Module Breakdown - MicroHouse: Difference between revisions

| Line 63: | Line 63: | ||

Do 4 pieces of allthred per side - | Do 4 pieces of allthred per side - | ||

[[File:Microhouse_foundation_p4.jpg|750px]] | [[File:Microhouse_foundation_p4.jpg|750px]] | ||

Revision as of 14:15, 19 March 2014

The MicroHouse is broken into modules to enable a social production model like all OSE machines/architecture.

Foundation Module

Development

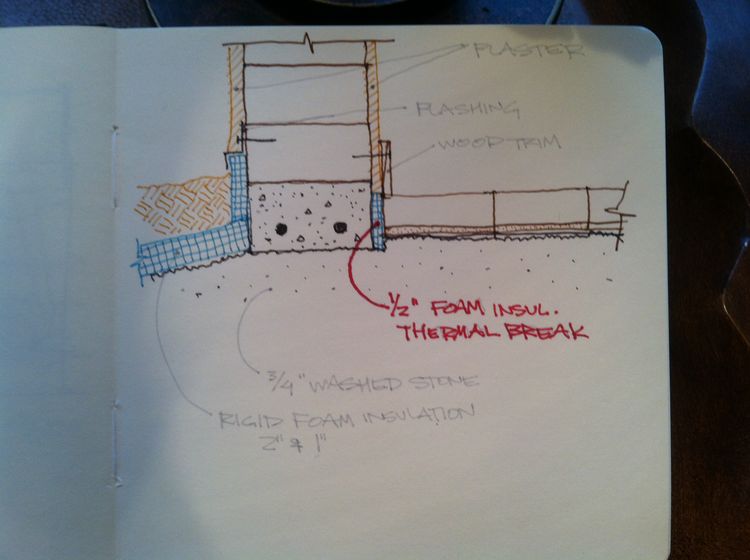

This early drawing explored a stemwall idea for the MicroHouse foundation and looked at various ways of insulating the foundation and siding the building.

Marcin was very interested in continuing to experiment with the shallow insulated footer concept. Here is a drawing based on design discussions between Floyd and Marcin. More information about the shallow insulated footer concept can be found here.

Based on conversations with Walter Grondzik, PE... One item we discussed was getting the best performance from the direct solar gain heating system (heating of the CEB floor by sun shining through windows). Walter highly recommended putting in a thermal break between the floor and the foundation. Without this break, there heat will travel easily from the floor to the foundation. He suggested a 1" thick piece of foam, but he agreed that a 1/2" piece would be acceptable. Even at 1", the plaster and a trim board would cover it.

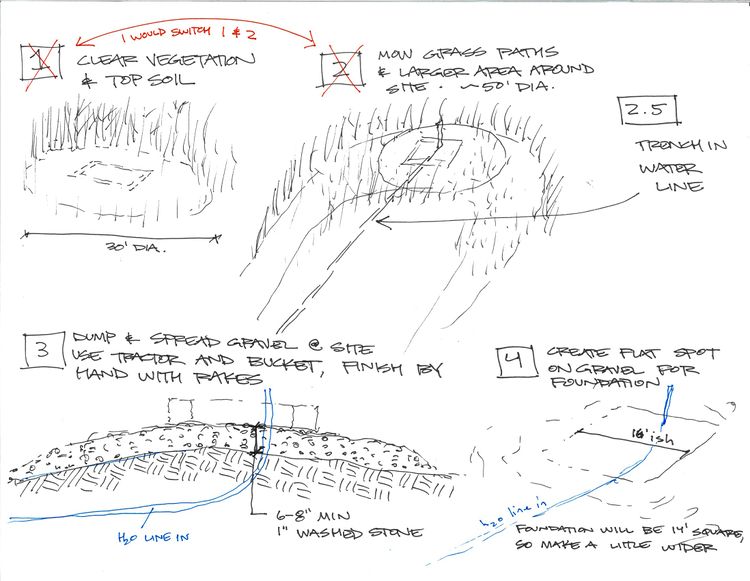

Here was the initial idea for foundation formwork, discarded in favor of the simpler, faster idea presented below in execution section.

