Tom Log

Tom Griffing's Log

Fri Feb 20, 2026

Took frames from yesterday's work and some others that were in the Learning Center and built the last full modules. Marcin asked that we also add diagonal compression supports on the end to prevent it from sagging. Installed the last roof section to the hangar. Yay!

8 hours.

Thu Feb 19, 2026

Worked with Collin to build short frames for building the last roof module, then continued with Roy to re-build the roof module jig for the short roof modules. It only had three of the frames instead of the usual five frame as on the full roof modules.

8 hours.

Wed Feb 18, 2026

Worked with Roy to build modules for roof sections. Before lunch, Collin arrived and Marcin asked that I work with him in the workshop to build "short" 16' frames for hangar modules. Built 8 of them before being re-directed to build two 11" wall headers: 7' 2" and 12". Spent the rest of the day working on them.

8 hours.

Tue Feb 17, 2026

Worked with Roy to build modules for roof sections. Helped Jeremy attach modules together to build roof sections, used Kioti to move modules to end of hangar. After the others had left, used the Kioti to grade the path from Willow to the end of the hangar, as it was very rough.

During lunch, reset password for Catarina to access the Wordpress admin page. Later, I received an email from her saying she couldn't add new themes, so researched it and enabled her to add themes.

8 hours.

Mon Feb 16, 2026

Work on roof modules, with Roy and Jeremy. Helped Marcin connect the dump trailer to the truck, then stopped for lunch. Catarina mentioned that she wasn't able to log into Wordpress admin dashboard, so reset her passwords for two accounts. Continued work on roof modules.

Sun Feb 15, 2026

Spent 1.5 hours tweaking wp-dev, getting access to the local admin dashboard and verifying credentials for Catarina and Marcin.

Went to Hablab and visited with Roy and Jeremy, talking about all manner of things, including some gripes about things OSE.

Returned to the house and relayed the gripes to Marcin.

Spent the balance of the day in the Hablab, cooking a dinner for us all and "hanging out" with the guys.

Sat Feb 14, 2026

Day off from Hangar construction. Spent most of the day working on wp-dev ose Wordpress site, back and forth with ChatGPT, trying to fix the website. The "Enigmatic" theme on the site was causing all manner of problems, throwing exceptions and ChatGPT kept suggesting to fix code in the theme. I found a problem in one file, asked ChatGPT what to do about it, changed some code to fix the issue, restart the server, then a problem would appear elsewhere in the same theme.

After hours of this, I queried about upgrading the theme. The answer was yes, but it is a paid theme and Catarina had said before that she wanted to change to a different theme - so I queried about changing themes. After downloading and changing themes, the system quit working and ChatGPT said the wordpress core should be upgraded, but when trying this, the upgrade failed due to the new theme in place.

Since this instance of Wordpress had been a migration from Hetzner2, I deleted it from Hetzner3 and fetched a fresh copy from the other server. I started with a new Wordpress installation, overlaid it with the content and database from Hetzner2, did some updates and the system was mostly working. 4 hours.

I spent a few hours with Roy and Jeremy, taking them to "The Old Cookstove" to Walmart (Jeremy needed some things), then to a restaurant in Cameron for lunch.

Fri Feb 13, 2026

Met Marcin early while having breakfast and he wanted to get an early start on the roof modules. I went to the Learning Center, where I met Roy and we started making the "jigs" for the roof modules. Roy and I built several roof modules and brought them to the hangar to compliment the existing modules so we could install them today. After we delivered the last module we built, we began work assembling them into a roof section. Following that, the others climbed to the roof and began removing the old plastic and preparing it for the new heavy plastic. They dropped the old plastic and I used it to cover the completed roof module, should we have rain. I also moved a light into the dark hangar area and repaired a nail gun with a jam of nails in the exit chute. 11 hours.

Thu Feb 12, 2026

Continued work on access for Marcin for the OSE development website. Much dialog with ChatGPT and did rebuild nginx_proxy as suggested yesterday and also making changes to nginx and wp-dev site. While doing that, the wiki went offline due to certificate expiration. I spent time getting it working again, as it was trying to use the cert from "learn" for the wiki and wp-dev. Finally got that corrected and the wiki came online, with the Time Log working again. 3 hours.

Worked alone in Learning Center to build roof modules. At the end of the day, Jeremy and Roy stopped by and we discussed building "jigs" to speed up module construction and do so more uniformly. We will build the jigs tomorrow morning. 5 hours.

Wed Feb 11, 2026

Marcin asked for logins for himself and Catarina to the ose_wp wordpress instance. Worked in the morning to make it accessible. No easy fix yet. Continued working on it after the hangar work, still no resolution. 1.5 hours.

Worked with Jeremy and Roy to secure the NE corner walls of the hangar. Following that, Marcin asked me to work with two Mormon boys to build roof modules. We built them and moved them to the East end of the hangar for installation. Asked Marcin for diesel fuel for the telehandler and added some fuel additive. 8 hours.

Marcin requesting access to hetzner3 wordpress ose_wp. I thought it was working some time ago, but it isn't currently accessible. I've been asking ChatGPT about it and getting lots of recommendations for changing the server, but the site is still not accessible. Added new domain for the site: wp-dev.opensourceecology.org, updated the docker-compose.yml for the changes, added a new record in Cloudflare for the new site, updated nginx config and file permissions to allow "dadm" user to write to the config files.

Now, it suggests completely rebuilding nginx_proxy. I expressed reservations and will perform a snapshot of the current docker image as follows:

Snapshot the running nginx container config Export the current container filesystem (this preserves everything as-is): docker commit nginx_proxy nginx_proxy_backup_image Confirm: docker images | grep nginx_proxy_backup_image This gives you a frozen image of the exact working state. Save current mounted nginx config (important) Since you bind-mounted /etc/nginx/conf.d, copy it: sudo cp -a /etc/nginx/conf.d /etc/nginx/conf.d.backup-$(date +%F) Also save certs just in case: sudo cp -a /etc/nginx/certs /etc/nginx/certs.backup-$(date +%F)

After rebuilding nginx_proxy, the websites weren't working, so I changed docker-compose.yml and uncommented the line:

- /etc/nginx/conf.d:/etc/nginx/conf.d:ro ## Removed per ChatGPT TLG 2-11-2026

Then rebuilt the nginx_proxy container:

$ docker compose up -d --force-recreate nginx_proxy

and the website worked again.

Tue Feb 10, 2026

Worked with Roy and Jeremy to secure the hangar section installed yesterday and on assembling the final corner section, got it mostly ready to hoist. Also worked on correcting the South/East corner section, as the door width was wider at the top than bottom. Later, drove to Menard's for more screws for tomorrow's addition of 3 new helpers to work on completing the roof sections. 10 hrs.

Mon Feb 9, 2026

Worked with Roy and Jeremy to remove wall modules from the provisional hangar doors, then assemble them into hangar wall sections and attach to the hangar. We assembled them on the ground and when ready, used the telehandler to lift them into place and secure with fasteners. 10 hrs

Sun Feb 8, 2026

Drove to OSE, arrived around 3:30 PM. Unpacked into the room by Marcin's house. Surveyed the hangar, hablab, etc to get an idea of the status of the place. Roy arrived adn we cleaned up the hablab while Roy settled in. Went with Marcin to get an idea of the work to be done: Continue building hangar - wall modules are complete and ready to put up, using the telehandler.

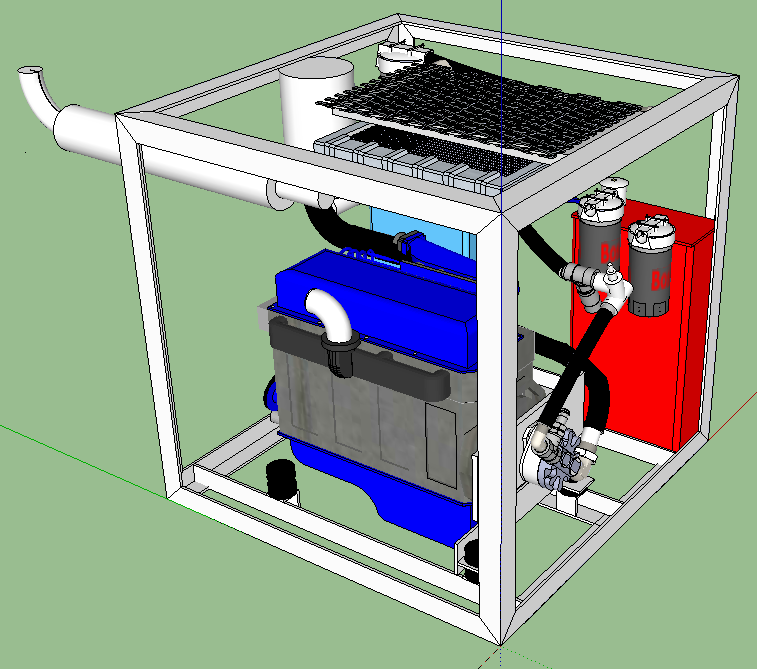

We checked the air compressor and it needs oil. Later, checked its documentation and its oil should be changed right away (supposed to change after 8 hours of operation). Also: Check the belt tension and add an electrical "On/Off" switch.

