Matt log: Difference between revisions

Jump to navigation

Jump to search

Matt Maier (talk | contribs) No edit summary |

Matt Maier (talk | contribs) No edit summary |

||

| Line 10: | Line 10: | ||

Image:Suspended rotor backside.jpg | Image:Suspended rotor backside.jpg | ||

</gallery> | </gallery> | ||

=12FEB2012= | |||

*Contacted [http://opensourceecology.org/wiki/Replication/CreationFlame James Slade of Creation Flame] since he's field-testing the LifeTrac. | |||

=11FEB2012= | =11FEB2012= | ||

Revision as of 16:32, 12 February 2012

What I've been up to. User:Matt_Maier

Documents

- LifeTrac Fabrication Draft File:LifeTrac Fabrication DRAFT 29JAN2012.pdf

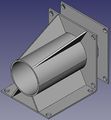

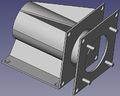

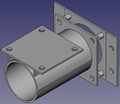

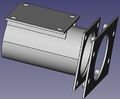

- modular vehicle kit suspended and unsuspended rotors

12FEB2012

- Contacted James Slade of Creation Flame since he's field-testing the LifeTrac.

11FEB2012

- Uploaded examples of building blocks for the modular vehicle kit. Rotors for low rpm, high weight (unsuspended) and high rpm, low weight (suspended).

- Contacted a custom metal fabricator in Houston.

- Contacted D&H Tractors about opening communication. They're high school seniors who are building a LifeTrac for South Central Farmers.

7FEB2012

- Joined Team Wikispeed and exchanged ideas with team lead Joe Justice on a possible OSE/Wikispeed collaboration.

6FEB2012

- Called in to scrum with Lex (Daily SCRUM). Trying to convince other active developers to invest in some kind of centralized update/discussion process to maximize creativity and generate a team atmosphere.

- Discussed CEBs on the forum.

5FEB2012

- Coordinated with Lex about his Collaborative Engineering project. He is going to upgrade FreeCAD with project management features.

- Added information and Lessons Learned about Team Wikispeed. They demonstrated how a nominally open source and distributed collaborative engineering project can do seriously impressive things. They produced a street-legal car that gets 100 mpg and a 5-star equivalent safety rating.

- Working on a concept for better machine fabrication documentation. After getting a bit stuck on the LifeTrac fabrication document, and having some time to step back and think, I realized that a dead, isolated document wasn't accomplishing enough goals simultaneously. I am experimenting with the open source and free OpenProj (basically a weak version of Microsoft Project) to see if documenting the machine fabrication as a project will better capture diverse pieces of information like time, ergonomics, and resources. Basically, replicating a machine IS a project, so it might as well be documented that way first. I predict that building the fabrication procedure in a project management program will automate the tracking of things like, say, how many bolts the tractor needs. Instead of tediously counting and double-checking, just enter the number of bolts at each step and the program will tally them all up in a report. Changes will be tracked automatically. Additionally, when it's finished people can download the free program, download the free project file, and input their own numbers (like how long it actually took them to do something). It will help them organize their project and it will help the FeF gather important feedback.

2FEB2012

- I've been posting on the forum and adding information to the wiki

- Communicating with individuals about the the ironworker and program management/CAD program

29JAN2012

- Converted the lifetrac working document into a PDF; it's about an 80% draft based on the information I have now File:LifeTrac Fabrication DRAFT 29JAN2012.pdf

27JAN2012

- Added FPGA rationale and resources

- compiled a list of people to contact re: FPGA-centered universal axis controller

- Added some specific info on construction vehicle modularity