Fluidized bed reactor

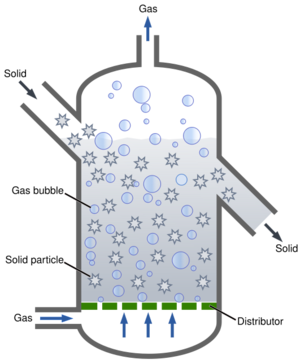

Fluidized bed reactor (FBR) are chambers that allow the mixing of liquid or gas substrates with powdered catalysts such that the catalyst acts like a fluid, maximizing mixing and interaction. The basic configuration is detailed to the right where a substrate is passed upward into the chamber under pressure through a plate that supports the catalyst. FBRs are essential for the production of many materials and chemicals, and could be an effective tool for several basic capabilities of the GVCS.

An OSE FBR should be built of discrete components that are integrated rather than dependent on one another, so a machine can be assembled into configurations for applications that use different pieces of equipment. This approach is also necessary for scrum and decentralized development by breaking down this complex machine into self-evident pieces. As a complex machine it will also be useful to develop components that are involved in a common task or reaction parameter as part of a subsystem, an example would be thermal flow controllers that control injection of substrate and vacuum pumps that remove products. Components of subsystems should be designed to control a specific parameter in the most flexible way possible while being under the control of a system controller (computer) that integrates the system components into a cohesive action. This will allow component actions in the form of programs be replicated and distributed. Much of this is already industry standard practice.

The reactor chamber itself will have no active role and will simply be a container that can be connected to different input and output lines, and is optimized for mixing of components and maintenance of optimal reaction conditions. Use of an external frame seems to be fairly standard in industry and would allow separate mixing, reaction, and velocity reduction zones to be simply, and securely combined.

FBR for bioplastic production

A variety of bioplastics are currently being produced including polycarbonate, polylactic acids, and polyethylene. Polyethylene is the most produced plastic in the world and can be made in high and low density forms based upon branching. A reactor that could be used for ethanol dehydration and ethylene polymerization is a proposed route to locally produced renewable bioplastic. Due to the nature of the subtrates, powdered catalysts, and optimal catalytic conditions FBRs have demonstrate superior performance in the both steps of ethanol to polyethylene with high process reactivity and selectivity. An OSE FBR could fulfill the specific need for synthesis of bioplastics and by being built along OSE guidelines could be configured for a variety of chemical engineering applications.

Defining the bioplastic requirements: Physic 1. Reactor chamber with ability to add or remove substrate, product, catalyst, gases, and control temperature, pressure, and the speed which substrate moves through the reactor. a. Dimensions based on reaction volume? b. Hoppers would have to be of adequate size to benefit reaction volume

2. Safety: able to withstand heat and pressure, dangerous chemicals kept behind two layers of protection, product handled with precautions a. reactor materials b. design for longterm quality

3. Recycling of unused substrate, carrier gas, catalyst. a. Catalyst regenerator to autoclave and activate used up catalyst.

4. Saving thermal energy: isothermal or adiabatic, heat catalyst and substrate with steam depending on moisture requirements

5. Control of atmosphere: gas content, increased and decreased pressure ranges, gas content in the reactor and downstream, gas mixture controls upstream

6. Control and interface: sensors of pertinent conditions and an easy to understand display of the conditions, controls over conditions and inputs and outputs

Collect user stories to decide upon most important features to incorporate into first prototype.

SEBD components:

2 processes: dehydration and polymerization

1. Reactor

2. Reduction zone

Gas input and makeup

3. Gas hookup for main port, substrate and catalyst.

4. Gas flow controller for main port and possibly substrate and catalyst. Pressure sensor and control.

Gas recycle and gaseous product collection

5. Gas analyzer

6. Gas and liquid phase separation.

7. Gas product separation for ethylene via gas fractionation column or gas scrubber gas recycle without gaseous production.

8. Compressor and heat removal from exothermic processes.

9. Gas recycle to main gas port.

Substrate control

10. Vaporization of liquid ethanol and passage through substrate port.

11. Control of input of gaseous ethylene substrate.

12. Product removal

Catalyst control

Catalyst maintenance, loading, removal, and regeneration.

