D3D CNC Circuit Mill: Difference between revisions

No edit summary |

|||

| Line 10: | Line 10: | ||

=Feb 2018 Update= | =Feb 2018 Update= | ||

<html><iframe src="http://opencircuitinstitute.org/content/circuit-mill-development-log-z-slip-fixed-promising-results#comment-form"></iframe></html> | <html><iframe src="http://opencircuitinstitute.org/content/circuit-mill-development-log-z-slip-fixed-promising-results#comment-form" height=500 width=500></iframe></html> | ||

=September 2017 Update= | =September 2017 Update= | ||

Revision as of 07:35, 16 February 2018

Basics

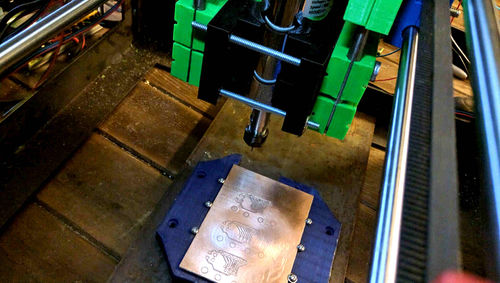

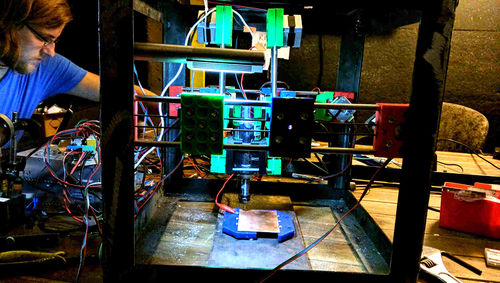

- A CNC mill used for PCB Milling

- Can't make as small of traces as a lithography+ethcing system, BUT it is far cheaper and easier to use (ie no chemical etchants or photoresists needed)

- Uses the D3D Univeral Axis

Used For

Feb 2018 Update

September 2017 Update

July 2017

Development Pictures

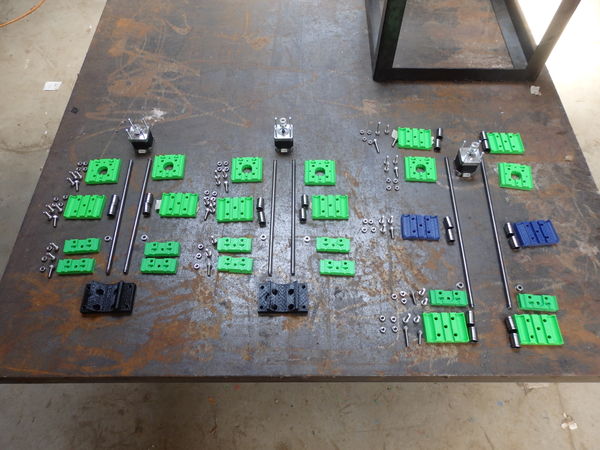

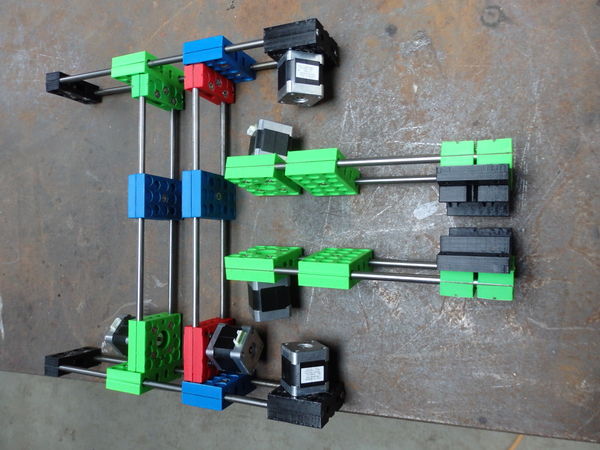

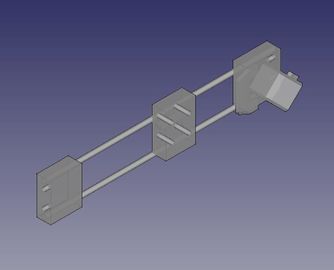

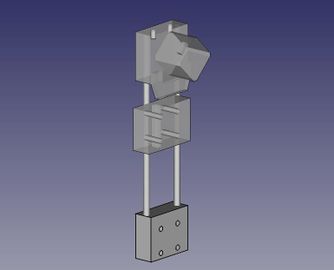

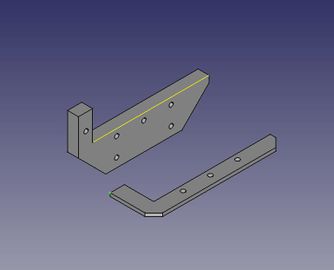

The disassembled axes required to convert the D3D printer to the circuit board mill

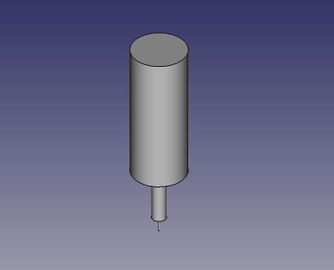

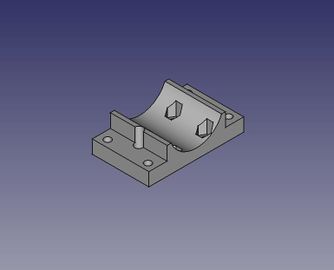

These are the required additional parts to transition from the 3D printer to the circuit board mill

