Chris Reinhart Log: Difference between revisions

No edit summary |

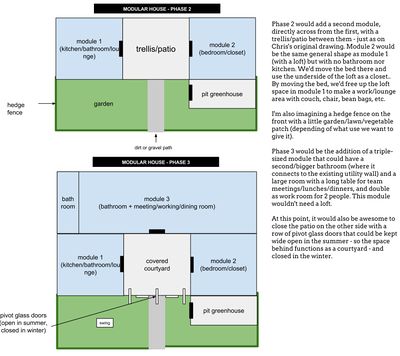

|||

| (493 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

[http://opensourceecology.org/wiki/Wiki_instructions#Wiki_User_Account Wiki Instructions] | |||

[http://opensourceecology.org/wiki/Development_Status_and_Needs# Development Status and Needs] | |||

[http://opensourceecology.org/wiki/Documentation_Standards# Documentation Standards] | |||

[http://en.wikipedia.org/wiki/Help:Cheatsheet# wiki markup cheatsheet] | |||

[http://opensourceecology.org/wiki/Wiki_Cheatsheet# OSE wiki markup cheatsheet] | |||

[http://opensourceecology.org/wiki/Dashboard# OSE dashboard] | |||

[http://opensourceecology.org/wiki/GVCS_Modules# Global Village Construction Set module breakdown] | |||

[http://opensourceecology.org/wiki/High_Resolution_Media# High Resolution Media] | |||

= Helpful Links= | |||

= | * MicroHouse Projects | ||

== | ** [http://opensourceecology.org/wiki/Microhouse_1_Development_Board MH 1 Dev Board] | ||

** [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdE5TUnozdXNuMEc5NXpCdThuZWRzdHc&usp=drive_web&pli=1#gid=1 MH 2 Dev Board] | |||

** [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdDFRUnh1VUNOWjhXWDNySXQwUC1kSlE#gid=0 MH 2 BOM] | |||

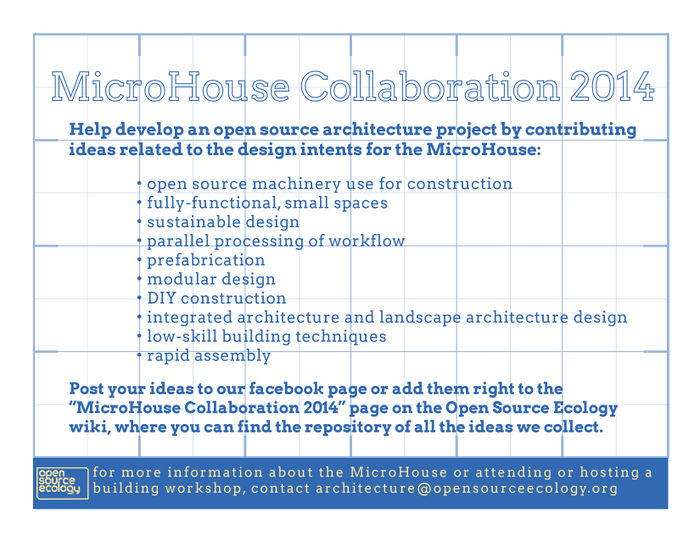

** [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014#MicroHouse_2/ MH Collab wiki page] | |||

* Weights of Building Materials | |||

** [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdHRSNmJ3a2p0bmw1U2N6MHlZQ0w3eFE#gid=0 OSE Framing Module Weight Calculator] | |||

** http://pubs.cas.psu.edu/freepubs/pdfs/H20.pdf | |||

** http://parr.com/PDFs/PG_pocketguide.pdf | |||

** GE-1_Weights_Building_Materials.pdf | |||

** http://www.hansenpolebuildings.com/blog/2013/02/2x6-lumber/ | |||

** http://www.woodweb.com/cgi-bin/calculators/calc.pl?calculator=weight_bd_ft | |||

* Plywood vs. OSB | |||

** http://bct.eco.umass.edu/publications/by-title/choosing-between-oriented-strandboard-and-plywood/ | |||

* Converting Cement weight to volume | |||

** [http://www.traditionaloven.com/building/masonry/cement/convert-pound-lb-of-cement-to-cubic-foot-cu-ft-cement.html Cement conversion calculator] | |||

=Thursday, August 14, 2014= | |||

While MH 3 is not finished yet, and the sharing of design assets has been sparse, a preliminary review can be made at this point, now that photos of the construction have been posted. Sometimes I ask myself why I keep doing this... I do it for anyone out there that might actually be looking to build a MicroHouse, and the hope that they might read this and find some honest information in it. In architecture school, one learns the importance of critique and peer review on the design process. It is key to remove the ego from this conversation. The building (or the design) is not you. You are not the building. Remain open to feedback from others, and you will make better buildings in the future. Enough preamble, here's my review: | |||

*Wall System: | |||

**The double-wythe cavity wall system is a huge improvement over MH 1 and MH 2, and so is laying the bricks flat instead of on edge. The wall looks more robust, and I'm guessing it feels that way, too. It will obviously perform better thermally than the walls we did for MH 1 and MH 2. I think the way the two walls are tied together is innovative, and it looks like it will resist the walls pulling apart from one another. It doesn't look so good in compression, though, if the walls were pushed towards each other. I am curious about the long-term viability of the blown cellulose insulation, too. I think perlite would have been a better choice for moisture resistance, but maybe this was cost-prohibitive. | |||

I | *Passive Solar: | ||

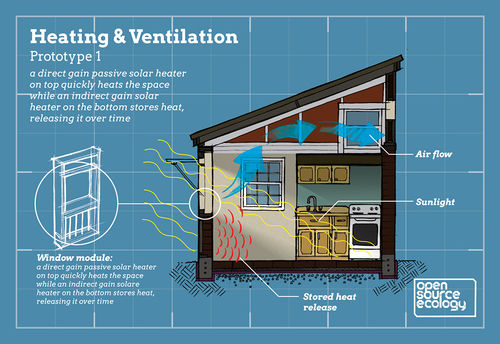

**Disappointingly, I'm not even sure that one could say MH 3 has a passive solar component. There is definitely not enough glass on the south side for adequate solar gain. I don't know why the design intent of passive solar heating was left out, but it should immediately be reincorporated into MH 4. All buildings are passive solar buildings, it's just that many of them (like MH 3) are in denial about it. When you don't design with the sun in mind, you impede the quality of life of all future inhabitants of the building. | |||

*Workflow: | |||

**While I noticed that Marcin's data gathering lead him to the conclusion that all 6000 bricks could be stacked in a day, I don't think that's realistic. As the information coming from OSE is not very open, it is hard to say why the brick stacking was so slow compared to the calculations. I imagine it is because there are practical limits to how fast volunteers can do good work, and taking a best-case-scenario number of how quickly bricks can be stacked and then extrapolating how quickly the building can be made will never work. OSE's estimates always feel like they are made to prove how quickly work can be accomplished. They would be more useful to the owner/builder if they were based on the reality of how long it has taken to stack bricks in the past. There is enough data to do this now, between the 3 MH builds. But instead of making projections for how fast it could be done, the numbers should be crunched to reflect what really happened. | |||

**Looks to me from the pictures that you had several experienced builders there to help with the construction. This is great. With the large number of workers you had there, having that extra experience made it possible to get more done. I think one experienced builder for every 10-12 volunteers is a good number, and it looks like you may have had this. (I think I saw Sam McAnti-Saladshake in the photos. This is awesome!) | |||

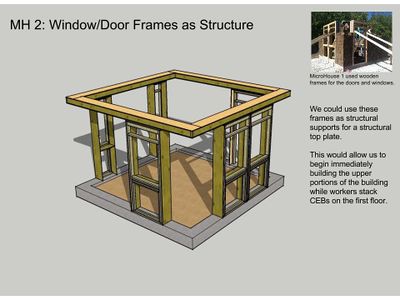

*Window/Door Frames | |||

**These look like they have been improved upon over the MH 1 and 2 builds. They look more robust, and it looks like it will be easier to trim them out, too, if that is the choice of how to finish them. I'm guessing they are made of 2x4 laid flat with 3/8 or 1/2" plywood on both sides. I wonder if the cavity space is filled with insulation. I think this would be a wise decision. | |||

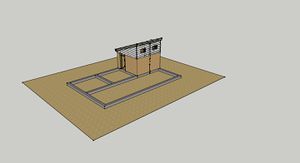

I wonder what the plan is now for finishing the MH 3. It looks like only half of the bricks have been stacked, and the half that remains always goes slower than the first half, because you have to lift the bricks up higher. Will OSE be running another workshop? This would be a viable way to do it, if you could get people out there that quickly. Perhaps, with the interns that are already on-site, progress can be made quickly enough if everyone is pulled off of their other jobs and assigned to brick stacking. There were no pictures of the carpentry progress in the shop, so I wonder if the roof components and other wall components are ready to go. | |||

All in all, I think the MH 3 looks like it is better constructed than the first two. If it had been kept a true "micro" house, you probably could have built it in closer to 5 days. 500+ square feet is not at all tiny, and to call it a microhouse is another example of OSE-news-speak. A "fully code-compliant" MH could have been made at half the size of MH 3, and the roof would be going on it right now. | |||

Good luck to those working on it. I hope that you are able to get the lid on it soon! | |||

=Monday, Aug 11, 2014= | |||

Great to see some pictures show up in Trovebox for the MH3 build. It looks like a large and diverse group, and it appears that they are enjoying themselves and working hard. I am very excited that the decision was made to finally lay the bricks on their flat side, like bricks are supposed to be laid! I wonder if the tolerances on the brick dimensions were tightened up somehow by tweaking the machine or how it is operated. Or perhaps, because there are mortar joints between the bricks, the subtle variations in thickness are being taken up in the mortar joint. I assume it's the latter, based on a photo where one could see some up-and-down along a course of bricks. This is a huge upgrade over the previous MHs. It always drove me crazy (and the other people working on the buildings, too) that we had to stack the bricks on edge - it just feels wrongs - so it's great to see OSE learning from this and moving forward. | |||

Keep the photos coming! It's looking good :) | |||

=Thursday, Aug 7, 2014= | |||

I have an intense curiosity about the outcome of the MicroHouse 3 workshop, having led the builds of the first two MHs. I looked through the schedule listed on the workshop page. Friday is the only day listed for CEB wall building, which seems unrealistic to the point of absurdity. I think three or four days for stacking the bricks sounds more appropriate, based on some rough extrapolation from the times we achieved in the first two MH builds. We were stacking about 50' or wall perimeter, with an average of 25 or 30 minutes per course. This project has double the perimeter, and double the thickness. Keeping the data from the build is very helpful to others, and if someone records these times diligently, there might actually be enough data between the three MH workshops to form some solid build-time estimates going forward. | |||

