Steam Engine Design/Bump Valve

Main > Energy > Steam Engine

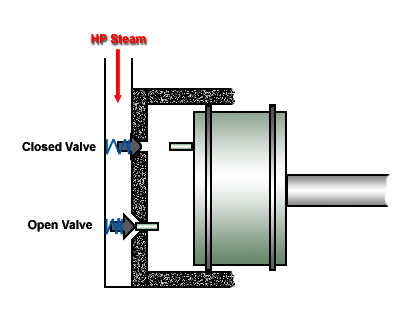

Design View

This valve design features the "chinese hat" profile mentioned in the SACA discussions below. It would be turned from high carbon steel and tempered to harden it It has a slightly flattened point where the bump pin hits it. This distributions contact and should improve wear. Seating of the valve is important or steam will leak into the cylinder chamber.

An improvement over the last bump valve design by having a valve enclosure that seats the valve springs and brings in steam from the top. Stem input port would be threaded to receive a standard dia (1/2" ?) cast iron nipple. Valve enclose now bolts through the cylinder end cap to a flange on the cylinder. We may need seals between these pieces, perhaps cut from a soft metal like copper.

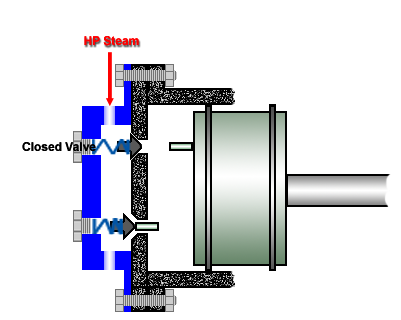

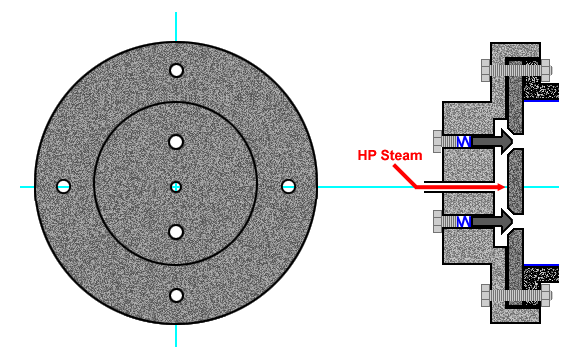

Improved Design

The steam inlet has been reduced in space in this design, allowing for a longer valve spring hole. With the springs fully enclosed in the holes, it is hoped to that the springs will not anneal from steam heat, or at the very least, extend their useful lifetime. Also included is an end view. The valve cover can be turned on a lathe and holes drilled out. No milling is needed.

Wear Characteristics

From SACA ([1]):

The ball has to be harder than the seat other wise the seat will line the ball and it will leak in short time. Steam is a whole new world. soft 304SS seat ,hard ball 440c SS 58r ball , ceramic ball, best. Anything will run on air.

Any idea how many hours you could expect from such a valve?

Depends on how many times it opens per hour, the pressure , the hole diameter in relation to the ball diameter, the temperature and the water quality ,they all add up . We did a lot of testing on valves it is a lot of work and time testing takes time.

The valve (ball?) and seat seem to be pretty straightforward issues--but the pin (or rod) and its mounting on the piston seem to be a source of endless problems. The load concentrations in these components is obvious. Personally, I think the Williams type of impulse valve is a superior solution to the ball and pin type.

Google for US patent 2,402,699

I do not know about the White Cliffs' project, but the two best bash valve work was done by Jay Carter and the Mobile Steam Society. Jay showed me two handfuls of experiments that were bent and bruised. He ended up with a Chinese hat shaped thing that had light weight, sealing on a flat surface, self centering, and a lot of area around the edge so he only needed 50 thousandths lift. The MSS went with an upside down mushroom shaped thing so that the bash impact was nowhere near the seating area, that was part of a spherical shape. The trick is to not use a ball bearing or any spherical shape because then the bashing impact will flatten a part of it, unless it is ceramic. These days the smart money is using recompression pressure to lift the bash valve and so then there is no metal touching metal. Tom Kimmel

The people who like bash valves, meaning Jay Carter, do the following analysis: they get about 5% cutoff and thus a 25 - 1 expansion ratio. They get approximately the rpm and torque of a conventional gasoline engine and thus the usual drive train will work. There are some interesting benefits to high speed, and Jay was getting 5,000 rpm, which is difficult to get with any other valve system. The benefits had to do with time. When high temperature, high pressure steam is admitted, you want a very short dwell time for the temperature to convect and the pressure to leak. Therefore there are some very good benefits to having a high speed steam engine. Few other people have explored this aspect of steam. In other words, the bash valve is a proven system, it is just an emotional issue. Tom Kimmel

For vehicles having a wheel diameter between 24 & 25 inches and fixed gear drive ratio between 2.0 and 2.5 to one (1), you can expect a state of the art bump valve to fail within 40 million cycles. However, if you get out of the "box" and incorporate some of the new ideas, you can expect that a failure may occur after 360 million cycles. This is my best guess based on observations combined with analysis.

The person who has the most experience with bash valves is Jay Carter. I have visited him several times in Wichita Falls and seen his shop and handfuls and coffee cans full of mis-shapen and broken clumps of metal, all tested experiments. Jay does not use the computer, he makes things. Therefore do not expect him to weigh in on this discussion as he is probably unaware of it and could not join if he wanted to. His final design, which Jerry Peoples says went 10,000 miles and I believe him, was a Chinese hat with 50 thousandths lift and a spring to push it down and prevent float. It worked up to 5,000 rpm because, first of all, there was a large, possibly close to one inch diameter, valve. The steam came in from the periphery and so there was a lot of area for the steam to move through. This is why a spherical ball is the wrong geometry; it is heavy and has a small cross-section and the square-cube rule starts to get you when you make it larger. Then, Jay used up to 2,000 psi steam. I have no idea how much wire drawing his system suffered from, but at least the steam got into the cylinder. A person might look at the cost, in energy, to make high pressure steam, and it is probably not much, just a little more power to drive the water pump, so one might as well start out with some high pressure steam. It is my opinion that Jay concluded that a bash valve was the only way to get a 25-1 expansion ratio and high rpm speed as any other valve train had too much inertia in it. One should always keep in mind when running a bash valve that clearance volume needs to be carefully considered. There needs to be some or there is no steam flow. Therefore all of the talk at the steam meets about small clearance volume and Jerry Peoples' calculations on the deleterious effects of high clearance volume do not apply to bash valves. Try to not get me started on all of the attempts to make a variable cut-off bash valve or about Bill Cartland's bash valve exhaust valve. Tom Kimmel