Torch Table Build: Difference between revisions

| Line 15: | Line 15: | ||

=Bill of Materials= | =Bill of Materials= | ||

[[Torch_Table_BoM | Bill of Materials]] | [[Torch_Table_BoM | Bill of Materials]] | ||

{| | {| {{table}} | ||

| align="center" style="background:#f0f0f0;"|'''Item''' | |||

| align="center" style="background:#f0f0f0;"|'''Discription''' | |||

| align="center" style="background:#f0f0f0;"|'''Amount''' | |||

| align="center" style="background:#f0f0f0;"|'''Cost per item''' | |||

| align="center" style="background:#f0f0f0;"|'''Total''' | |||

| align="center" style="background:#f0f0f0;"|'''Further Info''' | |||

| align="center" style="background:#f0f0f0;"|'''Purpose''' | |||

| align="center" style="background:#f0f0f0;"|'''Aquired?''' | |||

|- | |- | ||

|Computer | | Computer with parallel port||Total computer system||1||$300 ||$300.00||http://www.linuxcnc.org/||To run Linux cnc||yes, IBM Laptop | ||

|1 | |||

|$300 | |||

|http://www.linuxcnc.org/ | |||

|To run Linux cnc | |||

|yes, IBM Laptop | |||

|- | |- | ||

|Xylotex 4 Axis Drive Box with 425 oz.in. Motors and Cables | | Xylotex 4 Axis Drive Box || with 4 stepper 425 oz.in. Motors and Cables||1||$460.00 ||$460.00||Xylotex Stepper and controller||To provide motion control and movement precision||Yes | ||

|1 | |||

|$460.00 | |||

| | |||

|To provide motion control and movement precision | |||

|Yes | |||

|- | |- | ||

| | | PowerPlasma 50 Plasma Torch||Pilot Arc 50 Amps||1||$699.99 ||$699.99||Everlast||To provide the cutting torch for the cnc torch table||no | ||

| | |||

|$ | |||

| | |||

|To provide | |||

|no | |||

|- | |- | ||

| | | Bearing R6-2RS 3/8\"x7/8\"x9/32\" Sealed||10 pack||8||$14.95 ||$11.96||VXB Part Number: Kit711||For preventing the carrage from jumping the track||no | ||

| | |||

| | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | V-Groove Bearings 3/8 inch||single pack||12||$9.95 ||$119.40||VXB V-Groove bearings Part number: Kit8407||To provide low friction linear motion||no | ||

| | |||

| | |||

| | |||

|To provide | |||

|no | |||

|- | |- | ||

| | | 3/8 inch Hard Fiber Washers||Pack of 100||40||$2.50 ||$1.00||McMaster Part Number: 95601A330||Holding bearings||no | ||

| | |||

|$ | |||

| | |||

| | |||

| | |||

|- | |- | ||

| | | Hot rolled steel 3\"x1/8\" plate||10.0 Ft.||42.58333333||$12.70 ||$54.08||Metalsdepot||To provide material for motor mounts||no | ||

| | |||

| | |||

|To provide material | |||

|no | |||

|- | |- | ||

| | | Hot rolled steel 1\"x1\" square tubes 16 gauge||24ft for $23.28||502||$23.28 ||$486.94||Metalsdepot||To provide structural support||no | ||

| | |||

| $ | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | Gear Rack (1/2” sq. x 72” 20 DP 20 Deg)||6 feet per rack||16.83333333||$24.80 ||$69.58||Standard Steel Specialty Part Number: 200011||rack for gear to ride on||no | ||

| | |||

| | |||

| | |||

|for | |||

|no | |||

|- | |- | ||

|3/8 inch | | 3 x 1/8 inch cold rolled Plate||6.0 Ft.||32.33333333||$17.28 ||$93.12||Metalsdepot||To provide material to make rails||no | ||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | \"3/8 inch threaded rod, Overall Length | ||

|- | |- | ||

| | | 36\"\"\"|| Each||137.2||$1.94 ||$7.39||McMaster Part Number: 98837A031||for connecting the top and bottom carage||no | ||

| | |||

| | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | 3/8 inch nuts||Pack of 100||112||$4.20 ||$4.70||Part Number: 90473A031||For locking threaded rod in place||no | ||