User interface

Control unit - integration of reactor sensors with current status of thermal mass flow controller, liquid mass flow controller, gas analyzer, hopper temperature controllers, and a method for programming and automating processes.

Literature and patent review

Production of Polyethylene Using Gas Fluidized Bed Reactor written by Tham Chee Mun reviews the industrial processes that have been employed and are currently used. The history of industrial polyethylene processes including reactor design and catalyst evolution, differences in polyethylene fibers, mathematical modeling of the polymerization reaction, and recommendations for operation are covered. Early processes were for the production of low density polyethylene and required high pressures in the order of 3000 atm and elevated temperatures, and this process is still used in the production of polyethylene vinyl acetate. Newer catalysts can produce higher density fibers at lower temperature and pressure and should be simplified and bootstrapped for OSE. Further refinements to the technique included starting the reactor with prepolymers, reconfiguration of the gas recycle line to conserve heat and reduce fouling, and pretreatment of the substrate and catalyst. Modeling of the reaction process incorporates the total possible reactions and their probability. A recommendation that OSE should consider while developing lines of plastics is the loss of transition material and a production process that cycles through similar plastics to minimize wasted material.

FBRs for ethanol dehydration

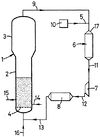

A reactor device detailed in U.S. patent 4,134,926 belonging to Tsao and Zasloff issued Jan 6 1979 utilizes a fluid bed reactor (11) to catalyzed the reaction of ethanol dehydration.

The reactor contains powdered catalyst supported on a distributor which can dispense feed ethanol through the catalyst. Ethanol is passed through the distributor in gas phase at 750 C into the reactor chamber at the same temperature. The catalyzed reaction takes place on the surface of the catalyst powder, and the product escapes as gas. The product is equal parts water and ethylene. Catalyst may be removed and loaded into reactor using hopper chambers, which offer the advantage of preparing the new catalyst to ideal temperature and conditions increasing control of the main reactors conditions. According to the patent ethylene yields of 99% are possible with fluidized bed reactors.

A thesis prepared by Michael James Skinner Ethanol Dehydration to Ethylene in a Stratified Autothermal Millisecond Reactor details the use of stratified reactors for ethanol dehydration. Stratified reactors have multiple catalyst beds that allow catalyzed reactions to take place in a rapid series, which previously had to be carried out by a combined cocatalyst or a support material. Chapter 1 deals with pairing of catalysts for the conversion of fast pyrolysis products to liquid hydrocarbons and should be reviewed in the context of that project. Chapter 2 covers novel research with a two layered stratified reactor and ethanol dehydration to ethylene under isothermal and adiabatic conditions. A noble metal and aluminum oxide is in the first layer reacts first followed by ZSM-5. The set-up achieved high conversion rates in the order of 90%+ however other simpler processes have shown better performance. Stratified reactors have the most practical use for biomass refining and takes intense process control.

FBRs for polymerization

Industry equipment often follows the dimensional guidelines of reactor bed height to width ratio of 6-7.5 and a reduction zone with a ratio 1:2 is connected to the top of the reactor with a sloping section that assists in separating catalyst and polymer from recycle gas. The reactor bed is usually kept at a pressure of 0.07 atm (1 psi). http://klmtechgroup.com/PDF/Articles/Fluidized-Bed-Reactor.pdf

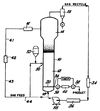

US patent 4,003,712 issued to Miller on Jan. 18, 1977 details a fluid bed reactor for use in a olefin polymerization.

The reactor contains a reaction zone 12 where substrate and catalyst are combined. The substrate is supported by a fluid bed which allows the injection of substrate which allows maximum mixing due to the fluid like behavior of the catalyst. Unused substrate, catalyst, and carrier gas can be recycled through the system. Above the reaction zone is a slow down zone 14 where products collect and are sorted. Gas collects the velocity reduction zone and recycle gas is collected through the a line at the top of the zone. An optional cyclone 22 can aid in gas collection and a filter 24 catches small particles. A heat exchanger 26 acts to recycle heat and maintain the system at a constant temperature and the gas is compressed by a compressor 28. New catalyst can be added through input 30 with a proper gas mixture and preheated, reserve catalyst is held in nitrogen in 32.