Sat Jan 24, 2026

Marcin sent email about bot activity impacting server performance. I did see bots, wrote the "showbots" script (run as dadm user). I also created a conf file to deny bots by IP address "/etc/nginx/conf.d/blocked_ips.conf. Also sent Marcin summary.

Thu Jan 8, 2026

Got up early and worked on the server, along with ChatGPT. Found problems with healthcheck blocking I/O and fixed it.

Also fixed the problem with the Time Log not appearing - turned out to be due to the authentication between osedev and pdb processes. Resolved it and the Time Log resumed working.

The wiki pages are still having pauses when rendering pages. With more diagnosis, I found that the "opcache" was not enabled in mediawiki. After enabling it, the performance seems better.

Wed Jan 7, 2026

Call from Marcin about Hetzner3. Walked him through getting logged into his own account via SSH with certificate and enabled him to log in using the "dadm" account for Docker administration. Checked the server status and found high load averages. Rebooted the server, performance did not improve immediately, but it did over the next few hours. Stopped and agreed to resume later.

Here is the chat link: ChatGPT_link

Sun Dec 14, 2025

Connected heat pump module and ran it, warming the room.

Worked with the attendees to pick up trash and burn in burn pile.

Late meeting in Hablab - got out after 9:30.

Sat Dec 13, 2025

Drove to Menard's for sheet rock, etc.

Worked on second Heat Pump module - got it mostly completed.

Fri Dec 5, 2025

8:00 meeting in Hablab. Completed Hangar utilities: Compressed air, ethernet WiFi and electricity to all 6 production bays. Reviewed the installation and updated some clips for compressed air lines to prevent condensate water from pooling.

Following that, Marcin asked to trench for a water line from the municipal water source to the Hangar, completed and retired for the day.

Thu Dec 11, 2025

Link to Hangar water supply design document: https://docs.google.com/presentation/d/1DkW8vWvtUWWCLe7rb1LnvKB-DyR8jWQ9DOva3jfAie8/edit?slide=id.g3ae1e878243_0_0&pli=1#slide=id.g3ae1e878243_0_0

Note: It will be changing in the next few minutes

Wed Dec 3, 2025

Drove to Menard's for yet another load of lumber. Ethernet progress: got Nick and Joe to work on terminating the wire from the hangar to the workshop. They were having trouble crimping connectors properly. Completed all but one bay's compressed air connections. Got Brandon working on loading OSE Linux 3.0 onto the Intel NUCs. Also requested installing the old version of Freecad (version 0.16) and adding a desktop GUI launcher to run the LD_PRELOAD command in the same command string as for launching the Freecad 16 appimage.

Tue Dec 2, 2025

8:00 meeting @ Hablab. Left early to bring Catarina's sink to the house. Got Roy to help.

Continued work on compressed air delivery. Found that the filter/regulator does have 1/2 inlet, but only a 1/4 regulator output. Found fittings to connect PEX to compressor - one 1/2" coupling was plastic and had a split along one side, leaking air. Discussed with Marcin and made a run to Sutherland's for connectors - they only had 3 sets, so purchased them, returned and connected 3 bays.

Mon Dec 1, 2025

Work on Hanger utilities. 9:00 meeting @ Hablab. Returned to Hanger, worked on air and electrical outlets. Break for lunch @ hablab. Had quick dinner, then made run to Menard's for partial load of lunber, as the roads were icy.

Sun Nov 30, 2025

8:45 meeting @ Hablab. Asked Mark to help with installation of electricity in hanger bays.

Collected supplies and connected 4 bays and compressor with electricity.

Sat Nov 29, 2025

Still composing and refining the lists for purchasing. Reached an end and sent to Marcin for final review / update.

Drove to Saint Jo Menard's to pickup the items from Harbor Freight, Home Depot and Menard's and fetched the items.

Collected computers, intending to reload them, but crashed to sleep instead.

Fri Nov 28, 2025

8:00 meeting in Hablab.

Drove to James' house and got the 5 computers for the workshop. Spent the balance of the day working on lists of items necessary for installing compressed air, electricity and networking in the hanger.

6:00 meeting in Hablab.

Back to the house to continue the lists and get input from Marcin.

Thu Nov 27, 2025

Attended 8:00 AM meeting @ Hablab.

Used Kubota & grader to level out the ground from all the clumps of clay. Dug hole for final run inside the hanger. Made long 3" spade drill and used it to make the hole - with Roy's help. The poly tube kinked again inside the hole. Fixed Roy's reciprocating saw. In the house, discussed finding a coupling and repairing the poly line below ground.

Marcin found pellets for the pellet stove and I fetched a bag for the house.

Wed Nov 26, 2025

Attended 7:45 meeting @ Hablab.

Asked Aiden to help laying wire and blue CTS tubing in the trench. The tubing was not flexible and "pinched" in several places. Discussed it with Marcin and used pieces of the CTS tube with hose clamps to repair the pinches One pinch was left in the ground, near the exit into the hanger - it will have to be fixed, but the decision was made to move the compressor to the hanger and connect locally. Also ran ethernet cable from the workshop to the hanger and buried the trench.

Late night run to Menard's in KSC to pick up insulation.

Tue Nov 25, 2025

Took the hose and drove to Sweiger Shop, where they repaired it for ~ $40. Returned to OSE, installed hose and ran trencher to continue trenching. Trouble with trench filling in from others and from my own efforts to lay the wire and tubing in the trench. The wire proved difficult to handle, as it is heavy and when straddling the trench backwards, the wheels of the skid steer got stuck. Marcin used telehandler to get it free.

Made late night run in truck/trailer to Menard's for more insulation.

Mon Nov 24, 2025

Drove truck/trailer to Menards, loaded OSB and 2x6's and returned to OSE. Connected trencher to Kubota skid steer and dug trench from Workshop to Learning Center. While running the trencher, one of the hydraulic hoses was "pinched" and had to be repaired to continue. Spent hours searching for a solution - none found. Got Aiden to help.Late night run to Menard's with truck/trailer for insulation. Only 1/2 of the order fit in the trailer.

Sun Nov 23, 2025

Arrive at OSE at 2:00 PM. Discussed needs with Marcin, started working on the Kioti skid steer: Change oil, clean filter and oil/water coolers, straightened safety bar. Drove truck/trailer to Menard's for supplies, but it was closed (Sunday).

Sun Nov 16, 2025

Email to Marcin/Catarina about coming up for the 1 week work exchange and workshop. All good to go. I'll arrive Sunday the 23rd (the day after the work exchange starts), resolved with Marcin. Began gathering tools for departure on Sunday the 23rd.

Fri Nov 7, 2025

Marcin called: take a look - when I click on these files - I get an error. The last one is a re-uploaded version which works.

https://wiki.opensourceecology.org/wiki/Hangar_3D_CAD

More testing showed that clicking on the "Date/Time" of the current version yields a "Not Found" page.

I ran it down and found the files were missing from the "images" folder. I got a copy of the "images" folder from Hetzner2 and did an extract, keeping all existing files and copying missing files to the "images" folder.

All 4 files are available now.

The files that were missing had dates of June 21 or so and may have been added while the server was being migrated.

Mon Oct 20, 2025

Marcin called at 5:23 AM, saying the redirect quit working. Troubleshooting with ChatGPT resulted in working on various things, but with no solution. It led me through troubleshooting of nginx, wordpress, varnish, DNS, server name ordering and other criteria. Each time, it stated it found the solution, but following each update, it failed to perform the redirect. At one point, it said the issue was with the cloud version of Varnish, which required a login to administer. I searched, but did not find credentials for the cloud version. Instead, I requested to bypass varnish entirely and tested it, but the result was inconclusive.

Finally, I called Marcin and told him of the diagnostic loops that I've experienced with AIs in the past and he said he'd have the video updated with the information so the redirect would be unnecessary.

Sun Oct 19, 2025

Continued on the redirect of the main page of opensourceecology.org, but not the subpages (per Marcin). Queried ChatGPT and did some checks to find that nginx was still doing the redirects and not apache. Changed the nginx config, restarted nginx and now it works. Verified that Marcin saw the result.

After seeing Marcin's message about a site outage, I did some digging and found a problem with database connections failing, due to the default limit of 50 connections. I added a startup config file (nano /etc/mysql/mariadb.conf.d/99-custom.cnf) to inclulde the following:

[mysqld] # Increase connection limit to handle multiple apps max_connections = 300 # Optional: shorten connection timeout to free stuck sessions faster wait_timeout = 180 interactive_timeout = 180

and restarted the server. I monitored the connections and saw that it is regularly exceeding 100 to 115 connections - which was likely throwing connection errors regularly.

Sat Oct 18, 2025

Marcin called with the need to do some web redirects to streamline content for new applicants. Consulted ChatGPT and made the suggested changes. Marcin called after a short time, saying it isn't redirecting as expected, so I restored the original config. Later, did some more Chatting and changes, but used "curl" to better diagnose the situation and found that redirects were happening in nginx that blocked the apache redirects. Marcin said to put back to the original config and start fresh tomorrow.