I wish everyone there the best of luck... building at FeF can be exciting and stressful and rewarding, too. Take the time estimates listed on the workshop website with a grain of salt. Have fun, learn as much as you can, and don't stress yourself out trying to meet another one of OSE's silly timelines. Above all, remember the proper hierarchy of a good job site: safety first, quality second, speed third. I hope people post lots of pictures and that some of the Dozuki work gets filled out, too. Can't wait to see it come to life :) | |||

[[ | =Sun, July 20, 2014= | ||

* Here's a great open source project for helping the homeless using an innovate structure housed between advertising billboards: [http://www.projectgregory.com/en/idea Project Gregory] | |||

**Here's an [http://inhabitat.com/awesome-billboard-homes-provide-housing-for-the-homeless/ article published by Inhabitat] on the same project: | |||

=Sat, July 19, 2014= | |||

* I've been at a permaculture workshop all week long, taught by Peter Bane and Rhonda Baird, learning immense amounts of practical information, all emerging from an ethical framework of caring for the earth, caring for people, and sharing the surplus. | |||

** Last night Peter delivered an incredible lecture about energy and appropriate technology. Among all the good information I gleaned from this session, there was a mention of the [https://www.ncat.org/about-us/ National Center for Appropriate Technology], NCAT. | |||

*** NCAT's stated mission: "Helping people by championing small-scale, local, and sustainable solutions to reduce poverty, promote healthy communities, and protect natural resources." | |||

*** "NCAT was originally created during the oil crisis of the 1970s to develop inexpensive energy-saving strategies for low-income communities. In 1987, as a natural outgrowth of our alternative and sustainable energy work for farmers and ranchers, we expanded our mission to include sustainable agriculture." | |||

** [http://www.permacultureactivist.net/ Permaculture Activist website] | |||

** [http://permaculturehandbook.com/ Permaculture Handbook -- Garden Farming for Town and Country, by Peter Bane] | |||

* I also learned from one of the other participants in the workshop who is a builder/contractor of the [http://www.buildingscience.com/glossary/raisedheeltruss "raised heel truss"] which allows for insulation above the wall to remain uncompressed. It's hard for me to believe that I hadn't noticed these before. | |||

=Sun, July 13, 2014= | |||

* Read through [http://issuu.com/golfstromen/docs/ken-isaacs-1974 Ken Isaacs book from the 70s] that Marcin posted to the wiki. | |||

=Sat, July 12, 2014= | |||

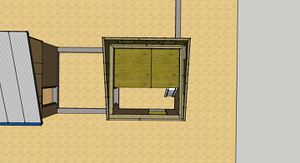

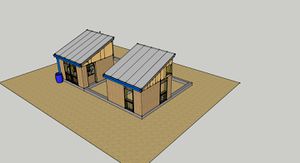

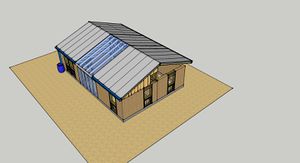

* Reviewed Curtis' Sketchup model for MHv3. I think the glazing area requirement is being met. Stairway looks good. Ceiling heights look more than adequate. Great to see so much progress! Looks like it is really coming together. The biggest issue I see remaining is the egress window in the loft. Not only is this code, but there is a moral imperative to provide people a window to get out of if there is a fire downstairs while they are upstairs. Now that the biggest code issues have been addressed (a complete code review requires a complete design), I have some questions. I don't expect anyone to answer these for me, but I am logging them, and perhaps they will be useful in one way or another to someone out there: | |||

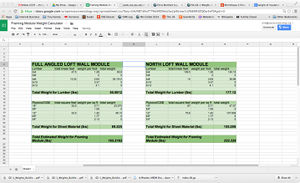

** Will any of the carpentry components be prefabbed? It looks like the window and door boxes are similar to MHv1 and MHv2. Planning to use the utility module again? Any changes to that design? When it comes to prefabbing components, weight is the big issue. To make it easier on myself in calculating this during MHv1 and MHv2, I created a weight calculator where you can input linear feet of framing material and square footage of sheet material and it spits out the total weight of the module. It's above in the links at the top of my log. | |||

*** [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdHRSNmJ3a2p0bmw1U2N6MHlZQ0w3eFE#gid=0 OSE Framing Module Weight Calculator] | |||

** Are you using any brick-tie-type material in the double wythe wall? I know on Zach Dwiel's project (built with the OSE brick press) that used a double wall system, they used a ladder-style wire reinforcing on every second or third course. Perhaps with the way the bricks are stacked at FeF (on edge, rather than the typical laid-flat method that Zach used) this is unnecessary. The FeF-way (required because the bricks are not dimensionally consistent enough to be dry-stacked when laid flat) does make a thicker wall, which wobbles less as going up than a laid-flat running bond stacking pattern. That said, I'd still like to see the soil drawer orientation changed so that the bricks can be properly laid. | |||

** This foundation looks much closer to code-approved than any of the previous MH foundations. I'm not an engineer, though, so I can't say that it meets engineering requirements. Even if I went through the calculations, I would have the expertise to say that they were correct. If you're not going to use an engineer to verify the design, I would look at standards for CMU walls with filled cores and another CMU or brick facing. This seems like it would be comparable in weight to the double-CEB wall. (Concrete has a rough weight of 150 pcf. Compacted soil, I hear, can be as high as 140 pcf.) | |||

= | =Fri, July 11, 2014= | ||

== | ==Firm Foundation Social Design Field Guide== | ||

* Found this great online resource describing the participatory design process used on a project by the Firm Foundation. | |||

** You can view the guide online [http://issuu.com/stephenjameskennedy/docs/2013_08_02_social_design_field_guid here.] | |||

** You can also [http://solokotakita.org/firmfoundation/img/Social-Design-Field-Guide.pdf download the pdf here.] | |||

=Thu, July 10, 2014= | |||

* Note on means of egress. It is implicit in the MHv3 design that the loft is intended for sleeping, thus: | |||

** "Basements and every sleeping room shall have at least one operable emergency escape and rescue opening. Such opening shall open directly into a public street, public alley, yard, or court." - R310.1, IRC2006 | |||

** This is in addition to a stair. An egress window is most definitely required for that loft sleeping space. | |||

* Very happy to see Curtis post work to his log, including a Sketchup model of the current MicroHouse 3 design and some photos of the site work. This is great! I'm excited to take a look at the model later this evening. | |||

** While you could consider a home under occupancy R-3 of the IBC, it appears it would be less restrictive to reference the IRC, the international Residential Code, not the IBC, International Building Code. Both are created and maintained by the International Code Council (ICC), but the IRC is primarily intended for one and two-family dwellings, where the IBC is intended primarily for commercial building. | |||

*** [http://www.nachi.org/bbsystem/viewtopic.php?t=11994&PHPSESSID=9903d7d68527f9f869b125a0e91ea96b Discussion thread] on difference between IRC and IBC. | |||

**** From a post in the thread on differences between IRC and IBC: "You could consider a home an R3 Occupancy under the IBC (some provisions would be more restrictive), but that is just one piece of the code puzzle. Using the multitude of more general assortment of codes gets to be very cumbersome for typical residential construction. Typical residential builders have some difficulty buying and understanding one stand-alone code book ... forget about a whole stack of sometimes confusing general code books and standards. Plus there are prescriptive construction requirements and some less restrictive provisions unique to residential construction scattered throughout the IRC ... such as the garage/dwelling fire separation requirements in IRC R309 and egress provisions in IRC R311. -From Difference between IBC and IRC - InterNACHI http://www.nachi.org#ixzz374UQmhTk" | |||

http:// | =Wed, July 9, 2014= | ||

* General Note: If you don't use the wiki to in some way log work, whether it is on a project page or your personal log, it's like it never happened -- from an open source perspective. Creating physical objects only becomes open source when the work is shared outside the place it is created, otherwise, it's just nominally "open source." | |||

==Some Notes on Code== | |||

General note: MicroHouse v1 and v2 did not mean any of these criteria. For an idea of the design intents of the first two, look back at early MicroHouse pages from before my time, or the [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014 MicroHouse Collaboration 2014 page], where I compiled the contributions that people would email to me or suggest through Facebook. These design intents listed there were the ones directly stated to me by Marcin, and like all the previous buildings there, code was expected to be met. I am glad to see that code compliance has become one of the design intents. This makes the project relevant to far more people. | |||

* Ceiling heights, see R305.1: Minimum Height. | |||

** 50% of the area in a room with a sloped ceiling must be taller than 7'-0". Different municipalities interpret the next part a bit differently. In some places, you must have side walls at a minimum of 5'-0". In other areas, you can have side walls as short as you want, you just don't count the area less than 5'-0" in your calculations. Fortunately, this is the case with the building department where I live, because that interpretation opens up more possibilities. | |||

* Egress, see R310: Emergency Escape and Rescue Openings. | |||

** An egress window on the second floor needs to be a minimum of 5.7 sf. The clear opening must be a minimum of 20" wide and 24" tall. The bottom of the opening must be no less than 22" and no higher than 44". | |||

* Stairways, see R311.5: Stairways. | |||

** Lots to mention here, but the basics are a minimum of 6'-8" head height over the stair, max riser is 7-3/4", typical tread dimension is 11". I don't have the exact maximums and minimums memorized yet. Lots of details on landings, door swings, etc. | |||

* R303.1: Habitable Rooms, to make sure that you are meeting the 8% of floor area as glazing requirement. | |||

** Ballpark: 500 sf x .08 = 40 sf of glazing, but I think the interpretation is room by room, so it should really be calculated that way. | |||

[ | ==Tiny House TV Show== | ||

* New TV show, [http://www.fyi.tv/shows/tiny-house-nation Tiny House Nation], premiers tonight. | |||

** From the website: "In “Tiny House Nation,” renovation experts and hosts, John Weisbarth and Zack Giffin, travel across America to show off ingenious small spaces and the inventive people who live in them, as well as help new families design and construct their own mini-dream home in a space no larger than 500 square feet. From a micro-apartment in New York City to a caboose car turned home in Montana to a micro-sized mobile home for road tripping – this is a series that celebrates the exploding movement of tiny homes. From pricey to budget friendly, “Tiny House Nation” is not a typical design show, but one that proves size doesn’t always matter – it’s creativity that counts." | |||

** I may try to watch this at a friend's house, and I'm having my parents record it, but I do not have TV service at my home and our satellite internet data usage is fairly limited, so streaming videos is (for the most part) out of the question. Sounds like a cool show, though... I hope it's as good as Treehouse Masters - the early episodes showed enough construction details to really satisfy a builder. | |||

