Incubator: Difference between revisions

| Line 123: | Line 123: | ||

#Assemble egg holders | #Assemble egg holders | ||

##Cut plastic pipe sections. [http://openfarmtech.org/images/thumb/d/da/Safety_goggles.JPG/120px-Safety_goggles.JPG Wear safety goggles when cutting]. | ##[http://openfarmtech.org/index.php?title=File:Hexahatch_construction_cut_pipes.jpg Cut plastic pipe sections.] [http://openfarmtech.org/images/thumb/d/da/Safety_goggles.JPG/120px-Safety_goggles.JPG Wear safety goggles when cutting]. | ||

##Cut notches for stoppers. Drill 1/4" holes in middle of pipe caps.[[image:hexahatch_construction_cut_drill_pipes.jpg|thumb]] | ##Cut notches for stoppers. Drill 1/4" holes in middle of pipe caps.[[image:hexahatch_construction_cut_drill_pipes.jpg|thumb]] | ||

##Attach pipe caps to 18" pipe. | ##Attach pipe caps to 18" pipe. | ||

Revision as of 19:59, 4 April 2009

In order to provide eggs and chickens to Factor e Farm Dream Team 30, we will need to raise our chicken population from 24 to about 300 chickens in 2009. For this, we need to hatch the chickens in an incubator, as natural brooding does not do the trick. We are getting 8 eggs per day even now, and this should increase to about 20. At this rate, it would take us one month of hatching to increase our flock to the needed level. We should aim for an incubator with 48 egg capacity, and do about 5 hatching runs.

Design Rationale

Naturally, hens take care of the eggs by turning them often and sitting on them to maintain the necessary conditions for hatching. Most types of chickens have been bred for high egg production though, which means they have been bred to not "brood", to not sit on eggs, because when they are brooding they won't lay any more eggs. Since most hens won't brood the eggs will never be warmed and protected until they hatch, and so an incubator is needed to hatch eggs from most hens. Bantam chickens are one of the few breeds that still brood, since they have been bred for looks and not eggs (they have small eggs) and they will brood on any eggs they are given, so a natural route for hatching chickens is to have an egg producing hen to lay eggs and a bantam hen to brood them.

An incubator keeps a large number of fertilized eggs safe and warm under ideal conditions until they hatch, in place of brooding hens.

Chickens may be propagated readily from fertile eggs - so freerange chickens can be maintained in a healthy population even in presence of heavy losses to predators. A simple incubator should be available on any diversified farm. Natural chicken birth rates typically happen too late and too infrequently in the season for the chicken population to become self-sustaining. Freerange chickens, which do not require supplemental feeding - could be a great part of a community local food strategy.

The important conditions under the hen are temperature, humidity, ventilation, and turning. The eggs need to be turned for circulation, or else the fluids just sit there.

Research

Resource Map

General Info

- http://www.ext.vt.edu/pubs/poultry/factsheets/8.html

- http://www.associatedcontent.com/article/308949/how_to_hatch_your_own_chicks_from_eggs.html?cat=53

Other Designs

- http://www.msstate.edu/dept/poultry/avianemb.htm

- Constructing a Plywood Incubator - Pictures and BOM. No description. Has an apparently manual egg turner. No motor or timer. Has thermostat with simple wiring diagram.

- http://msucares.com/poultry/reproductions/poultry_make_incubator.html

- http://www.extension.umn.edu/distribution/livestocksystems/DI0631.html

- http://www.backyardchickens.com/LC-howto.html

- http://www.motherearthnews.com/Do-It-Yourself/1982-03-01/Build-Your-Own-Incubator.aspx

Links

Past Work

See Open Source Chicken Incubator

- Critique of past work - manual turning of eggs at least 3 times per day becomes a chore for an integrated human.

Research Summary

- There is a lack of adequate design. University references have no automatic incubator designs. Mother Earth News is the only one with automatic turning, and the mechanism there is unnecessarily complex.

- Infuriated with such nonsense, Marcin proposes HexaHatch.