Thu Oct 9, 2025

Noticed that the "www.opensourceecology.org" page is yielding a certificate error. Worked with ChatGPT, but no resolution yet. Will continue tomorrow.

Wed Sep 17, 2025

Marcin sent email, reporting that error messages were appearing from the ConfirmAccount extension:

Deprecated: strlen(): Passing null to parameter #1 ($string) of type string is deprecated in /var/www/html/extensions/ConfirmAccount/includes/backend/UserAccountRequest.php on line 51

The error was coming from the following code:

$req->fileName = strlen( $row->acr_filename ) ? $row->acr_filename : null;

The call to strlen passes a null filename, causing the exception, so the fix was to change it as follows:

Original: strlen( $row->acr_filename ) Changed: strlen( $row->acr_filename ?? )

This passes an empty string to "strlen()" rather than a null, suppressing the error.

Fri Sep 5, 2025

Marcin email: User having trouble. Send screenshot and copy Tom.

I received the error and tracked it down to a config error - fixed it in LocalSettings.php, tested and verified working now. Sent user update.

Sat Aug 30, 2025

Marcin issue with Time Log. He now says he was only able to access it from his computer using the Firefox browser, but can now access it using Chromium - so it's OK on his computer.

His phone still can't display the Time Log, though. It fails with the message "osedev.org redirected you too many times".

Fri Aug 29, 2025

I came across a company in Australia casting Lego like blocks of perlite for building houses:

I just came across a video about these blocks for building walls with LEGO like blocks:

https://www.youtube.com/shorts/1EWpcrFTYHo

I had seen some in the past, but these look more interesting.

Apparently, it is from the Australian company "System3E":

https://system3e.com.au/

They claim:

Made of perlite (recyclable)

LOW TOXIC HOME – natural materials, safer for your family

THERMALLY INSULATED – 10x better than the standard Australian house brick

MOULD RESISTANT – perfect for humid regions of Australia

FIRE-RATED 240/240/240 – resistance to temperatures from 200°C to 900°C → no mortar → no water → no glue → no additional insulation → no freedom of movement in any dimension

While the block design looks good and I like perlite, I don't know its cost, availability or suitability for a building material.

- - - - -

Yesterday, I came across a video of a guy making blocks out of "AIRcrete":

https://bastyon.com/index?v=7fbdf470f514561b3aad7351dfea2c10c12317e8fb2148b2c6327f94e66cccd7&video=1&ref=P8s7mXn1msepNnpCp3FyoxXoGzxNSWHxxz

I was interested, did more searching and found some info about AIRcrete:

This article claims that AIRcrete gets R-6 / inch:

https://www.buildwithrise.com/stories/aircrete-everything-you-need-to-know

I also found a website about "Aircrete Europe" that already builds with blocks and panels:

- - - - -

Following that, I found information about HEMPcrete (also called "hemp-lime") which has passed European and US standards for use as insulation and had been measured with R-value of 2.2 / inch:

https://www.hempbuildmag.com/home/hemp-lime-astm-r-value

It goes on to say that HEMPcrete has "thermal inertia", which benefits heat propagation.

Homeland Hempcrete makes prefab hempcrete wall panels that look familiar:

https://porpoise-jaguar-g36w.squarespace.com/

Fri Aug 22, 2025

Email from Marcin saying he was blocked when trying to create an account with the URL:

https://wiki.opensourceecology.org/wiki/Special:RequestAccount

I tried this from my login and it worked normally, with a form to complete for the account request.

When looking at the mediawiki logs, I saw an unusual number of attempts to invoke this "Special:RequestAccount" URL - they were failing, but still showing in the logs.

Marcin called later in the day and I reviewed this with him. I also informed him that the "Time Log" was working. We visited my "Tom Log" and he could see it working, but when visiting his Log, he got something different - he will pursue this later.

Thu Aug 21, 2025

11:00 PM call from Marcin: "User account creation has been hacked". I checked it out and found 373 users created in the last 2 days - most without Marcin's approval.

Inquired about it to ChatGPT and made some changes to the LocalSettings.php file on mediawiki, with the help of ChatGPT and also queried the database and found the bogus users. Notified Marcin and will check on it tomorrow.

SQL to show users created since yesterday:

SELECT user_id, user_name, user_registration FROM user WHERE user_registration >= '2025-08-20' ORDER BY user_registration DESC;

It identifies 373 users. Marcin looked at the list and recognized some entries, so we can't just delete them all (via UserMerge).

Locked down self-registration with the following settings in mediawiki LocalSettings.php:

# Disable normal self-registration $wgGroupPermissions['*']['createaccount'] = false; $wgGroupPermissions['user']['createaccount'] = false; # Allow only sysops (or bureaucrats) to create accounts manually $wgGroupPermissions['sysop']['createaccount'] = true; # ConfirmAccount will handle public requests wfLoadExtension( 'ConfirmAccount' ); $wgGroupPermissions['sysop']['confirmaccount'] = true; $wgGroupPermissions['sysop']['confirmaccount'] = true; $wgConfirmAccountRequestEmail = true; # email admins when new requests arrive

Sat Aug 16, 2025

Worked on the OBI web service in early morning - per agreed maintenance window of midnight - 9:00 AM.

Changing certificate config in nginx_letsencrypt container and regenerating certificates for nginx_proxy. It required restarts of both to make effective.

Got call from Marcin at 8:30 AM, saying website down. He must have hit it during restart of nginx_proxy, as it was up when he called. Stopping for today.

Fri Aug 15, 2025

Working on OBI Wordpress: Downgraded the container to php 7.0 and Wordpress 4.8.1.

Trouble with the domain names, nginx and SSL: Couldn't access site via https. ChatGPT suggested adding both "openbuildinginstitute.org" and "www.openbuildinginstitute.org" to the "VIRTUAL_HOST" definition of obi_wp, but this ended up breaking nginx_proxy and all sites. Scramble to get it working again and got a call from Marcin about it. Once restored, called Marcin and notified. Stopped for the day.

Thu Aug 14, 2025

Enabled users to create their own accounts and enabled ConfirmAccount extension so Marcin approves accounts before creation.

Fixed bug with strlen() due to new version PHP.

Fixed osedev Time Log reporting in mediawiki iframe.

Added osedev's postgres database dump and backup to system scripts.

Working on getting the OBI wordpress container "cloned" from H2 to H3.

This appeared to be easy, but is taking time, due to incompatibilities with wordpress, PHP, base docker images and so on.

Here is the dialog with ChatGPT: https://chatgpt.com/share/687596c4-8470-800e-8513-e7e3bbed6976

Wed Aug 13, 2025

Marcin called with priorities:

* Enable users to create accounts on wiki * OSEdev integration * OBI: Clone from Hetzner2

Enabled user account creation with: Mediawiki -> LocalSettings.php -> $wgGroupPermissions['*']['createaccount'] = 'true';

Fri Aug 8, 2025

Video call with Lex about osedev.

I had installed the osedev apps and a postgres database in a container and we decided to split them into separate containers. Defined, built and started the "pdb" (Postgres DataBase) container and imported the data from Lex.

Setup an "osedev" container and loaded the apps using Lex's docker config information. We were able to start it and connect it to the database, but the access via https was not working. Did some work to get it connected using the domain name "osedev.opensourceecology.org", but had trouble with the nginx configuration and SSL certificates. Reviewed the current configuration and found changes needing to be done. Worked with Lex on it for some time and he is confident that the app is working, just not connecting.

He had to go, so I'll work on it and get back with him as necessary.

Note that Lex has put the code for osedev in github: https://github.com/osedev/osedev/tree/master

Thu Aug 7, 2025

Video call with Lex about osedev.

Did screen share to show the current config and we discussed the use of docker-compose to define the containers.

Lex did some coding on-screen, trying to get docker-compose to automate the pull from Github and build of the container. We worked at it for some time, then Lex ran out of time and said he would complete it and get back with me.

Tue Aug 5, 2025

Re-exported the postgres database into text dump file. Installed "pgloader" and tried it for converting the postgres file into MySQL - it failed. Un-installed it.

Fetched the perl script: pg2mysql.pl and used it to convert the postgres dump into a MySQL ".sql" file. Looked it over and found it creates and loads into the "public" database. Loaded it into my MySQL database. It largely went OK, but threw some errors over "timedate" exceptions. Notified Lex and Marcin.

Also: Sent Lex request for the GUI portion of his app.

Mon Aug 4, 2025

Got postgres database dump from Lex, created postgres v10 container on my PC and imported the database.

Wed Jul 30, 2025

Fixed the phplist site after the "build" broke it. Updated docker-compose.yml and the Dockerfile to restore the config if rebuilt again. Got the phplist functionality working.

The Dockerfile and site configurations are in "/home/dadm/OSE/phplist-3.6.16".

Also checked on the obi_wp site, as it was showing as "unhealthy". Turns out the "oshin" theme was set for the site, but was not to be found. Fetched and installed it from Hetzner2, but got an error saying it is not compatible with the updated version of wordpress. Switched it to the "twentyfive" theme and sent email to Catarina about the switch.

After all this the sites all show as "healthy" and are accessible from the Internet.

