April 2011 Production Run BOM: Difference between revisions

Jump to navigation

Jump to search

(→Bolts) |

No edit summary |

||

| (39 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

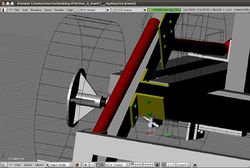

[[Image:lt24.jpg|250px]] | [[Image:lt24.jpg|250px]] | ||

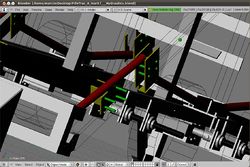

[[Image:lt25.jpg|250px]] | [[Image:lt25.jpg|250px]] | ||

| Line 10: | Line 5: | ||

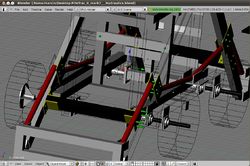

Download open source tractor [http://openpario.mime.oregonstate.edu/projects/lifetrac3d/files 3D source code] | Download open source tractor [http://openpario.mime.oregonstate.edu/projects/lifetrac3d/files 3D source code] | ||

=Cut List= | =Cut List: Tractor= | ||

Square tube: | Square tube: '''90.3' total''' | ||

* | |||

* | *[4] 76"×4"×4" tubes for base (shortened by 16") | ||

* | *[3] 5'×4"×4" under base tubes. | ||

* | *[2] 52"×4"×4" vertical chassis centre tubes. | ||

* | *[2] 55"×4"×4" vertical chassis tubes for front corners. | ||

* | *[2] 59"×4"×4" vertical chassis tubes for rear corners (PC mounting area). | ||

* | *[2] 68"×4"×4" top chassis tubes. | ||

*[3] 44"×4"×4" top chassis tubes. | |||

Rounds: | Rounds: | ||

* | *[4] 28" × 1-7/8" axle shafts (22" before; turn gussets around for easy wheel takeoff) | ||

* | *[1] 56"×1-7/8" loader mounting shaft. | ||

Sleeves: | |||

*[4] 8” sections for shaft – loose for wheels | |||

Rectangle: | Rectangle: | ||

* | *[2] 100"6"×3" 3/8" tubes for front loader arms. | ||

* | *[1] 45” more for cross support | ||

* | *[4] 6"×4" 1/2" angle-iron to attach re-enforcing tunes to Loader arms. | ||

* | *[4] 4-1/2" 1-7/8" DOM to mount shafts through the frame. | ||

* | *[4] 3-1/2" 1-7/8" DOM to mount loader shafts to loader arms. | ||

*[8] thrust bearings - in the form of large washers with 1-7/8" hole to go between frame-shaft-DOM-mounts and loader arm mounts. | |||

*<span style="color:green">[4] 6" bushings/DOM to weld in gussets and wheel mounts. | *<span style="color:green">[4] 6" bushings/DOM to weld in gussets and wheel mounts. | ||

Plate: | Plate: | ||

* | *[12] 10"×8"×0.5" steel plates to mount flange bearings and hydraulic motors to frame. | ||

* | *[4] 6"×8"×1/2" QA-plate to mount motors to QA-motor plate. | ||

* | *[2] 6"×12"×1/2" plate to mount H-cylinders to frame base. | ||

* | *[4] 6"×4"×1/2" plate to weld to H-cylinder base plates. | ||

* | *[12] 1" diameter-hole nuts to weld into above plates. | ||

* | *[1] 1/4"x4×36" plate to mount Valves to. | ||

* | *[4] 5"×12"×1/2" plate to connect Front H-cylinders to loader-arms. | ||

* | *[4] 10×10×1/2" plates to make wheel mounts. | ||

* | *[8] 4"×4"×1/2" plate cut diagonally to make [16] gussets. | ||

* | *[16] thrust bearings - in the form of large washers with 1-7/8" hole - '''torch these on torch table from 1/8" stock''' | ||

