LifeTrac III/Manufacturing Instructions: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

{{ToolBuildOperate|ToolParent=LifeTrac|ToolName=LifeTrac III}} | {{ToolBuildOperate|ToolParent=LifeTrac|ToolName=LifeTrac III}} | ||

{{LifeTrac Manufacturing Instructions Navbox}} | {{LifeTrac Manufacturing Instructions Navbox}} | ||

=Overview= | |||

This page gives you all the information you need to make your LifeTrac III from stock steel and parts. | |||

Please note that the LifeTrac III uses one or two [[Power_Cube|Power Cubes]] to provide power. Please see the [[Power_Cube/Manufacturing_Instructions| Power Cube Manufacturing Instructions]] for information on how to manufacture it. | |||

{{Warning|The LifeTrac design is in development. Some information contained in these pages may be out of date.}} | |||

=Tools and Materials= | =Tools and Materials= | ||

| Line 14: | Line 21: | ||

https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdFVFLWd1Y21fTllEb3JJNjhDd2dYZUE | https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdFVFLWd1Y21fTllEb3JJNjhDd2dYZUE | ||

==Preparation== | ==Preparation== | ||

Revision as of 20:47, 25 January 2012

| LifeTrac / LifeTrac III |

|

|---|---|

| Home | Research & Development | Build It | User's Manual | Community Feedback | |

| Manufacturing Instructions | BOM | CAD & CAM Files | Additional Resources |

| ||||||||||||||||||||||||||

Overview

This page gives you all the information you need to make your LifeTrac III from stock steel and parts.

Please note that the LifeTrac III uses one or two Power Cubes to provide power. Please see the Power Cube Manufacturing Instructions for information on how to manufacture it.

![]() Warning: The LifeTrac design is in development. Some information contained in these pages may be out of date.

Warning: The LifeTrac design is in development. Some information contained in these pages may be out of date.

Tools and Materials

- Edit

https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdFVFLWd1Y21fTllEb3JJNjhDd2dYZUE

Preparation

Safety

- Hearing Protection

- Eye Protection

- Steel Toe Boots

- Welding

- Gloves

- Hood

- Apron/Jacket

Workspace

This section describes the various workspace areas that we have found to be useful in fabricating the LifeTrac. It is provided as a suggestion for preparing your work area.

- Storage: For raw steel and parts

- Cutting Area: For use with cutting torch - Made from non-flammable materials

- Welding Table: Usually steel, suitable for use with arc welder (MIG, TIG, stick, etc)

- Ventilation for cutting / welding areas

Tools

- Welder

- Angle Grinder

- Hand Tools

- Crescent wrench

- Socket set

- Hammer

- Metal Cutting Tools

- Bandsaw

- Chopsaw

- Torch

- Paint Tools

- Gravity Fed Paint Sprayer

- Air compressor

Cut Sheet

- This list contains instructions for cutting the raw steel into pieces for assembly. Most will require further cuts before being ready for assembly.

3/8” Thick, 8" Plate

- 4 @ 12 1/2"

1/2" Thick, 4" Plate

- 6 @ 6"

- 8 @ 4" (cut each diagonally for 16 triangles)

1/2" Thick, 8" Plate

- 4 @ 6"

- 8 @ 10"

1/2" Thick, 10" Plate

- 8 @ 10"

- 4 @ 6 3/4"

1/2" Thick, 12" Plate

- 5 @ 12"

1" Thick, 8" Plate

- 4 @ 4 1/2"

1/2” Thick, 4" x 6" Angle

- 4 @ 6"

¼” Thick, 2 3/8" Dia Steel Tube

- 1 @ 4 1/2"

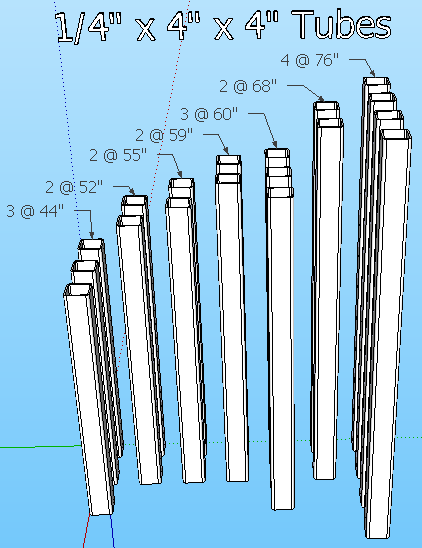

¼” Thick, 4" x 4" Steel Tube

- 3 @ 44"

