D3D CNC Circuit Mill: Difference between revisions

(→BOM) |

|||

| Line 3: | Line 3: | ||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10214031283793314&width=500" width="500" height="752" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe></html> | <html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10214031283793314&width=500" width="500" height="752" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe></html> | ||

=Publication= | |||

Published in ''Inventions'', http://mdpi.com/2411-5134/3/3/64 | |||

=Build Instructions= | =Build Instructions= | ||

*Drill frame | *Drill frame | ||

Revision as of 05:48, 11 September 2018

![]() Hint: July 2018 - OSE Germany is working on a version of their MPPT Solar Charge Controller which can be filled with the OSE D3D CNC Circuit Mill - https://github.com/LibreSolar/MPPT-Charger_20A/issues/28

Hint: July 2018 - OSE Germany is working on a version of their MPPT Solar Charge Controller which can be filled with the OSE D3D CNC Circuit Mill - https://github.com/LibreSolar/MPPT-Charger_20A/issues/28

Publication

Published in Inventions, http://mdpi.com/2411-5134/3/3/64

Build Instructions

- Drill frame

- Do Cut List below - rods, belt

- Cut bed plate

- Assemble electronics mounting plate

- Assemble spindle in holder

- Test electronics - motion

- Test calibration code

- Run a milling job

Cut List

(400, 350, and 300 lengths would work)

- Belt - x - [2] 29"

- Belt - y - [2] 33"

- Belt - z - [2] 23"

- Rods - x - [4] 14"- = 56"

- Rods - y - [4] 16"- = 64"

- Rods - z - [4] 11" = 44"

- Frame if welded from flats - [24] 1/8"x1"x15" flats -

- Electronics mounting panel - 1/10" plexiglass - 8"x16"

Rods if Using 6' Stock

Try 1

- If use 6 foot stock- 72" - 4x11=44 + 28 = 72.

- 4x16 = 64 (8 left over). It's useful to rework design to allow for 8" rod on Z

- 2x14 = 28 (44 left over)

- 3 rods needed for 162" = 13.5'

Try 2

- 4x14 + 16 => perfect.

- 3x16 + 2x11 = 70 for 2" left over- great.

- 2x11 = 22 with 50 left over. Nice.

Continuing:

- 3x16= 2" left over from last one.

- 4x14 + 16 => perfect

- 1x16+4x11 = 60 - 12 left over.

Basics

- A CNC mill used for PCB Milling

- Can't make as small of traces as a lithography+ethcing system, BUT it is far cheaper and easier to use (ie no chemical etchants or photoresists needed)

- Uses the D3D Univeral Axis

July 2017

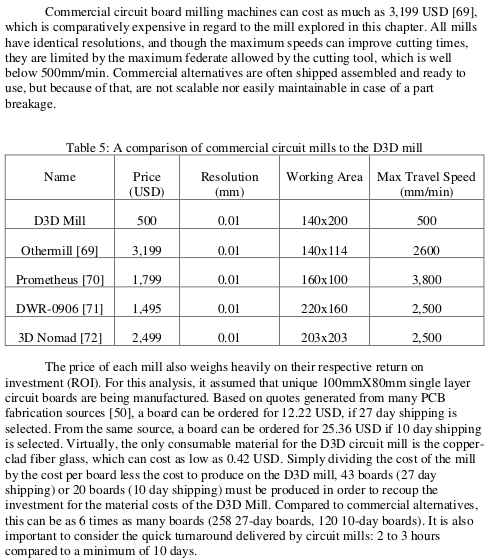

Comparison to Industry Standards

BOM

Other Supplies

Single Sided Copper Clad Laminate PCB Circuit Board 4X3 (50pcs) Paramount CCL Link: http://a.co/3YcKSBe

Xuchuan 10Pcs PCB Print Circuit Board Carbide Micro Drill Bits 0.3-1.2mm Xuchuan Link: http://a.co/0KviIvf

JIUWU 1.0mm Tungsten Steel Carbide PCB CNC End Mill Engraving Bits Milling Machine Pack of 10 by JIUWU Link: http://a.co/1CL0H32

You can try these tools out - they are inexpensive and may yield good results for milling traces. But if you run into issues, the tools are likely chipping Autek 10x Titanium Coated Carbide PCB Engraving CNC Bit Router Tool 30 Degree 0.1mm Tip(J3.3001Tix10) by Autek Link: http://a.co/6UR8F9T