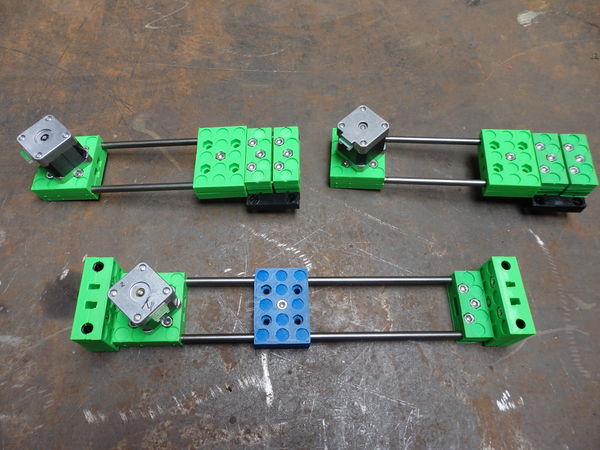

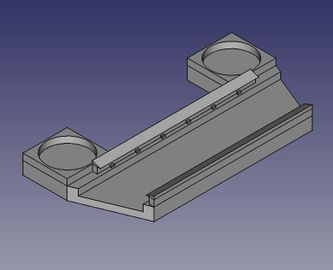

The complete set of axes for the D3D circuit mill

Working Document

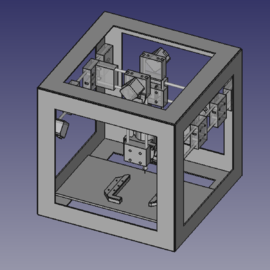

Design

Data Collection

CAD files

Simplified Files

Assembly: File:D3D Circuit Mill.fcstd

D3D frame 16": File:D3D frame assembled 16 inch.FCStd

Single x axis: File:D3D Circuit Mill X Axis.fcstd

Single y axis: File:D3D Circuit Mill Y Axis.fcstd

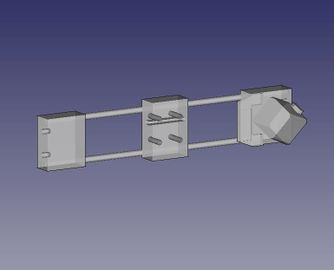

Single z axis: File:D3D Circuit Mill Z Axis.fcstd

spindle motor: File:T-king spindlemotor.fcstd

Spindle Motor Mount: File:D3D Circuit Mill Motor Mount.fcstd

PCB holder: File:PCBholder simplified.FCStd

Accurate Files

3x End Stop interface: File:D3D End stop interface.fcstd

16x carriage piece: [[1]]

16x idler piece short: [[2]]

12x motor piece: [[3]]

2x Spindle Motor Mount: File:D3D Circuit Mill Motor Mount.fcstd

PCB holder: [[4]]

List of Files

- Assembly: File:D3D Circuit Mill.fcstd

- Frame 16" assembled: File:Full Frame 16in.FCStd

- Single 16" frame: File:Single Frame 16in.fcstd

- Single x axis: File:D3D Circuit Mill X Axis.fcstd

- Single y axis: File:D3D Circuit Mill Y Axis.fcstd

- Single z axis: File:D3D Circuit Mill Z Axis.fcstd

- Spindle Motor: File:T-king spindlemotor.fcstd

- Spindle Motor Mount: File:D3D Circuit Mill Motor Mount.fcstd. STL - File:D3D Circuit Mill Motor Mount.stl

- PCB Holder: File:D3dcnccm PCB holder.stl File:PCBholder simplified.FCStd

Design Notes

Note on CAD Procedure and Organization:

- Draw a frame piece, and create a complete frame made of 6 of these pieces.

- Save file: File:D3D 13" Frame.fcstd

- Begin the design by downloading the X axis - File:D3D 16 Sub-assembly X Axis.fcstd

- Correct the length of the axis to 11" length (for 13" frame - 1" shorter on each side to accommodate mounting on the Y axes). Rotate the axis such that the orientation - when looking according to the Viewing Direction and XYZ axis orientation of Slide 1 in Working Document - is that the motor is on the left side of the axis (note that the orientation shown in First Slide in the Working Document has the motor on the right hand side, which is not correct).

- Save the file as File:D3D Circuit Mill X Axis.fcstd once the length is 11" and orientation is correct. This will be the file you can use later for the x axis (2 of them) to merge into the final assembly - with the second x axis being a mirror image.

- Now create the Y axis according to the orientation convention of the First Slide in the Working Document. This axis should be 13" long.

- Save the y axis file as File:D3D Circuit Mill Y Axis.fcstd.

- Now create the Z axis as in the working document. This axis can be 8" long - as we don't need a lot of z travel.

- Save the Z axis file as File:D3D Circuit Mill Z Axis.fcstd.

- Import the

Industry Standards

- Hackaday projects - [5]

Existing Open Source Designs

See Also

Usefull Links

![16x carriage piece: [[1]]](/images/thumb/6/65/Universal_axis_carriage_side.jpeg/324px-Universal_axis_carriage_side.jpeg)

![16x idler piece short: [[2]]](/images/thumb/d/d4/Universal_Axis_Idler_piece_short_complex.jpeg/333px-Universal_Axis_Idler_piece_short_complex.jpeg)

![12x motor piece: [[3]]](/images/thumb/9/91/Universal_axis_motor_side_complex.jpeg/324px-Universal_axis_motor_side_complex.jpeg)

![PCB holder: [[4]]](/images/thumb/6/6d/PCBholderaccurate.jpeg/344px-PCBholderaccurate.jpeg)