*[4] 1”x3”x6” slabs for loader eyes | |||

Steel Tracks (for Wheels) | |||

* | *Chain - 70 feet - $270 at $3.37/foot | ||

* | *Links - $28 | ||

* | *Rebar - 140' at $1.57/foot - $220 – minus 12-16 bars | ||

Power Cube & Seat mounting metal: | |||

*[4] 36" 4×4" 1/4" thick angle Iron | |||

*[ | *[1] 88" 2×2" 1/4" angle iron | ||

*[1] 192"×4"x3/8" plate | |||

* | |||

* | |||

=Cut List: Power Cube III= | |||

1/4"x4"x8" mild steel square tubing - 22 feet @$8.15/foot - $180 - 286 lb | |||

1/4"x4"x4" angle verticals – 2 of them 20” tall | |||

*27x29 base | |||

* | * Pump mount plate - 1/4"x6"x8" | ||

* Engine mounting - angle | |||

* | * Pump mounting plate | ||

* | * Eyes | ||

* | * Fingers - | ||

* | |||

=Cut List: Pulverizer= | |||

* | *[3] plates 1/2"x8"x12", shaft mounting | ||

* | *[12] tines sleeves 3” long - tube to fit 1-7/8" shaft | ||

* | *[48] tine blades, 3/16"x2"x5”long | ||

*[1] 1/4"x2"x4" is 56" long | |||

*[2] arms 1/4"x2"x2" square tube, 2' | |||

*[2] arm sleeve, 3/16"x2.5"x12” | |||

*[2] depth sleeve, 3/16"x2.5"x6” | |||

*shaft, 1-7/8"x54” long | |||

*[2] height adjust 15” | |||

*sheet 4'x33” | |||

*[2] sleeve attach 4x6x1/2 | |||

*1/2"x4"x22" cut into 4,10-12 right trapezoid | |||

*1/2"x3"x48" finger | |||

*[2] 1/4"x2'x4' bucket metal | |||

*1/4"x2'x2' square for 2 sides | |||

*38” rostrum, ¼"x2"x2" tube | |||

*3/16"x2.5"x6” rostrum sleeve | |||

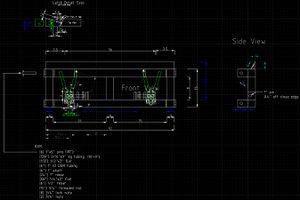

=Cut List: Quick Attach Plates= | |||

[[Image:qaplates.jpg|thumb|Quick attach plate with levers.]] | |||

(See [http://openpario.mime.oregonstate.edu/projects/oselifetrac/documents Open Pario for design]) | |||

[[Image: | |||

( | |||

*[6]1"x5" pins (30") | |||

*[129"] 3/16"x3" sq tubing | |||

*[113"] 1/2"x3" flat | |||

*[6"] 1" DOM tubing | |||

*[24"] 1" rebar | |||

*[66"] 1/4"x2" flat | |||

*[6"] 1/2" rebar | |||

*[15"] 3/4" threaded rod | |||

*[8] 3/4" lock nuts | |||

*[2] 3/4" nuts | |||

== | =Cut List: The Liberator= | ||

U-Channel Frame- 7/16" thick heavy u-channel, 6" wide | |||

*<span style="color: | *<span style="color:purple"> - Dalton Hydraulics cylinders and solenoid valve | ||

* | *[2] 42" - verticals | ||

* | *[2] 29" - table holders | ||

* | *[4] 21" - bottoms and tops | ||

* | *[2] 10” - chamber spacers | ||

* | *[2] 2”x2” angle for closing off compression chamber | ||

Arms, feet, hopper supports, hopper mounting | |||

*[4] 4”x6”x3/8” – 72” long – heavy angle arms | |||

*[4] 1/4”x10”x10” plate - feet | |||

*[2] 1/4”x2”x2” sq. tubing, 48” long – back support | |||

*[2] 1/4”x4”x4” angle , 40” long – angle front support | |||

*[2] 1/2”x3”x12” flat - hopper mounting plate | |||

*[2] 1/2"x3"x14" flat - hopper mounting plate | |||

* | Drawer | ||

* | *[1] 1"x8" flat, 12" long | ||

* | *[2] 1/4"x5"x13.5 flat -sides | ||

* | *[1] 4x6x1/2 tube - spacer | ||

*[1] 3x6x1/2 angle, 12" long – back of drawer | |||

*[2] 1/2"x2"x31.5” flat - roller guides | |||

*[2] 1/4"x2.5"x31.5” flat - roller guides | |||

*[2] 1/2”x3”x12” v groove mounts | |||

*[1] 1/2”x12”x4” vertical support | |||

Press Foot and Cylinder Assembly | |||

*1”x4”x10” plate | |||

* | *1”x6”x12” plate | ||

* | *[2] eyes | ||

*10” pin, 1” diameter | |||

* | |||

* | |||

Grate | |||

*[2] 1/4”x2”x2” angle, 6' | |||

*[2] 1/4”x2”x2” angle, 3' | |||

*1/4”x2” bar, 71.5” | |||

*3/8” rebar, 105' | |||

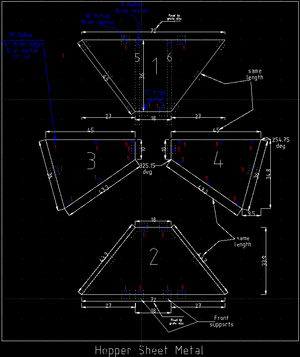

Hopper Sheet | |||

*[1] 5'x10'x1/8" sheet | |||

[[Image:hopperfab.png|thumb]] | |||

Other | |||

*[6] 3”x3”x1/2” - cylinder mounts for both cylinders | |||

* | *2.5”x3/16” sq. tubing, 98" long, but 6" pieces - sleeves | ||

* | *1” shaft, 10” long - main cylinder mount | ||

* | *1” shaft, 6.5” long (shaker) | ||

* | *2”x2”x1/4” tubing, 3' long (2) | ||

* | *4”x4”x1/4” angle, 3' long (2) | ||

*2 | *table – 1/8x10x28, and 12x28 | ||

*Hopper shaker assembly | |||

*Magnet adjusters | |||

*Cylinder adjusters | |||

*Sensor mounting | |||

See [[April_2011_Production_Run_BOM_Combined_Cut_List]] | |||

[[Category:April 2011 Production Run]] | |||

[[Category:LifeTrac III]] | |||

[[Category:BOM]] | |||

Latest revision as of 21:13, 2 June 2011

Download open source tractor 3D source code

Cut List: Tractor

Square tube: 90.3' total

- [4] 76"×4"×4" tubes for base (shortened by 16")

- [3] 5'×4"×4" under base tubes.

- [2] 52"×4"×4" vertical chassis centre tubes.

- [2] 55"×4"×4" vertical chassis tubes for front corners.

- [2] 59"×4"×4" vertical chassis tubes for rear corners (PC mounting area).

- [2] 68"×4"×4" top chassis tubes.

- [3] 44"×4"×4" top chassis tubes.

Rounds:

- [4] 28" × 1-7/8" axle shafts (22" before; turn gussets around for easy wheel takeoff)

- [1] 56"×1-7/8" loader mounting shaft.

Sleeves:

- [4] 8” sections for shaft – loose for wheels

Rectangle:

- [2] 100"6"×3" 3/8" tubes for front loader arms.

- [1] 45” more for cross support

- [4] 6"×4" 1/2" angle-iron to attach re-enforcing tunes to Loader arms.

- [4] 4-1/2" 1-7/8" DOM to mount shafts through the frame.

- [4] 3-1/2" 1-7/8" DOM to mount loader shafts to loader arms.

- [8] thrust bearings - in the form of large washers with 1-7/8" hole to go between frame-shaft-DOM-mounts and loader arm mounts.

- [4] 6" bushings/DOM to weld in gussets and wheel mounts.

Plate:

- [12] 10"×8"×0.5" steel plates to mount flange bearings and hydraulic motors to frame.

- [4] 6"×8"×1/2" QA-plate to mount motors to QA-motor plate.

- [2] 6"×12"×1/2" plate to mount H-cylinders to frame base.

- [4] 6"×4"×1/2" plate to weld to H-cylinder base plates.

- [12] 1" diameter-hole nuts to weld into above plates.

- [1] 1/4"x4×36" plate to mount Valves to.

- [4] 5"×12"×1/2" plate to connect Front H-cylinders to loader-arms.

- [4] 10×10×1/2" plates to make wheel mounts.

- [8] 4"×4"×1/2" plate cut diagonally to make [16] gussets.

