3D Printed Electric Motor

Basics

- This page goes over various OSE efforts for mostly 3d printed, diy, electric motors

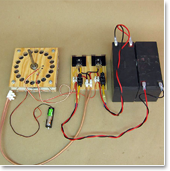

- Can be used as a "Dumb" motor, or as a ODrive servo motor

- Can we make Hobby Quadcopter Motor level specs for cheaper?

- Can an "industrial" motor be made with a gearbox, and perhaps metal parts and/or better cooling? These can be a large componet of the cost in some larger machines

OSE August 2020 Candidate

OSE March 2020 Candidate

- Colombian project on axial flux motor, 3 phase - https://www.emworks.com/ckfinder/userfiles/files/Axial%20Flux%20Motor.pdf

OSE 2019

See Michel_Log#Fri_Sep_20.2C_2019

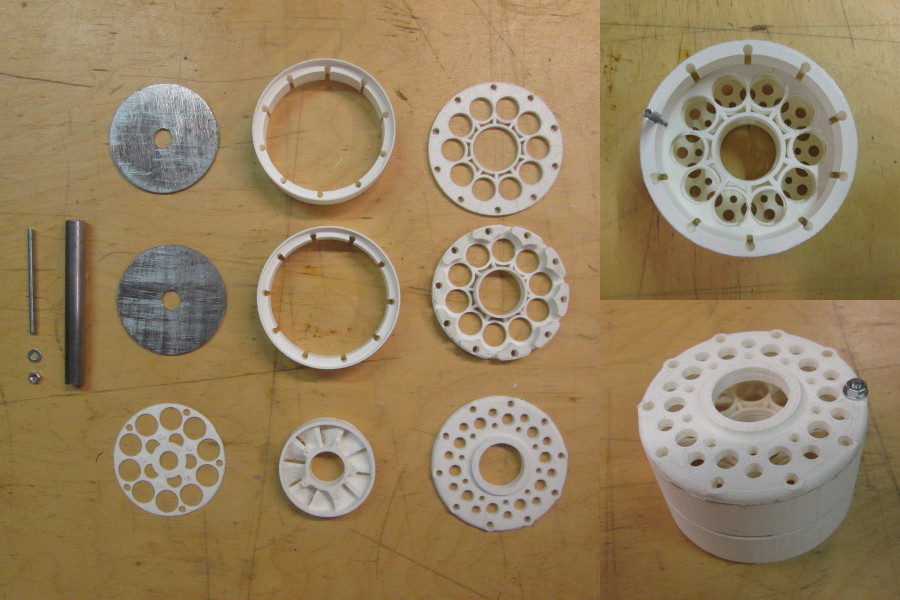

Open Source Modular Axial Flux Motor v02 - https://mi_shell.gitlab.io/models_online/ose_webgl/motor_v02_01.html

Axial Flux

- Dual rotor 500W motor with controller. Best starting point for a motor. - [1]

- Most complete plans

- has 8 kW version as well

- Late 2018, TU Delft students on axial flux coreless - [2]

- John Reimers - early 2019 - McMaster U grad student - [3]

- French student project - no plans - [4]

- 100W, about 1 in lb torque - 7000 RPM - so 70 RPM geardown gets you 100 in lb. Comparable to current motors.

- 260g

- Not bad.

Magnets

Magnetic Material Types

Halbach Arrays

The typical motor efficiency metric of electrical/mechanical power in/out doesn't take into account the total ecology. Using Halbach Arrays to direct the magnetic flux density with less magnetic material decreases the total embodied energy improving the environmental impact.

- https://www.emworks.com/ckfinder/userfiles/files/Axial%20Flux%20Motor.pdf

- https://iopscience.iop.org/article/10.1088/1755-1315/93/1/012058/pdf

Supply Chain

- https://www.hsmagnets.com/motor-magnets/

- https://www.thomasnet.com/products/motor-magnets-95984084-1.html

Coils

Another issue with many 3D printed designs is the requirement of carefully hand-winding the coils. Hand-winding results in poorly formed coils with a potentially higher voltage between contacting coils and damage to the enamel. If the motor takes a long time to build and has sporadic fails it will not be popular to replicate. Axial motor windings may be easier to wind due to their more planar patterns, but can still have complex shapes.

Radial Flux

- Thingiverse - [5]

- Generator - https://www.thingiverse.com/thing:2635188

Halbach PMDC

- MakeSEA 600W motor - [6]. MakeSEA 40 and 90W - 0.06 peak Nm torque - about 70% efficiency. MakeSEA 60W -[7]

- Testing on an ultralight aircraft with 600W motor - [8]

- French project - radial motor - .14 Nm torque - 100W - [9]

- Small Halbach array generator - 7W per 1000 rpm - [10]

PMDC

- Great scott - [11]

Linear

- Model steam engine - Solenoid Model Steam Engine

Simple BLDC Outrunner

- Including Howto - [12]

- Inrunner BLDC with embedded 3D printing from the WM Keck Center for 3D Innovation - [13]

PCB Motor

- Circuit mill + 3DP - axial flux - [14]. By Carl Bugeja

3 Phase BLDC Simple Jet Motor

- Magnets + coils. Doea lack of a magnetic core make it very inefficient, or can this do well upon geardown? High speed geardown is not easy, though. [15]

- Isn't this a ducted fan, not a pulse, turbo, or ram jet etc?

Alternator - Axial

- Decent at low speed - [16]