Steel Production: Difference between revisions

Jump to navigation

Jump to search

| Line 6: | Line 6: | ||

*Recycling of steel from scrap at 1kWhr/kg | *Recycling of steel from scrap at 1kWhr/kg | ||

energy input. See [[Solar Steel]]. | energy input. See [[Solar Steel]]. | ||

*Another route is reduction of ore using hydrogen. | *Another route is reduction of ore using hydrogen. See [[Hydrogen Reduction Smelting]] | ||

*OSE's case would be to produce steel from direct reduction, which is more efficient and lower temperature than a blast furnace. https://en.wikipedia.org/wiki/Direct_reduced_iron | *OSE's case would be to produce steel from direct reduction, which is more efficient and lower temperature than a blast furnace. https://en.wikipedia.org/wiki/Direct_reduced_iron | ||

*Iron mining in the USA - [https://en.wikipedia.org/wiki/Iron_mining_in_the_United_States] | *Iron mining in the USA - [https://en.wikipedia.org/wiki/Iron_mining_in_the_United_States] | ||

Revision as of 15:32, 21 August 2023

https://edge.alluremedia.com.au/uploads/businessinsider/2017/11/iron-ore-steel.jpg

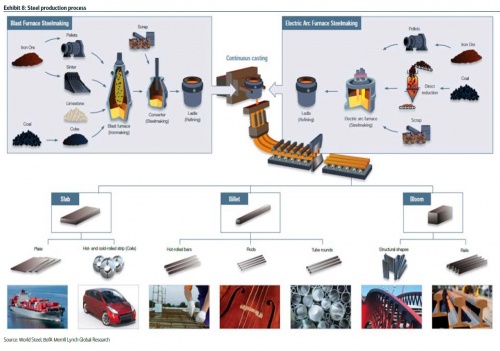

OSE Case

- Recycling of steel from scrap at 1kWhr/kg

energy input. See Solar Steel.

- Another route is reduction of ore using hydrogen. See Hydrogen Reduction Smelting

- OSE's case would be to produce steel from direct reduction, which is more efficient and lower temperature than a blast furnace. https://en.wikipedia.org/wiki/Direct_reduced_iron

- Iron mining in the USA - [1]

- Chromium mining (for stainless steel) - Chromite (FeCrO) is reduced to Ferrochrome (FeCr) via carbothermic reduction. Chromite in Oregon, Montana, California - [2]

OSE Workflow

Sourcing

- Recycling

- Ore?

Refining

- Froth Floatation and other ore methods?

- Direct Reduction , and Charcoal Blast Furnace