- [16] thrust bearings - in the form of large washers with 1-7/8" hole - torch these on torch table from 1/8" stock

- [4] 1”x3”x6” slabs for loader eyes

Steel Tracks (for Wheels)

- Chain - 70 feet - $270 at $3.37/foot

- Links - $28

- Rebar - 140' at $1.57/foot - $220 – minus 12-16 bars

Power Cube & Seat mounting metal:

- [4] 36" 4×4" 1/4" thick angle Iron

- [1] 88" 2×2" 1/4" angle iron

- [1] 192"×4"x3/8" plate

Cut List: Power Cube III

1/4"x4"x8" mild steel square tubing - 22 feet @$8.15/foot - $180 - 286 lb 1/4"x4"x4" angle verticals – 2 of them 20” tall

- 27x29 base

- Pump mount plate - 1/4"x6"x8"

- Engine mounting - angle

- Pump mounting plate

- Eyes

- Fingers -

Cut List: Pulverizer

- [3] plates 1/2"x8"x12", shaft mounting

- [12] tines sleeves 3” long - tube to fit 1-7/8" shaft

- [48] tine blades, 3/16"x2"x5”long

- [1] 1/4"x2"x4" is 56" long

- [2] arms 1/4"x2"x2" square tube, 2'

- [2] arm sleeve, 3/16"x2.5"x12”

- [2] depth sleeve, 3/16"x2.5"x6”

- shaft, 1-7/8"x54” long

- [2] height adjust 15”

- sheet 4'x33”

- [2] sleeve attach 4x6x1/2

- 1/2"x4"x22" cut into 4,10-12 right trapezoid

- 1/2"x3"x48" finger

- [2] 1/4"x2'x4' bucket metal

- 1/4"x2'x2' square for 2 sides

- 38” rostrum, ¼"x2"x2" tube

- 3/16"x2.5"x6” rostrum sleeve

Cut List: Quick Attach Plates

(See Open Pario for design)

- [6]1"x5" pins (30")

- [129"] 3/16"x3" sq tubing

- [113"] 1/2"x3" flat

- [6"] 1" DOM tubing

- [24"] 1" rebar

- [66"] 1/4"x2" flat

- [6"] 1/2" rebar

- [15"] 3/4" threaded rod

- [8] 3/4" lock nuts

- [2] 3/4" nuts

Cut List: The Liberator

U-Channel Frame- 7/16" thick heavy u-channel, 6" wide

- - Dalton Hydraulics cylinders and solenoid valve

- [2] 42" - verticals

- [2] 29" - table holders

- [4] 21" - bottoms and tops

- [2] 10” - chamber spacers

- [2] 2”x2” angle for closing off compression chamber

Arms, feet, hopper supports, hopper mounting

- [4] 4”x6”x3/8” – 72” long – heavy angle arms

- [4] 1/4”x10”x10” plate - feet

- [2] 1/4”x2”x2” sq. tubing, 48” long – back support

- [2] 1/4”x4”x4” angle , 40” long – angle front support

- [2] 1/2”x3”x12” flat - hopper mounting plate

- [2] 1/2"x3"x14" flat - hopper mounting plate

Drawer

- [1] 1"x8" flat, 12" long

- [2] 1/4"x5"x13.5 flat -sides

- [1] 4x6x1/2 tube - spacer

- [1] 3x6x1/2 angle, 12" long – back of drawer

- [2] 1/2"x2"x31.5” flat - roller guides

- [2] 1/4"x2.5"x31.5” flat - roller guides

- [2] 1/2”x3”x12” v groove mounts

- [1] 1/2”x12”x4” vertical support

Press Foot and Cylinder Assembly

- 1”x4”x10” plate

- 1”x6”x12” plate

- [2] eyes

- 10” pin, 1” diameter

Grate

- [2] 1/4”x2”x2” angle, 6'

- [2] 1/4”x2”x2” angle, 3'

- 1/4”x2” bar, 71.5”

- 3/8” rebar, 105'

Hopper Sheet

- [1] 5'x10'x1/8" sheet

Other

- [6] 3”x3”x1/2” - cylinder mounts for both cylinders

- 2.5”x3/16” sq. tubing, 98" long, but 6" pieces - sleeves

- 1” shaft, 10” long - main cylinder mount

- 1” shaft, 6.5” long (shaker)

- 2”x2”x1/4” tubing, 3' long (2)

- 4”x4”x1/4” angle, 3' long (2)

- table – 1/8x10x28, and 12x28

- Hopper shaker assembly

- Magnet adjusters

- Cylinder adjusters

- Sensor mounting