D3D Ohio v18.02: Difference between revisions

(added pics of assym so far before starting today's work) |

|||

| Line 68: | Line 68: | ||

all cuts took a half hour. I like this fit. ! Pictures as soon as I get my file server up again... | all cuts took a half hour. I like this fit. ! Pictures as soon as I get my file server up again... | ||

Update 5/20 picture of build at this time: | |||

[[File:5 8 d3d Build.jpg|1000x1000px|border|PVC frame and X and Y assym]] | |||

===3/2/2018=== | ===3/2/2018=== | ||

Revision as of 17:50, 20 May 2018

Basics

- A variation of the D3D 3D Plastic FDM Printer that has a 12 inch print bed, Made with a PVC frame

http://opensourceecology.org/wiki/D3D_Extruder

CAD

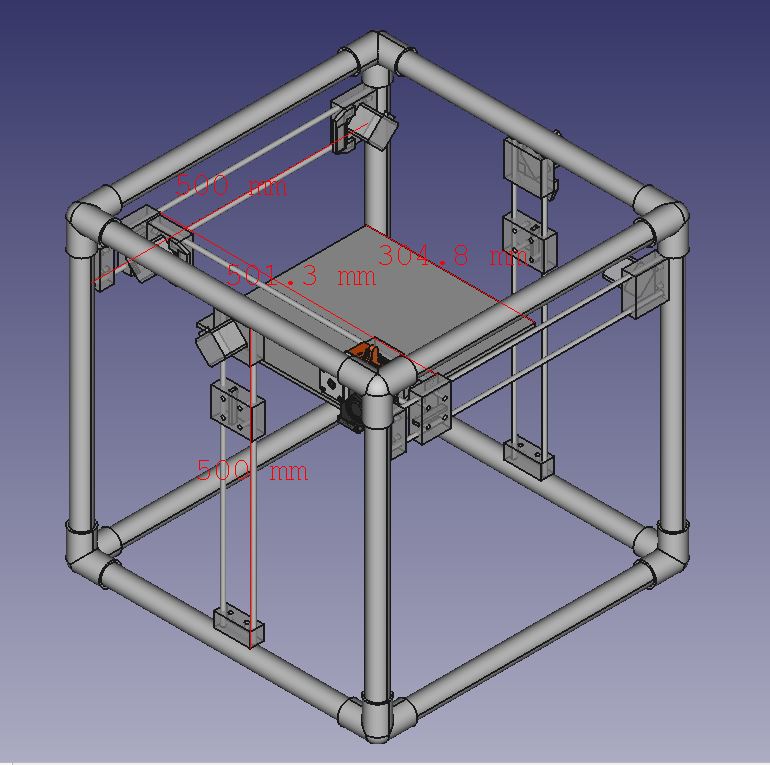

Most recent Render: http://opensourceecology.org/wiki/File:D3D_OHIO_18.01_V0.3_WIP.fcstd

BOM

- Sensor - 8 mm sensing - 18 mm diameter - [1]

Modeling

The intention of this section is to show the most up-to-date CAD module visually as it is developed. Versus the development log, this will attempt to show the "best" work or "Stable" versions

V1.0.0 Latest version uploaded.

-Uses short idler. 500mm steel rods. allows for an extra inch on x and y axis.

V0.3 DONE - This will be a rendering with 1" PVC tube and corners, 12" bed and a http://opensourceecology.org/wiki/File:Prusa_i3_mk2_extruder_adapted.fcstd extruder changed for what is currently present in V0.2

This file has been uploaded as is, currently we just have some part movement and a 12" bed

FILE V1.0

12" bed. check calcs for measurements. File:D3D OHIO 18.01 V0.3 WIP.fcstd

Video

Packing

Development

[WIP NEEDS DONE}

Development Log

5/8/2018

To get this up to date, the CAD is rendered.