Catarina sent email with attachments of receipt and the oshine theme. I installed it and after some testing, the site appears to work, but with little content. I requested that Catarina check it out and let me know if working properly.

Notes:

Wordpress version 6.8.1 is currently installed in the docker containers. PHP is at version 8.2.29

ChatGPT had a few things to say about this theme and Wordpress versions and the oshine theme:

The theme is loading translations before the WordPress init hook, which is not allowed anymore as of WordPress 6.7.

“Optional parameter declared before required parameter” - This is caused by PHP 8+ strict rules. The theme uses outdated PHP 7-style function signatures.

Attempt to modify property "admin_notices" on null This means the Redux global object the theme expects wasn't initialized properly — likely due to changes in the WP core or incompatible plugin code.

Final Notes

WordPress 6.7 tightened the rules for translation loading timing.

Oshin (or at least its bundled libs) hasn’t caught up.

Best practice is to hook all load_theme_textdomain() calls into init — but older themes often don’t.

With these considerations, it may be best to use a different theme.

Tue Jul 29, 2025

Continuing with mail setup: Added new container "mail-relay" to handle outbound email for all containers. Added this block added to docker-compose.yml, then ran "docker-compose up -d" to create the container:

mail-relay:

image: boky/postfix

container_name: mail-relay

hostname: mailer.opensourceecology.org

restart: unless-stopped

environment:

# Change these to match your actual SMTP relay credentials

RELAYHOST: ""

# RELAYHOST_USERNAME: "postmaster@yourdomain.com"

# RELAYHOST_PASSWORD: "your-password"

MYHOSTNAME: "mailer.opensourceecology.org"

SENDER_CANONICAL_MAP: "phplist@opensourceecology.org"

ALLOW_EMPTY_SENDER_DOMAINS: "true"

networks:

- ose-net

I tested different package configurations, settled on using only exim4 in each container to forward email to mail-relay as follows:

As "dadm", start a shell in each container to install the packages and create the initial config:

dadm@hetzner3:~/OSE$ docker exec -it wiki bash # apt update && apt install -y vim-tiny exim4 bsd-mailx # vi /etc/exim4/update-exim4.conf.conf # Add the following, changing "wiki" to the container name:

dc_eximconfig_configtype='smarthost' dc_other_hostnames='wiki.opensourceecology.org' dc_local_interfaces='127.0.0.1 ; ::1' dc_readhost='wiki.opensourceecology.org' dc_relay_domains= dc_minimaldns='false' dc_smarthost='mail-relay:25' CFILEMODE='644' dc_use_split_config='false' dc_hide_mailname='true' dc_mailname_in_oh='true'

Run these commands to update the config and restart the mail service:

# update-exim4.conf # service exim4 restart

Test for email sending and delivery to my email client:

# echo "Test from ose_wp" | mail -v -s "Test Email" tgriff@tuta.io

I set up this mail service for the following containers:

wiki ose_wp obi_wp learn phplist

Received an email from Lex, saying osedev.org was broken and offering to assist with migrating the timekeeping app to Hetzner3. It uses postgresql and I have concerns that it may be rather "heavy" for adding to Hetzner3.

Mon Jul 28, 2025

Per Marcin's request, turned on user self-registration by adding the following to Mediawiki's "LocalSettings.php" file:

wfLoadExtension( 'ConfirmEdit/ConfirmEdit.php' ); wfLoadExtension( 'ConfirmEdit/ReCaptchaNoCaptcha' ); $wgCaptchaClass = 'ReCaptchaNoCaptcha'; $wgReCaptchaSiteKey = 'your-site-key-here'; $wgReCaptchaSecretKey = 'your-secret-key-here'; // Optional: Enable CAPTCHA for self-registration $wgGroupPermissions['*']['createaccount'] = true; $wgCaptchaTriggers['createaccount'] = true;

I accessed the Google reCaptcha website to generate the keys for it to work. While there, it asked which type reCaptcha to use and I selected "Score based (v3)", which uses a score and is invisible to the user.

After installing the keys, I visited my OSE wiki page for logs and found the iFrame with user hours and graph had been replaced by an error message about a certificate issue with "osedev.org". Since I don't know this server, I sent Marcin an inquiry about it and am waiting for his response.

Also configured the following:

ConfirmEdit - Prevent bot submission email verification - Block junk account editing StopForumSpam - Check against known spammers wgAccountCreationTrottle Limit account creation to 1 per IP addr per day AbuseFilter - Detect sketchy usernames, etc. ConfirmAccount - Manual review of signups

Started configuring and found the hourly tracking feature not working on personal log pages. Looked into it and found the iFrame content was blocked from osedev.org (Lex's machine). Later, had to disable several of the options as the wiki server wasn't rendering pages.

Configured limits on log files in the docker-config.yml.

Sat Jul 26, 2025

Monitoring backups, checking into automating monitoring for the rsyslog events. Marcin email: Enable "Create user" function from main page? I looked and found a way to enable it in the sidebar menu only for administrators.

Thu Jul 24, 2025

Reviewing the security of the newly installed Hetzner3, I used "nmap" to test each port for accessibility:

$ nmap 144.76.164.201 Starting Nmap 6.40 ( http://nmap.org ) at 2025-07-24 07:20 UTC Nmap scan report for hetzner3 (144.76.164.201) Host is up (0.00032s latency). Not shown: 998 closed ports PORT STATE SERVICE 80/tcp open http 443/tcp open https Nmap done: 1 IP address (1 host up) scanned in 0.03 seconds

This is good, as only two "priviliged" web server ports are exposed to the Internet.

The web services provided by Hetzner3 are "front-ended" by nginx configured as a "reverse proxy" to secure the back-end server processes. In a query with ChatGPT about the benefits of using this configuration follow:

Me: Describe how using nginx to provide "reverse proxy" interface to web servers enhances security.

ChatGPT:

Using Nginx as a reverse proxy enhances security for your web servers in several key ways. Here’s how: 🔒 1. Isolation of Backend Services

Direct access to backend servers is blocked.

Clients only communicate with Nginx, not the actual web servers (like Apache, PHP apps, Node.js, etc.).

This reduces exposure to vulnerabilities in those backend services.

🔑 2. SSL Termination

Nginx can handle TLS (HTTPS), even if backend services only support HTTP.

It centralizes certificate management and:

Ensures secure connections with clients.

Prevents misconfigured backend HTTPS.

🧱 3. Rate Limiting and Throttling

Nginx can apply rate limits per IP, defending against:

Brute-force login attempts.

API abuse.

DDoS attacks (to some extent).

🚫 4. Access Control and IP Whitelisting

Nginx can restrict access to certain routes, IPs, or headers before traffic reaches your application.

Example:

location /admin {

allow 192.168.1.0/24; deny all;

}

🧼 5. Input Sanitization & Filtering

Nginx can block common attacks like:

SQL injection attempts.

Malformed requests.

Unexpected methods (TRACE, TRACK).

Tools like ModSecurity or ngx_http_limit_req_module enhance this further. 🎭 6. Obscuring Backend Details

Headers like X-Powered-By: PHP/7.4 can be removed.

Backend IPs and server software versions are hidden.

Makes fingerprinting your infrastructure harder.

🕵️ 7. WAF Integration

Nginx can be used with a Web Application Firewall (e.g., ModSecurity or NAXSI) to inspect traffic for malicious patterns.

📜 8. Centralized Logging and Monitoring

Logs from all services pass through Nginx.

Easier to detect anomalies, attacks, or unusual patterns in one place.

🧩 9. Buffering and Request Validation

Nginx buffers client requests and can reject oversized payloads or invalid content types.

This protects slower or less robust backends from being overwhelmed.

🛑 10. Preventing Open Redirects & Proxy Abuse

Nginx can tightly control which headers and URLs are passed to the backend, blocking:

Open redirect vulnerabilities.

Abuse of internal-only APIs.

In addition, docker has been installed as "rootless" so if a container is compromised, any access is limited to the Docker Runtime user.

Worked on the retention script for backups. I implemented it in two parts: one for local backups and a second for remote (backblaze) backups. The schedule is to keep the following backups:

7 Daily 4 Weekly 12 Monthly 5 Annual

I used python with an API library to access Backblaze for inventory and deletion of old backups. After much testing, finally arrived at a version that works well. Tested it to success and appended it to the main backup.sh script.

Also checked the backup log file and found it lacking. Tweaked the backup script for clarity. The scheduled backup ran just as I finished. Checked the log file again. Deleted an unnecessary 4.5 GB database backup file to save space on disk and on the backup.

Wed Jul 23, 2025

Copied phplist images from H2 to H3 and installed them. Tested and found the resulting content updated with images. It appears the phplist implementation is complete.

Mon Jul 21, 2025

Resolved the issue with phplist content loading into iframes on www.opensourceecology.org - now it loads properly. It was due to the "DocumentRoot" not serving up the same directory path as the prior server.

Communicated with Marcin about a cutover of the www OSE wordpress site and phplist to the new server - will wait until the current campaign is over and we've reached a time of minimal updates.