Instead it may be good to opt for higher quality milling tools. They should last a good long while:

Universal Milling Tools 100% Carbide universal milling tool for milling printed circuit board isolation tracks. V-shaped profile for variable milling width. 1.42" (36 mm) overall length.

https://www.lpkfusa.com/Store/pages/ProductDetail.aspx?cat=11%2f42&cid=42&pid=30

All Industrial Tool Supply TR72020 Dial Indicator (Magnetic Base and Point Precision Inspection Set), 1 Pack by All Industrial Tool Supply Link: http://a.co/5EgkHa0

Software: See this link - it has all of the software we used and then some: http://opencircuitinstitute.org/content/software

Additionally here is my web-based leveling utility: http://voltfolio.com/utilities/levelgcode.html

https://www.lpkfusa.com/Store/pages/ProductDetail.aspx?cat=11%2f38&cid=38&pid=76

Sorry I must make one amendment - I linked the incorrect milling tools from LPKF. Here are the correct ones:

https://www.lpkfusa.com/Store/pages/ProductDetail.aspx?cat=11%2f38&cid=38&pid=76

vBOM

Visual BOM:

Calculations

Sources

- File:Backlash Pattern.odg - editable drawing of backlash pattern.

Electronics

Source

- Diagram in Libre Office - File:D3D Circuit Diagram.odg

Videos

- Mill Experiment - Backlash Compensation Stress Test - [5]

- Leveled circuit - holder slides at the end - [6]

- Mill Experiment - Large Leveled Circuit Take 2 - [7]

- Auto Probing Experiment - [8]

- Stepper driver breakout board - [9]