| | |||

|$ | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | 3/8 inch washers||Pack of 140||112||$3.23 ||$2.58||Part Number: 90126A031||For locking nuts and for spacers||no | ||

| | |||

| $ | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | Steel 20 Deg Pressure Angle Spur Gear 20 Pitch, 20 Teeth, 1\" Pitch Dia, 1/2\" Bore||Each||4||$15.37 ||$61.48||McMaster Part Number: 5172T12||Attaches to stepper motors and interfaces with gear rack||no | ||

| | |||

| $ | |||

| | |||

|stepper | |||

|no | |||

|- | |- | ||

| | | sleeve bearing||Each||4||$1.34 ||$5.36||McMaster Part Number: 6391K143||to connect between the stepper motor and the gear, will also add a bit of adjustable length||no | ||

| | |||

| $1. | |||

| | |||

|stepper | |||

|no | |||

|- | |- | ||

| | | 10-32 set screw 7/16\"||per Pack of 100||4||$5.44 ||$0.22||Part Number: 92311A428||Set screw for attaching spur gear, sleeve bearing to stepper shaft||no | ||

|100 | |||

|$ | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | 10 gauge bolts|| Pack of 50||92||$7.78 ||$14.32||McMaster Part Number: 92610A245||stepper||no | ||

| | |||

| | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | 10 gauge nuts||Pack of 100||104||$1.54 ||$1.60||McMaster Part Number: 90480A011||stepper||no | ||

| | |||

| | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | Zinc-Pltd Stl Pan Head Phillips Machine Screw 1/4\"-20 Thread, 1-1/2\" Length||Pack of 100||16||$10.75 ||$1.72||McMaster Part Number: 90272A546||Connects the mount plate arms to the carrage||no | ||

| | |||

|$10. | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | Zinc & Yellow Plated Grade 8 Steel Hex Nut 1/4\"-20 Thread Size, 7/16\" Width, 7/32\" Height||Packs of 100||40||$3.06 ||$1.22||McMaster Part Number: 94895A029||For locking the mount plate swing tightness||no | ||

| | |||

|1 | |||

| | |||

| | |||

|no | |||

|- | |- | ||

| | | 1/4 inch Nylon Thrust Bearing||Each||16||$1.05 ||$16.80||McMaster Part Number: 2797T1||allows the motor to swing freely||no | ||

| | |||

|$ | |||

| | |||

| | |||

|no | |||

|- | |- | ||

|10 gauge drill bit | | stepper spring||pack of 6||4||$10.00 ||$40.00||McMaster Part Number: 3114T79||Prevents stepper motor shaft from crunching ||no | ||

|1 | |- | ||

|$1.74 | | Multipurpose White Lithium Grease 10.25-Ounce Net Weight Aerosol||single pack||1||$5.62 ||$5.62||1380K29||For greasing rails, bearings, gears, rack, etc…||no | ||

| | |- | ||

|For drilling holes in rail, stepper plate, stepper plate swing | | Kerosene cutting lubricant||1/2 gallon||1||||$0.00||||Wikipedia Cutting Fluid Tapping holes and such, might not be needed||no | ||

|no | |- | ||

| 10 gauge drill bit||single pack||1||$1.74 ||$1.74||McMaster Part Number: 2930A21||For drilling holes in rail, stepper plate, stepper plate swing||no | |||

|- | |||

| Gen Purp Black Oxide HSS Jobbers\' Drill Bit 3/8\", 5\" L Overall, 3.1\" Drill Depth, 118 Deg Point||single pack||1||$4.46 ||$4.46||Part Number: 2931A34||For drilling holes in rail for threaded rod||no | |||

|- | |||

| Gen Purp Black-Oxide HSS Jobbers\' Drill Bit 1/4\", 4\" Oal, 2.4\" Drill Depth, 135 Deg Point||single pack||1||$2.26 ||$2.26||Part Number: 2901A124||For dtilling holes in the stepper plate swing mount||no | |||

|- | |||

| |||||||||||||| | |||

|- | |||

| Total||$2,467.55|||||||||||| | |||

|} | |} | ||

Revision as of 16:06, 31 August 2009

Proposal

See proposal at http://openfarmtech.org/Lawrence_Proposal.pdf .

You can also see the working agreement,Lawrence Kincheloe Contract

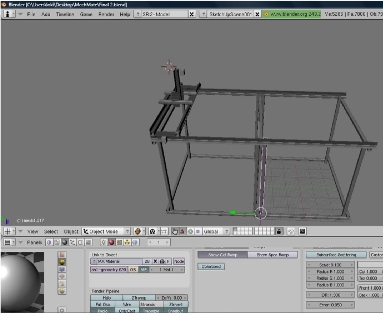

The purpose of this project is to enrich both the participant and the Factor e Farm project. The scope of this specific project is to build the seeds for a MegaRap, which is a modification of the origional Torch Table designed to expand the range of build materials and capabilities. This is in the spirit of the RepRap project, but at a larger scale and lower precision. The initial goal is to design and build a torch table that can be added on to in the future but is still functional in its own right.

Bill of Materials

| align="center" style="background:#f0f0f0;"|Item | align="center" style="background:#f0f0f0;"|Discription | align="center" style="background:#f0f0f0;"|Amount | align="center" style="background:#f0f0f0;"|Cost per item | align="center" style="background:#f0f0f0;"|Total | align="center" style="background:#f0f0f0;"|Further Info | align="center" style="background:#f0f0f0;"|Purpose | align="center" style="background:#f0f0f0;"|Aquired? |- | Computer with parallel port||Total computer system||1||$300 ||$300.00||http://www.linuxcnc.org/%7C%7CTo run Linux cnc||yes, IBM Laptop |- | Xylotex 4 Axis Drive Box || with 4 stepper 425 oz.in. Motors and Cables||1||$460.00 ||$460.00||Xylotex Stepper and controller||To provide motion control and movement precision||Yes |- | PowerPlasma 50 Plasma Torch||Pilot Arc 50 Amps||1||$699.99 ||$699.99||Everlast||To provide the cutting torch for the cnc torch table||no |- | Bearing R6-2RS 3/8\"x7/8\"x9/32\" Sealed||10 pack||8||$14.95 ||$11.96||VXB Part Number: Kit711||For preventing the carrage from jumping the track||no |- | V-Groove Bearings 3/8 inch||single pack||12||$9.95 ||$119.40||VXB V-Groove bearings Part number: Kit8407||To provide low friction linear motion||no |- | 3/8 inch Hard Fiber Washers||Pack of 100||40||$2.50 ||$1.00||McMaster Part Number: 95601A330||Holding bearings||no |- | Hot rolled steel 3\"x1/8\" plate||10.0 Ft.||42.58333333||$12.70 ||$54.08||Metalsdepot||To provide material for motor mounts||no |- | Hot rolled steel 1\"x1\" square tubes 16 gauge||24ft for $23.28||502||$23.28 ||$486.94||Metalsdepot||To provide structural support||no |- | Gear Rack (1/2” sq. x 72” 20 DP 20 Deg)||6 feet per rack||16.83333333||$24.80 ||$69.58||Standard Steel Specialty Part Number: 200011||rack for gear to ride on||no |- | 3 x 1/8 inch cold rolled Plate||6.0 Ft.