Design

Humidity and Temperature

- Humidity - $6 analog hygrometer at Amazon -1

- Temperature - two thermometers

- Thermostat and lightbulb for temperature control

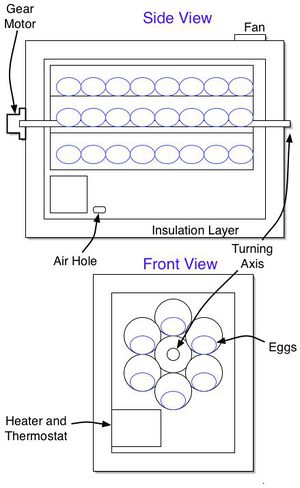

Design 1 - HexaHatch Revolution

Hexahatch is a simple, compact, low cost, scalable design incubator with automatic turning via a $10 gear motor.

Design Rationale

- Uses simple on-off wall timer, set for 3 turning sessions per day, 15 minutes long

- Gear motor plugs in directly to timer

- Gear motor is coupled directly to turning shaft

- Symmetry is utilized for low turning torque requirement

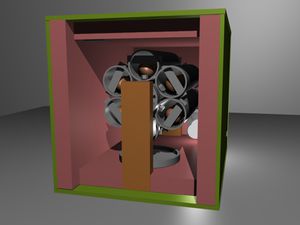

- 3" PVC tube (schedule 20) is used for egg holding, arranged in hexagonal pattern

- Inner PVC tube holds turning axle

- Bearings hold axle at ends

- 48 egg capacity

- Thermostat operates a 15W light bulb for heat

- 2" styrofoam insulation is used around box

- OSB is used as a case

- Small fan removes temperature stratification along vertical direction

- Tub of water is found at bottom for humidity

- Incubator opens from the end

- Small air hole is found towards bottom

- Approximate 1x1.5x2 foot box

- Max 60 egg capacity

Design

Bill of Materials

- Wall timer, $8

- Motor with 1/4" shaft, $10

- 1/4" coupler $4

- 1/4" threaded rod $3

- 1/4" nuts, x 6

- 16" of 4", schedule 20 PVC pipe, x 6

- 18" of 4", schedule 20 PVC pipe

- $8

- 4" PVC caps, x 2 $5

- Thermostat, 90-130F range, $10

- Light socket and bulb, $5

- Spare power cords

- 2 metal bushings, $2

- fan

- 2x4" posts

- 2" insulation, 14 square feet, $7

- 20x15" x 2 for front/back

- 20x27" x 2 for sides

- 23x15" x 2 for top/bottom

- OSB shell, $3

- 20x27", x 4 for top/bottom/sides

- 20x21", x 2 for front/back

- 3000 square inches out of 8x4' 4608 sq/in OSB sheet

Total: about $70

Implementation

- Assemble egg holders

- Cut plastic pipe sections. Wear safety goggles when cutting.

- Cut notches for stoppers. Drill 1/4" holes in middle of pipe caps.

- Attach pipe caps to 18" pipe.

- Attach 16" pipes to 18" pipe with screws.

- Put threaded rod through pipe cap holes, put nuts on both ends loosely. Leave one end sticking out further.

- Cut out the insulation and OSB pieces.

- Assemble the bottom and back insulation and OSB. Attach with screws.

- Drill holes in the OSB and insulation for the motor on the back.

- Wire and attach the light fixture to the 2x4.

- Attach the light fixture 2x4 post to the OSB.

- Attach the egg holders.

- Drill holes in the 2x4"s and metal bushings.

- Attach the bushings to the 2x4"s.

- Attach the thermostat to the front 2x4".

- Put the long end of the egg holder shaft through the rear 2x4" bushing.

- Attach the coupler to the threaded rod end.

- Attach the coupler to the motor.

- Attach the motor to the back OSB.

- Attach the rear 2x4 post to the OSB.

- Adjust the nuts on the threaded rod to hold the pipe caps tightly, so that the egg holders turn with the rod.

- Put the front 2x4 post with the threaded rod through the bushing and attach the front 2x4 to the OSB. The motor should be able to turn the egg holders now.

- Wire the light to connect to the thermostat.

- Assemble the rest of the box.

- Assemble the rest of the insulation box.

- Assemble the OSB around the insulation. Attach with screws. Leave one end open.

- Drill holes in the side for the air intake and wires, and in the top for the fan.