Tom Log: Difference between revisions

| Line 22: | Line 22: | ||

The "dd" command (ie: "Data Dumper") that I mentioned writes data from an input (ie: ISO file) to an output (ie: the USB stick). | The "dd" command (ie: "Data Dumper") that I mentioned writes data from an input (ie: ISO file) to an output (ie: the USB stick). | ||

First: Identify the device for the USB stick. You can use commands like "lsblk", the "fdisk -l" or the Ubuntu "disks" GUI to find the device. In a single disk system, the "/dev/hda" device is your main hard drive and "/dev/hdb" is often the USB stick. The following writes the ISO to the " | First: Identify the device for the USB stick. You can use commands like "lsblk", the "fdisk -l" or the Ubuntu "disks" GUI to find the device. In a single disk system, the "/dev/hda" device is your main hard drive and "/dev/hdb" is often the USB stick. The following writes the ISO to the "sdxx" device: | ||

dd if=Porteus-D3D-Workshop-x86_64-v2.iso of=/dev/sdxx bs=1024b | dd if=Porteus-D3D-Workshop-x86_64-v2.iso of=/dev/sdxx bs=1024b | ||

Revision as of 08:46, 17 March 2016

Tom Griffing's Log

March 14, 2016

OK ... there's been a gap in my log. Concerning the upcoming lab for the 3D printer, the original ISO file for the Linux distro wasn't bootable from a memory stick. The site shows how to convert an ISO file into a "hybrid" file, bootable from optical or memory stick:

Here is the original ISO image that didn't work well for booting from USB sticks:

Here is the image for the 3D printer workshop that has already been converted:

All that needs to be done is do a raw copy of this file to the USB stick using "dd" (Linux), "Disk Utility" (Mac) or some similar disk utility.

Update: The "ddrescue" program is for data recovery and it addresses a different function.

The "dd" command (ie: "Data Dumper") that I mentioned writes data from an input (ie: ISO file) to an output (ie: the USB stick).

First: Identify the device for the USB stick. You can use commands like "lsblk", the "fdisk -l" or the Ubuntu "disks" GUI to find the device. In a single disk system, the "/dev/hda" device is your main hard drive and "/dev/hdb" is often the USB stick. The following writes the ISO to the "sdxx" device:

dd if=Porteus-D3D-Workshop-x86_64-v2.iso of=/dev/sdxx bs=1024b

Please note that the "dd" command performs a raw write and will overwrite the destination device (ie: "of=..."), including all partitioning, formatting, data, etc.

Marcin Notes

sudo apt-get install gddrescue - installs ISO creation program ddrescue

July 26, 2015

Worked on OSE wiki, fixed an issue with the user account approval.

July 25, 2015

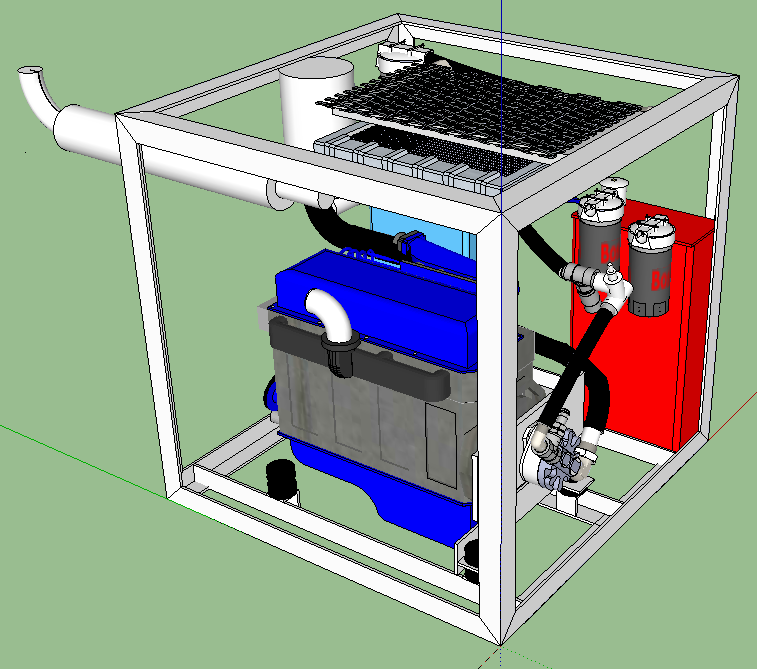

I've been working on multiple fixes and updates for the Power Cube design and recently changed it to version 15.7 in the 3D Warehouse. The changes were adjustments from the results of the July Power Cube workshop.

July 15, 2015

Gasifier Workshiop, Day 2 Torched some steel for the gasifier folk. Didn't get much done as there was a personnel issue. Spent time resolving it and documenting jigs. Marcin bought 5 T Shirts and we discussed further sales - I told him that I could ship them individually.