Workshop Preparation

Development Template

Burndown

Feb 2018 Update

September 2017 Update

Development Pictures

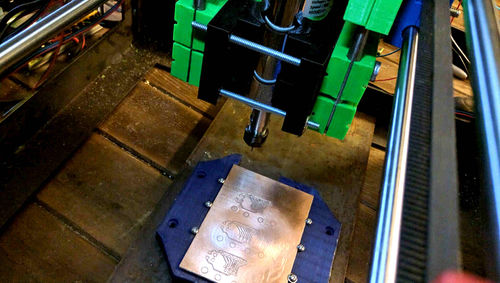

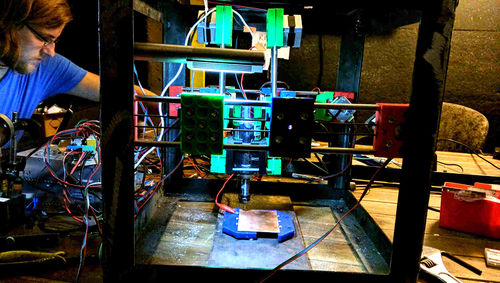

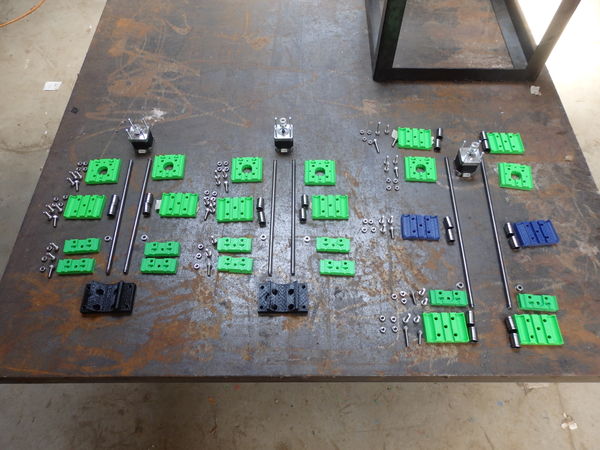

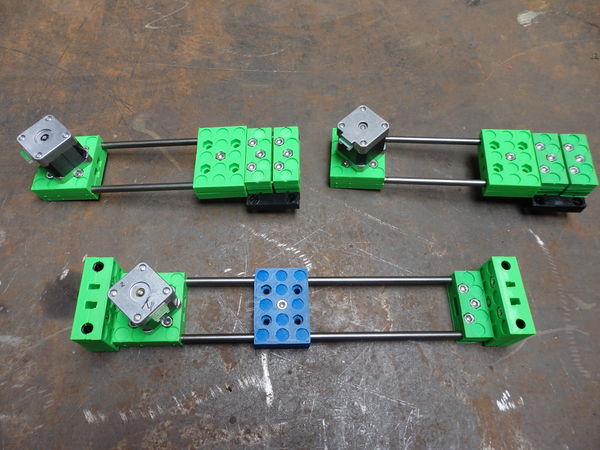

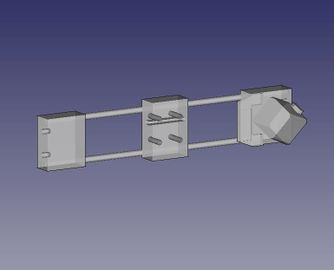

The disassembled axes required to convert the D3D printer to the circuit board mill

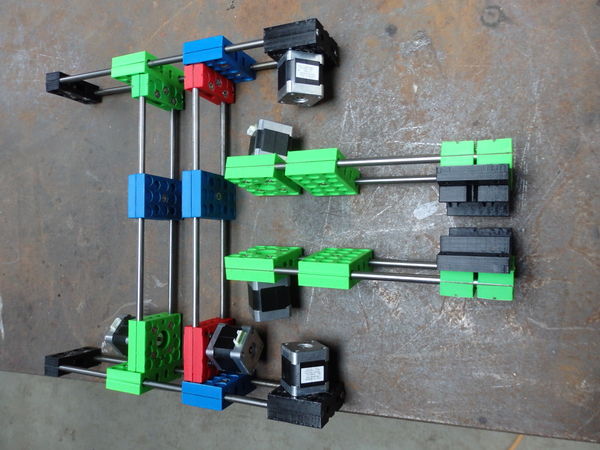

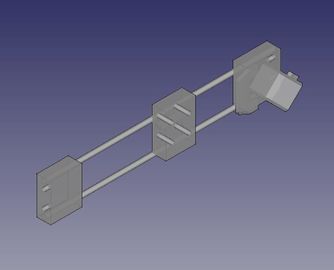

These are the required additional parts to transition from the 3D printer to the circuit board mill

