Talk:3D Printer Design Evolution: Difference between revisions

Jump to navigation

Jump to search

(Created page with "=CNC torch table concept design comments= *Will axis sag in the middle? **If the traveling carriage is longer will it minimize rod bending? **does it need an I-beam and some...") |

|||

| (5 intermediate revisions by the same user not shown) | |||

| Line 4: | Line 4: | ||

**If the traveling carriage is longer will it minimize rod bending? | **If the traveling carriage is longer will it minimize rod bending? | ||

**does it need an I-beam and some sort of way to hang from the beam? | **does it need an I-beam and some sort of way to hang from the beam? | ||

**could Z-axis be programmed to adjust for minor sagging? | |||

*protection for pulley belt | *protection for pulley belt | ||

== Spacer Idea == | |||

in order to insure equal spacing between the frame plates, perhaps a spacer could be placed near the bracket connections | |||

can also be made to include a foot in order to lift the threads and nuts that face downward | |||

[[Image:UCAprinterspacer.png|400px]] | |||

<nowiki> | |||

foot_height = 0; | |||

width = 12; | |||

depth = 12; | |||

platethickness = 3.6; | |||

distance_from_corner = 5.1; | |||

spacerthickness = 3; | |||

radiusI = 3; | |||

radiusO = 6; | |||

$fn=20; | |||

difference() | |||

{ | |||

union() | |||

{ | |||

cube([(spacerthickness+distance_from_corner+depth),(spacerthickness+distance_from_corner+depth),width]); | |||

translate([radiusO+foot_height-spacerthickness,0,0]) | |||

cylinder(r=foot_height-spacerthickness,width); | |||

} | |||

translate([spacerthickness+distance_from_corner,spacerthickness,0]) | |||

cube([depth,platethickness,width+2]); | |||

translate([spacerthickness,spacerthickness+distance_from_corner,0]) | |||

cube([platethickness,depth,width+2]); | |||

translate([spacerthickness+platethickness+spacerthickness+radiusI,spacerthickness+platethickness+spacerthickness+radiusI,0]) | |||

minkowski() | |||

{ | |||

cube([(spacerthickness+distance_from_corner+depth),(spacerthickness+distance_from_corner+depth),width+2]); cylinder(r=radiusI,h=width); | |||

} | |||

difference() | |||

{ | |||

cube([radiusO,radiusO,width+2]); | |||

translate([radiusO,radiusO,0]) | |||

cylinder(r=radiusO,h=width+2); | |||

} | |||

} | |||

echo("Thinnest point =",sqrt(pow((distance_from_corner-platethickness),2)+pow((distance_from_corner-platethickness),2))); | |||

</nowiki> | |||

Latest revision as of 00:35, 2 November 2016

CNC torch table concept design comments

- Will axis sag in the middle?

- If the traveling carriage is longer will it minimize rod bending?

- does it need an I-beam and some sort of way to hang from the beam?

- could Z-axis be programmed to adjust for minor sagging?

- protection for pulley belt

Spacer Idea

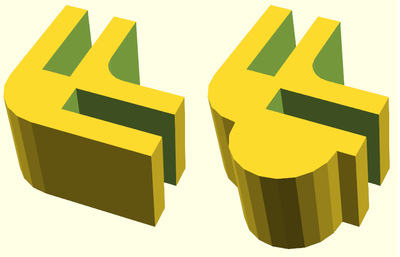

in order to insure equal spacing between the frame plates, perhaps a spacer could be placed near the bracket connections

can also be made to include a foot in order to lift the threads and nuts that face downward

foot_height = 0;

width = 12;

depth = 12;

platethickness = 3.6;

distance_from_corner = 5.1;

spacerthickness = 3;

radiusI = 3;

radiusO = 6;

$fn=20;

difference()

{

union()

{

cube([(spacerthickness+distance_from_corner+depth),(spacerthickness+distance_from_corner+depth),width]);

translate([radiusO+foot_height-spacerthickness,0,0])

cylinder(r=foot_height-spacerthickness,width);

}

translate([spacerthickness+distance_from_corner,spacerthickness,0])

cube([depth,platethickness,width+2]);

translate([spacerthickness,spacerthickness+distance_from_corner,0])

cube([platethickness,depth,width+2]);

translate([spacerthickness+platethickness+spacerthickness+radiusI,spacerthickness+platethickness+spacerthickness+radiusI,0])

minkowski()

{

cube([(spacerthickness+distance_from_corner+depth),(spacerthickness+distance_from_corner+depth),width+2]); cylinder(r=radiusI,h=width);

}

difference()

{

cube([radiusO,radiusO,width+2]);

translate([radiusO,radiusO,0])

cylinder(r=radiusO,h=width+2);

}

}

echo("Thinnest point =",sqrt(pow((distance_from_corner-platethickness),2)+pow((distance_from_corner-platethickness),2)));