Power Cube VII

Assembly Video:

Powercube v7 Assembly. from Open Source Ecology on Vimeo.

Introduction

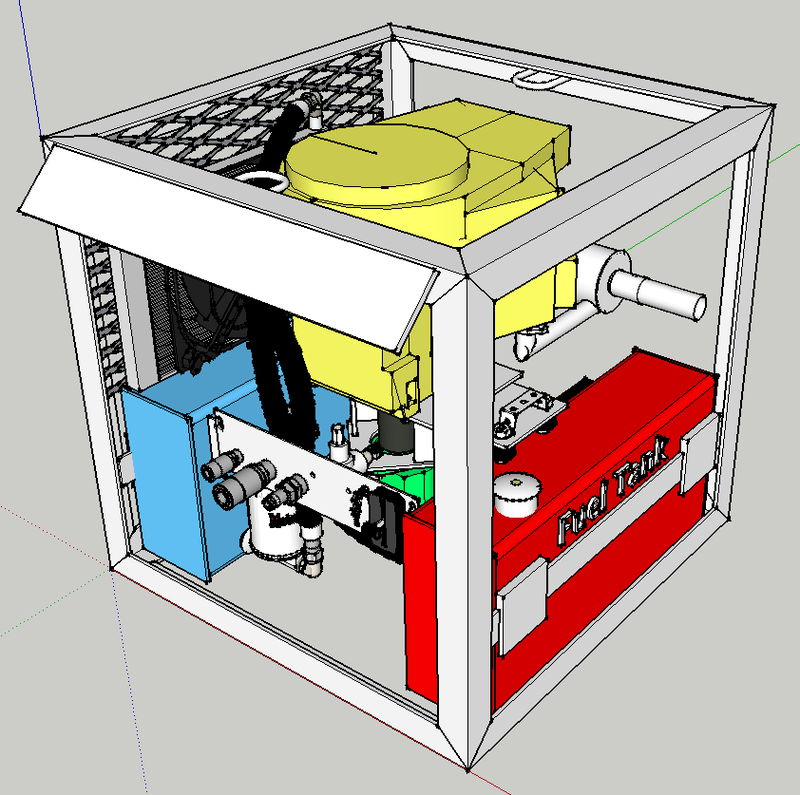

The purpose of Power Cube is to supply hydraulic fluid power for other machines. While the Power Cube designs are meant to be scalable, this design uses a 28 HP engine and hydraulic components that have proven to work well with OSE machines.

Power Cube VII marks the next level of modularity in the power cube with quick-connected: engine assembly, pump assembly, hydraulic tank, fuel tank, control panel. This is on top of the hydraulic quick connects that allow the power cube to function as a power module for any power equipment in the Global Village Construction Set.

Development

The Power Cube has gone through a series of updates and this page reflects the current designs of Version 7 of the Power Cube.

This design has proven to work well and has had few updates lately. Here are the latest updates:

Oct 2014: Added a pressure relief valve and associated plumbing - TLG. Oct 2014: Changed sight gauge to shorter model and moved above the suction strainer for greater visibility - TLG.

Files for Power Cube VII

Sketchup

please upload new version by clicking on existing version - the wiki has file versioning

- Latest file (see revision history for versions) - File:Power Cube VII.skp

- July 4, 2014 - File:Power Cube VII July.skp

- June 2014: File:Power Cube VII June.skp

- May 2014: File:Power Cube VII.skp

Bill Of Materials (BOM)

- Latest BOM: File:Power Cube VII BOM.pdf

Module Drawings

- Control Panel File:Control Panel.skp

- Control Panel Assembly File:Control Panel Assy.skp

- Oil Cooler File:Oil Cooler.skp

- Frame File:Frame.skp

- Fuel Tank File:Fuel Tank Assy.skp

- Hydraulic Reservoir File:Hydraulic Reservoir.skp

- Wiring Harness File:Frame.skp

Power Cube Working Document

Fabrication Steps

The Power Cube is assembled from a variety of modules and the fabrication begins with the modules, then completed by integrating the modules. The order of module fabrication is not important, as long as they are completed for the final integration.