US patent 4,383,095 issued to Goeke on May 10 1983 details a high activity catalyst and a the operation of the fluid bed reactor for its use. The FBR adds activator compounds at the hottest point of the gas recycle line which would be downstream of the compressor and before the heat exchanger?, however the patent calls for placement downstream of the heat exchanger.

US patent 5,028,670 issued to Chinhe and Dumain on July 1, 1991 details a fluid bed reactor configured for olefin polymerization so as to avoid fouling by particles carried into the gas recycle line.

A liquid vapor separation The device utilizes two heat exchangers in the gas recycle line downstream.

A thesis prepared by Michiel Friso Bergstra made kinetic measurements of ethylene and hexene polymerization in gas and slurry phase generators with multiple catalysts and details components of a laboratory grade/scale olefin polymerization reactor. The reactor chamber is a commercial 1600 ml stainless steel model with a jacket and other components are largely off the shelf. An an automated injection mechanism for dry catalyst uses a pressurized tube to add catalyst from the top of the reactor. Flow of gaseous ethylene, nitrogen, and hydrogen is controlled by thermal mass controllers and 1-hexene flow is controlled by thermal liquid mass flow. All components are mixed and brought to gas phase by a Controlled Evaporative Mixer (CEM, Bronckhorst HiTech) before passage to the reactor. A helical stirrer with a propeller tip maximizes circulation which is important for catalyst and reagent interaction and transfer of heat from the reaction to the cooling. Products are removed by a low pressure port through a mass thermal flow controller to gas analyzers. Infrared beam gas analyzers Servomax Xendos 2500 and 2500 are used to measure ethylene and 1-hexene concentration.

Proposed plan of action

1. Construction of simple small (laboratory) scale reactor that may or may not incorporate ability to remove and reload catalyst or recycle gases.

2. Demonstration of reactors capabilities to catalyze ethanol dehydration and ethylene polymerization using purchased catalysts and substrates. Successful creation of polyethylene will demonstrate the ability to conduct the process on a small scale.

3. Construction of second generation reactor that incorporates more advanced loading and unloading abilities and environmental controls that can operate in continuous mode.

4. Testing of reactor and for high purity ethylene production and polyethylene polymerization. Refinement of operation and production of second generation bioplastic polyethylene vinyl acetate for use in greenhouse glazing.

5. Construction of full scale reactor capable of supporting village sized population with ability to load multiple substrates, catalyst hopper, gas control and recycling, and which can be operated in extended continuous for long periods and is rapidly reconfigured.

6. Demonstration of industrial standard open source fluid bed reactor in a variety of applications.

7. Material abundance from local feedstocks and catalysts.

Prototype 1

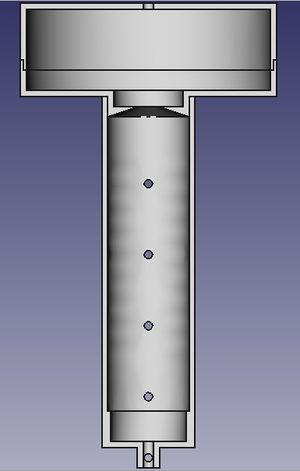

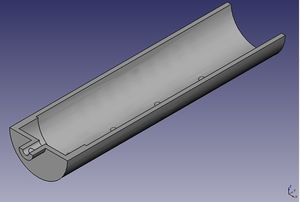

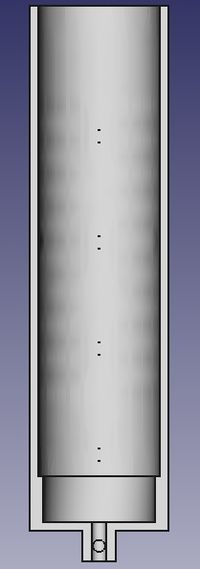

Prototype 1 will be designed to be a small scale reactor that contains only core components of a reactor chamber, reduction chamber, gas fluidization and recycle system, substrate mixing system and temperature controls. The reactor is 20 cm internal diameter with a reaction zone of 1.4 meters. The reactor is made of single piece of material to which a distributor plate is attached and it may be possible to alter the reaction zone by changing the height of the distributor plate and amount of catalyst. The reduction zone is designed to made of two pieces for easy manufacture and assembly and will have dimensions of 30 cm tall and 60 cm in diameter. The reactor will be assembled in a reinforced frame which will be mounted to the floor. Depending on the reaction parameters the reactor may be made from stainless steel, however more temperature robust reactors will be made of a material that is able to withstand high heat such as silicon carbide or a ceramic material. A firebrick jacket will be built around the machine with a small air gap between the two and serve as a thermal block and for physical containment.