The complete set of axes for the D3D circuit mill

Working Document

Design

Data Collection

CAD files

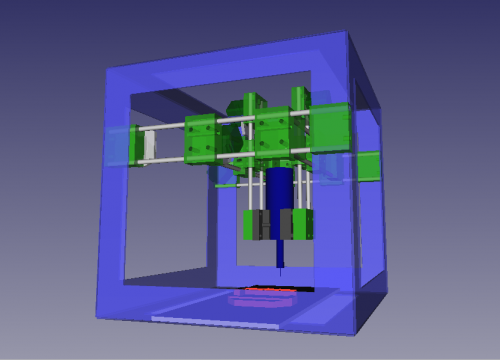

- Assembly: File:D3D Circuit Mill.fcstd

Simplified Files

Assembly: File:D3D Circuit Mill.fcstd

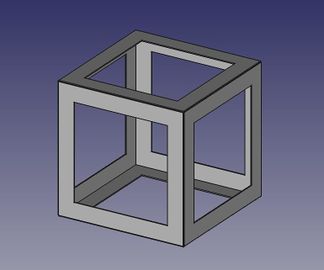

D3D frame 16": File:D3D frame assembled 16 inch.FCStd

Single x axis: File:D3D Circuit Mill X Axis.fcstd

Single y axis: File:D3D Circuit Mill Y Axis.fcstd

Single z axis: File:D3D Circuit Mill Z Axis.fcstd

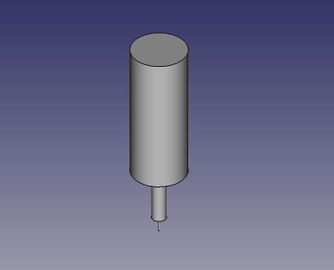

spindle motor: File:T-king spindlemotor.fcstd

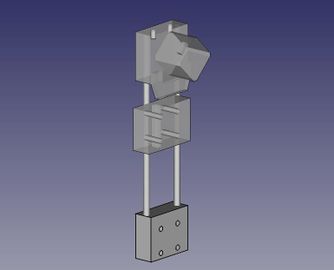

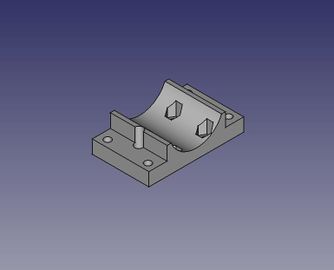

Spindle Motor Mount: File:D3D Circuit Mill Motor Mount.fcstd

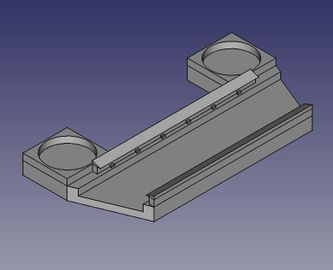

PCB holder: File:PCBholder simplified.FCStd

Accurate Files

3x End Stop interface: File:D3D End stop interface.fcstd

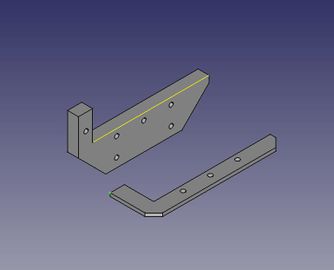

16x carriage piece: [[1]]

16x idler piece short: [[2]]

12x motor piece: [[3]]

2x Spindle Motor Mount: File:D3D Circuit Mill Motor Mount.fcstd

PCB holder: [[4]] and File:D3dcnccm PCB holder.stl

List of Files

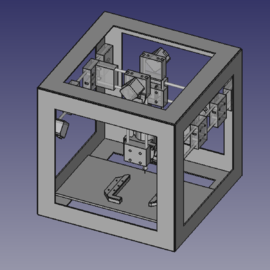

- Assembly: File:D3D Circuit Mill.fcstd

- Frame 16" assembled: File:Full Frame 16in.FCStd

- Single 16" frame: File:Single Frame 16in.fcstd

- Single x axis: File:D3D Circuit Mill X Axis.fcstd

- Single y axis: File:D3D Circuit Mill Y Axis.fcstd

- Single z axis: File:D3D Circuit Mill Z Axis.fcstd

- Spindle Motor: File:T-king spindlemotor.fcstd

- Spindle Motor Mount: File:D3D Circuit Mill Motor Mount.fcstd. STL - File:D3D Circuit Mill Motor Mount.stl

- PCB Holder: File:D3dcnccm PCB holder.stl File:PCBholder simplified.FCStd

Design Notes

Note on CAD Procedure and Organization:

- Draw a frame piece, and create a complete frame made of 6 of these pieces.

- Save file: File:D3D 13" Frame.fcstd

- Begin the design by downloading the X axis - File:D3D 16 Sub-assembly X Axis.fcstd

- Correct the length of the axis to 11" length (for 13" frame - 1" shorter on each side to accommodate mounting on the Y axes). Rotate the axis such that the orientation - when looking according to the Viewing Direction and XYZ axis orientation of Slide 1 in Working Document - is that the motor is on the left side of the axis (note that the orientation shown in First Slide in the Working Document has the motor on the right hand side, which is not correct).

- Save the file as File:D3D Circuit Mill X Axis.fcstd once the length is 11" and orientation is correct. This will be the file you can use later for the x axis (2 of them) to merge into the final assembly - with the second x axis being a mirror image.

- Now create the Y axis according to the orientation convention of the First Slide in the Working Document. This axis should be 13" long.

- Save the y axis file as File:D3D Circuit Mill Y Axis.fcstd.

- Now create the Z axis as in the working document. This axis can be 8" long - as we don't need a lot of z travel.

- Save the Z axis file as File:D3D Circuit Mill Z Axis.fcstd.

- Import the

Industry Standards

Existing Open Source Designs

Curriculum

- Working doc - [12]

See Also

Useful Links

- Tom's Guide 2018 discussing inferiority of mill conversions - [13]

![16x carriage piece: [[1]]](/images/thumb/6/65/Universal_axis_carriage_side.jpeg/324px-Universal_axis_carriage_side.jpeg)

![16x idler piece short: [[2]]](/images/thumb/d/d4/Universal_Axis_Idler_piece_short_complex.jpeg/333px-Universal_Axis_Idler_piece_short_complex.jpeg)

![12x motor piece: [[3]]](/images/thumb/9/91/Universal_axis_motor_side_complex.jpeg/324px-Universal_axis_motor_side_complex.jpeg)

![PCB holder: [[4]] and File:D3dcnccm PCB holder.stl](/images/thumb/6/6d/PCBholderaccurate.jpeg/344px-PCBholderaccurate.jpeg)