D3D v20.04 Data Collection: Difference between revisions

Jump to navigation

Jump to search

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=TPU Printing= | |||

<html> <iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10219757047973840&width=500" width="500" height="420" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe> </html> | |||

=Stepper Drivers= | =Stepper Drivers= | ||

*DRV 8825 is used for more current on Z. [https://www.pololu.com/product/2982/specs] | *DRV 8825 is used for more current on Z. [https://www.pololu.com/product/2982/specs] | ||

| Line 21: | Line 24: | ||

<html> <iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10219748398037597&width=500" width="500" height="586" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe> </html> | <html> <iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10219748398037597&width=500" width="500" height="586" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe> </html> | ||

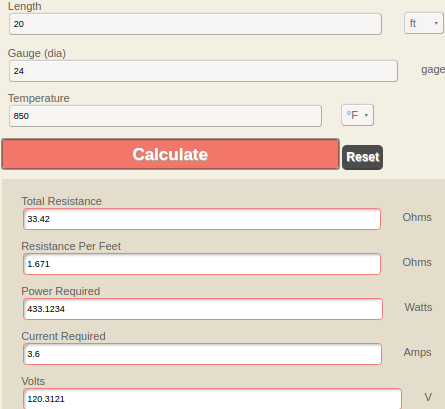

*Redesigning for 430W each by lengthening 24 ga nichrome to 20' from 14' | *Redesigning for 430W each by lengthening 24 ga nichrome to 20' from 14', yielding max 850F temperature of element. | ||

[[File:430wbed.png]] | [[File:430wbed.png]] | ||

=Retraction Settings= | |||

*Had default at 2 mm at 40 mm/s retraction at 1.2 nozzle. | |||

*Increased to 4 mm - first clog ever. Reduced retraction to 3 mm | |||

=Z Motors= | |||

*Either more Z motors for better balance - or counterweight - are useful for handling the heavy weight of the bed. Motor skip upon going all the way to the top of bed in Z direction. | |||

*Z motors will provide better balance if there are 4 corners of them. This will stabilize print quality. | |||

*But also, another option is wider z parts. But this gets away from the natural modularity of the system. | |||

*Added cost of 2 motors is about $50 for 2 axes. | |||

*Added cost otherwise is a counterweight, which is lower cost. | |||

*Less design change is favorable for going with 4 motors - the main case being for stability (larger weight handling is also a plus but secondary) | |||

=Links= | =Links= | ||

*[[D3D_v20.04]] | *[[D3D_v20.04]] | ||

Latest revision as of 02:34, 7 July 2020

TPU Printing

Stepper Drivers

- DRV 8825 is used for more current on Z. [1]

- Initially, one side motor on Z was 44 mm long (17PM-K402-P4V Minebea Motor Mfg Corp, V and A not shown), and the other was 48 mm long (17PM-K402-P5VS, 3.9V 1.3A). *Small motor was easy to stop - pound or 2, whereas larger motor was more like 10lb to stop.

Heating Time

- Extruder - at 11C from 11C to 230C - 2:15

- Bed - 2:47 at 11C from 11C-100C, 20C hysteresis at top

Physical

- Print volume - 12x12x10 inches - 1440 cu in - or 24 lb max weight of print. Bed can be lowered to attain 12x12x11 or more print volume.

Bed Weight Holding Capacity

- From D3D v20.04 Calculations, bed is 12 lb, and we should be able to lift a total of 40 lb withe the stepper motors - so an additional 25 lb.

- Weight of 1/8" steel plate, 8x8" - 2.3 lb. 10 or 11 of these should be held up.

- 3 could be held up reliably. So 7 lb of print mass - 3 spools of filament.

- Up to 6-7 could move up a little, but then they slammed down once the DRV8825 got hot.

Bed Burnout

- Need to redesign for 1000F max temp. Currently it's designed for 1200F.

- Burnout:

- Redesigning for 430W each by lengthening 24 ga nichrome to 20' from 14', yielding max 850F temperature of element.

Retraction Settings

- Had default at 2 mm at 40 mm/s retraction at 1.2 nozzle.

- Increased to 4 mm - first clog ever. Reduced retraction to 3 mm

Z Motors

- Either more Z motors for better balance - or counterweight - are useful for handling the heavy weight of the bed. Motor skip upon going all the way to the top of bed in Z direction.

- Z motors will provide better balance if there are 4 corners of them. This will stabilize print quality.

- But also, another option is wider z parts. But this gets away from the natural modularity of the system.

- Added cost of 2 motors is about $50 for 2 axes.

- Added cost otherwise is a counterweight, which is lower cost.

- Less design change is favorable for going with 4 motors - the main case being for stability (larger weight handling is also a plus but secondary)