The modules are detailed below:

Modules

- Fuel Tank Module: File:Fuel tank.pdf, File:Fuel tank assy.pdf

- Hydraulic Reservoir Module: File:Hyd reservoir.pdf, File:Reservoir.pdf

- Hydraulic Reservoir Module: File:Reservoir.pdf, File:Reservoir assy.pdf

- Engine Module: File:Engine.pdf

- Hydraulic Pump Module: File:Pump.pdf, File:Pump assy.pdf

- Oil Cooler Module: File:Oil cooler.pdf

- Control Panel Module: File:Control panel.pdf, File:Control panel assy.pdf

- Frame Module: File:PCVII frame.pdf

- Solenoid Module: File:Solenoid.pdf

- Wiring Harness: File:Wiringharness.pdf, File:Wiringharness.dia

Detailed Fabrication Steps

Fuel Tank

- Cut holes (drill small hole, torch large hole)

- Grind tube and plate edges to 45 degrees

- Clean all edges for welding

- Weld fuel filler neck

- Let tank cool, mount fuel pickup tube

- Weld end plates

- Precision Note: Use gap between tank and plate

- Weld mounting brackets together, then to tank

- Weld control panel bracket to tank

- Weld bolts to tank

- Pressure test, re-weld, pressure test, etc

Hydraulic Reservoir

- Cut holes (drill small holes, torch large holes)

- Grind tube and plate edges to 45 degrees

- Clean all edges for welding

- Weld tank flanges

- Tap hole for tank return

- Mount sight gauge

- Weld end plates

- Precision Note: Use gap between tank and plate

- Weld mounting brackets together, then to tank

- Weld control panel bracket to reservoir

- Pressure test, re-weld, pressure test

Engine Module

- Cut plate: 8“ x 15 1/2“, grind edges

- Torch and grind large holes

- Drill small (5/16“) holes, grind slots

- (paint plate, let dry)

- Bolt plate to engine

- Bolt muffler to engine with gaskets

- Bolt muffler extension to muffler

- Cut shaft couplings in half, lengthwise

- Insert plug, clamp and weld together

- Note: Touching coupling faces should be machined faces (not cut)

- Precision Note: Coupling halves must be aligned precisely, else shaft will bind

- Cut 1/2“ from end of engine shaft

- Let cool, then secure coupling to engine shaft with key and set screw

Pump Module

- Cut plates and angle iron

- Torch large holes, drill small (5/16“) holes

- Grind edges, test fit pump & bolts

- Space angle iron evenly on 6“ plate, tackweld inside corner

- Weld inside and out

- Align plates with spacers, clamp with “C“ clamps

- Precision note: Plates must be parallel else shaft may bind

- Tackweld inside corners (do not weld spacers)

- Weld inside and out, remove clamps & spacers

- Bolt pump to plate assembly

- Install hosebarb on pump

- Install elbow on pump loosely

- Note: keep holes on pump plugged to prevent debris

Oil Cooler Module

- Carefully unbox oil cooler

- Wrap NPTM elbow threads with teflon tape

- Screw NPTM ends of elbows into cooler, tighten so JIC elbow ends point as in illustration

- Secure fan to cooler

=Control Panel Module

- Torch large holes, drill small holes

- File key hole to fit switch

- Grind all edges

- Weld bracket for throttle

- Install throttle and keyswitch

- Install quick connectors using teflon tape

Frame Modul

- Cut angle iron, flat bar and expanded steel

- Grind ends of angle iron at 45 degrees

- Align and weld 4 “V“s from angle iron

- Align and weld “V“s to form two squares

- Weld two more pieces to the squares

- Weld the two haves to form a cube

- Add the battery box and tank supports

- Weld the expanded steel in place

- Add the hoist hooks and QA plates

Solenoid Module

- Bend one cooler support to match holes on fuel tank

- Mount solenoid on support braket (made above)

Final Assembly

- Install tanks in frame (fuel tank goes beside battery box)

- Install oil cooler and fan to expanded steel

- Install oil filter head and filter

- Install hoses to oil cooler, oil filter

- Connect hose to filter

- Install pump module and solenoid

Overview: File:PCVII Fabrication.pdf

Fabrication Diagrams

See Fabrication Diagram explanation.

Overview:

Overview Diagram

https://docs.google.com/drawings/d/1KmkEsN6OPySaH11YeaQg51PJVuTzHqHMuWSajwRU8_4/edit

Frame

Rahul Dhinakaran-Custom Machine Designer - 14 November, 2012

Manufacturing Drawings of some of the PowerCube parts. [1]

See Power Cube 6 for latest Power Cube Documentation. Tom is currently building Power Cube VII - optimizing form factor for ergonomics. The power cube after that is Power Cube VIII. See Machine Naming Convention.

- Date: Sun Nov 11 - Monday Nov 12, 2012.

- Tom Griffing is Guest Collaborative Production Run Director

Preparation

- Lathe up and running for spline coupler

- Tom has a coupler jig

- Lathe gearing via PowerCube + 6 Spline PTO Motor

- Ordering hose crimping dies from Sweiger

- Getting 2 more Millermatic 200 Welders.