Sun Jul 20, 2025

Continued on phplist and configured it to auto-build into the docker framework. Had a few slowdowns, mostly related to the auto-build in Docker, but got past it and the configuration went easier. Connected phplist to the database.

Sat Jul 19, 2025

Started into phplist and got into postfix for mail delivery. It appears that emails are sent directly to subscribers with no middleware. Studied the setup and started working on phplist. Found incompatibilities with it and PHP 8.1. Kept hitting stopping points that required debugging to find / fix the incompatibility.

Since I didn't know how many more of these issues would present themselves, decided to upgrade to the latest version of phplist, which is compatible. Installed phplist 3.6.16 and began configuring.

Fri Jul 18, 2025

Working on phplist server, drilling down into the processing, found and fixed some errors in scripts that were prevent it from working. Found email service needs to be configured, so set about copying the config from hetzner2.

Thu Jul 17, 2025

The phplist content from hetzner3 still isn't working. When I bring up www.opensourceecology.org from Hetzner3, everything is working except the iframe from phplist. When using phplist from Hetzner2, it works fine, but when switching phplist back to Hetzner3, the iframe is blank. I've been using ChatGPT to assist in diagnosing the cause, but still haven't found a solution.

Wed Jul 16, 2025

Monitoring Hetzner3, verifying backups working as expected and uploaded to Backblaze.

Following the migration of www.opensourceecology.org to Hetzner3, began work on the site to get it working properly, as the old installation didn't work cleanly on Wordpress 6.8.1.

ChatGPT proved very helpful with this, in getting the former "Enigmatic" theme moved from Hetzner2 copied over and modified until it worked properly on H3. The only thing not working is the iframe of the phplist content. I will resolve this after phplist is working on this server.

Worked on getting www.opensourceecology.org to display the iframe from phplist correctly, but ChatGPT keeps running in circles and changing models, making it very challenging. Stopping for today, will continue tomorrow.

Tue Jul 15, 2025

Continued with phplist to completion. Emailed Marcin on progress, saying I can move the DNS for phplist when he gives the word. Starting on www.opensourceecology.org migration, got the database and files for www.openbuildinginstitute.org as well. Installed the new wordpress containers and started them, but now all three wordpress sites defaulted to the "learn" container. Did some troubleshooting with ChatGPT and re-configured nginx_proxy to distinguish between the different wordpress instances and handle connections accordingly. Also reconfigured the auto-renewal of HTTPS certificates. Tested the wiki and learn sites and found them working normally. Tried again later and found them down. Some troubleshooting showed that the auto-regeneration of certificates was failing and in a loop. Finally resolved a misconfiguration issue, restarted the services and all was working again.

Here is a listing of the docker containers on hetzner3:

dadm@hetzner3:~/OSE$ docker ps CONTAINER ID IMAGE COMMAND CREATED STATUS NAMES f64a49c6b8d5 wordpress "docker-entrypoint.s…" 12 minutes ago Up 12 minutes ose_wp bcafb6df7e08 wordpress "docker-entrypoint.s…" 12 minutes ago Up 12 minutes obi_wp 74fba413ffe6 wordpress "docker-entrypoint.s…" 12 minutes ago Up 12 minutes (healthy) learn d1b03cf07d49 php:8.1-apache "docker-php-entrypoi…" 12 minutes ago Up 12 minutes (unhealthy) phplist f21d22b021cb mediawiki:1.39 "docker-php-entrypoi…" 12 minutes ago Up 12 minutes (healthy) wiki 22c6db58ce4c nginxproxy/acme-companion "/bin/bash /app/entr…" 12 minutes ago Up 12 minutes nginx_letsencrypt 7d2857bd09ef mariadb "docker-entrypoint.s…" 12 minutes ago Up 12 minutes (healthy) db 9ad111499f58 nginxproxy/nginx-proxy:alpine "/app/docker-entrypo…" 12 minutes ago Up 12 minutes nginx_proxy

Checking the versions of the newly migrated containers:

NAME Hetzner2 ver Hetzner3 ver ose_wp 4.9.4 6.8.1 obi_wp 4.8.1 6.8.1 phplist 3.3.1 3.3.1

Now for the backups:

The Hetzner3 archives are being created normally:

-rw-r--r-- 1 root root 20G Jul 14 05:40 /var/backups/Hetzner3-Backup-20250714_052001.tgz -rw-r--r-- 1 root root 21G Jul 15 02:23 /var/backups/Hetzner3-Backup-20250715_020001.tgz -rw-r--r-- 1 root root 22G Jul 16 02:24 /var/backups/Hetzner3-Backup-20250716_020001.tgz

These archives are being copied successfully to Backblaze:

Name Size Uploaded Hetzner3-Backup-20250714_052001.tgz 20.6 GB 07/14/2025 03:44 Hetzner3-Backup-20250715_020001.tgz 21.9 GB 07/15/2025 00:27 Hetzner3-Backup-20250716_020001.tgz 23.1 GB 07/16/2025 00:28

The uploaded archive for Hetzner2 is only 8.1 GB

Name Size Uploaded daily_hetzner2_20250715_072001.tar.gpg 8.1 GB 07/15/2025 07:31

Even though the www sites and phplist have been moved, they don't seem to be working and aren't available via HTTPS.

I will continue troubleshooting to get them working.

Mon Jul 14, 2025

Call from Marcin: Can we recover missing page: "Video_Index_for_Kainos"? I looked on H2 and H3, but didn't find it. Also, downloaded backup from July 1st and it wasn't there either. Wiki / db / wp1 / nginx_proxy working well now. What next? 1. phplist 2. www.opensourceecology.org 3. OBI

Started on phplist

Sun Jul 13, 2025

Fixed the image problem, two variables were missing from the LocalSettings.php file in mediawiki:

$wgUploadPath = "$wgScriptPath/images"; $wgUploadDirectory = "$IP/images";

Tested and tweaked the backup scripts to run as root and to do a more extensive backup. It also generates a full database backup and adds it to the archive. Finally, it sends the backup to backblaze. Also spent some time on Hetzner2 and found that the backup archives were being generated locally, but failing to send to Backblaze, as they were too large. Deleted some unnecessary files and removed the wiki from the archive. Will monitor scheduled backups / uploads. Deleted the old partial backups from backblaze. Followup: Monitored backup progress, made changes as the upload to backblaze wasn't working. Added code to verify backup integrity and retention backups and improved logging.

Sat Jul 12, 2025

Started troubleshooting a problem with the wiki, where thumbnail images are not appearing. Instead, a box is shown with text: "Error creating thumbnail: File missing". Consulted ChatGPT, which led through troubleshooting, but going down a rabbit hole and prompted to delete the database, but I moved it aside instead. After some fails, I restored the system. During the process, I found that the backups as the "dadm" user are no good, as docker spawn other users to create files that dadm can't read. I revised the backup scripts to perform database backup as dadm, then file backups as root. Scheduled backups at 2:00 AM and tested, but no success in getting the backup from the container database to the external filesystem, but I think I see a way.

Installed rsyslog, enabled and started it - it works.

Cron doesn't seem to be working, but is already installed. Enabled it and started it, and got it working.

Fri Jul 11, 2025

Marcin called: Website images not rendering, showing up as box with text inside: "Error creating thumbnail: File missing". Updated all installed extensions - no help. Internet search found many people with the problem - no conclusive answers. Queried ChatGPT, did some troubleshooting, but it led down a path I wasn't comfortable with continuing. Queried Grok, better answers. Getting late, went to bed.

Thu Jul 10, 2025

Call from Marcin: Notified of server status and suggested a way to copy logs from H2 to H3 using entries in /etc/hosts file, but later found this wasn't working due to certificate issues and DNS.

Suggested temporary DNS switch back to H2, copy logs, switch back to H3 to paste logs. I set a time to switch from 9:30 PM - 10:00 PM and copied my logs during this window. I don't think Marcin got his logs copied, so will have to try again later.

Reset the wordpress container, as it had been accessed and wasn't functioning properly, then notified Marcin that it should be configured.

Wed Jul 9, 2025

Continued configuration with restores. Started rootless docker, implemented backups via docker-compose.yml file, but it was cumbersome and didn't get all of docker. Switched to cron driven backups including all of docker.

Sent info to Marcin to notify of H3 cutover.

Tue Jul 8, 2025

Completed uploading backups to server. Did some basic security setup, then started installing Docker.

Ran into conflict between apparmor and Docker rootless. Many attempts to resolve with assistance from Grok. When it reached a stopping point, queried ChatGPT - it suggested fully disabling apparmor, which I did. It didn't take initially, so ChatGPT suggested disabling apparmor from GRUB. I did so and rebooted the server to make it effective. Then I could no longer log in, ssh attempts failed, saying "Connection refused".