=Tues, July 8, 2014= | |||

* Sent an email to Marcin last evening expressing my interest in helping bring the MicroHouse 3 design into code-compliance. | |||

* Found a very interesting Open Source house project with lots of documentation and learnings by [http://enviu.org/ Enviu.] | |||

** Here is their a [http://enviu.org/wp-content/uploads/2014/01/OS-House-Learning-Case.pdf great little booklet] they put together to describe the project. | |||

*** From their booklet: "Our top-7 key lessons: 1) Focus on asking the right questions, instead of jumping to solutions. 2) If you want to start a company, start developing the business model, and then the business case, as early as possible. 3) Do this intertwined with involving the end-user, in their role as a possible customer, not as a non-binding think tank. 4) Attract a financing/funding mix for your development that allows this iterative development, also allow time for emerging insights. 5) Preferably the entrepreneur is the idea-owner and otherwise involve the entrepreneur as early as possible. Make sure the entrepreneurial team has the right skill set for this particular start-up idea. 6) Innovation is seldom about (just) technology. 7) Cherish crowdsourcing but use it wisely. Accurately assess its position in the whole process from Idea to Start-up." | |||

* Noticed that some of my earlier links were not working because of an extra / placed in the link. Note to self to check links immediately after placing to make sure they are usable to others. | |||

=Mon, July 7, 2014= | |||

* Notes on code compliance from the International Residential Code. (Most municipalities have adopted some form of this code. In Indiana, we use the 2006 code, so the following notes come from that version.) | |||

** Ceiling heights, see R305.1: Minimum Height. | |||

** Egress, see R310: Emergency Escape and Rescue Openings. | |||

** Stairways, see R311.5: Stairways. | |||

** Foundations, see Chapter 4: Foundations. | |||

** I would also take a look at R303.1: Habitable Rooms, to make sure that you are meeting the 8% of floor area as glazing requirement. | |||

* See [http://www.iccsafe.org/gr/Documents/stateadoptions.pdf this table compiled by the International Code Council] to find out which states use which versions of the code. | |||

** Looks to me like Missouri has statewide adoption of the 2000 IRC. | |||

== | =Sun, July 6, 2014= | ||

* Read through [https://www.planning.org/pas/at60/report37.htm link from Curtis' Log] on minimum lot size and minimum building size from the American Planning Association. | |||

** Important to note that many of the codes listed in this article do not apply in most places. | |||

** Also important to note that the article is from 1952. Not that it is irrelevant, because the conversation is just as relevant as ever, just important to keep in mind that this article is over 60 years old. | |||

** I will post references to the IRC sections on minimum building size that will be widely applicable. | |||

** Most recommendations I have heard for building small echo the sentiments from the article linked above - about 300 sf per person is a number often used as a rule of thumb by those promoting small building. | |||

=Sat, July 5, 2014= | |||

* Found some of the [https://docs.google.com/presentation/d/1GlG8Gt-IZXIzrR4CN56FKVZp-SmVDH3PfoPT8LR-mvw/edit#slide=id.p/ MicroHouse 3 work.] Still have not seen where any of the design assets are located. | |||

* Code Issues that I can see from the animated fly-through - I will add references to the IRC on Monday when I have the code book in front of me. | |||

** The loft space needs an egress window. | |||

** The ceiling heights in the loft space are non-complying. Must have minimum of 50% of the square footage over 7'-0" tall. | |||

** Need a complying stairway that has a head clearance of 6'-8" over it -- this looks difficult to achieve in the volume shown. | |||

** Foundation. | |||

* Other design review: | |||

** Need more glass for passive solar gain. | |||

** Need a much larger cistern than the rain barrel for a roof area of that size. | |||

** Need lintels to support the CEBs over the window openings in the two-story section of the building. | |||

https:// | =Thu, July 3, 2014= | ||

* No answer back from Open Tech Collaborative on the progress of the Forever Home Challenge, but I did find a link to their [https://github.com/AfH-Denver/Forever_Home_Design_Challenge/issues/ Q&A page on Github.] | |||

** No posts since late January. Aaron was responding to most of the posts - no response to the last post about when will winners be announced. | |||

* Watched the [https://www.youtube.com/watch?v=94rQw1Ur2aQ/ MicroHouse 3 workshop commercial.] Great to finally see some design work shared! Still curious why the development was not open, and when/if the design assets will be shared. Perhaps the culture has changed, but during MH 1 and MH 2, developing designs in the open was part and parcel of working with OSE. A bit surprised that the square footage has jumped so much. It seems unfeasible to me that people can build a 500+ sf house with a double thickness wall in 5 days. | |||

=Wed, July 2, 2014= | |||

* Read through the [http://www.midwestearthbuilders.com/code.html/ New Mexico CEB Building Code], that Curtis had posted a link to on [http://opensourceecology.org/wiki/Curtis_Log/ his log.] | |||

** Although his log page says there are links to the CEB code in UBC and IBC, there is just a mention of those codes and where CEB is found in them, as follows: "However, CEB construction can also be approved under the Uniform Building Code (UBC) under “unfired clay masonry.” CEB can also fall under the code for Adobe which also appears in the new International Building Code (IBC) and the Southern and Standard Building Codes under “adobe." | |||

* Although various logs contain references to working on the new MicroHouse design, I can find no design assets for MicroHouse 3 on the wiki. | |||

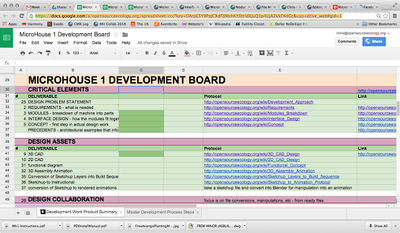

** Has the development board idea been abandoned? Although I felt some frustration in conversations with Marcin about the Dev Board during MicroHouse 2, I think the concept of the Development Board is strong and that it is a very useful tool for people to observe and interact with the project remotely. | |||

*FWIW, here's a link to the [http://www.strawbale.com/wp-content/uploads/IRC_StrawbaleConstructionAppendix_Approved_10.4.13r2.pdf Straw Bale Code Appendix] that has been adopted into the 2015 International Residential Code. | |||

=Tue, July 1, 2014= | |||

* [http://codes.lp.findlaw.com/incode/36/7/8/36-7-8-3/ Indiana's Log Cabin Act] | |||

** The last line in this section is very helpful to owner-builders working in Indiana. It states, "(d) An ordinance adopted under this section does not apply to private homes that are built by individuals and used for their own occupancy." This gives legal protection to those building their own homes. | |||

** Individuals from other states interested in advocacy could use this legal precedent to promote similar legislation. | |||

* The Living Building Challenge has been updated to a newer version. | |||

** [http://living-future.org/node/207/ Overview] of the LBC 3.0. | |||

** [http://living-future.org/node/94/ Requirements] of the LBC 3.0. | |||

* [http://homestead-and-survival.com/107-ingenious-pallet-projects-ideas/ Link] to DIY projects using shipping pallets. Over 100 ideas here. | |||

* Curious how the [http://www.opentechcollaborative.cc/index.html/ Open Tech Collaborative Forever] Home Challenge is going... no information available from their website. Sent Facebook message to find out the status. | |||

* Also curious about the [http://www.ecolodge.be/ Ecolodge] open source home project. No updates on their Facebook page for months. Sent them a message to find out the stage of development. | |||

=Sun, June 29, 2014= | |||

* TEDx Talk on the MicroHouse 1 and 2. | |||

** <html><iframe width="560" height="315" src="//www.youtube.com/embed/C_3JAyS0Ixo" frameborder="0" allowfullscreen></iframe></html> | |||

* Curious why no one seems to be updating their logs. Very bummed to see zero documentation on MicroHouse 3. | |||

= | =Tue, May 6, 2014= | ||

* Uploaded SketchUp for module 3 design to wiki: | |||

** [[File:MH_2_mod_3_design_SKP13.skp]] | |||

*** Note: Do not take dimensions from this model. It was made very quickly just to create a materials order (it was determined that we would order materials for module 3 along with module 2 the night before the order was delivered). The model just shows a schematic idea of one way to frame up the walls. | |||

* Added | |||

=Tue, April 29, 2014= | |||

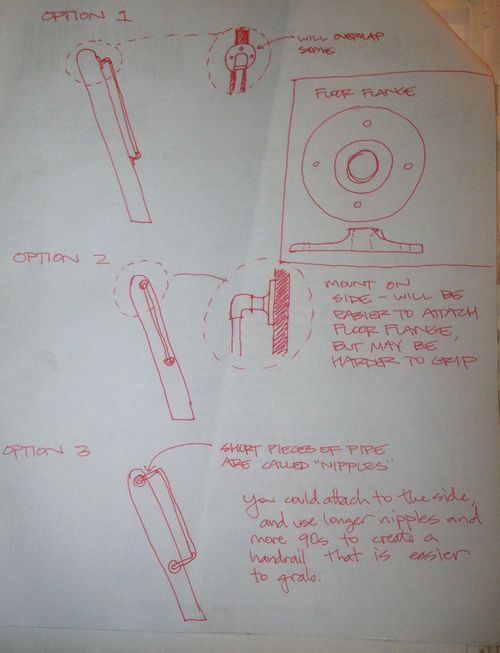

* Made sketch of ladder options for Catarina. | |||

** [[Image:MH 2 ladder options.JPG|500px]] | |||

* Created guide for how to measure an angle in sketchup on [http://opensourceecology.dozuki.com/Guide/Measuring+an+Angle+in+Sketchup/154 Dozuki]. | |||

* Uploaded my photos from MH 2 build to [https://opensourceecology.trovebox.com/photos/page-1/list Trovebox]. Excited to see that some of the other workshop collaborators have done the same! | |||

* Emailed workshop collaborators re: uploading photos to Trovebox. | |||

=Wed, April 24, 2014= | |||

Uploaded SketchUp file used for instructions for the workshop to the wiki and added it to the MH 2 Development Board. | |||

[[File:MH_2_Final_for_Workshop_SKPv13.skp]] | |||

=TEDxBloomington Talk= | |||

* Gave my 8-minute talk "Re-Imagining the Barn-Raising for the 21st Century" at TEDxBloomington 2014. | |||

* Great feedback from the audience. Meeting with a City Council member on Thursday to discuss how we might apply some of these ideas to aid the homeless in Bloomington. | |||

* Videos for the individual talks have not been made, but you can see my talk at about 2h40m into the show, by visiting this [http://new.livestream.com/tedx/events/2922548 Live Stream Link.] It's the top video on the page. | |||

=MicroHouse 2 Build Week= | |||

* | * We accomplished the enclosure of the shell, including metal roofing, taped foam wrap with purlins for siding, and windows. | ||

* | * We lost the majority of the first day due to machine delays and part of another day due to inclement weather. | ||

