I had) |

(→Intro) |

||

| (13 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

=Intro= | =Intro= | ||

This is work on a rubber-optimized 3D printer 3mm extruder. | |||

This is work on a rubber-optimized 3D printer 3mm extruder. An optimized rubber extruder is an optimized extruder in general. By principle of [[Degeneracy]], OSE favors an optimized extruder and an optimized rubber extruder to be one and the same. Further, OSE endorses 3 mm and larger filament, as it is easier to make larger filament in terms of quality control. | |||

When exploring an optimized extruder - we start with 3mm as the universal case, for degeneracy of the 3D printer filament in the [[GVCS]]. | |||

=Working Document= | |||

<html><iframe src="https://docs.google.com/presentation/d/e/2PACX-1vStvIoyN2ekYW9jvpvjjyLIzo0xV0bXxDVj2OHjyvaWrTQ8idbs4YdVMZWhEpzcBI8TcaeQBZcDOx-0/embed?start=false&loop=false&delayms=3000" frameborder="0" width="480" height="299" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | |||

[https://docs.google.com/presentation/d/1YXDye7YEDvVF4IjwahPZLLduxRA3UE-OymgHhMkZKHo/edit#slide=id.g1861bf60d5_0_6 edit] | |||

=Design Rationale= | |||

*Use Nema 17 motor with 3x geardown | |||

*Use double drive wheel extruder for better grip | |||

*Move drive wheel down as far to the nozzle as possible | |||

*Use a clamp-on nozzle | |||

* | |||

=Part Library= | =Part Library= | ||

- | [[File:framev1902.png|100px]][[File:rubberextruder.png|100px]][[File:extrudermotor_v1904.png|100px]] | ||

<gallery perrow=6> | |||

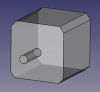

File:rubberextruder_v1904.png|'''OSE Rubber Extruder''' - FreeCAD -[[File:rubberextruder_v1904.fcstd]] | |||

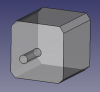

File:extrudermotor_v1904.png|'''Extruder Motor''' - FreeCAD -[[File:extrudermotor_v1904.fcstd]] | |||

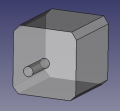

File:extrudergeardown_v1904.png|'''Extruder geardown assembly''' - FreeCAD -[[File:extrudergeardown_v1904.fcstd]] | |||

</gallery> | |||

=Links= | =Links= | ||

*[[Simple Extruder]] | *[[Simple Extruder]] | ||

*[[Open Source Flexible 3D Printing Filament Specialized Extruder]] | |||

*[[Flexion]] | |||

*[[3D Printing Webinar]] | |||

=External= | |||

*Minimalistic MK7 extruder - [https://www.thingiverse.com/thing:15718] | |||

*Bondtech gears - [https://www.google.com/search?client=ubuntu&hs=AhI&ei=DQu_XJHIO8KUtQWGkI7QBw&q=bondtech+gears+3.0+mm&oq=bondtech+gears+3.0+mm&gs_l=psy-ab.3...4984.8532..8901...2.0..0.118.945.1j8......0....1..gws-wiz.......0i71j0j0i22i30j33i299j33i160.JQJDuUIV35c] | |||

*Review of Bondtech Extruder - [https://www.youtube.com/watch?v=dc6wg0DOW3w] | |||

Latest revision as of 21:27, 26 July 2019

Intro

This is work on a rubber-optimized 3D printer 3mm extruder. An optimized rubber extruder is an optimized extruder in general. By principle of Degeneracy, OSE favors an optimized extruder and an optimized rubber extruder to be one and the same. Further, OSE endorses 3 mm and larger filament, as it is easier to make larger filament in terms of quality control.

When exploring an optimized extruder - we start with 3mm as the universal case, for degeneracy of the 3D printer filament in the GVCS.

Working Document

Design Rationale

- Use Nema 17 motor with 3x geardown

- Use double drive wheel extruder for better grip

- Move drive wheel down as far to the nozzle as possible

- Use a clamp-on nozzle

Part Library

- Rubberextruder v1904.png

OSE Rubber Extruder - FreeCAD -File:Rubberextruder v1904.fcstd

Extruder Motor - FreeCAD -File:Extrudermotor v1904.fcstd

- Extrudergeardown v1904.png

Extruder geardown assembly - FreeCAD -File:Extrudergeardown v1904.fcstd

Links

- Simple Extruder

- Open Source Flexible 3D Printing Filament Specialized Extruder

- Flexion

- 3D Printing Webinar