Execution

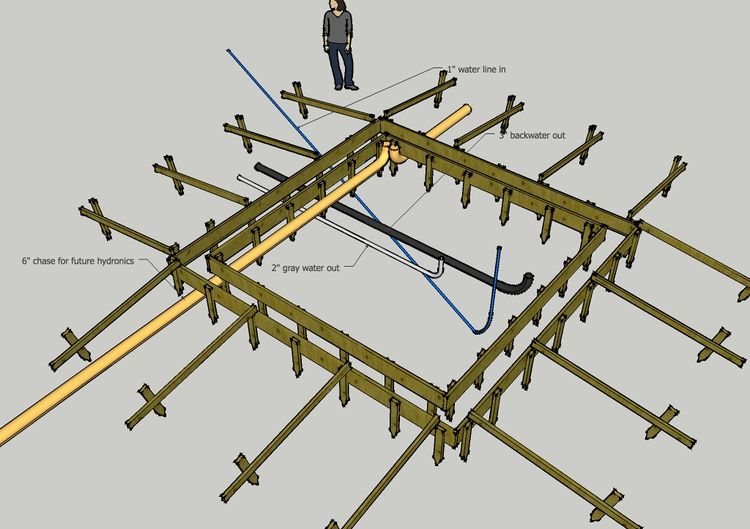

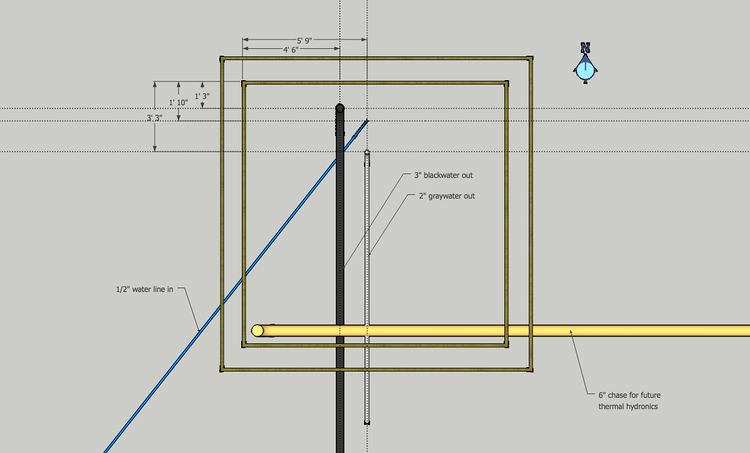

Precise dimensions for pipe layouts

Notes:

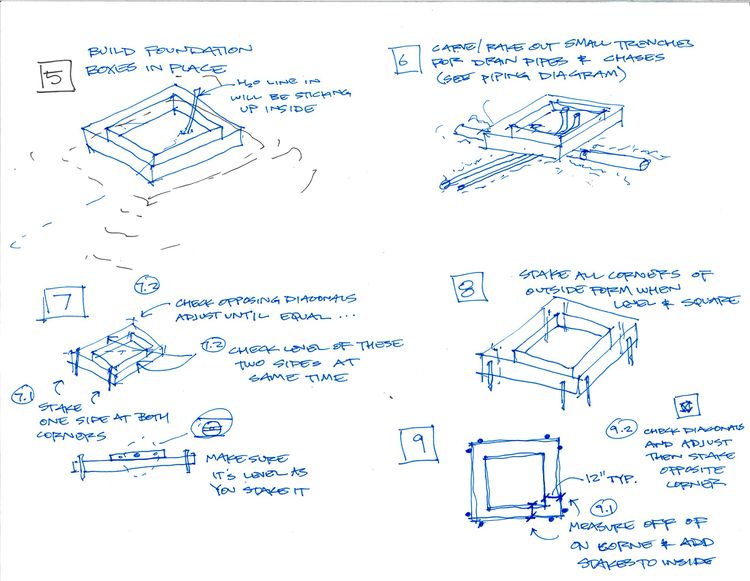

1. Measure and mark opposing interior form boards with dimensions listed.

1a. Measure from outside of inner form board (in other words, from what will be inside of concrete).

