Stepper Motor: Difference between revisions

No edit summary |

No edit summary |

||

| Line 3: | Line 3: | ||

A stepper motor (or step motor) is a brushless, electric motor that can divide a full rotation into a large number of steps. The motor's position can be controlled precisely without any feedback mechanism (see Open-loop controller), as long as the motor is carefully sized to the application. | A stepper motor (or step motor) is a brushless, electric motor that can divide a full rotation into a large number of steps. The motor's position can be controlled precisely without any feedback mechanism (see Open-loop controller), as long as the motor is carefully sized to the application. | ||

=How Stepper Motors Work= | =How Stepper Motors Work= | ||

| Line 12: | Line 9: | ||

*https://www.motioncontroltips.com/faq-what-are-stepper-drives-and-how-do-they-work/ | *https://www.motioncontroltips.com/faq-what-are-stepper-drives-and-how-do-they-work/ | ||

=Holding Torque vs Moving Torque= | |||

*125 oz in hold for nema 17, example - [https://www.digikey.com/product-detail/en/sparkfun-electronics/ROB-13656/1568-1376-ND/5995079?&gclid=EAIaIQobChMIvZKS_-jK3wIVBi1pCh0n5Qx7EAQYASABEgL2GvD_BwE] | |||

=Gecko Drives Tutorial= | =Gecko Drives Tutorial= | ||

Revision as of 18:46, 15 April 2019

Overview

A stepper motor (or step motor) is a brushless, electric motor that can divide a full rotation into a large number of steps. The motor's position can be controlled precisely without any feedback mechanism (see Open-loop controller), as long as the motor is carefully sized to the application.

How Stepper Motors Work

- See good overview of 2-rotor stepper motors - [1]

- Difference between 2 phase and 5 phase stepper motors - [2]

Holding Torque vs Moving Torque

- 125 oz in hold for nema 17, example - [3]

Gecko Drives Tutorial

Good start.

Voltage

Running steppers at higher voltage produces more torque. 20x rated voltage is ok. [4]

Gecko Drives Tutorial

Good start.

Voltage

Running steppers at higher voltage produces more torque. 20x rated voltage is ok. [5]

Lifetime

The typical lifetime for a stepper motor is 10,000 operating hours. This approximates to 4.8 years; given the stepper motor operates one eight-hour shift per day. The lifetime of a stepper motor may vary in regards to user application and how rigorous the stepper motor is run.[6]

See Also

- Open Source Stepper Motor

- Stepper Motor Controller

- Rotary Encoder

- Open Source Stepper Motor Controller

- Open Source Stepper Motor Controller Problem Statement

- Torch Table Bill of Materials

- Motor

- Wikipedia: Stepper Motor

- [7]

- Stepper Overview Youtube Video

Torque Tests

Test 1

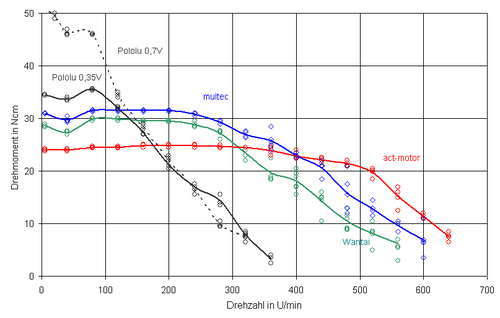

This test used Nema17 stepper motors driven by A4988 driver boards http://reprap.org/wiki/Stepper_torque

Summary: All motors perform well at speeds < 100 revs/min. Dynamical torque starts to drop off at speeds higher than 300 rev/min. The higher the rated current and the lower the inductance, the better the performance at high speeds.

inside a stepper motor

- http://www.homemodelenginemachinist.com/index.php?topic=6748.0

- http://www.robotgear.com.au/Cache/Files/ProductImageOriginals/676_The%20inside%20of%20a%20bipolar%20stepper%20motor.jpg

- http://www.bg-cnc.com/wordpress/wp-content/uploads/2011/01/631.jpg

- http://www.designworldonline.com/articles/5409/267/New-Stepper-Motors-Beat-Corrosion-Without-Seals.aspx

- https://www.cdli.ca/courses/isys1205/unit02_org05_ilo07/b_activity.html

- http://electronics-control.info/Stepper_types.htm

- http://electronic-schematic.blogspot.com/2011/04/circuit-for-driving-stepper-motors.html

- http://www.cibomahto.com/2008/02/thing-a-day-day-20-dissecting-stepper-motors/

Types of Stepper Motors

- 17PM-K402 - Hybrid 2 and 4 phase - 6 volts rated - [8] - RAMPS wouldn't run it.

- 12 V rated - [9] - RAMPS wouldn't run it

Sourcing

NEMA 34

Driver

Small

By Origin

- MAE Ametek - made in eu

- Oriental Motor - made in japan