3D Printed GT2 Belts: Difference between revisions

Jump to navigation

Jump to search

(Minor Text Formating Fix) |

|||

| (9 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

*This page goes over the use of FDM 3D Printers to produce [[GT2 Belts]] | *This page goes over the use of FDM 3D Printers to produce [[GT2 Belts]] | ||

*This would allow the [[Universal Axis]] to be all OSE made minus the rods and screws | *This would allow the [[Universal Axis]] to be all OSE made minus the rods and screws | ||

*Need to check the accuracy of the "teeth" being printed, and the strength of the weld if a segment joining method is used | |||

*Perhaps use a smaller diameter nozzle? | |||

=Print Methods= | =Print Methods= | ||

== | |||

*It would be printed flat and merged together | ==Flat Method== | ||

*It would be printed flat in a strip or strips and merged together once done | |||

*Has the advantage of being perhaps more accurate/less likely to fail? | |||

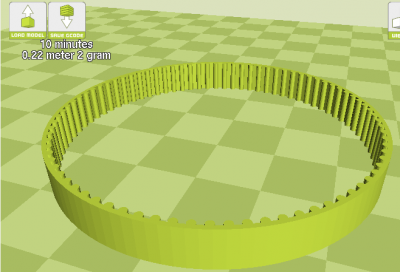

==Vertical Loop Method== | |||

*Printed in one peice in a circular loop | |||

*Has the advantage of not requiring post print welding | |||

*Has the disadvantage of limiting size to the largest circle withing the print bed | |||

[[File:beltgt2.png|400px]] | |||

==Vertical Snake== | |||

*Prints a snaking ribbon with the thin edge contacting the print bed | |||

*Hybrid of the flat and vertical methods | |||

*Requires post merging, but maximises printable amount | |||

==Conveyor Belt Printer== | ==Conveyor Belt Printer== | ||

*With one of these, the belt could be printed near continously and cut + fused when needed | *With one of these, the belt could be printed near continously and cut + fused when needed | ||

=Download= | |||

*'''Belt in OpenSCAD with customizer - https://www.thingiverse.com/thing:1975381''' | |||

=Section Fusing Methods= | =Section Fusing Methods= | ||

| Line 14: | Line 32: | ||

*Did some research and this is supposedly the technical industry name for this process | *Did some research and this is supposedly the technical industry name for this process | ||

*For OSE Use perhaps a soldering iron on low, and a custom toolhead (flat metal rectangle slightly more wide than the belt?) | *For OSE Use perhaps a soldering iron on low, and a custom toolhead (flat metal rectangle slightly more wide than the belt?) | ||

==Ultrasonic Welding== | |||

*More complex | |||

*Advantages may not apply here? | |||

=Files= | =Files= | ||

| Line 24: | Line 46: | ||

At 2 grams/6 inch - or 10 grams per 30" of the D3D Pro 8" bed - This makes 50 g for 5 axes (12.5 feet), or $1.5 belt cost with $30/kg filament. Compare to $5 for 30'. Price is about 1/2 as much for the 3D printed version using COTS filament, and much cheaper once own filament is made. | At 2 grams/6 inch - or 10 grams per 30" of the D3D Pro 8" bed - This makes 50 g for 5 axes (12.5 feet), or $1.5 belt cost with $30/kg filament. Compare to $5 for 30'. Price is about 1/2 as much for the 3D printed version using COTS filament, and much cheaper once own filament is made. | ||

= | =Internal Links= | ||

* | *[[GT2 Belts]] | ||

*[[Universal Axis]] | |||

*[[Mostly 3D Printed]] | |||

*[[Reprap]] | |||

*[[3D Printed Belts]] - clothing. | |||

= | =External Links= | ||

* | *articles on this? | ||

[[ | [[Category:Reprap]] [[Category:Belts Gears and Pulleys ? idk | ||

Latest revision as of 01:34, 1 June 2020

Basics

- This page goes over the use of FDM 3D Printers to produce GT2 Belts

- This would allow the Universal Axis to be all OSE made minus the rods and screws

- Need to check the accuracy of the "teeth" being printed, and the strength of the weld if a segment joining method is used

- Perhaps use a smaller diameter nozzle?

Print Methods

Flat Method

- It would be printed flat in a strip or strips and merged together once done

- Has the advantage of being perhaps more accurate/less likely to fail?

Vertical Loop Method

- Printed in one peice in a circular loop

- Has the advantage of not requiring post print welding

- Has the disadvantage of limiting size to the largest circle withing the print bed

Vertical Snake

- Prints a snaking ribbon with the thin edge contacting the print bed

- Hybrid of the flat and vertical methods

- Requires post merging, but maximises printable amount

Conveyor Belt Printer

- With one of these, the belt could be printed near continously and cut + fused when needed

Download

- Belt in OpenSCAD with customizer - https://www.thingiverse.com/thing:1975381

Section Fusing Methods

Hot Plate Welding

- Did some research and this is supposedly the technical industry name for this process

- For OSE Use perhaps a soldering iron on low, and a custom toolhead (flat metal rectangle slightly more wide than the belt?)

Ultrasonic Welding

- More complex

- Advantages may not apply here?

Files

- https://www.thingiverse.com/thing:165792

- Seems to work:

Cost Analysis

At 2 grams/6 inch - or 10 grams per 30" of the D3D Pro 8" bed - This makes 50 g for 5 axes (12.5 feet), or $1.5 belt cost with $30/kg filament. Compare to $5 for 30'. Price is about 1/2 as much for the 3D printed version using COTS filament, and much cheaper once own filament is made.

Internal Links

- GT2 Belts

- Universal Axis

- Mostly 3D Printed

- Reprap

- 3D Printed Belts - clothing.

External Links

- articles on this? [[Category:Belts Gears and Pulleys ? idk