ChatGPT: "Disabling AppArmor completely on Ubuntu 24.04 can break SSH, especially if /usr/sbin/sshd or related services were protected by enforced AppArmor profiles. "

Install procedure

Install server with Debian 12 (Bookworm)

Login as root, set root password:

ssh root@<server password: <root password>

# passwd New password: Retype new password:

Create "admin" users, beginning with Docker Admin user (dadm), repeat for others:

# useradd -mc "Docker Admin" dadm ## Enter user name in comment and user login # usermod -aG sudo dadm ## Grant "sudo" access # passwd dadm New password: Retype new password: passwd: password updated successfully

Edit config for SSH: port #, disable root SSH login

# vi /etc/ssh/sshd_config

Update operating system

# apt update # apt upgrade -y

Log out, then connect again as dadm

$ ssh -p <SSH Port> dadm@<ip address> dadm@<ip address>'s password:

Create ssh key for dadm:

$ ssh-keygen

Spoke with Marcin, discussed the options and decided to reload with Ubuntu 22.04, retry rootless Docker and if painful, switch to rootful Docker. Following the talk with Marcin, did more digging and found rootless docker <-> apparmor problems due to Ubuntu kernel modifications, better to use Debian 12 (Bookworm). Re-installed server with bookworm. Followed "howto" document:

https://linuxhandbook.com/rootless-docker/

with a few exceptions. Here is the procedure I used:

id -u 1001

whoami testuser

Next, check that the user has 65,536 sub UIDs:

grep ^$(whoami): /etc/subuid testuser:231072:65536

grep ^$(whoami): /etc/subgid testuser:231072:65536

What do these numbers mean? The first number is the first id allowed to use and the next one tells how many id do you have. For example, it starts with 231072, id 0 means 231072 and id 1000 means 241072.

Install the dbus-user-session and fuse-overlayfs packages.

For Debian, use the command to install dbus-user-session:

sudo apt install -y dbus-user-session

And then install fuse-overlayfs:

sudo apt install -y fuse-overlayfs

It is recommended to use Kernel 5.11 or later. Installing docker in rootless mode

Now you come to the main part. The first part is the normal Docker installation and then go with the rootless part.

I'll show the steps for Ubuntu. Install the usual Docker packages

Uninstall any existing Docker package first:

sudo apt remove docker docker-engine docker.io containerd runc

And then install Docker on Ubuntu:

sudo apt update sudo apt install docker-ce docker-ce-cli containerd.io

Verify that Docker Engine is installed correctly by running the hello-world image.

sudo docker run hello-world

Considering that the Docker daemon is already running, disable it first.

sudo systemctl disable --now docker.service docker.socket

#### Necessary commands for install to succeed

sudo reboot ## Reboot before rootless docker will install!

sudo apt-get -y install uidmap ## Install uidmap

modprobe nf_tables ## Load nf_tables

####

Install the rootless package

Now install the docker-ce-rootless-extras package by downloading the official script using curl command:

curl -fsSL https://get.docker.com/rootless | sh

Follow the on-screen suggestions and you'll have the rootless Docker installed.

At the end of this installation screen, there will be two things written: export=xxx

Copy and paste them into the last .bashrc file or if you are using ZSH, the .zshrc file. Source the rc files you just changed.

Once the installation completes, run daemon docker rootless:

systemctl --user start docker

Run rootless docker automatically at each startup:

systemctl --user enable docker sudo loginctl enable-linger $(whoami)

Mon Jul 7, 2025

Preparing for wiping hetzner3 and reloading fresh operating system.

Checked backups on backblaze and reported to Marcin about Hetzner 3 and 2. Found hetzner2 backups were 0 bytes for several days.

Took backus of critical folders on Hetzner 3 and downloaded to my laptop. Verified backups and copied to external disk.

Logged into Hetzner and navigated to the admin page for H3:

https://robot.hetzner.com/server

Upon selecting the "Linux" tab, I noticed that they also have the new Ubuntu: 24.04 LTS base:

I queried grok about the operating systems available from Hetzner:

"which of these server operating systems do you consider the most secure and easiest to administer?" AlmaLinux 8 base AlmaLinux 9 base Arch Linux latest minimal CentOS Stream 10 base CentOS Stream 9 base Debian 11 base Debian 12 base openSUSE 15.6 base Rocky Linux 8 base Rocky Linux 9 base Ubuntu 22.04.2 LTS base Ubuntu 22.04.2 LTS Nextcloud Ubuntu 24.04 LTS base

It gave a long winded answer, but summarized:

Given your urgency and Docker-based setup, Ubuntu 22.04.2 LTS base is recommended for reinstallation due to its ease of use and Docker support, but we’ll focus on fixing the current Debian 12 setup first.

So, while debian has a good reputation, I think it best to go with Ubuntu LTS (Long Term Support). I've used it before with good experience and it is very polished and well supported.

I checked the Ubuntu server downloads and while they do have 25.04 LTS available, it's not their default server release. It's not supported by Hetzner, either - so I settled on 24.04 LTS base.

I clicked to begin the reinstallation and got the following message:

The Linux installation was activated successfully. To start the installation, you have to reboot your server now.

A notification will be sent to your given address as soon as the installation completed.

From then on you can log into your server via SSH2 as user "root" with the following password: ubvU8G2rduT9uJ

So, I'll reboot and watch for updates.

BTW: I noticed that under the Linux tab for re-installation, it lists Michael's ssh key and I couldn't find a way to remove it. I'll check the resulting installation and remove if found.

Here goes the reboot . . .

First: Set the root password. I'll find a way to send it to you securely.

Check out the operating system footprint - 1% of the disk:

root@Ubuntu-2404-noble-amd64-base ~ # df -h / Filesystem Size Used Avail Use% Mounted on /dev/md2 436G 2.4G 412G 1% /

Updated software packages and rebooted for new kernel.

Created logins for Marcin and Catarina, sent instructions for login and password reset.

Sun Jul 6, 2025

Beginning second attempt at setup rootless docker environment, but using Grok instead.

First: run the "rootless" script as the non-root user "dockera":

dockera@hetzner3:~$ curl -fsSL https://get.docker.com/rootless | sh

- Installing stable version 28.3.1

- Executing docker rootless install script, commit: fb10f07

% Total % Received % Xferd Average Speed Time Time Time Current

Dload Upload Total Spent Left Speed

100 78.0M 100 78.0M 0 0 97.2M 0 --:--:-- --:--:-- --:--:-- 97.2M

% Total % Received % Xferd Average Speed Time Time Time Current

Dload Upload Total Spent Left Speed

100 16.6M 100 16.6M 0 0 66.2M 0 --:--:-- --:--:-- --:--:-- 66.2M + PATH=/home/dockera/bin:/home/dockera/.local/bin:/home/dockera/bin:/usr/local/bin:/usr/bin:/bin:/usr/local/games:/usr/games:/usr/sbin /home/dockera/bin/dockerd-rootless-setuptool.sh install --force [WARNING] File already exists, skipping: /home/dockera/.config/systemd/user/docker.service [INFO] starting systemd service docker.service + systemctl --user start docker.service + sleep 3 + systemctl --user --no-pager --full status docker.service ● docker.service - Docker Application Container Engine (Rootless)

Loaded: loaded (/home/dockera/.config/systemd/user/docker.service; disabled; preset: enabled)

Drop-In: /home/dockera/.config/systemd/user/docker.service.d

└─override.conf

Active: active (running) since Sun 2025-07-06 14:27:36 UTC; 3s ago

Docs: https://docs.docker.com/go/rootless/

Main PID: 456491 (rootlesskit)

Tasks: 47

Memory: 47.4M

CPU: 816ms

CGroup: /user.slice/user-1012.slice/user@1012.service/app.slice/docker.service

├─456491 rootlesskit --state-dir=/run/user/1012/dockerd-rootless --net=slirp4netns --mtu=65520 --slirp4netns-sandbox=auto --slirp4netns-seccomp=auto --disable-host-loopback --port-driver=builtin --copy-up=/etc --copy-up=/run --propagation=rslave /usr/bin/dockerd-rootless.sh

├─456503 /proc/self/exe --state-dir=/run/user/1012/dockerd-rootless --net=slirp4netns --mtu=65520 --slirp4netns-sandbox=auto --slirp4netns-seccomp=auto --disable-host-loopback --port-driver=builtin --copy-up=/etc --copy-up=/run --propagation=rslave /usr/bin/dockerd-rootless.sh

├─456525 slirp4netns --mtu 65520 -r 3 --disable-host-loopback --enable-sandbox --enable-seccomp 456503 tap0

├─456534 dockerd

└─456558 containerd --config /run/user/1012/docker/containerd/containerd.toml

Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.374438665Z" level=warning msg="WARNING: No io.weight (per device) support" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.374450503Z" level=warning msg="WARNING: No io.max (rbps) support" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.374461805Z" level=warning msg="WARNING: No io.max (wbps) support" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.374471232Z" level=warning msg="WARNING: No io.max (riops) support" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.374480486Z" level=warning msg="WARNING: No io.max (wiops) support" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.374506651Z" level=info msg="Docker daemon" commit=5beb93d containerd-snapshotter=false storage-driver=overlay2 version=28.3.1 Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.374583502Z" level=info msg="Initializing buildkit" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.419890443Z" level=info msg="Completed buildkit initialization" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.427041860Z" level=info msg="Daemon has completed initialization" Jul 06 14:27:37 hetzner3 dockerd-rootless.sh[456534]: time="2025-07-06T14:27:37.427121434Z" level=info msg="API listen on /run/user/1012/docker.sock" + DOCKER_HOST=unix:///run/user/1012/docker.sock /home/dockera/bin/docker version Client:

