Open Source Fab Lab

See introduction to our program in Factor e Live Distillations - Episode 6 - Personal Fabrication:

See corresponding blog post

What is an Open Source Fab Lab

The Open Source Fab Lab is a robust flexible and digital fabrication facility. When the enabling information is available, a skilled worker may replicate the Fab Lab at the cost of materials. The tooling package that we are considered is based loosely around the MIT Fab Lab item list, but is expanded beyond electronic circuit fabrication and laser cutting of Christmas ornaments - to foundry and heavy machinery production. The latter is accomplished with a 300 lb/hour steel melting furnace, CNC torch and plasma cutting, and welding as part of the basic components.

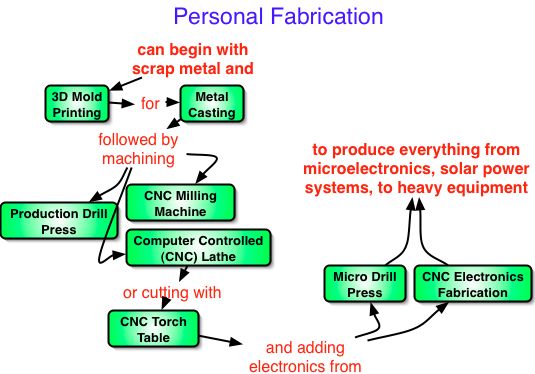

The formula for recasting a new civilization at the cost of scrap metal is:

Specific Fab Lab Components

We are proposing the following equipment infrastructure, in order of priorities, which is in addition to a number of small tools and diagnostics:

- 300 lb/hour steel melting Foundry - $1000

- Multimachine-based Lathe, mill, and drill, with addition of CNC control - $1500

- CNC Torch Table (plasma and oxyacetylene), adaptable to a router table

- RepRap or similar 3D printer for printing casting molds - $400

- Circuit fabrication - precise xyz router table

- Open Source Wire Feed Welder

The first 3 are in development. See Status.

Further descriptions are:

- XYZ Acetylene Torch, Plasma Cutter, and Router table - CNC controlled, $1200 in parts. Three different cutting heads are interchangeable. This is for heavy duty metal, wood, and other material cutting with applications to tractor parts, CEB parts, sheet metal cutting, etc. Preparation of structure for many electromechanical devices.

- Multimachine - $700 in parts, $1500 with CNC control. This is for general purpose lathing, milling, drilling, and other rotary cutting/abrading/tooling applications. It is relevant to the preparation of rotors, shafts, bolting holes and patterns, milling metal shapes, fabricating cutting tools, and other cutting, abrading, and subtractive machining operations.

- Circuit Fabrication - $600 in parts - high precision version of XYZ table for fabricating electronic circuits and other very precise objects.

- RepRap - $500 in parts - a 3D printer for additive fabrication. We are interested especially in fittings for custom plumbing applications (water systems, chemical engineering processes, etc) and small parts for many applications. This printer can be used to make molds for casting plastics and metals

- Laser Cutter - $3000 in parts - extremely precise cutting of metals and other substances, requiring no finishing of edges. Useful for making precise rotor disks (solar turbine) and many other parts.

- Casting and Extrusion - plastics, metals, glass, and ceramics. This is for casting engine blocks and other metal parts; for sheet extrusion of plastics (glazing applications); making glass windows or glass blocks; making insulators. Also for making extruded metals and plastics - wire, tubes, rods; as well as insulated wires. Alloys and composites may be mixed with this equipment.

Goals and Specifications

Consensus amoung the Maker or Fab community seems to indicate that there are no concerted open source efforts to build an open source Fab Lab - outside of a number of individual efforts. We have proposed an open source Personal Fabrication infrastructure as part of the Global Village Construction Set - and are presently looking to deploy the set via the 1000 True Fans - 1000 Global Villages campaign and the First World Conference on Open Source Ecology.

We are proposing an open source Fab Lab with at least the above components. Tooling specifications should follow OSE Specifications, and in particular, those of modularity, scalability, flexibility, and replicability.

OSE Open Source Fab Lab

See the video on our goals:

See corresponding blog post

For the particular purposes of OSE's Global Village Construction Set, here is a tool set that we need. It relies on proven techniques - no new inventions are needed - and immediate applications are the focus. The list of OS Fab Lab components belongs to Phase 1 technologies - primarily the equipment used in flexible and digital fabrication. Subsequent OS Fab Lab development stages include Fab Lab Phase 2, Fab Lab Phase 3, Fab Lab Phase 4, and Fab Lab Phase 5.

Existing Work

- New Work (Frithjof Bergmann) - good publicity material on high-tech self-providing in German

- http://reprap.org/bin/view/Main/WebHome - a well-developed 3D printer project - already achieved self-replication

- http://opensourcemachine.org/node/2 - project implementations built by developer - I don't know if anyone replicated this yet; documentation needs development; Factor e Farm engagement - parts list and drawings being developed (6.08) and implementation scheduled for July, 08

- http://openfarmtech.org/index.php?title=Torch_Table - Factor e Farm progress - all materials sourced, torch table ready for assembly and connection to LinuxCNC - need a volunteer to visit us here to build this

- http://www.appropedia.org/Callooh - circuit fabrication router - project on paper; code work in progress

- http://www.instructables.com/id/CO2-laser-that-cuts-sheet-metal/ - CNC laser cutter for metal. There is evidence that by using laser engraver tubes ($200 each), say 10 of them, an industrial power laser can be put together at reasonable cost. The challenge is to work out the optics for paralleling the beams

Collaboration

Agroblogger has asked the most important question affecting humanity today. See here.

Software

Message from Sam:

Marcin, I am in transit right now. But, a quick reply:

Although it is extremely difficult to learn to use, http://www.brlcad.org/ is the most robust that I have tried this far.

http://www.qcad.org/qcad.html is also really nice for 2D CAD work.

http://www.linuxcnc.org/ looks awesome, but is only an "Enhanced Machine Controller", and doesn't provide CAD drawing, nor CAM toolpaths (G-code drawing). What it does is interpret g-code toolpaths to move the actual XYZ table, or whatever machine you are controlling.

So, linuxcnc is essential, but as I have no machines to run yet, i have not had much of a way to test it out.

Also, for non-commercial use http://fab.cba.mit.edu/about/fab/ (cam.py and cad.py) those are some simple but useful software programs both cad drawing and cam toolpath generation (but are not fully open source, as we discussed earlier)

I am still searching for other software, but you can really do a lot with brl-cad and q-cad.

I still want to try http://www-rocq.inria.fr/OpenFEM/ and http://avocado-cad.sourceforge.net/ and http://www.cademia.org/frontend/index.php?sub=29 and http://www.opencascade.org/ don't know anything about those yet.

BRL-CAD

If you plan on trying to use BRL-CAD, the PDF's on this page are essential reading http://www.brlcad.org/wiki/Documentation

BRL-CAD Industry Diagram

Other Software Sam Rose is evaluating

- [Fandango http://www.soffernet.com/jaime/fandango/kfandango-doc.html] a C++ 3D CAD package with Python extensions.[]

- http://www.pythoncad.org/ (2D CAD a dead project but workable software QCAD probably a better choice here)

- GIT DARCS or Mercurial as a repository for DFX or other formats

- also will be copying to this tag http://delicious.com/srose/opensourceecology

Links

- Good PR material on the personal fabricator is here.