* | * Again, the build portion proceeded very well, given the challenges mentioned, but the documentation was hard to capture. Fortunately, people have been adding their photos to Trovebox, so now it is just a matter of adding photos to the existing Dozuki guides. | ||

* Found Curtis, an M.A. with hands-on experience and a great attitude to help finish the MH 2 and to collaborate further on the project. | |||

=Tue, Apr 15, 2014= | |||

* | * Gather tools needed for departure tomorrow morning. | ||

* | ** tool belt including hammer, tape measure, speed square, pencils, markers, utility knife with fresh blade, wood chisel, fouled chisel, screwdriver, electrician's pliers. | ||

* | ** cordless drill, extra batteries, and chargers, set of bits | ||

* | ** camera and tripod | ||

** extra hammers | |||

* Upload Menard's picking list pdf to wiki and add to Dev Board. | |||

** [[File:MH 2 picking list for Menards.pdf]] | |||

=Mon, Apr 14, 2014= | |||

* [https://docs.google.com/a/opensourceecology.org/document/d/1r6MKuEjC7qbi8eX3EtcQMc5GIeYVQAyvmexas_XxQx4/edit Final Preparations email] to workshop participants, letting them know what to bring. | |||

** Add final prep email to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdE5TUnozdXNuMEc5NXpCdThuZWRzdHc&usp=drive_web#gid=1 MH 2 Dev Board.] | |||

* Submit order to Menard's. | |||

** Check picking list sent back to me by Brian at Menard's. | |||

** Make corrections to picking list and resubmit. | |||

** Several more phone conversations back-and-forth with building materials department. Fewer than the MH 1 order, but on an order with this many items, it seems that there are always several mistakes when they transfer it into their computer. Fortunately, this time we only had to make 2 substitutions on materials (wood stain and ceiling insulation) based on low stock at Menards. | |||

** Recheck final picking list and approve for payment. | |||

** Delivery scheduled for Thursday morning. Yay! | |||

= | =Sun, Apr 13, 2014= | ||

== | * Assemble final BOM for MH 2. | ||

** [https://docs.google.com/spreadsheet/ccc?key=0ArNBTd6xfT7MdDFRUnh1VUNOWjhXWDNySXQwUC1kSlE#gid=0 MH 2 BOM by Module] | |||

** [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdHdhZmp3UWFzelZMeTQyRjlxN04yU1E&usp=drive_web#gid=6 MH 2 BOM Order Sheets for Menard's] | |||

*** Includes two sheets - the first is the totals worksheet, where the counts from the different modules are tallied. The second is just the final totals that were submitted to menard's for the order. | |||

=Sat, Apr 12, 2014= | |||

* [http://www.tedxbloomington.com/ TEDxBloomington] rehearsal all day long :) The talk is coming along very well, and having the visual slideshow for it finally complete really brings it to life. I hadn't worked on it at all for the past week-and-a-half, because I've been focusing so much on final preparations for the MicroHouse 2 build. Giving it a full day of attention - especially after some time away from it - made it easy to bring the details together. | |||

* Shared [https://www.facebook.com/OpenSourceEcology/posts/10152767091371562?stream_ref=1 post about my talk from TEDxBloomington] on OSE facebook site. | |||

[[ | =Fri, Apr 11, 2014= | ||

* Continue adding final details to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdDFRUnh1VUNOWjhXWDNySXQwUC1kSlE#gid=0 BOM]. | |||

* [https://www.facebook.com/OpenSourceEcology/posts/10152763076681562?stream_ref=10 Post] soil mixer build to Facebook. | |||

== | =Thu, Apr 10, 2014= | ||

* [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdDFRUnh1VUNOWjhXWDNySXQwUC1kSlE#gid=0 BOM] all day long :) | |||

* Added pre-workshop information to [http://opensourceecology.org/wiki/MicroHouse_April_2014_Workshop workshop wiki page]. | |||

=Wed, Apr 9, 2014= | |||

Late Night Work: | |||

* TEDx talk refinement in preparation for Saturday's practice session. | |||

* Extended email to Catarina re:function of door recesses and relationship of foundation height to finish floor and finish grade levels. | |||

* Created [http://opensourceecology.org/wiki/MicroHouse_April_2014_Workshop wiki page] for this event. It's a repository for the participants logs and we'll fill it out with pictures and links to other assets during the workshop. Then, in the future when people have questions about what a workshop is like, we can point them there. | |||

* Added [http://opensourceecology.org/wiki/Naiomi_log Naomi Log] to List of Participants' Logs. | |||

[[ | Day Work: | ||

* Created [http://opensourceecology.dozuki.com/c/MicroHouse_2_Loft_Module Loft Module Framing Guide] on Dozuki. Also, began the decking guide, too. | |||

* Continue filling out [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdDFRUnh1VUNOWjhXWDNySXQwUC1kSlE#gid=0 BOM.] | |||

* Re-work loft design to include notch for ladder. | |||

* Conversation w/ Catarina re: mod 3, overall BOM, ladder and loft design, floor coverings. | |||

* Added mod 3 document to Dev Board. | |||

* Add notes and images for contractor to [https://docs.google.com/a/opensourceecology.org/document/d/199eSBGlAVZpeICAyxhrwKUvEk83Gqo31pMXF4_YxLv0/edit# Mod 3 document] | |||

=Tue, Apr 8, 2014= | |||

Late Night Work: | |||

* Worked on model for mod 3 for contractor's meeting. | |||

* Added more to [http://opensourceecology.dozuki.com/c/Microhouse_2_Walls CEB Wall Stacking Guide] on Dozuki. | |||

* Found this awesome German Silent Film on creating compressed earth-straw blocks. | |||

** <html><iframe width="420" height="315" src="//www.youtube.com/embed/vBn-TanzkGQ" frameborder="0" allowfullscreen></iframe></html> | |||

Day Work: | |||

* Begin [http://opensourceecology.dozuki.com/c/Microhouse_2_Walls CEB Wall Stacking Guide] on Dozuki. | |||

* Finish [http://opensourceecology.dozuki.com/Guide/Building+the+MicroHouse+2+Door+Module./143 Door Module Guide] on Dozuki. | |||

* Create [http://opensourceecology.dozuki.com/c/Window_Module Window Module Guide] on Dozuki. | |||

* [https://docs.google.com/a/opensourceecology.org/document/d/1RM0uk4Knjv62XPwtPsBqJlwpFGJdPgemXv_HciQ1BO0/edit Email reminder] to workshop participants about filling out the rest of their information regarding travel, etc. | |||

* Updated [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdEVQQ2lDcHp2WFUyN1FPeWhacTVoeXc&usp=gmail#gid=0 MH 2 Participant List]. | |||

* Created links of Workshop Participant Logs on my wiki page. Tyler Ross is our first participant to send me his log :) | |||

* Tweaked various Dozuki guides based on Catarina's feedback. | |||

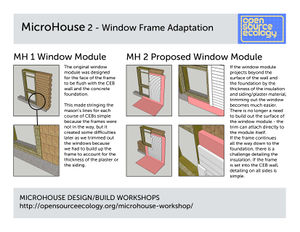

* Added final window mod to Dev Board and to the Dozuki Guide. | |||

* Upload FINAL WINDOW MODEL SKETCHUP [[File:MH_2_-_Window_Module_SKPv13.skp]]. | |||

** Includes scenes created for full module, for steps of assembly, and for cut pieces. | |||

* Send [https://docs.google.com/a/opensourceecology.org/document/d/1ujBVVG4cw7DiQxu7URh9UAuSbeTnP7X_gdZD7jN5dKI/edit second email to MH workshop participants]. | |||

** Introduces wiki and log process. | |||

** Instructs participants to set up their own logs. | |||

* Add rebar cut lengths to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdGhhRVdVeVR0UHp3c25pZThqOTVUcWc#gid=0 MH 2 Cut List]. | |||

* Add rebar cut length image to [http://opensourceecology.dozuki.com/Guide/Installing+Microhouse+2+Foundation+Module/92 Dozuki Foundation Mod Guide]. | |||

=Mon, Apr 7, 2014= | |||

* Talked to Tyler Moore who is interested in taking the CEB press workshop and/or the MH workshop. Based on his skill set and goals, I encouraged him to take the CEB press workshop if he can take only one. He is well-primed to immediately put the information to use in an enterprise fashion. | |||

* Add link from Dozuki Door Module Guide to sketchup file. | |||

* Upload FINAL DOOR MODULE SKETCHUP (version 13) [[File:MH2_-_Door_Module_SKPv13.skp]] | |||

** Model has scenes created for each step of assembly, for the full assembly, and for the dimensioned cut pieces. | |||

* Create cut list for Door Module and add to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdGhhRVdVeVR0UHp3c25pZThqOTVUcWc#gid=0 MH 2 Cut List.] | |||

* Add materials and tools list, along with cut steps and cut list to [http://opensourceecology.dozuki.com/Guide/Building+the+MicroHouse+2+Door+Module./143 Dozuki Door Module Guide] | |||

* Update [http://opensourceecology.dozuki.com/Guide/Installing+Microhouse+2+Foundation+Module/92 Dozuki foundation guide] for MH 2: | |||

* Email catch-up - make plan for phone call with Marcin and Catarina. | |||

* Email Anthony and Andrew re: visual inventory for certain tools. | |||

=Fri | =Fri, Apr 4, 2014= | ||

== | * Double-check rough openings of windows and doors with window and door frames in 3d model. | ||

* Review [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdHdwdzEwY1BXaXAwaHFEblVVaVpxVEE#gid=0 Participant responses] for alternative spring break evaluation. | |||

* Send first email to MH 2 workshop participants along with Marcin, Catarina, and Rob. | |||

** Email introduces the Dev Board, Dozuki, and the asks participants to fill in the rest of their information on the Participants' Spreadsheet. | |||

* Create [https://docs.google.com/a/opensourceecology.org/document/d/1R2V1Xi9PUzZhhFR3uwCiP-vJUTjK_mqXdY_Z4infwAg/edit First email with MH workshop participants] and add link to the MH 2 Dev Board. | |||

* Create [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdEVQQ2lDcHp2WFUyN1FPeWhacTVoeXc#gid=0 MH 2 April Workshop Participants Spreadsheet] and add link to the MH 2 Dev Board. | |||

* Reviewed Eventbrite roster for workshop. 8 for five day + 3 more for the weekend. | |||