Version: 28.3.1 API version: 1.51 Go version: go1.24.4 Git commit: 38b7060 Built: Wed Jul 2 20:55:19 2025 OS/Arch: linux/amd64 Context: default

Server: Docker Engine - Community

Engine: Version: 28.3.1 API version: 1.51 (minimum version 1.24) Go version: go1.24.4 Git commit: 5beb93d Built: Wed Jul 2 20:56:35 2025 OS/Arch: linux/amd64 Experimental: false containerd: Version: v1.7.27 GitCommit: 05044ec0a9a75232cad458027ca83437aae3f4da runc: Version: 1.2.6 GitCommit: v1.2.6-0-ge89a299 docker-init: Version: 0.19.0 GitCommit: de40ad0 rootlesskit: Version: 2.3.4 ApiVersion: 1.1.1 NetworkDriver: slirp4netns PortDriver: builtin StateDir: /run/user/1012/dockerd-rootless slirp4netns: Version: 1.2.0 GitCommit: 656041d45cfca7a4176f6b7eed9e4fe6c11e8383

+ systemctl --user enable docker.service Created symlink /home/dockera/.config/systemd/user/default.target.wants/docker.service → /home/dockera/.config/systemd/user/docker.service. [INFO] Installed docker.service successfully. [INFO] To control docker.service, run: `systemctl --user (start|stop|restart) docker.service` [INFO] To run docker.service on system startup, run: `sudo loginctl enable-linger dockera`

[INFO] Creating CLI context "rootless" Successfully created context "rootless" [INFO] Using CLI context "rootless" Current context is now "rootless" Warning: DOCKER_HOST environment variable overrides the active context. To use "rootless", either set the global --context flag, or unset DOCKER_HOST environment variable.

[INFO] Make sure the following environment variable(s) are set (or add them to ~/.bashrc): export PATH=/home/dockera/bin:$PATH

[INFO] Some applications may require the following environment variable too: export DOCKER_HOST=unix:///run/user/1012/docker.sock

Sat Jul 5, 2025

Started a ticket with Hetzner for a remote console session to the server at 10:00 AM. Meanwhile, I accessed their control panel for Hetzner3 and issued a reboot to the server. Shortly afterward, found it had come back online and working normally. Apparently, the firewall rules weren't permanent. Switched back to the "rootful" environment and got it working again, but left "wiki" pointing to H2. Started looking into the backup scripts and also at how to create MariadDB daily transaction logs, for granular restorations, as necessary.

It is time to optimize the backups. First: Check with ChatGPT about which tool to use:

- - - - -

Me: Is mysqldump as good as the mariadb-backup program? ChatGPT said:

Great question. In short:

✅ mariadb-backup is more powerful and efficient than mysqldump for large or production systems — but mysqldump is still reliable and simpler for smaller setups. 🔍 Key Differences

Feature mysqldump mariadb-backup (aka MariaDB Backup)

Backup type Logical (SQL text) Physical (binary files, same as on disk)

Speed Slower Faster, especially on large datasets

Backup size Larger Smaller and compressed by default

Incremental support ❌ No ✅ Yes

Restores to different versions ✅ More portable ⚠️ Same version required (or close)

Ease of use in Docker ✅ Very easy ⚠️ More complex to set up in containers

Locks / downtime Uses --single-transaction, minimal locks Zero-downtime hot backups

Supports all engine features (e.g., InnoDB buffer pool dump) ❌ No ✅ Yes

Ideal for Small setups, dev, quick SQL restore Large DBs, production, disaster recovery 🧠 When to Use Which? Use mysqldump if:

You have small-to-medium databases

You need human-readable backups

You want a simple tool for automated daily backups

You want to migrate to another DB server/version easily

Use mariadb-backup if:

You have large datasets (e.g., >1–2 GB)

You need fast, consistent backups with minimal performance impact

You want incremental backups

You need hot backups of InnoDB-heavy workloads

⚙️ Docker Considerations

mariadb-backup is not included in the standard mariadb image. You would need to:

Build a custom image that includes it or

Run a dedicated container to mount the volume and run backups

🔚 Recommendation

For your current setup with WordPress and MediaWiki, mysqldump is likely sufficient, especially if:

The total data size is under ~10 GB

You only need daily full backups

If you want incremental backups or low-overhead hot backups, then it's worth exploring mariadb-backup.

Me: My mariadb installations already include mariadb-backup as well as mariadb-dump and I will be doing daily incremental backups as well.

ChatGPT said:

Great — since you have mariadb-backup available and plan to do daily incremental backups, it's a solid choice. mariadb-backup offers physical backups and is more efficient for large databases or frequent incremental jobs, especially when compared to mysqldump or mariadb-dump, which are logical and slower for large datasets.

Me: I created a docker volume for the db container for the backups, so I don't need to do the "cp":

volumes:

- /var/backups/mariadb:/var/backups/mariadb

ChatGPT said:

Perfect — using a bind mount like this is a clean and efficient way to handle backups.

Me: What frequency of full / incremental backups would be suitable for full backup size of 4.4GB uncompressed / 1.2GB compressed? ChatGPT said:

With a full backup size of 4.4 GB uncompressed / 1.2 GB compressed, here's a recommended backup strategy that balances reliability, storage efficiency, and restore speed: 🔄 Recommended Backup Frequency Backup Type Frequency Reason Full Weekly (e.g. Sundays) Ensures recovery point never lags more than 7 days; keeps storage manageable Incremental Daily (Mon–Sat) Captures daily changes without using much space; fast to create 🧠 Why This Works Well

Incremental backups are typically small unless large data loads or schema changes occur daily.

Weekly full backups avoid overly long restore chains (e.g., restoring a full + 6 incrementals is manageable).

Compressed size of 1.2 GB makes it reasonable to store several weeks/months of full backups.

It also created backup scripts, purge scripts and crontab entries to automate the backup and purge.

- - - - -

Created cron jobs and associated script to create Daily incremental and Weekly full backups:

# Full backup every Sunday at 3:30am 30 3 * * 0 /usr/local/bin/run-full-backup.sh >> /var/log/mariadb/full-backup.log 2>&1 # Incremental backup Mon–Sat at 3:30am 30 3 * * 1-6 /usr/local/bin/run-incremental-backup.sh >> /var/log/mariadb/incremental-backup.log 2>&1

# Prune old incremental backups daily at 4:15am 15 4 * * * /usr/local/bin/prune-incrementals-keep-since-last-full.sh >> /var/log/mariadb/prune-incrementals.log 2>&1

The scripts and backups are in the /var/backup/mariadb directory.

The scripts are as follows:

run-full-backup.sh full-backup.sh run-incremental-backup.sh incremental-backup.sh

prune-incrementals-keep-since-last-full.sh

Note: This script does not remove or compress any full backups - this is left to the system backup.

The "run" scripts are wrappers to be executed on the host. They start the backup scripts inside the container.

The "prune" script removes incremental backups older than the latest "full" backup.

I ran the full backup script to verify its operation and to examine the resulting files and found it ran in a fraction of the time required for mysqldump. The backup was in a folder in /var/backups/mariadb/full named "2025-07-06" - for the date. It also had a symbolic link to the latest full backup:

lrwxrwxrwx 1 root root 36 Jul 6 01:53 latest -> /var/backups/mariadb/full/2025-07-06

The backup folder had the following content:

# ls 2025-07-06 aria_log.00000001 backup-my.cnf ib_logfile0 mariadb_backup_info performance_schema undo001 undo003 wp1_db aria_log_control ibdata1 mariadb_backup_checkpoints mysql sys undo002 wikidb xtrabackup_binlog_pos_innodb

Apparently, it had separate backups for the wiki and wordpress containers.

The backup folder was 5.6 GBytes in size, but compressed to 1.46 GBytes - comparable to a backup with mysqldump:

# ls -l *z -rw-r--r-- 1 root root 1459941761 Jul 6 01:58 2025-07-06.tgz

The "bind mount" makes the backup available inside the docker container and also to the host system - in the same directory path: /var/backups/mysql.

I also requested a script to restore from full and incremental backups. I saved it as "restore-backup.sh". Here was the dialog:

Me: Can you also show scripts to restore from full and incremental backups?

ChatGPT said:

Yes! Here's how you can restore your MariaDB database from a full backup and any incremental backups using mariadb-backup. ✅ Overview

To restore:

Prepare a copy of the full backup with --prepare.

Apply incremental backups in sequence with --prepare --incremental-dir=....

Use --copy-back to restore to the data directory.

Set correct permissions.

We'll assume the following:

Backups are stored in /var/backups/mariadb

Full backups go to /var/backups/mariadb/full/YYYY-MM-DD

Incremental backups go to /var/backups/mariadb/incremental/YYYY-MM-DD-HHMMSS

You want to restore everything under /var/lib/mysql inside the MariaDB Docker container

Fri Jul 4, 2025

Searched for most current / best database backup, found only the one from Jun 22nd. I was again using ChatGPT and found it regularly got stuck in diagnostic loops, having me run the same checks again and again, but with little tweaks. After telling it of the repetition several times, I told it to try disable the nginx_proxy to simplify the problem. Then it wanted to update firewall rules. After updating some rules, the server became totally inoperative, so I switched the DNS record for "wiki" to H2 and gave up for the day to get some much needed sleep.