Notes

- Use ironworker for mitered cuts

- 3 corners should fit so there is no more than 1/8" space anywhere

- When welding each member check for parallelism and flat planes

Notes: 1 hour 15 minutes to cut all of mitered frame, 2 tank hangers, 4 hanger fingers and 4 spacers, pump mount plate (6"x6"), and to troubleshoot slow cutting on bandsaw and helping Graham align frame welding. Started approximately 10:30 after discussions.

Engine Mount

Download 27 hp Briggs and Stratton Engine Manual

Hydraulic Fluid Tank and Fuel Tank

Note on welding from Ben Horton: The three "C's" of welding are clean, clean, clean. Tack the entire tank together, then after you clean the work pieces leave a gap between them about 1/6" and fixture the joints so that it is very uniform then weld down hill with minimal torch manipulation (mig). The next thing is to listen you will be able to hear the arc in side the tank as it penetrates. Remember watch the puddle not the arc. With 1/4" material you shouldn't have to stitch weld it but move from joint to joint opposite the one prior. Call me if you have questions. Results- Using above procedure, I welded the fuel tank (1/4" steel, so easy on High-4, 70 wire speed, Millermatic 200) on first pass (except for filler cap, which is sheet metal)! That's a first, as I always had at least one pinhole leak, and about 8-10 at worst in prior production runs. For the end caps - grind edge + top and bottom around edge to 3/8" away from edge, with no factory scale on metal - just clean shiny metal. Grind edges of 6"x12" tube also 3/8" from edge. If cut by bandsaw (our case)

Instructions:

- Cut stock 6x12" tube into [2] 25" sections

- Cut End Plates on Ironworker

- Weld quick connect hangers at ______" above bottom

Fuel Tank:

- Torch out hole for fuel tank

- Drill 7/16" hole for tapping a 1/4" fuel connection

- Tap 1/4" NPT hole for fuel barb

Hydraulic Tank:

- Torch out all bungs

- Suction on side

- Sight gauge on side

- Filler

- Case Drain

- Return line filter

Both:

- Weld end caps

Diagrams

Hydraulics Diagram

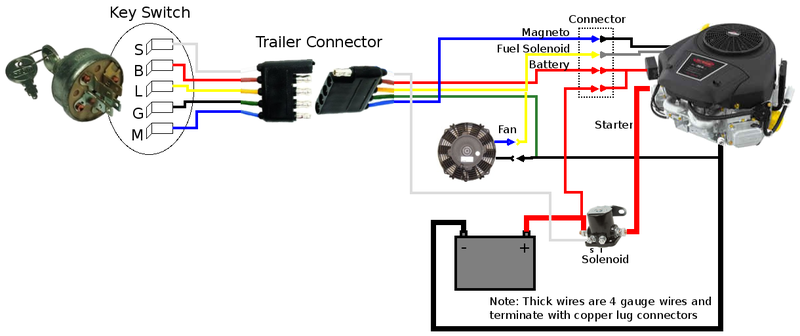

Electrical Diagram

Resolving Correct Labeling on Key Switch

Note: Convention on back of key switch. M and B have different label on the metal stud - I am assuming we go by the label imprinted in the plastic.

- Verification of wiring from Tom - Metal tab / plastic / Connection

- C / M / Magneto

- S / S / starter

- " " / B / Battery

- G / G / Ground

- L / L / Lights

Power HyperCube VII

HyperCube for Hypermodularity. Concept:

- Quick attach tanks

- Quick-attach, self-contained engine unit with engine controls - disconnectable by 2 large bolts

- Quick-attach hydraulic pump unit - disconnectable via 2 bolts

Quick Connect Plate for Power Cube Pump Detail

Fabrication

Coupler

Rubber Vibration Mounts

Wiring Harness

Hydraulic Cooler

Battery Terminals

Engine Connections

Hydraulic Sight Gauge

Hydraulic Pump and Coupler

Power Cube Assembly Video Script

Steps for Instructional Assembly Video Script

Finishing the July Workshop Build

- Fuel Tank: Weld bolts in place

- Hydraulic Reservoir: Finish plumbing

- Drill/torch holes in 2” tank brackets, bolt in place

- Drill/trorch holes in expanded steel (make plate if necessary), bolt in place

- Mount tanks

- Drill 4 holes in pump plate and mount across tanks

- Cut 1/2” from engine shaft, mount engine plate to engine

- Mount cooler

- Finish plumbing

- Finish Wiring Harness

Research

- Mechanical shaft quick coupling patent - [2]

July 2014 - Structural Power Cube

The frame of the Structural Power Cube is designed for stacking of multiple power cubes. This documents is about the angle iron frame Power Cube for applications where only one or two Power Cubes are required. Here is the link to the Structural Power Cube:

Link: Structural Power Cube