- 2 @ 52"

- 2 @ 55"

- 2 @ 59"

- 3 @ 60"

- 2 @ 68"

- 4 @ 76"

5/16” Thick, 2 1/2" Dia Steel Tube

- 4 @ 5"

3/8” Thick, 3" x 6" Steel Tube

- 1 @ 45"

- 2 @ 100"

1 7/8" Shaft

- 4 @ 28"

- 1 @ 56"

Parts Fabrication

- The purpose of this section is to prepare the components for final assembly. This includes cutting steel into required lengths and shapes, drilling, welding and shaping as required for final assembly.

¼” x 4" x 4" Steel Tube

- Verify the following 4" x 4" tubes have already been cut:

- To simplify hole placement, here is an image of a jig (click to enlarge):

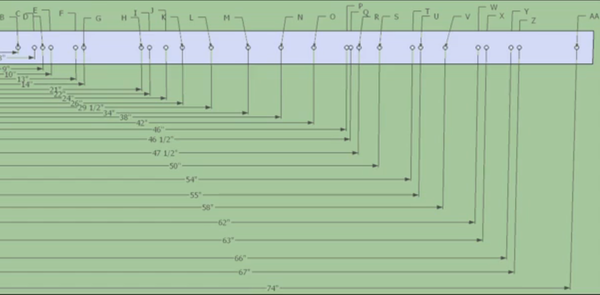

Drilling Tubes

- Unless otherwise specified, drill all holes at 13/16" diameter.

- Drill holes through entire tube (ie: through both sides).

- For each tube, measure all holes from one end of tube.

- 3 Lower cross tubes, 60" long

- Drill holes at 14", 46"

- Rotate 90 degrees, drill holes at 2", 10", 50", 58"

- 2 Bottom Inner North-South tubes, 76" long

- Drill holes at 6", 9", 13", 30", 63", 67", 70"

- Rotate 90 degrees, drill holes at 2", 10", 50", 58"

- 2 Bottom Outer North-South tubes, 76" long

- Drill holes at 9", 13", 63", 67"

- Rotate 90 degrees, drill holes at 2", 34", 58 1/2" 62", 74"

- 2 Front Vertical tubes, 55" long

- Drill holes at 6", 50"

- Rotate 90 degrees, drill holes at 2", 46"

- 2 Middle Vertical tubes, 52" long

- Drill holes at 6", 24", 50"

- Rotate 90 degrees, drill holes at 2", 46"

- 2 Rear Vertical tubes, 59" long

- Drill holes at 2", 21", 29 1/2", 47 1/2", 54"

- Rotate 90 degrees, drill holes at 6", 50"

- 2 Top North-South tubes, 68" long

- Drill holes at 6", 22", 62"

- Rotate 90 degrees, drill holes at 2", 26", 66" and a 2 3/8" hole @ 48" (with cutting torch)

- 3 Top Cross tubes, 44" long

- Drill holes at 6", 38"

- Rotate 90 degrees, drill holes at 2", 42"