July 15, 2015

MicroTrac Workshiop, Day 1 Focused mostly on finishing the Power Cubes and with the updates to one engine to enable operation with the gasifier.

July 15, 2015

MicroTrac 2.0 Workshiop, Day 3 Worked on Power Cubes and assisted from time to time with the MicroTrac. Welded the plates in the hole punch to prevent drift. The MicroTrac T Shirts arrived - Sold several.

July 14, 2015

MicroTrac 2.0 Workshiop, Day 2 24 links completed! Discussed the idea of a fab shop in a shipping container.

July 13, 2015

MicroTrac 2.0 Workshiop, Day 1: Late start, as Marcin had an eye issue. Worked with Will Turner to make a jig for cutting and punching chain links. Problem with hole punch - dies getting out of alignment. Made first batch of tracks and tested.

July 12, 2015

PC 15.6 Workshop, Day 3: Met with Marcin and Jonathan for planning, then went to the workshop where everyone was gathered and working. Integration day - we found some design issues along the way:

- The 4 x 4 tube at the rear of the engine had to be removed before the engine / muffler could be seated.

- The geometry of the return plumbing could not be used intact and the oil filter had to be unscrewed from the bracket.

- The keyswitch on the old control bracket conflicted with the 4 x 4 tube and had to be rotated 90 degrees.

- The 1 1/2" coupling was made of cast iron and posed a problem for welding the Hydraulic Reservoirs.

- The wiring harness diagram had two wires crossed, which burned out the diodes before the magnetos.

- The bolts securing the bottom of the oil cooler expanded steel to the lower tube could not fit through to the back side of the tube, as the Hydraulic Reservoir was there - so it would have to be secured with short bolts from within the tube (difficult).

These issues were overcome and four of us (Jonathan, Natalia, Will and I) worked on one Power Cube and finally got it going.

July 11, 2015

PC 15.6 Workshop, Day 2: Met with Marcin and Jonathan for planning, then went to the HabLab for discussion before continuing. Continued welding tanks and started on assembling the modules - oil cooler, return plumbing, pressure plumbing, After burning out the diodes, found some replacements in the HabLab, replaced them and got the Power Cube working around midnight.

July 10, 2013

PC 15.6 Workshop, Day 1: Met with Marcin and Jonathan for planning, then went to the HabLab for introductions and lecture. Spent the time cleaning up the shop in preparation for the workshop. Proceeded afterward to the workshop, held the safety briefing and started the build. We planned to do the "dirty stuff" today, cutting steel & welding. The tanks took the full 3 days to complete. Moved the LifeTrac near the door, ran the hoses between it and the iron worker and cut steel for the tank end plates. Only one MIG welder worked initially. Marcin told me what had to be done and I disassembled, replaced liner and wire on two other welders to get them working.

July 9, 2013

Continued cleaning the shop and organizing for the workshop.

July 8, 2013

Arrived at KCI. Marcin arrived in the truck and we drove to MoKan Fasterners for bolts, Harbor Freight for tools and then for Factor E Farm. Spent several hours resolving automotive issues. Spent time organizing the shop and layout out supplies.

June 19, 2015

Updated MediaWiki with extension to require admin approval for new accounts. The other means of blocking spambots just wasn't working. Uploaded newest Power Cube 15.6 BOM.

June 1, 2015

Updated MediaWiki to enable ReCaptcha. Still having some issues with bogus user registration.

January 17, 2015

Power cube arrived this week (Yahoo!). After the shipment, the shipping company charged me an additional $84.60 for a "limited access fee". They claimed the fee is standard across the shipping industry when delivering to schools/universities.

January 13, 2015

Power cube shipment delayed to avoid holiday shipping maddness. Shipped Power Cube kit (ie: Power Cube, less engine & battery).

October 26, 2014

Received an order for a Power Cube, Version 7, less the engine. I've been updating the Sketchup model to include the pressure relief valve and the updated BOM for current pricing. Now to complete the model & BOM and start ordering parts tomorrow. I've also begun inquiries about information about sensors for the hydraulic flow, pressure and temperature - to accommodate new power cube certification requirements.

MicroHouse 4 Workshop

Attended this workshop to get better acquainted with MicroHouse design and CEB construction techniques.

Tue Sep 30, 2014

Back to Dallas.

Mon Sep 29, 2014

Met the electrician from the power company with connectors and tools. Replaced connectors and added MicroHouse wiring. Installed electrical conduit, elbows and ran wiring from the electric panel to the MicroHouse for all lights, sockets, stove and dryer. Other crews completed the roof and began installing windows.