* Late night last night (3 am) finishing my taxes for 2013. Phew! | |||

=Thu, Apr 3, 2014= | |||

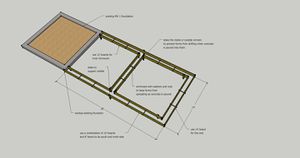

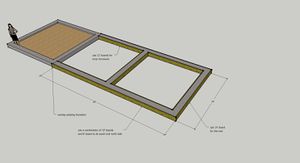

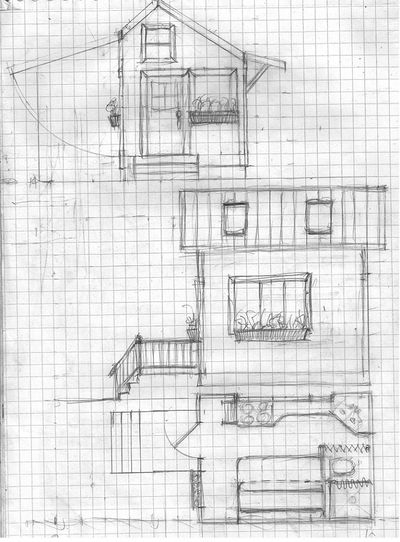

* Current sketchup files - working out details to the 1/4" - nearly complete | |||

** [[Image:MH2_rough_final.jpg|300px]] | |||

** [[File:MH_2_Rough_Final_v13.skp]] | |||

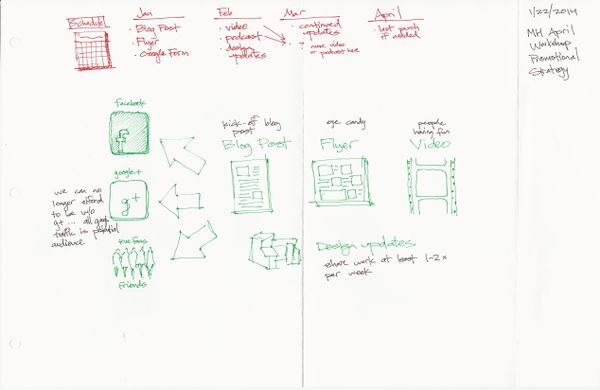

* Begin workshop layout for MH 2 Event. | |||

** <html><img src="https://docs.google.com/drawings/d/1_VjClzqrhhds4fuLuNxpt7uUFwtGHfw_uGmlI3QLS7k/pub?w=1341&h=400"></html> | |||

** [https://docs.google.com/drawings/d/1_VjClzqrhhds4fuLuNxpt7uUFwtGHfw_uGmlI3QLS7k/pub?w=1341&h=685 Link to google drawing of workshop layout document.] | |||

* Create [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdHRSNmJ3a2p0bmw1U2N6MHlZQ0w3eFE#gid=0 Framing Module Weight Estimator.] | |||

** [[Image:Framing_Module_Weight.jpg|300px]] | |||

** At a total of ~165 lbs., angled side modules can be made single units instead of 2 pieces fitting together, simplifying both fabrication and assembly. | |||

** North-side, full-height wall will remain two sub-modules. If it were one wall it would weight ~332 lbs. At 14' in length, this would be very awkward to maneuver. | |||

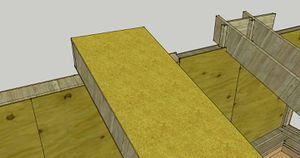

* Bond beam adjustments: | |||

** MH 1 style bond beam was placed flush with the outside of the CEB wall | |||

*:: [[Image:MH_1_style_bond_beam.jpg|300px]] | |||

** MH 2 bond beam will be recessed 1/2" from CEB wall - this will allow the sheathing to end up flush with the wall, simplifying adding the insulation, siding, and finish details. | |||

*:: [[Image:MH_2_bond_beam.jpg|300px]] | |||

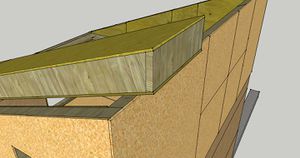

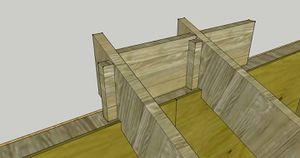

* Roof module work | |||

** MH 1 roof mod required angled cuts for all the studs and beveled cuts for the top plates... lots of added construction time. | |||

*:: [[Image:MH_1_roof_mod_in_place.jpg|300px]] | |||

** MH 2 improved roof mod eliminates all bevel cuts - replaces with bird's mouth cut on rafter. The long block and short block attached to the rafter make proper positioning a no-brainer. Rafter modules are placed next to each other quickly and screwed into position. | |||

*:: [[Image:New_roof_mod.jpg|300px]] [[Image:New_roof_mod_with_2_in_place.jpg|300px]] | |||

** Side-by-side of MH 1 roof module and beveled loft wall module with simplified MH 2 rafter module and flat-topped loft wall module. | |||

*:: [[Image:New_and_old_roof_mods_side_by_side.jpg|300px]] | |||

* Screen capture of my work late last night on Dozuki: | |||

*: [[Image:MH_2_Assembly.jpg|300px]] | |||

* Flooded in to my house for the day - big storm - means working from home which is great, but due to thunderstorm also means spotty satellite internet signal. | |||

*: [[Image:baby creek flood.JPG|300px]] | |||

== | =Wed, Apr 2, 2014= | ||

* Created final assembly diagram images and seeded them into [http://opensourceecology.dozuki.com/c/Microhouse_2_Final_Assembly Dozuki Final Assembly] | |||

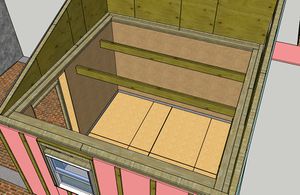

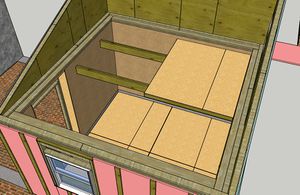

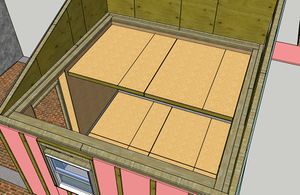

* Create detail design for loft modules. | |||

** First image shows double 2x8 that is embedded into CEB wall. Next images show the two modules being placed. "Design for Tolerancing" includes 1/2" space between modules. | |||

** [[image:Loft_beams_image.jpg|300px]] [[image:Loft_image_w_one_module.jpg|300px]] [[image:Loft image with both modules.jpg|300px]] | |||

** framing for loft modules can be 2x4, because the beams beneath reduce the span | |||

* [http://opensourceecology.dozuki.com/c/Microhouse_2_Modules MH 2 Dozuki:] organize modules, add images and descriptions for modules. | |||

* Add links from previous days' two days work to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdE5TUnozdXNuMEc5NXpCdThuZWRzdHc&usp=sheets_web#gid=1 MH 2 Dev Board]. | |||

* Create [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdERaS0tmRUQwWm5OUldPbjM1WlpzU3c#gid=0 MicroHouse 2 Time Log] | |||

* Morning emails (MicroHouse attendees, Marcin and Catarina re: construction details, Catarina re: May workshop) | |||

=Tue, Apr 1, 2014= | |||

* Added Floor Module materials to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdDFRUnh1VUNOWjhXWDNySXQwUC1kSlE#gid=0 MH 2 BOM]. | |||

* Create Dozuki guide for [http://opensourceecology.dozuki.com/Guide/Building+the+MH+2+Floor+Modules/140 MicroHouse 2 Floor Module Frame Construction.] | |||

* Create Dozuki guide for [http://opensourceecology.dozuki.com/Guide/Cutting+the+MicroHouse+2+Floor+Decking+Pieces/142 MicroHouse 2 Floor Decking Installation.] | |||

* follow-up phone call to Scott Mader to find out if he's attending the MicroHouse workshop - no answer, left msg | |||

* added tools, parts, and remaining steps to [http://opensourceecology.dozuki.com/Guide/Building+the+Microhouse+Utility+Module+Frame/96 MH 1 Utility Module Dozuki guide.] | |||

* create and send [https://docs.google.com/a/opensourceecology.org/forms/d/1YVNL2F-rqWDup99lM90H7UQlok1zxLXsz5FUp4AzsZM/viewform Form for Alternative Spring Break Feedback.] | |||

* look over [http://opensourceecology.dozuki.com/c/Rototiller_and_Soil_Pulverizer/ Dozuki guide for Soil Mixer] created by [http://opensourceecology.org/wiki/Andrew_Graham_Log/ Andrew Graham]. Looks fantastic! | |||

=Mon, Mar 31, 2014= | |||

* add images to [http://opensourceecology.dozuki.com/Guide/Building+the+Microhouse+Utility+Module/96/ utility module on MH 2 dozuki] | |||

* create floor system options for upper level of MH 2 - the first shows one large module that would be temporarily supported and then lag screwed into place - the second shows two built-up beams that could be set into the CEB wall and then could support a series of floor modules to make them easier to move by human power - either 2 or 3 modules could lay over the beams | |||

** [[Image:One floor module lag screwed into wall.jpg|300px]] [[Image:3_modules_with_beams.jpg|300px]] | |||

* create floor system for lower level of MH 2 - involves 4 modules that rest on concrete blocks | |||

** [[Image:Lower_level_floor_modules.jpg|300px]] | |||

* span table pdf (link below in my log seems to be broken): | |||

** http://www.wclib.org/pdfs/simpspantbls.pdf | |||

* Note: 6'8" is height to underside of loft in MH 1. | |||

* MH 2 Dozuki Work | |||

* Dozuki tutorial with Rob | |||

** Change image on [http://opensourceecology.dozuki.com/c/Microhouse_v2?revisionid=HEAD/ MH 2 Dozuki Landing Page] | |||

* review Dozuki for MH 1 | |||

** add proper link to [http://opensourceecology.org/wiki/Microhouse_Development_Board/ MH 1 Dev Board wiki page] - old link was to unused Dev Board template | |||

* review [http://opensourceecology.dozuki.com/c/CEB_Press CEB Press Dozuki Pages] | |||

** Some great content has been added here. | |||

** The landing page has a different format than the way the MicroHouse page is set up. Do we want "Installation Guides to appear on the landing page? If so, what content goes under the "Modules?" | |||

* emails to Marcin, Catarina re: MicroHouse workshop scholarship ideas, and documentation thoughts | |||

* compile list of scholarship candidates for MicroHouse workshop | |||

=Fri, Mar 28, 2014= | |||

* took a moment to research indoor air quality in tiny houses - found this [http://tinyhouseblog.com/tiny-house/tiny-houses-and-indoor-air-quality-part-1// interesting article on the Tiny House Blog] | |||

** mostly recommendations to cook and bathe outside | |||

** also recommends using a propane heater that vents to outside and brings in makeup air from outside | |||

** recommends using A/C to control humidity in the summer | |||

* sketch ideas for how the upper and lower modules come together to integrate insulation layer | |||