The gas input will be attached to the lowest point of the reactor and substrate inputs will be located slightly above. The reactor will be designed to prevent any solid formations or fouling a main technical problem in current industry. The distributor plate will be attached to a lip located 15 cm above the input zone and attachments to raise the distributor shouldn't be difficult to incorporate. A series of screw-in ports in the reactor zone will allow additions and removal reagents and a design that allows the passage of gas, liquid, and solid phase material should be a goal. To minimize thermal losses and increase efficiency it is proposed that the substrate hopper, catalyst hopper and gas input be clustered in a thermal mass that will be maintained at the same temperature. As detailed in US patent 4234752 passing the dehydration products through chambers of decreasing temperature (e.g. 50 C, 0 C, -70 C) is effective at removing water and unreacted alcohol from the product stream and this method of purification is suggested for prototype 1.

Thermal mass flow controllers seem to be the preferred way to measure gas inputs and outputs and can be found commercially for a few thousand dollars. Alternatively, arduino based thermal mass flow controller using a IST FS5 thermal mass flow sensor have been built by hobbyists. An overview of the design and components of a mass flow controllers can be found here http://www.advanced-energy.com/upload/File/White_Papers/SL-MFCFUND-270-01.pdf. Alicat Scientific sells a variety of products http://www.alicatscientific.com/products.php for the measuring and control of flow, pressure and temperature. Gas flow controllers that are factory configured to handle ethylene, nitrogen, and hydrogen and can be connected to a computer or arduino through a serial port.

The Xendos 2550 is a multicomponent gas analyzer cited for its use in laboratory scale reactors and can quantify ethylene, CO2, CO, and other contaminants http://www.sanwell-tech.com/webEdit/UploadFile/2009920173050784.pdf. User Manual

The reactor will be in conformity to the OSE design standards and allow for easy manufacture, assembly, and reconfiguration. Beyond the reactor and reduction chamber which will be produced on-site off the shelf gas analyzers, gas flow controllers, gas compressor and various other components will be utilized. In order for the reactor to be able to control both the dehydration and polymerization reactions it must be able to control exothermic and endothermic reactions. Prior art has found that reactor chambers usually are adiabatic and temperature control should be incorporated into the gas stream; so heat must be removed from the product stream in exothermic reactions and added to the input streams in endothermic reactions.

Used reactors of all sizes and for many different applications are for sale at http://www.labx.com/v2/newad.cfm?catid=379 if a cheap industry standard reactor needs to be acquired first for standards examination.

Subsystems and components breakdown: 1. Reactor core 2. Gas loop 3. Substrate loader 4. Catalyst loader

Steps in operation of FBR : 1. Establish steady state reactor pressure and temperature conditions with catalyst in chamber. 2. Pass substrate into reaction chamber and move through catalyst for optimal length of time. 3. Collection of product from gas stream or from reaction zone. 4. Collection of flow through gas from reduction zone. 5. Preparation of gas for recycle. 6. Gas recycle through main gas port.

FBR for iron production

The design detailed above is largely for the production of bioplasics. With major design modifications, an FBR could be devised for the reduction of iron oxide to metallic iron. The process is described on the Direct_Reduced_Iron_(DRI) page. As the reducing gas, one would feed either syngas or methane into the bottom of the FBR. Iron oxide, possibly extracted from subsoil, sand or river sediments by magnetic sorting, would go in at the top left. Exiting gas will be a mixture of CO2, CO and H2. Out comes hot reduced iron. If exposed to air, this hot powder would immediately be re-oxidized. Therefore, it should be put in an induction Furnace right away, while still hot.

http://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=786321&fileOId=786858

http://www.jstage.jst.go.jp/article/isijinternational/45/2/151/_pdf

http://www.fischer-tropsch.org/Bureau_of_Mines/ri/ri_6209/ri_6209.pdf