RepRap: Difference between revisions

No edit summary |

Marie.Byleen (talk | contribs) mNo edit summary |

||

| Line 1: | Line 1: | ||

{{Template:Category=RepRap}} | |||

[[Image:reprapicon.jpg|right|250px]]RepRap - the self '''rep'''licating '''rap'''id prototyper- is a 3D printer, a machine capable of instantiating any shape you can think of in plastic. It was designed to be able to replicate all its own structural components. It is one of the most famous and successful open hardware projects completed to date and is a key tool in [[RepLab]], our proposed self-replicating [[Digital Fabrication|digital fabrication]] workshop. | [[Image:reprapicon.jpg|right|250px]]RepRap - the self '''rep'''licating '''rap'''id prototyper- is a 3D printer, a machine capable of instantiating any shape you can think of in plastic. It was designed to be able to replicate all its own structural components. It is one of the most famous and successful open hardware projects completed to date and is a key tool in [[RepLab]], our proposed self-replicating [[Digital Fabrication|digital fabrication]] workshop. | ||

Revision as of 15:33, 21 January 2011

Main > Digital Fabrication > RepLab Tools > RepRap

RepRap - the self replicating rapid prototyper- is a 3D printer, a machine capable of instantiating any shape you can think of in plastic. It was designed to be able to replicate all its own structural components. It is one of the most famous and successful open hardware projects completed to date and is a key tool in RepLab, our proposed self-replicating digital fabrication workshop.

The plastic shapes that RepRap prints can even be used as molds for casting metal objects, for example the Solar Turbine Prototype at Factor e Farm. Its primary feedstock is PLA (polylactic acid). This can be made by fermenting starch.

RepRap.org is the projects home page, and includes very clear instructions on how to build your own RepRap.

The open-source designs allow a great deal of flexibility and customization. A digitally-controlled tool that is free to move in three dimensions has many uses beyond 3D printing plastic. It has also been used to print circuit boards by replacing the plastic extruder head with a small router. The motors and control board have been adapted for our Torch Table

RepRap, like all healthy open-source projects, is continually evolving. The picture to the right shows the first generation, called Darwin. There is now a second generation RepRap called Mendel and there are prototypes of the third generation: Huxley. (All RepRap iterations are called after prominent biologists because RepRap is technology with the biological attributes of evolution and self-replication.)

- Also adaptable to solid state laser head, so it could do circuits via lithography?

- Connecting rods extrudable on a small scale, see Metal Extrusion Specifications

- Rapid Prototyping

Latest Update - 9.20.09

Chris of HydraRaptor just printed a set of parts for the Factor e Farm RepRap. See his blog post on the replication.

Here are some additional pictures:

Electronics

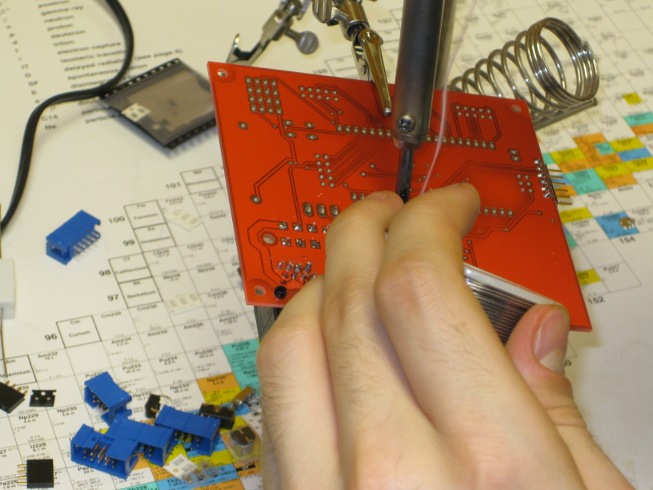

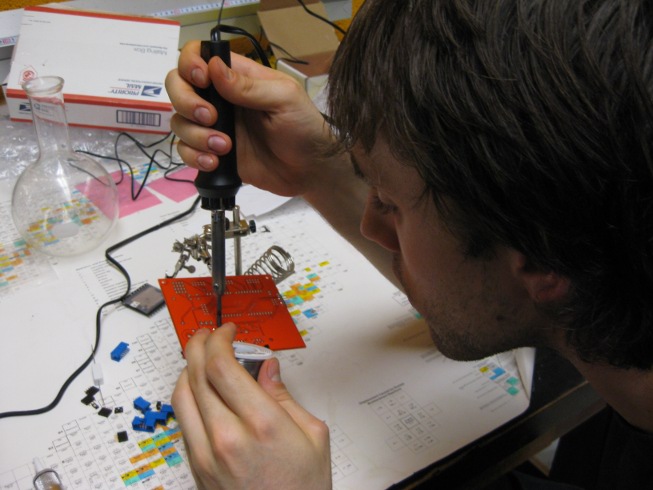

The newest generation of reprap electronics is Generation 3. http://reprap.org/bin/view/Main/Generation3Electronics

Here is Edward, one of our True Fans, holding up the semi-completed Motherboard which he will use to build Factor e Farm's first

The chips come in kits that must be soldered and surface mounted.

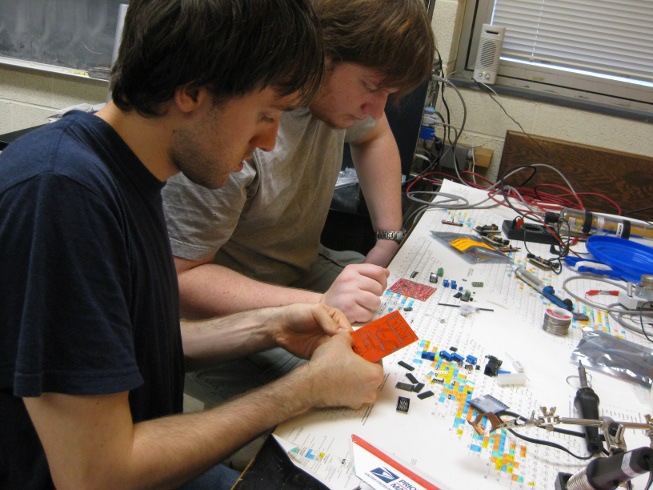

Here is Edward and a friend working on the Motherboard and Extruder Controller.

Sourcing

- z axis motors - http://www.surplusshed.com/pages/item/m2038p.html they are $4.50,

- and here http://www.surplusshed.com/pages/item/r2028.html they are only $2.00!

open questions

- Can the RepRap print out a working steam engine? See Steam Engine Construction Set.

In Spanish, a comment about convergence of open technologies: http://imagina-canarias.blogspot.com/2008/10/convergencia-de-tecnologas-abiertas.html