Sun Sep 28, 2014

Painted initial coat on the plywood side of lower roof modules to save time later. Upper roof module construction using screws, 2" x 6" x 16' boards and struts. Other crews installed the roof modules. Dug trench and set conduit into ground for incoming and outgoing cables. Connected the incoming cables to the box main power and prepared connections for the cables to the MicroHouse 3. Secured the electrical connections on the MicroHouse, as it is to "go live" in the morning.

Sat Sep 27, 2014

Lower roof module construction using screws, 3/8" plywood, 2" x 6" x 16' boards and struts.

Fri Sep 26, 2014

Completed digging the trench for the electric cable. Met the electrician from the power company, who opened up the panel only to find that we would need replacement connectors to continue. Closed the panel and informed Marcin of the situation. Worked with several teams to set the CEB blocks for the walls and to make additional blocks from soil and lime. Walls mostly completed today.

Thu Sep 25, 2014

Worked on Micro House misc tasks - including preparing landings and placing the hydronic stove. Checked out the electric panel at the MicroHouse and prepared it to "go live". Drove to Menard's to get supplies for wiring the electric cables from the Micro House to the panel on the workshop.

Wed Sep 24, 2014

Caught a ride to OSE, Missouri with Marshall (from Austin). Checked out the progress made on the Structural Frame Power Cubes and gave a few suggestions for completing one kit.

Sat Sep 14, 2013: 50 HP Power Cube Design

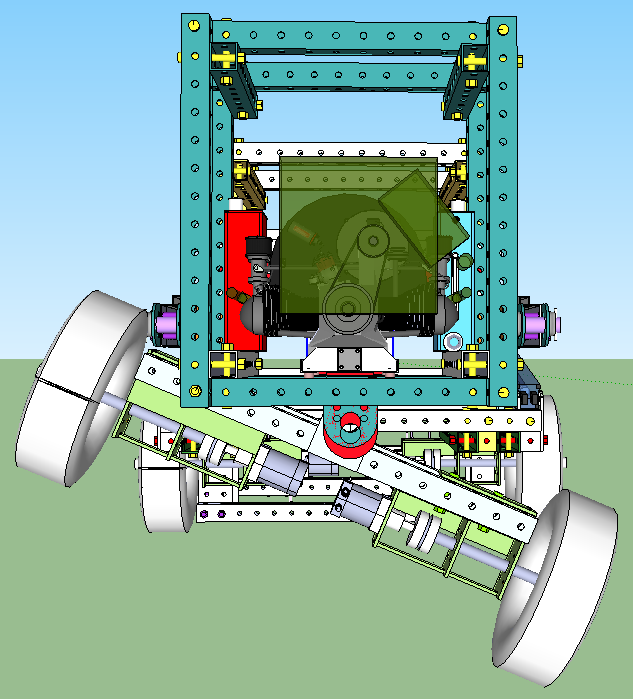

We've had a lot of discussion about the new PowerCube and the new LifeTrac designs and I think I have wrapped my mind around the new frame design. Here is a screenshot:

Latest 50 hp Power Cube Suggestion: File:PowerCube 35 Tom.zip

Thursday, July 8, 2013

Drove up to Missouri and to Factor E Farm for the Power Cube / LifeTrac build for Blair Grocery in New Orleans. Spent time designing the new Power Cube with the Kubota diesel engine. Drove to secure the engine, radiator and other parts necessary for the build. Used Sketchup to update the design according to the newly secured Kubota engine. Cut steel for the new 36" frame and began gathering other necessary parts - such as the fan and oil cooler.

James Slade arrived and received instructions to assist with Power Cube development. The crew from Blair Grocery arrived and were oriented for assisting in the build of the LifeTrac. The LifeTrac and Power Cube development proceeded at the same time.

I headed back to Dallas and a few days later, the LifeTrac was functioning and was loaded onto the trailer for transport to New Orleans with the 27 hp Power Cube and the unfinished Kubota Power Cube. The transport stopped at my farm in East Texas, where the Kubota Power Cube was completed, loaded in the LifeTrac, tested and then loaded for shipping to New Orleans - where it was tested successfully.

Latest Kubota Power Cube Design: File:PowerCube Kubota.zip

Thursday, May 25 2013 (Date needs verification)

It's been some time since my last update. The latest activity concerns the new Power Cube design - using a Volkswagen engine. I expect to meet with Jay early this next week to complete the rebuild of the engine and secure the engine. I still have a few more parts to get - especially for mounting the shaft coupling and engine mounts. I have been working on the component layout for the new Power Cube - it will be quite different from before, as the engine/pump mounting is horizontal rather than vertical. Also, the plumbing and engine are larger and heavier and I will be adding a pressure relief valve. The sizing of the hydraulic pump has been a big issue and is documented here:

http://opensourceecology.org/wiki/Hydraulic_Hose_Sizing