||32.33333333||$17.28 ||$93.12||Metalsdepot||To provide material to make rails||no |- | \"3/8 inch threaded rod, Overall Length |- | 36\"\"\"|| Each||137.2||$1.94 ||$7.39||McMaster Part Number: 98837A031||for connecting the top and bottom carage||no |- | 3/8 inch nuts||Pack of 100||112||$4.20 ||$4.70||Part Number: 90473A031||For locking threaded rod in place||no |- | 3/8 inch washers||Pack of 140||112||$3.23 ||$2.58||Part Number: 90126A031||For locking nuts and for spacers||no |- | Steel 20 Deg Pressure Angle Spur Gear 20 Pitch, 20 Teeth, 1\" Pitch Dia, 1/2\" Bore||Each||4||$15.37 ||$61.48||McMaster Part Number: 5172T12||Attaches to stepper motors and interfaces with gear rack||no |- | sleeve bearing||Each||4||$1.34 ||$5.36||McMaster Part Number: 6391K143||to connect between the stepper motor and the gear, will also add a bit of adjustable length||no |- | 10-32 set screw 7/16\"||per Pack of 100||4||$5.44 ||$0.22||Part Number: 92311A428||Set screw for attaching spur gear, sleeve bearing to stepper shaft||no |- | 10 gauge bolts|| Pack of 50||92||$7.78 ||$14.32||McMaster Part Number: 92610A245||stepper||no |- | 10 gauge nuts||Pack of 100||104||$1.54 ||$1.60||McMaster Part Number: 90480A011||stepper||no |- | Zinc-Pltd Stl Pan Head Phillips Machine Screw 1/4\"-20 Thread, 1-1/2\" Length||Pack of 100||16||$10.75 ||$1.72||McMaster Part Number: 90272A546||Connects the mount plate arms to the carrage||no |- | Zinc & Yellow Plated Grade 8 Steel Hex Nut 1/4\"-20 Thread Size, 7/16\" Width, 7/32\" Height||Packs of 100||40||$3.06 ||$1.22||McMaster Part Number: 94895A029||For locking the mount plate swing tightness||no |- | 1/4 inch Nylon Thrust Bearing||Each||16||$1.05 ||$16.80||McMaster Part Number: 2797T1||allows the motor to swing freely||no |- | stepper spring||pack of 6||4||$10.00 ||$40.00||McMaster Part Number: 3114T79||Prevents stepper motor shaft from crunching ||no |- | Multipurpose White Lithium Grease 10.25-Ounce Net Weight Aerosol||single pack||1||$5.62 ||$5.62||1380K29||For greasing rails, bearings, gears, rack, etc…||no |- | Kerosene cutting lubricant||1/2 gallon||1||||$0.00||||Wikipedia Cutting Fluid Tapping holes and such, might not be needed||no |- | 10 gauge drill bit||single pack||1||$1.74 ||$1.74||McMaster Part Number: 2930A21||For drilling holes in rail, stepper plate, stepper plate swing||no |- | Gen Purp Black Oxide HSS Jobbers\' Drill Bit 3/8\", 5\" L Overall, 3.1\" Drill Depth, 118 Deg Point||single pack||1||$4.46 ||$4.46||Part Number: 2931A34||For drilling holes in rail for threaded rod||no |- | Gen Purp Black-Oxide HSS Jobbers\' Drill Bit 1/4\", 4\" Oal, 2.4\" Drill Depth, 135 Deg Point||single pack||1||$2.26 ||$2.26||Part Number: 2901A124||For dtilling holes in the stepper plate swing mount||no |- | |||||||||||||| |- | Total||$2,467.55|||||||||||| |}

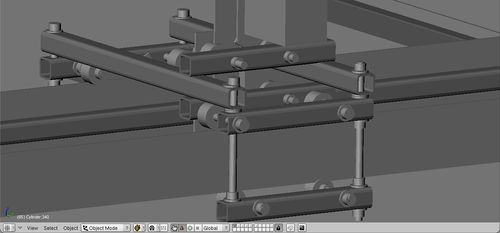

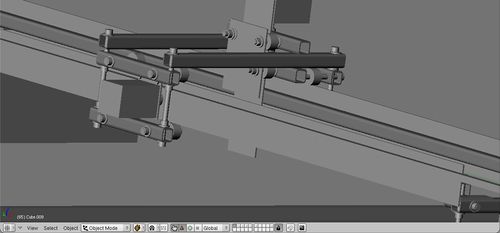

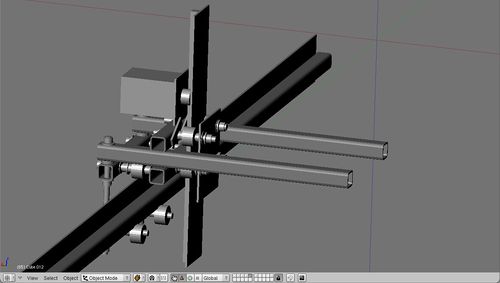

Working Concepts

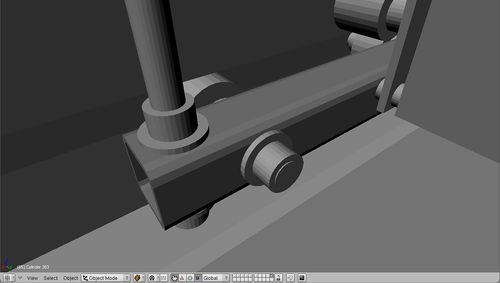

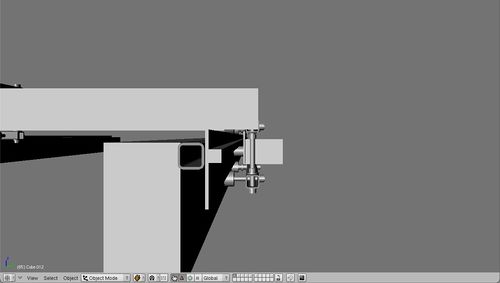

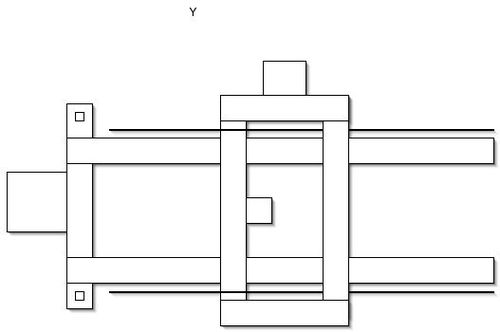

X axis

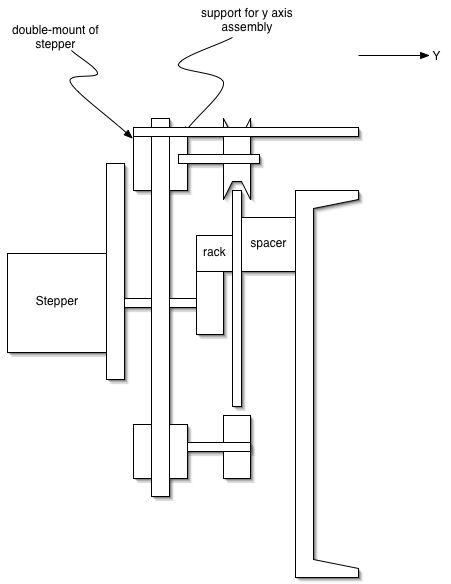

Design Rationale

- Rack for x motion - cheapest, most robust solution for precise motion

- Spring-loaded x and y motors

Y axis

Design Rationale

Z axis

Design Rationale

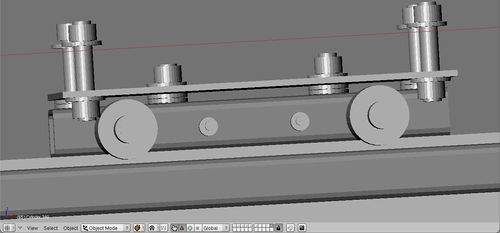

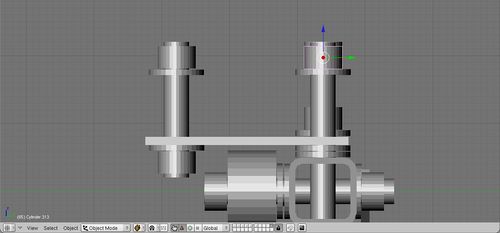

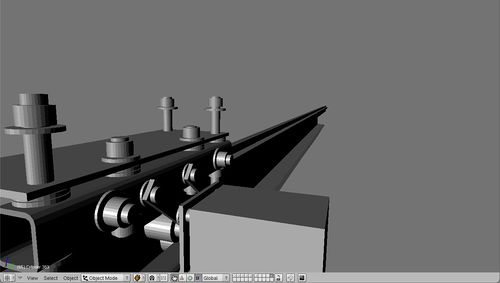

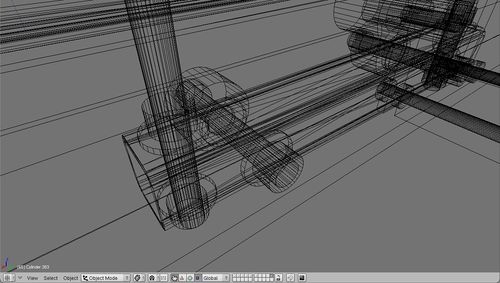

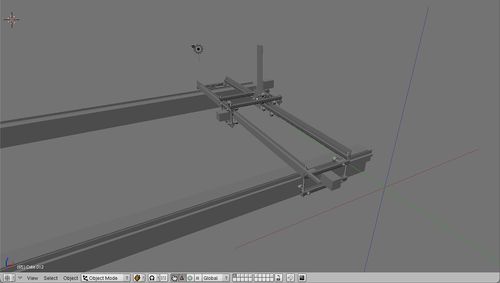

Blender Concept

File:Factor e Torch Alpha 3.blend

Plasma Torch

Torch vs. Plasma Cutter

- Comes down to initial cost versus long-term cost

- Plasma cutters - consumables cost $20 for 5 new electrodes and nozzle heads

- Electrodes are rated for 45 minutes to 60 minutes for 1/2" steel

- More expensive versions state they last 4 times longer - are heavier and have better temperature control

- For anything above 1 inch, torch is better

- Can be interfaced with a computer cheaper than Torch

Desired Characteristics

We are looking for a machine rated for 1" milled steel that will cost roughly between $700-$1100. We are limited on budget because we are funded primarily through donations at the moment.

Since we want to use the machine for cnc work, we are interested in the pilot arc starting, or touch off starting. We could also use high frequency starting, but we would have to shield our motor controller and any other equipment in the area. Would it be possible to shield the plasma cutter? We want to be able to cut thin material with the torch so it is likely we will want the pilot arc starting feature.

Do you have any suggestions on a best practice method of attaching a plasma torch head on a cnc machine?

We would also be interested in a plasma cutting head that would be easier to mount. Currently in your accessories page you only list a model that is appropriate for plasma cutting by hand. Also, since this machine needs to be flexible we would also like the option of using the plasma cutting head by hand. Through looking at competitors websites, its clear that its easy to offer one or the other and switch them at the DC power inverter, but how easy would it be to add a 45 degree flexible head that can be fixed for either cnc overhang cutting or hand cutting? This seems like an easy adaption, but I might be missing something.

Also, we are interested in the engraving feature. Especially the controlled plasma pulse feature. The reason is that we are interested in precision surface removal, and gouging because we have an idea to use this machine as a plasma lathe, combined with a cnc controlled head. This isn't a requirement, but we are very interested in getting the maximum amount of utility from this tool.

Plasma Cutters Considered

- cheap

- 5 year warranty

- made in china

- cheap

- 1 year warranty

- made in america

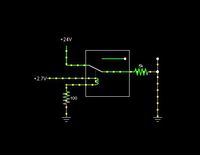

Plasma Cutter PC Interface

A simple relay circuit, the components depend on the plasma cutter interface.

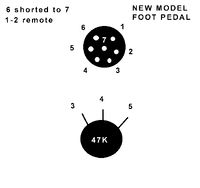

Since the Xylotex stepper controller pipes out unused pins to a second parallel port, we'll isolate the parallel port using an optoislolater and switch on a relay switch which replaces the manual torch ignition switch. If the torch allows for proportional current control, usually done with a voltage divider circuit built with a potentiometer, then we might use a pwm modulated rheostat control with the computer providing the pwm signal. If all that fails, there is alway hacking into the plasma cutter circuit board and taking over control using a microprocessor... maybe version 2.

A simple relay circuit, the components depend on the plasma cutter interface.

Since the Xylotex stepper controller pipes out unused pins to a second parallel port, we'll isolate the parallel port using an optoislolater and switch on a relay switch which replaces the manual torch ignition switch. If the torch allows for proportional current control, usually done with a voltage divider circuit built with a potentiometer, then we might use a pwm modulated rheostat control with the computer providing the pwm signal. If all that fails, there is alway hacking into the plasma cutter circuit board and taking over control using a microprocessor... maybe version 2.

Team

- Deep in the continental US underground...