** [[Image:upper and lower modules interface.JPG|300px]] | |||

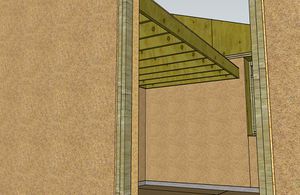

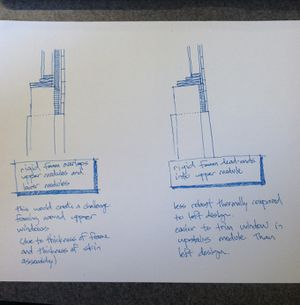

* create detail proposal for MH 2 window frame module | |||

** [[Image:MH_2_Window_Frame_Proposal2.jpg|300px]] | |||

** [https://www.facebook.com/photo.php?fbid=10152730076196562&set=a.10151381815921562.574965.66469461561&type=1&stream_ref=10/ Post image to Facebook.] | |||

** [[File:Window_detail_exploration13.skp]] | |||

* upload sketches from last night's thinking about window modules | |||

** [[Image:window_frame_sketch.JPG|300px]] | |||

* another MicroHouse 5-Day workshop sign-up this morning | |||

=Thu, Mar 27, 2014= | |||

* create clean, detailed SketchUp model to facilitate final decisions, detail design, and exploded diagram for construction. | |||

** [[File:MH_2_clean_for_detail_design_13.skp]] | |||

* create rough step-by-step | |||

** [[Image:MH_2_steps_rough.jpg|300px]] | |||

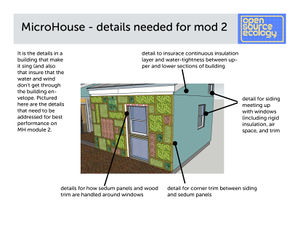

* create graphic showing needed details | |||

** [[Image:MH_2_needed_details.jpg|300px]] | |||

[[ | =Wed, Mar 26, 2014= | ||

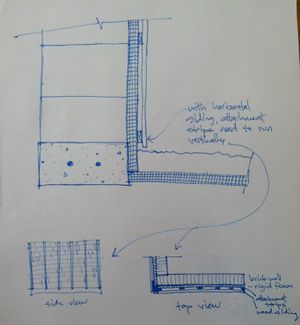

[[ | * sketch of siding detail for east side | ||

** [[Image:siding.JPG|300px]] | |||

==MicroHouse 2 Build Workshop == | |||

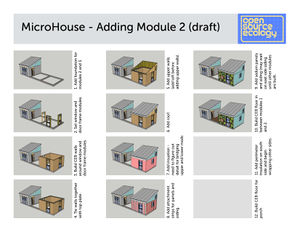

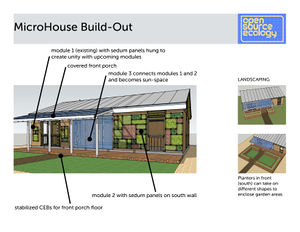

* create full MicroHouse build-out poster and [https://www.facebook.com/photo.php?fbid=10152725699231562&set=a.10151381815921562.574965.66469461561&type=1&stream_ref=10/ post to Facebook] for feedback and workshop promotion | |||

** [[Image:Overall_MH_2.jpg|300px]] | |||

* show panels on module 1, too, in order to create more unity between original and added modules | |||

** [[Image:Panels_on_module_1_too.jpg|300px]] | |||

** Panels can be easily attached to existing siding on module 1. | |||

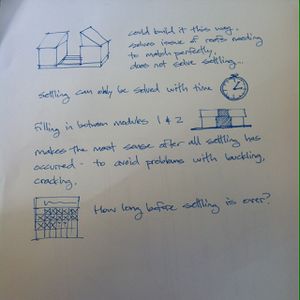

* settling issue may challenge creating connections between modules 1 and 2 immediately | |||

** [[Image:Settling of Bricks.JPG|300px]] | |||

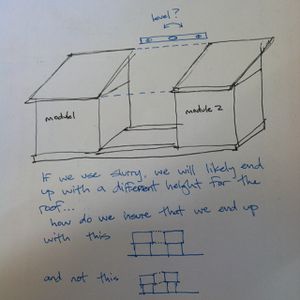

* identify main challenge with roofs coming together | |||

** [[Image:module 1 and module 2 levels.JPG|300px]] | |||

** If bricks are not done changing dimension - even if we hit it dead-on at time of construction, may shift over time. | |||

** Could use framing system to support roof. This would keep the height much more consistent over time. May causing cracking in between brick wall and top plate as bricks shrink over time. | |||

** Without the load of the roof resting fully on the block walls, walls are less stable. Since we are not wrapping them with chicken wire, I believe we need the rigidity provide by bearing the roof on the walls. | |||

* first pass at sedum panel layout inspired by Mondrian | |||

** [[Image:First_pass_sedum_panels.jpg|300px]] | |||

** [[Image:panel_attachment_square.JPG|300px]] | |||

* reviewed Laurynn's drawing for summer camp and added the sketchup file to her [http://opensourceecology.org/wiki/Laurynn_log#Wed.2C_Mar_26.2C_2014/ log page] | |||

* Notes from last night's brainstorming about long-term MicroHouse: | |||

** The MicroHouse could become even lower cost by taking advantage of materials salvaging. To simplify this, the basic modules have worksheets to fill out and pointers for what types of materials to salvage. For instance - Basic module, 144 sq ft of downstairs flooring - | |||

** Decisions on doors and windows and other components could be made simple with parametrically-controlled components. | |||

** Find a window. Type in the measurements of the frame and the program turns it into 3D CAD window module right-sized for the salvaged window. | |||

** Same for the door. | |||

** User could be led through simple process: | |||

** Lofted or not, and size of loft which controls shape of roof and height of walls. | |||

** Utilities or not, which controls site work, room layout, partition walls… | |||

** Heating system, which controls room layout, ventilation requirements… | |||

** Then, details like floor, wall, ceiling finishes… wall and roof skins… | |||

** A 3D model is updating live as you make these choices, like a video game. | |||

** The house can be rotated and you can also create section cuts to expose the inside of the house as you modify it. Alongside the house is a sticker price for the materials that updates as one makes decisions on building features and materials. | |||

** You can play in "dream" mode, where you are just imagining your house, or you can use it as a planning tool for your own house, where you create the design, and then you can learn how to build it and track your progress and your budget. If many players were doing this, the data from their shared experience could help guide others through the design and build process. | |||

=Tue, Mar 25, 2014= | |||

* reviewed Frank's [https://docs.google.com/a/opensourceecology.org/document/d/18pwKogDRLef6J6-fU0Y0ugUSF4YVxsKKkd07ypLS_9w/edit/ Hospitality Executive] document. | |||

* explore courtyard wall options | |||

** simple planters at edge of porch | |||

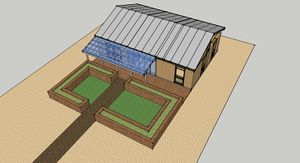

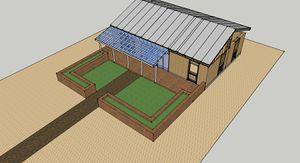

** [[Image:Planting_beds_in_front_of_house.jpg|300px]] | |||

** larger courtyard area with planter at porch edge, too | |||

** [[Image:Courtyard_enclosed_by_raised_planters.jpg|300px]] | |||

** larger courtyard but without planter at porch edge | |||

** [[Image:Larger_courtyard_area.jpg|300px]] | |||

* Phone conversation with Marcin and Catarina: | |||

** siding on east side of module 2 will be wood | |||

** south wall will be sedum panels | |||

** interiors will be exposed brick, whitewashed or painted - so will west and north walls, which will be interior walls in the completed design | |||

** door placement and entry to porch will be determined based on forthcoming images of design | |||

** gravel added to BOM | |||

** add raised planting beds made of stabilized CEBs | |||

** sedum panels will be in different sizes and will be used artistically - inspired by Modrian | |||

*** [[Image:Piet-mondrian.jpg|100px]] | |||

* add all-thread supports to sketchup foundation model | |||

[[Image:Forms_with_all-thread.jpg|300px]] | |||

* generate [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdDFRUnh1VUNOWjhXWDNySXQwUC1kSlE#gid=0/ Bill of Materials] and add to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdE5TUnozdXNuMEc5NXpCdThuZWRzdHc&usp=drive_web#gid=1/ MicroHouse 2 Dev Board.] | |||

* begin creating annotated foundation formwork images | |||

[[Image:Foundation_construction.jpg|300px]] | |||

* create porch on MicroHouse cluster | |||

** Porch can be shaded in summer with viney plants growing under the clear roof or with shade cloths that can be hung underneath (or placed over) the clear roof. | |||

[[Image:Covered_porch.jpg|300px]] | |||

* call Dustin Fraze re: MicroHouse assistant. | |||

** has a degree in aeronautical engineering technology (straight As, btw) | |||

** returned to school for engineering (motivated by interest in sustainable housing), found it to be all oil-based, not interested in that direction | |||

** also exposed to permaculture when he returned to school | |||

** has taken workshops in the past: | |||

*** tiny house workshop with Jay Schaffer (Tumbleweed) | |||

*** cob workshops | |||

*** rocket stove workshops | |||

** has lots of learning, and some limited hands-on experience | |||

* email Kyle re: arrangements for both CEB Press and MicroHouse workshops. | |||

=Mon, Mar 24, 2014= | |||

* | * Research on wiki on previous documentation ideas in as reference for Development Board work. | ||

* | ** [http://opensourceecology.org/wiki/Documentation_Standards/ Documentation Standards] | ||

*** I looked at the [http://opensourceecology.org/wiki/CEB_Press_Test CEB Press Test] page, and I think it has much more initial appeal than a spreadsheet as a public interface with the content. I it made me again wonder why we weren't using the wiki as the main tool for the documentation. | |||

*** I thought that overall this page was a much better explanation of how to do documentation than the development board currently is, even if it gets incredibly long-winded and many of the diagrams are not clear. I like the idea of a central wiki page for each machine linked to the website, Dozuki, etc. Even though I find a well-filled out spreadsheet to be beautiful, landing on a wiki page is a hell of a lot more exciting than landing on a spreadsheet. And the wiki is backed up and versioned in a way that a google spreadsheet is not. | |||

** [http://opensourceecology.org/wiki/How_to_Structure_the_Wiki_for_GVCS_Machines/ How to Structure the Wiki for GVCS Machines] | |||

*** I like the way Dan gives the templates of the code right there in the body. | |||

*** His explanations are also very clear and more accessible to a larger audience than the Documentation Standards page above. | |||