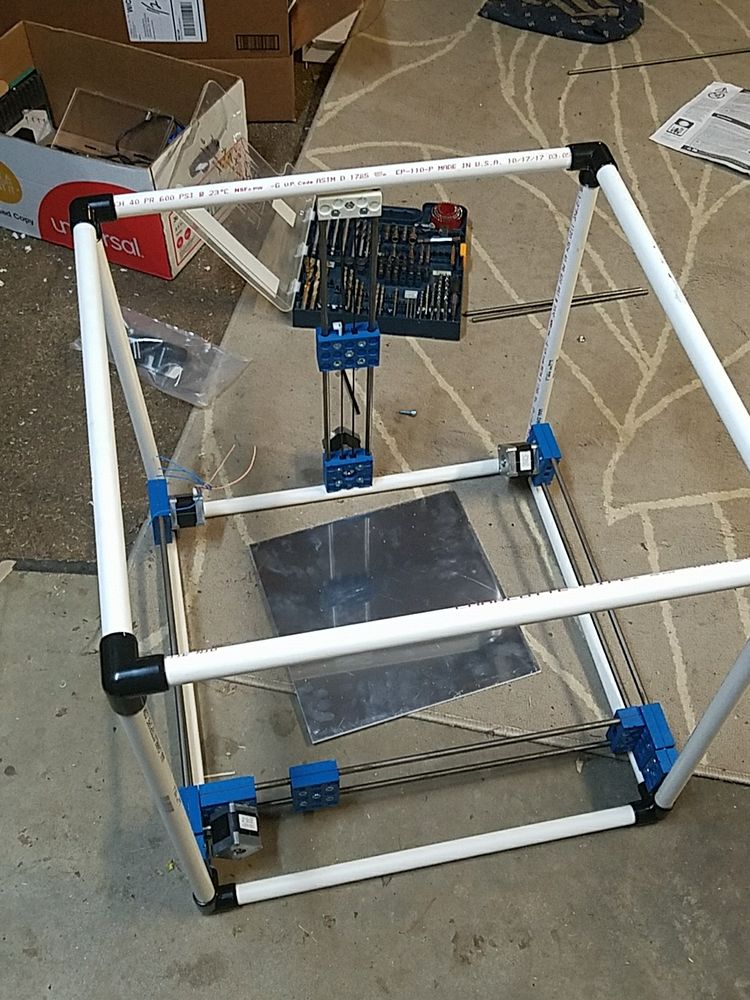

Today, I am assymbuling the printer. I have 4 of the Universal Axis Units built, but only have the timing belt in one of them.

GOAL: From today, I am going to try and cut the PVC pipes.

11:30 From the D3D frame gen, I have a pipe length of precisely 493.546mm that's 19.43094488"... so, I'll rationalize this down to 19 1/25" because then, you can push the pipe in so it totally snugly grabs around the corner fitting. I'll see how this cut works.

all cuts took a half hour. I like this fit. ! Pictures as soon as I get my file server up again...

Update 5/20 picture of build at this time:

3/2/2018

Found a Basis for a render http://opensourceecology.org/wiki/File:Medium_Size_Version_12_in.FCStd

I have a great deal to learn in Freecad on more adv. assym work. Such as how There are parameters for assymblies, and there is a linked parameter for rod lenght between the Right and left Y universal axis so you can change lenght in one spot. super cool.

See Also

- D3D

- 3d Printing Techniques

- Open Source Digital Fabrication Construction Set

- D3D 1612 Product Manual

- TakacsLog

Useful Links

- Here is a note on the simplified model - https://www.youtube.com/watch?time_continue=38&v=Epit8c9zp8Q

- here are the simplified models we will build this off of past v0.3:http://opensourceecology.org/wiki/D3D_CNC_Circuit_Mill

- http://opensourceecology.org/wiki/3D_Printer_Genealogy

- https://www.youtube.com/watch?v=a7XAZhXt6Hk&feature=youtu.be

- D3D v18.02 BOM

- http://opensourceecology.org/wiki/D3D_Part_Library#Assembly_Index - This is all of our D3D assy. modules so far.

- http://opensourceecology.org/wiki/File:Prusa_i3_mk2_extruder_adapted.fcstd Extruder we will use