2. Put small nail into form top at location of mark - string between similar mark on opposing form board.

3. Run designated pipes under foundation formwork and make sure vertical pipe is directly under

proper intersecting strings.

4. 6" chase for future hydronics does not need to be at any slope.

5. 2" graywater and 3" blackwater lines MUST BE AT 1/4" slope per 1' of length.

This is required for proper drainage, otherwise liquids will outrun solids.

6. Pipe layout shows 6" chase running over 2" and 3" lines, however, it is typical to conserve as much

elevation as possible when exiting graywater pipes... best practice will be to run 2" and 3" pipe

out just below bottom of foundation formwork. 6" pipe will most likely run beneath level of 2" and 3" pipes.

7. Run pipes past foundation forms by roughly 5' and cap with cardboard/duct tape or old rag, etc.

Leave vertical pipes at a length of 1' taller than foundation forms. Cap this end, as well.

Staking the vertical pipe in place with rebar will prevent it from getting disturbed.

Pipe Elevations:

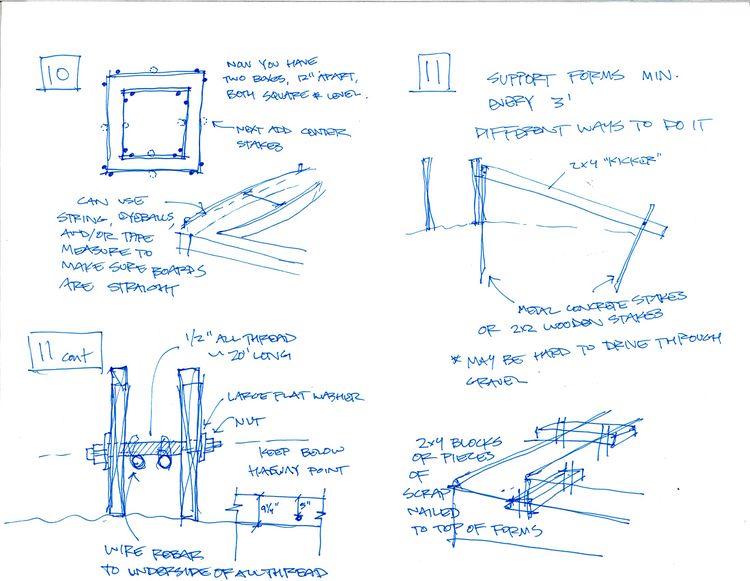

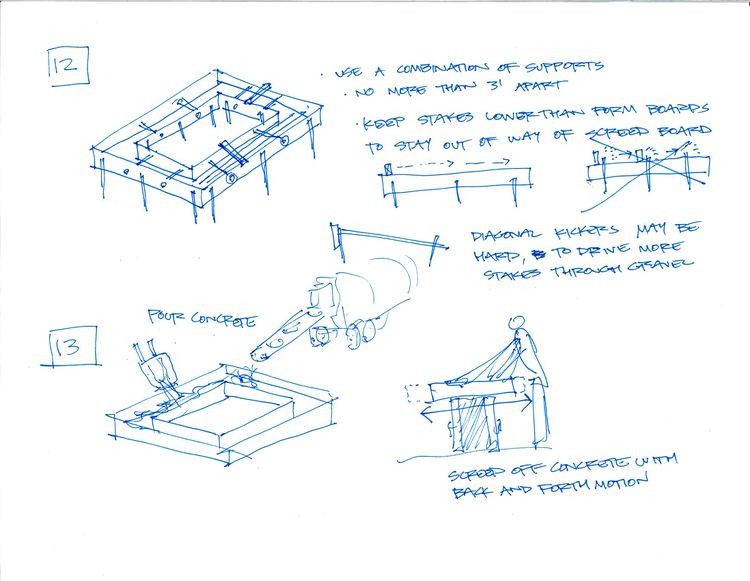

Instructions Sketches

For allthread, do 2 at corners and 2 in middel - 4 per side. For blowout, do 2 of them per side - 1/3 way each. Rebar ends up at bottom 1/3 of boundation. Allthread about 5 inches down from top.

Stub out 8-12" of rebar.

Do 4 pieces of allthred per side -