* Phone meeting with Marcin and Catarina: | |||

** focus on modules 2 and 3 - not so much presently on 4, 5, and 6 | |||

** create porch plan | |||

*** porch covered with clear roof + trellis for summer shading and winter solar gain | |||

*** porch will be post and beam framed | |||

*** porch goes in front of #3 and #1 | |||

** create foundation BOM and plan | |||

** floor downstairs and upstairs in module 2 will be laminate | |||

** floor in module 3 will be CEB | |||

* Link to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0AkNG-lv1ELQvdDRFN3RXdjI1RDNkRjYyUjk2NUJJUnc&usp=sharing#gid=0/ FeF Infrastructure Work Plan] shared by Catarina. | |||

* MH 2 work, posted to both [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014#MicroHouse_2/ MicroHouse 2014 Collaboration page] and to the [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArNBTd6xfT7MdE5TUnozdXNuMEc5NXpCdThuZWRzdHc&usp=drive_web&pli=1#gid=1/ MicroHouse 2 Development Board.] | |||

* The layout for MH 2 is much simpler - it is one large first floor space and one large loft. | |||

[[Image:Mh 2 overhead.jpg|300px]] | |||

* This shows the foundation expanded to accommodate Catarina's concept plan of using six module spaces for the final design. | |||

[[Image:Foundation_Concept.jpg|300px]] | |||

* The image below shows MH 1 and MH 2 together on the foundation. | |||

[[ | [[Image:Mh_1_and_Mh2_on_foundation.jpg|300px]] | ||

* This image looks at a 1-story addition along the north side. In order to keep the upper story window in the MH 1 loft, and using an 8' tall CEB wall on the northern addition, pitch of the roof becomes too shallow for using a metal roof. | |||

[[Image:North roof at super low slope.jpg|300px]] | |||

* Below is shown using a 7' CEB wall for the north sections which could more easily accommodate the same pitch of roof used on the first module. The upper window is lost in this scheme, though. | |||

[[Image:North_roof_at_same_slope.jpg|300px]] | |||

* Once the first and second modules are in place, the space in between them can be closed off. Shown here is a greenhouse style enclosure. | |||

* | |||

[[Image:Middle_greenhouse_roof.jpg|300px]] | |||

* This image shows the roofs coming together to form a central peak. | |||

[[Image:Same_at_ridge.jpg|300px]] | |||

* emailed Dustin re: MicroHouse workshop assistant | |||

* | * [http://www.awc.org/calculators/span/calc/timbercalcstyle.asp/ Span Table Calculator Link] | ||

* | * Create foundation plan, MH 2 plan, and overall cluster plan. | ||

*2 | * Catch up on emails. | ||

* | |||

=Thu, Mar 20, 2014= | |||

* | ==Notes on Continued Dev Board Work== | ||

* Excited to continue work on the Development Board and hopefully create something that feels less cumbersome and more functional. I love the intent, and it is clear that OSE has content management needs that are not currently being met, but it is a problem has not been cracked yet. I remember Dan B. doing work in this direction on the wiki, but I recall there being reasons that this did not meet all the needs. I am pleased to be a part of figuring this out. | |||

* | ==Dev Board Work== | ||

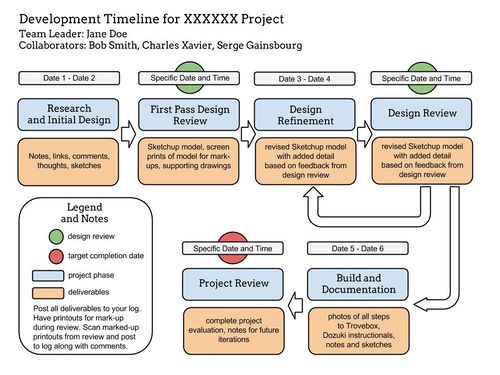

* In addition to adding content, I spent half of the work time today focusing on adapting the structure of the Development Board Template that I started with to be the most useful for an architecture project. | |||

[[Image:MH_1_Dev_Board.jpg|400px]] | |||

= | * Finished [http://opensourceecology.org/wiki/Interface_Design_-_MicroHouse/ Interface Design] specs. | ||

== | * Added [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0AqmZomxPTKkodGZEMXgxZjFBU3ZUdWhCTmFUUjAxREE&usp=drive_web#gid=3/ Final BOM] to Dev Board. | ||

* Added [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014#Links_and_Files/ Links to 3d Files] to Dev Board. Currently takes one the links page on the MH Collab 2014 page. | |||

* Added [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014#Videos/ Link to Time Lapse Build Videos] to Dev Board. Current Repository is on MH Collab 2014 page. | |||

* Added [https://opensourceecology.trovebox.com/photos/album-a/list/ Link to Build Photos on Trovebox] to Dev Board. | |||

* Added [http://opensourceecology.dozuki.com/c/Microhouse_Modules/ Link to Dozuki] to Dev Board. | |||

* Added [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0AqmZomxPTKkodGZiZ2dsYTEzNWdrZ05DQU5zRkhCdVE&usp=drive_web#gid=0/ Build Time Data] to Dev Board. | |||

* Added [https://docs.google.com/a/opensourceecology.org/file/d/0B6mZomxPTKkoeGVCdlVUZnFiQ19raV9vWGxvQThqVWZacHRn/edit/ Cut List and Fabrication Drawings] to Dev Board. | |||

* Added [http://opensourceecology.org/wiki/Module_Breakdown_-_MicroHouse#Development_2/ Instructions for Erecting rough Frames] to [http://opensourceecology.org/wiki/Module_Breakdown_-_MicroHouse#Development_2Module Breakdown page.] | |||

* Added [http://opensourceecology.org/wiki/Module_Breakdown_-_MicroHouse#Upper_Wall_Modules/ Exploded Parts Diagram] to Dev Board. | |||

* Added [https://docs.google.com/a/opensourceecology.org/document/d/1ViixwxMwXGQpulr6DlymmxLcnc3r1yHr1uhZy-qBQkI/edit/ MicroHouse Prototype Review] with Chris, Marcin, Katie, Audrey, Lucas, and Dan to Dev Board and to [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014#Links/ MicroHouse Collab 2014 - Links]. | |||

* Gave up adding links for every addition to Dev Board... have added links to 26 out of the 48 entries. Need to add more fields for existing content, and still have some content for existing fields. | |||

=Wed, Mar 19, 2014= | |||

==Initial Notes/Questions on Dev Board Process== | |||

* If Dev Board is supposed to be "one-stop-shop," why are the Dashboard and the Requirements other speadsheets? This adds to the perceived complexity of the process and violates the one-stop-shop idea. I propose that since the Dev Board is intended to be the place for everything, we eliminate every possible other spreadsheet. Maybe a rule like "anything less than 10-15 rows goes in the Dev Board" or something. Endless links to other spreadsheets is mind-numbing. | |||

* Same type of idea is true for wiki. If there is a one-stop-shop as a spreadsheet, we need a one-stop-shop on the wiki. The instructions in the Dev Board protocols require creating numerous new wiki pages. While this makes sense to always do in a similar structure, it is not clear what the catch-all page is that guides people to the content. Is it the Dashboard, which is simply an embedded spreadsheet? This can't be it because it doesn't have nearly enough information and not information that most people care about. Even if it had everything, a spreadsheet is not a way to navigate information, it is just a way to store it. In addition to the Dev Board being filled out, there needs to be a clear protocol for the information architecture on the wiki. | |||

* It should be made clear which work has a more public face, like a required entry on the wiki page, and which work only lives in the spreadsheet. Right now, this is the most confusing part of filling it out. Some items call for an wiki entry to be made, others are just links to information that could be useful to only a select few and just get embedded in the spreadsheet. | |||

* Filling out an identical spreadsheet for each module of the design has to be simplified - a new template should be created. For instance, the [http://opensourceecology.org/wiki/Requirements_Spreadsheet/ Requirements] asked for on each sheet is a mere six entries (most of which are covered in other fields in the Dev Board), and yet it is its own spreadsheet? And one is supposed to fill it out twice as links from two other speadsheets? If we can eliminate this kind of circular workflow of filling out the same information in multiple places, the chance of this method working increase dramatically. Right now, the Development Board has the feeling of further complicating the design process because it seems to be a process of just creating more and more spreadsheets and wiki pages. | |||

[[ | ==Dev Board Work== | ||

* Port assets from my Log Archive to [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArpE5Y9PpJCXdFlJMzhKY0tHdXJuQ3p4UjA2VkF4dGc&usp=sharing#gid=1/ MH Dev Board.] | |||

* New wiki pages created in the process. | |||

** [http://opensourceecology.org/wiki/Dashboard_-_Microhouse/ Dashboard] | |||

** [http://opensourceecology.org/wiki/Requirements_-_MicroHouse/ Overall Requirements] | |||

** [http://opensourceecology.org/wiki/Module_Breakdown_-_MicroHouse/ Module Breakdown] This one | |||

** [http://opensourceecology.org/wiki/Concept_-_MicroHouse/ Concept] This page needs content added from the MicroHouse design work that was done before I came on the scene. Marcin knows where on the wiki this lives. | |||

=Tue, Mar 18, 2014= | |||

* Phone conversation with Marcin re: transition plan. | |||

= | =Mon, Mar 17, 2014= | ||

* Compose email to Marcin re: transitioning work plan to balance with my life as 100% full-time single dad. | |||

* Email conversation with Catarina re: transitioning work plan. | |||

* Phone conversation with Catarina re: MH 2 design and overall MH additions design. | |||

* Email with Charlie the carpenter re: next steps for his work at FeF. | |||

=End of Spring Break Trip= | |||

* Flurry of activity at end of spring break trip, lost touch with log for Wednesday and Thursday. | |||

* Continued work on whitewash. | |||

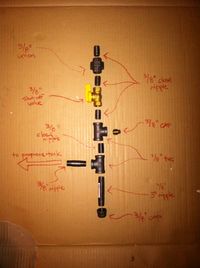

* Connect hot water heater in MH. | |||

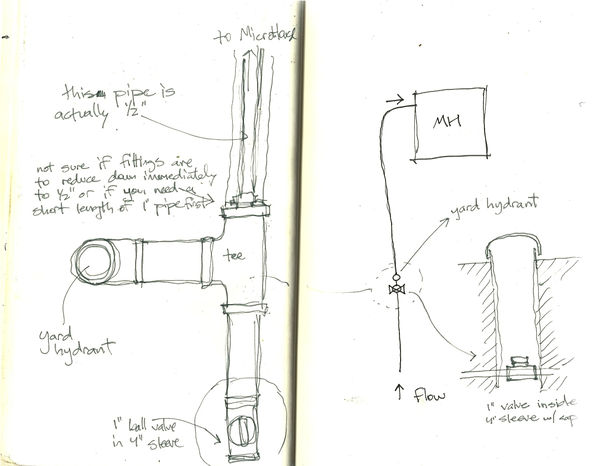

* Test MicroHouse plumbing for leaks. | |||

* Finish gypsum plaster downstairs in MH. | |||

* Make final connections for new MH sink. | |||

* Enclose MH bathroom piping in trim box. | |||

=Wed, Mar 12, 2014= | |||

* Day begins with documentation to make sure that work is being logged and recorded for others to build from. | |||