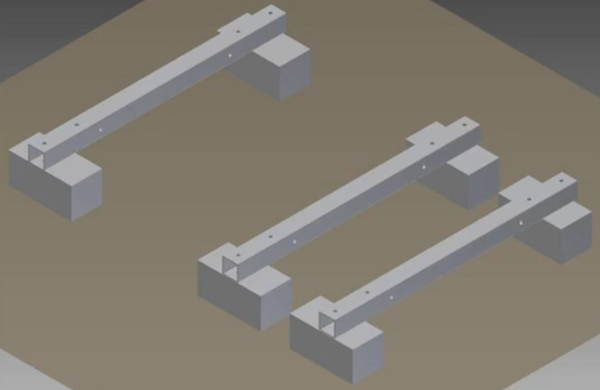

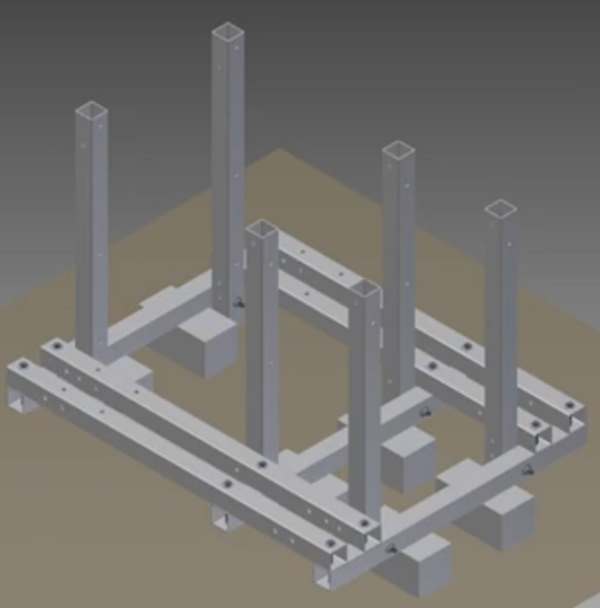

Assembly

- Use 6 blocks to support the 3 bottom cross members

- Place the 4 bottom North-South members on bottom cross members, secure loosely with 9 1/2" bolts, washers and lock nuts.

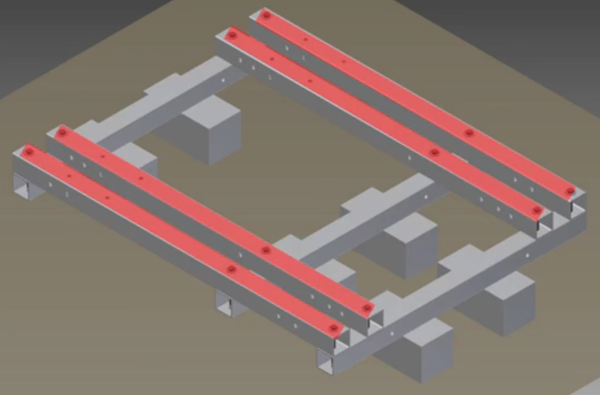

- Align the 6 Vertical members with holes in the lower frame, secure loosely with 9 1/2" bolts, washers and lock nuts.

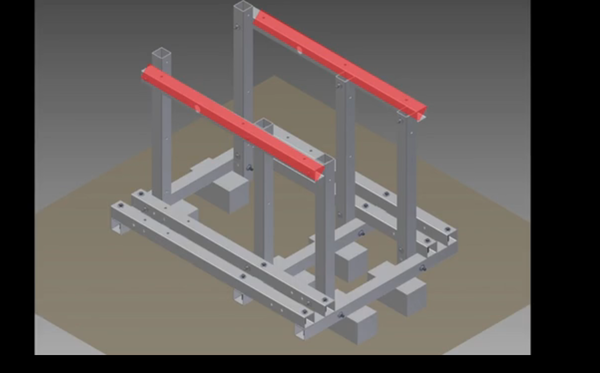

- Align the 2 Top North-South members with upper holes in the vertical members, secure loosely with 9 1/2" bolts, washers and lock nuts.

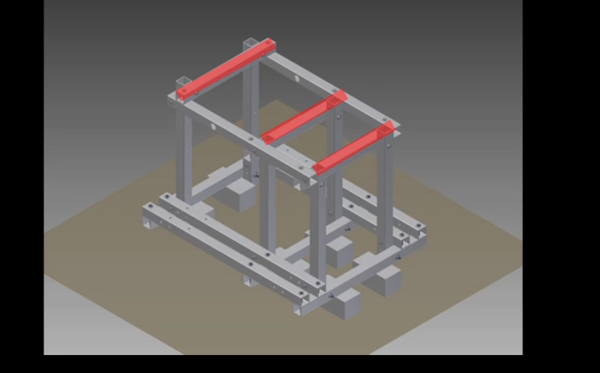

- Align the 3 Upper Cross members with holes in the upper North-South members, secure with 9 1/2" bolts, washers and lock nuts.

- Tighten all bolts / nuts.