Thu Jul 3, 2025

Marcin sent email inquiring about Michael's stated concerns about the stability and security of docker containers for the Hetzner server and I inquired os ChatGPT to compare server based vs docker containers and sent the reply to Marcin:

Certainly. Here's a breakdown of the security comparison between Dockerized MediaWiki/WordPress services (behind Nginx HTTPS reverse proxy) and the same setup on a non-Docker (traditional) server, along with an estimate of relative risk.

✅ Key Assumptions

You're using Docker Compose with explicitly named volumes.

Nginx is handling TLS (HTTPS) and acts as a reverse proxy.

Docker host is kept up to date, and containers are built from official or trusted images.

Services are properly configured and not publicly exposing container internals (e.g., admin panels or database ports).

🔐 Security Comparison Summary

Feature / Threat Area

Dockerized Setup (with HTTPS & Reverse Proxy)

Traditional Non-Docker Setup

Notes

Process Isolation

✅ Strong (via container namespaces)

⚠️ Weaker (all services share OS userspace)

Docker provides default namespace & capability isolation

Resource Limits (CPU/mem/disk)

✅ Enforced per-container with cgroups

⚠️ Manual setup needed via ulimit, cgroups, etc.

Docker makes resource limits easier to apply

Reverse Proxy & TLS

✅ Centralized Nginx with certs per service

✅ Centralized Nginx or Apache with similar TLS setup

Equal if configured properly

Service Port Exposure

✅ Only proxy ports exposed (others internal)

⚠️ Manual firewalling required to prevent open ports

Docker networks isolate containers by default

Filesystem Changes / Rollback

✅ Container images immutable + volumes

⚠️ Risk of drift / corruption unless Snapshotted

Docker encourages clean separation

Software Updates & Patching

✅ Easier with versioned images

⚠️ Manual, higher chance of missed patches

Easier to reproduce and test in Docker

Malware Containment

✅ Affected container can be stopped & rebuilt

⚠️ Full host might be compromised

Containers reduce blast radius

Least Privilege Access

✅ Can drop Linux capabilities per container

⚠️ Manual sudo/file permission management

Docker can run unprivileged with fine-tuned capability profiles

Log Separation & Monitoring

✅ Clear per-container logging

⚠️ Harder to manage cleanly for many services

Easier to logrotate/containerize logs

Image Supply Chain Risk

⚠️ Must trust image sources and verify updates

✅ More control over package installations

Docker adds attack surface if images aren't audited

📉 Potential Docker Security Weaknesses

Bad image sources: Always use official base images and pin versions.

Docker daemon = root access: Misconfigured Docker socket (/var/run/docker.sock) can be a severe risk.

Network visibility: Containers on the same bridge network can talk to each other unless restricted.

Volume persistence: Malicious code could write to host-mounted volumes if not read-only or sandboxed.

Recommendations to Harden Docker Setup

Nginx:

Use Let’s Encrypt with auto-renewing certs.

Set Content-Security-Policy, X-Frame-Options, and similar headers.

Disable unused HTTP methods (TRACE, OPTIONS).

Docker:

Use named Docker networks with explicit scoping (ose-net is good).

Run containers as non-root users if possible.

Use read-only mounts where applicable.

Set memory/CPU limits for containers.

Images:

Use official images (e.g., mediawiki, wordpress, mariadb).

Pin versions and scan for vulnerabilities (e.g., docker scan or Trivy).

Keep docker-compose.yml under version control to track image drift.

Container Runtime:

Do not expose the Docker socket (/var/run/docker.sock) to containers.

Consider AppArmor or Seccomp profiles for stricter control.

Database:

Keep MariaDB container internal (no external port).

Use strong credentials, and avoid exposing phpMyAdmin or adminer unless protected.

📊 Security Estimate

Scenario

Security Score (1–10)

Notes

Docker w/ reverse proxy

8.5 / 10

High isolation, maintainable if best practices are followed

Non-Docker (bare metal)

6.5 / 10

Flexible but prone to config drift and greater lateral movement

✅ Verdict

Your current Docker-based architecture with Nginx reverse proxy and HTTPS is more secure than a traditional bare-metal setup if:

You patch regularly,

Use official images and networks correctly,

Limit container capabilities.

Let me know if you'd like a hardening checklist or automated security scan tools (e.g., Docker Bench, Trivy) integrated into your backup or deployment routine.

So I began work on "hardening" the docker installation, starting with switching it to a "rootless" environment.

I was getting assistance from ChatGPT and it had me restart the docker containers and didn't mention the command, so I did a "docker-compose up", but without the "-d" flag. Somehow, this removed the database. After searching through the backups and finding that the database backups weren't complete and would have to search for the most up-to-date complete backup.

Mon Jun 30, 2025

Updated and enabled the “WikiEdit” extension.

Sun Jun 29, 2025

Modified backup script to include everything for the docker installation. Updated and enabled the “WikiEdit” extension, per Marcin.

Sat Jun 28, 2025

Continued debugging and fixed the probable issue, then switched DNS back to H3 - and it worked for the main page (yahoo!). Tried to log in and got an error. Debugged / fixed it and notified Marcin that the migration is largely done. Fixed issues with Iframes, “formatting” issue by upgrading and enabling “ParserFunctions” extention. Enabled “FileUpload” extension.

Fri Jun 27, 2025

Migrated the wiki database and necessary files from my computer to Hetzner3 and began the integration with the existing Docker configuration. Loaded the database, moved the "mediawiki" directory in place, moved the image files from Hetzner2 into the mediawiki folder, tweaked the docker configuration file (docker-compose.yml) and did much testing and re-configuration of the system for running in a docker container, using the shared database and for rendering output to encrypted (https) connections. Did some testing, it seemed to be working, so changed the DNS to point to this server and got errors. Tried a few fixes, but restored the DNS to H2 and stopped sometime after midnight.

Thu Jun 26, 2025

Began the upgrades, upgrading Mediawiki and required softwares from version 1.7 to 1.16 and verifying success, then to 1.29 (failed), then back down to 1.27 (success!), then to 1.35, then to 1.39 LTS (current version). Took backups between updates (just in case) and another backup once complete. Had ChatGPT reorganize the LocalSettings.php file for Mediawiki for a much improved structure, as this is the key config file for Mediawiki.

Wed Jun 25, 2025

Began migration of wiki from Hetzner2 to Hetzner3, with the help of ChatGPT. I needed an intermediate computer for the migration, so I used my own laptop. Downloaded database, images, installed docker and created containers with an version 1.7 of Mediawiki, config files and imported database from hetzner2 backup.

Sun Jun 22, 2025

After spending too much time on trying to get the "Rootless" feature implemented, I decided against the "Rootless" option and removed the config from the server and generated a new docker-compose.yml file, but with some additional features, like healthchecks.

Some detailed information follows.

- - - - -

Description of your docker-compose.yml:

This docker-compose.yml defines a multi-container application setup with:

Nginx reverse proxy

Two CMS containers: WordPress and MediaWiki

MariaDB database container

Persistent volumes for data and uploads

Services 1. nginx_proxy

Image: nginx:alpine (lightweight official Nginx image)

Purpose: Acts as a reverse proxy to route incoming HTTP/HTTPS traffic to your WordPress and MediaWiki containers.

Ports:

Exposes host ports 80 (HTTP) and 443 (HTTPS) mapped to container.

Volumes:

Loads a custom Nginx configuration from ./nginx/nginx.conf.

Mounts SSL certificates from /etc/letsencrypt/live/mydomain.com (read-only).

Dependencies: Waits for WordPress (wp1) and MediaWiki (mediawiki) services to start.

2. wp1 (WordPress site)

Image: wordpress (official WordPress image)

Container name: learn

Purpose: Runs a WordPress site connected to the MariaDB database.

Environment Variables:

Database host (db container)

Database name, user, and password (from environment variables for security)

Expose: Exposes port 80 internally for communication with Nginx proxy.

Volumes:

Named volume wp1_uploads mounted to /var/www/html/wp-content/uploads to persist WordPress uploads (images, documents).

Depends on: MariaDB database (db).

3. mediawiki (MediaWiki site)

Image: mediawiki (official MediaWiki image)

Container name: wiki

Purpose: Runs a MediaWiki site connected to the same MariaDB database.

Environment Variables:

Database host, name, user, and password.

Expose: Port 80 internally for Nginx proxy.

Volumes:

Named volume mediawiki_images mounted to /var/www/html/images for MediaWiki uploaded files.

Depends on: MariaDB database (db).

4. db (MariaDB database)

Image: mariadb (official MariaDB image)

Container name: db

Purpose: Provides the database backend for WordPress and MediaWiki.

Environment Variables:

Root password is supplied securely via environment variable.

Volumes:

Named volume dbdata mounted to /var/lib/mysql to persist all database data.

Volumes