=Tue, Mar 11, 2014= | |||

* Talked to Charlie on phone re: his initial ballpark bid. | |||

** $1200 in materials and roughly $1200 in labor for all three projects. | |||

** Need to pick material for underside of soffit and siding for cabins. | |||

** Also need to speak with Charlie again and ask for bids to be based on three separate projects, to be done in this order: | |||

# Solar Cabin upgrades: siding, floor, bunk beds, and door. | |||

## Need to add to scope of work: finish flooring. | |||

# Finish out skylights in HabLab. | |||

# Install soffit material. | |||

* Showed Charlie, potential carpenter, the HabLab and Solar Cabin projects. | |||

** Upgrade Solar Cabins with siding, new floor, and bunk bed. | |||

** Finish out skylights inside HabLab. | |||

** Install soffit material. | |||

* Infrastructure work done today by group: | |||

** Gypsum plaster in MicroHouse. | |||

** Continued whitewashing the HabLab exterior: | |||

*** Encountered challenges with cracking of second batches. Suspected that the mix may have been too thick and perhaps not enough salt. Also may need to wet wall first. Interestingly, the batch from the first day went on thick and was applied to a dry wall - it worked great. Experimented on west wall with two test areas with a thinner mix. One test area had the wall wet down first. The other was applied to the dry wall. Also created a much more controlled mix for tomorrow to study the results more scientifically. | |||

[[Image:HabLab_whitewash.JPG|400px]] | |||

** Trim around chalkboard paint feature wall begun. | |||

=Mon, Mar 10, 2014= | |||

* Infrastructure work done today by group: | |||

** Began whitewashing the HabLab exterior. | |||

** Trim painting inside HabLab. | |||

** Plastering in MicroHouse. | |||

** Install H2O heater. | |||

** Create wooden stoop for HabLab. | |||

** Chalkboard paint applied to feature wall in HabLab. | |||

* Source Gypsolite in Cameron | |||

** Porter's Building Supply - do not carry | |||

** Sutherland's Building Supply - do not carry | |||

** Cameron Lumber - do not carry | |||

* Source Gypsolite in St. Joe | |||

** G L Painting and Coating - no answer | |||

** Les Collins Plastering - no retail | |||

** J & L Drywall | |||

*** 25 lb. bag - $10 | |||

*** 80 lb. bag $22.50 | |||

*** Hours: M-F 7 - 5 | |||

*** Address: 5002 Lake Ave. 64504 on 59 highway | |||

* Manufacturer's Recommendations for Gypsolite installation: http://www.nationalgypsum.com/products/..%5CFile%5C09%2023%2000-28.pdf | |||

=Sun, Mar 9, 2014= | |||

Afternoon Build Session - Multiple Groups Doing the Following... | |||

* Begin h20 heater install. | |||

* Cut and paint plywood. | |||

* Paint door frames inside HabLab. | |||

* Begin wood ceiling trim inside front bedroom. | |||

* Move old stove pipe to grain silo with scrap metal. | |||

* Lay down more straw to ease movement along muddy paths. | |||

* Remove crumbling plaster in MicroHouse, stuff cracks with mud, add chicken wire. | |||

Morning Design Session | |||

* | * Begin moving items from [http://opensourceecology.org/wiki/Chris_Reinhart_Log_Archive/ Chris Reinhart Log Archive] and [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014/ MicroHouse Collaboration 2014] to [https://docs.google.com/spreadsheet/ccc?key=0ArpE5Y9PpJCXdDhPbmh6aXYxQ2NDWG5jWDZqUFozR2c#gid=1/ MicroHouse 1 Dev Board] and [https://docs.google.com/a/opensourceecology.org/spreadsheet/ccc?key=0ArpE5Y9PpJCXdEE0eFBRcERYSE5uYXd2bDJpa2FJSXc&usp=drive_web#gid=1/ MicroHouse 2 Overall Development Board]. | ||

* | * Group gathered measurements to create base map for all future site planning. | ||

* | * Share Development Boards | ||

* Set Up Logs in Infrastructure Group | |||

** [http://opensourceecology.org/wiki/Wes_Log Wes Log] | |||

** [http://opensourceecology.org/wiki/Chrisc_log ChrisC Log] | |||

** [http://opensourceecology.org/wiki/Kyle_log Kyle Log] | |||

** [http://opensourceecology.org/wiki/Laurynn_log Laurynn Log] | |||

** [http://opensourceecology.org/wiki/Catwilmes_log/ Cat Log] | |||

* Introductory session with Marcin | |||

* Give tour to entire group | |||

== | =Fri, Mar 7, 2014= | ||

* Facebook post on [https://www.facebook.com/OpenSourceEcology/posts/10152293688864188?stream_ref=10/ guerrilla-engineered fusion reactor.] | |||

* Work on [https://docs.google.com/a/opensourceecology.org/document/d/1KDbUSCS-T3VEm5JwOF-kLlC8eduATp99yitW0d8dJ0k/edit#/ shopping list] for Alternative Spring Break with Catarina. | |||

* Create [https://docs.google.com/a/opensourceecology.org/document/d/1cjO09M7M4V8miJuzWzSmT0E0c8HYNaD1n7hnAcebkNA/edit/ Plans] for Alternative Spring Break with Catarina. | |||

=Thu, Mar 6, 2014= | |||

* | * First TEDxBloomington meeting -- 4 hours long! | ||

* | * Reserved rental car for pick-up on Saturday morning at 8am. Avis, located at the Sears automotive desk at the Muncie Mall. | ||

* Posted comments in response to [http://opensourceecology.org/seeking-microhouse-client-in-the-southern-usa/#comment-3536/ Blog Post.] Comments are awaiting moderation. | |||

* Create [http://opensourceecology.org/wiki/Lime_Plaster_and_Wash Lime Plaster and Wash page] on wiki to record research and experiments at FeF with lime. | |||

* Respond to inquiry for MH interior photos with link to Facebook album, [https://www.facebook.com/media/set/?set=a.10152483593761562.1073741827.66469461561&type=3/ MicroHouse 1 Interior.] | |||

* Create and send [https://docs.google.com/a/opensourceecology.org/document/d/15ULMRiyDFBbV96NZsmnYDKodYM80gIvDPiiymrKiUao/edit Transportation Logistics for Those Arriving Separately email] for spring break trip. | |||

* Create and send [https://docs.google.com/a/opensourceecology.org/document/d/1t-sJoW39WMKwM_cCynFiB2MO-JtVOQjofl8kaYc_7hU/edit Transportation Overview Mass Email] for spring break trip. | |||

=Wed, Mar 5, 2014= | |||

* Fly from KCI to ATL to IND - delays - returned home late evening to Bloomington. | |||

* Pick Marcin up at airpot. | |||

=Tue, Mar 4, 2014= | |||

'' | * Purchase paint and wood from Home Depot for HabLab upgrades. | ||

* Measure wall areas to determine materials quantities for spring break work. | |||

** Trim. (begin with 42 8' 1x4 boards, 6 8' 1x6 boards, and 2 sheets of 1/4" plywood) | |||

** Paint. (begin with 3 gal yellow and 1 gal green) | |||

* Make decisions with Catarina re: painting plan for HabLab. | |||

* Clean HabLab with Catarina. | |||

* Finish installing LP wall heater. Test plumbing for leaks. Everything in working condition, but performance of heater is disappointing - unless you lean right over the top of it! | |||

* Pick up filter for ShopVac and pressure regulator for LP wall-heater on return from airport. | |||

* Take Marcin to airport. | |||

=Mon, Mar 3, 2014= | |||

* [https://www.facebook.com/OpenSourceEcology/posts/10152286288804188?stream_ref=10/ Posted Open Source Beehives project] to Facebook. | |||

* Cleaned HabLab | |||

** Cleared cobwebs and dusted throughout HabLab (this took much longer than I thought it would - 3 hours.) | |||

** Scrubbed inside of freezer in kitchen. | |||

** Took out trash. | |||

** Discovered that out of 2 vacuum cleaners and 2 Shop-Vacs, none are in proper working order. Need to replace filters in both Shop-Vacs. | |||

** Scrubbed outside of freezer in laundry room. | |||

** Cleaned bathroom counter and mirror. | |||

* Sent email with info to alternative spring break group. | |||

* Investigate van rental options, from Sat, Mar 8 through Sat, Mar 15. Approx 1100 miles. Leave from Muncie, IN. | |||

** Enterprise/National | |||

*** 12 passenger van | |||

*** $100/day (includes 150 miles/day) (.20/mi overage charge) | |||

*** $25-$30 day for insurance. | |||

*** Total cost approx: $950 | |||

** Budget/Avis | |||

*** 12 passenger van for 7 days = $903 | |||

*** $1307 with insurance coverage for vehicle, third-party damages, and personal injury for driver and passengers. | |||

*** price includes tax, so can be reduced by 7% if we provide them with our tax-exempt form. | |||

* Look at [http://www.weather.com/weather/tenday/64469/ 10-day weather forecast for spring break.] Weather looks like it will be great! 40s and 50s during day and 30s at night. | |||

* Compose [https://docs.google.com/a/opensourceecology.org/document/d/1hRy6_YLDnqcdVCw83xsbf1MQH2X1BX8pfHFDEHXZyFE/edit/ email] to Alternative Spring Break attendees. | |||

* Add new frame idea and accompanying Facebook discussion to [http://opensourceecology.org/wiki/MicroHouse_Collaboration_2014#MicroHouse_2_Ideas/ MH Collab Page.] | |||

=Sun, Mar 2, 2014= | |||

[[ | * Spring Break trip SOLD OUT! | ||

* Added "MicroHouse Workshop Scholarship Fund" as a donation option to the [https://www.eventbrite.com/e/microhouse-workshop-april-2014-tickets-10652518971/ Eventbrite listing for April Workshop.] | |||

* Communicate with all spring break attendees regarding travel. | |||

** Create [https://mail.google.com/mail/u/0/?shva=1#search/christopher+chou/14479bce5bb9f8aa/ Alternative Spring Break Attendees Master Spreadsheet.] | |||

* Finished installing supply lines and drain lines for new sink in MicroHouse bathroom. | |||

* Keep pumping the alternative spring break via [https://www.facebook.com/OpenSourceEcology/posts/10152282557404188?stream_ref=10/ Facebook conversation.] | |||

* Look up tankless H2O heater used in MH to replace one in HabLab. | |||