China Replication

see also Metric CEB Press

People

Context

From William Neal, left in picture above:

Here are a few details of the background leading up to this replication effort:

When I saw the TED talk in March of 2011, I was immediately taken by the approach and vision of the OSE and applied for a dedicated project visit which I completed on July 31st of 2011. I returned to London Ontario inspired by what I saw and determined to carry through with a replication of the CEB Press in August. We sourced materials, identified a welder, secured shop space and put together a financial plan before other realities intervened: work. My position as a Vice Principal was simply too taxing and volatile to permit productive work on OSE projects. I ended up taking a different job at a different school as a teacher which, in the short term, took even more of my free time but, over the course of the year, allowed for unforeseen beneficial circumstances to arise.

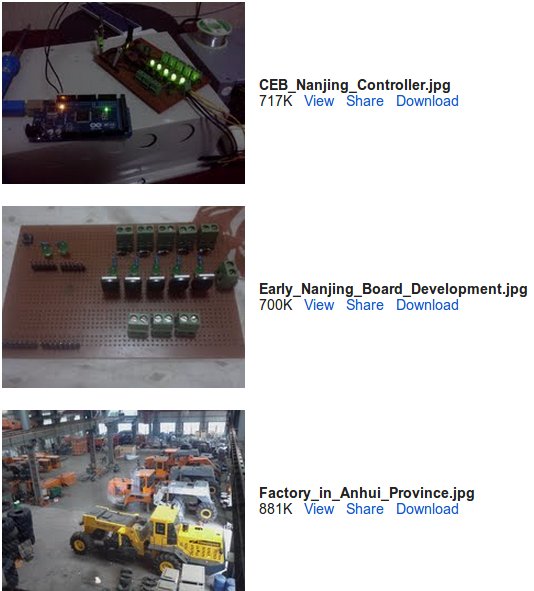

My OSE activities went dormant for several months as I found that much of the footage that I took at FeF was not useful (I missed the bulk of the CEB building due to delays and the design was changing rapidly before my eyes, rendering other footage obsolete!) and I learned the particulars of my new job. In March, out of the Blue, the administration of my new school asked me to travel to China for ten weeks. Meanwhile, determined to continue learning about Open Source hardware, I had just acquired the parts for a RepRap, a 3D printer also on the GVCS 50 list but with much safer and modest fabrication requirements. I took the RepRap parts to China with me and began working on that when my colleague, Tony Mensah, noticed it. He was fascinated by the idea of the 3D printer and asked to learn more about it whereupon I told him the story of the OSE and my visit to FeF. When he heard about the CEB press, Tony, originally from Ghana, became quite excited about it as he saw great potential for its immediate use in his home country. Much to my surprise, he stated that we should build a CEB press right away! When I realized that he was serious, I drew up a plan for completing this project in the remaining several weeks of my stay in China (see link). The first order of business would be to completely redesign the CEB Press to metric specifications.

At first, we hoped to source the parts and bring them to a small metal shop near Tony's house and pay a welder to fabricate them. When we visited Mr. Lu at his metal supply business, that plan quickly changed. Mr. Lu became very interested in our order of metal and asked for more details. We showed him some pictures of the CEB press (video doesn't cross the Great Firewall of China that easily) and agreed to help us. On the first weekend, he brought us to the Steel Yards of Nanjing and showed us more steel than I have ever seen in my life. We clearly had our steel sourced. It was the next weekend that we realized that we had a communication issue. We arrived at his shop, hoping to pick up the steel. Instead, he asked us to get in his car. After about 90 minutes of driving, we arrived in Ma'anshan, an industrial city in Anhui province and he pulled up at a factory! Evidently, he thought that we were looking into mass production! We worked through this misunderstanding and, in the end, had the factory build the Press.

The electronics and hydraulics were sourced in the subsequent weekends. We inquired about shipping these parts to the USA and found that it would not be cost effective. In fact, a Chinese-sourced CEB would likely only be cost effective under mass manufacturing conditions as the total cost is within about U$200 of the American version.

During the course of the project, we received a lot of help and support from numerous individuals. Most notable among these are the following: Mark Amo-Boateng, a friend of Tony's who joined us as a full partner in the project. James Slade who provided photos of a new design for the Press Foot and additional video footage James Wise who provided support for a custom build of the solenoid driver board. Adam Messer who contributed significantly to the metric redesign of the CEB Jacopo Amistani Guarda who contributed some CAD drawings of the CEB Additional Details are at the following locations: Metric CEB design: OSE Wiki - search for Metric CEB Blog entries: http://www.metaciv.org

We are not finished the project as the machine now needs to be tested. Any suggestions or support in this regard would be appreciated.

The attached photos are of Mark, Tony and I with the proprietor of the hydraulics supply shop in Nanjing. Tony appears on the right in each picture. If you have any additional questions, I would be glad to answer them.

Kind regards,

William Neal

More Images

Images: