AbeAnd Logs 2018

Sun Dec 20, 2018

I've been working on my old greenhouse monitor instead of CAD during the break since I think it would be more useful immediately. It would be better to rewrite with more classes for future additions, but I could use a simple climate monitor currently. Currently I'm thining how to get a simple menu system working. There are many menu libraries, but I'm trying to keep it simpler if possible.

https://github.com/Witz0/Climate-Monitoring-and-Control-Station

Sun Dec 2, 2018

I tried different positions for axis' & clamps and checking against arrangement on other printers. However, most previous CNC designs are slightly different. It appears the ~14.5" arrangement may be ok for the Z-axis. The mount for the bed works at the bottom mount point in the extremes. At the top it appears to clear the clamp accounting for the the limit switch distance. Getting the Y & X axis' mounted as high as possible isn't as hard as I thought, but there are poassible collision points with corners & X carriage if it is mounted to high.

The ~14.4" rod length is 0.6378" to long relative to the X axis distance between the clamp extents where the Y's mount. So the option is to make the clamps thicker by ~0.3", which wouldn't hurt the clamp bolting strength. Also, shorter axis lengths could be considered. There are only 3 position options for the clamps and for the axis' one side seems ideal for completing axis' assembly as much as possible first and not using the idler wheel bolt.

There are other potential mount issues as well. I think the most efficient direction for the X axis motor(s) is away from the Z axis. This is different from other printers, but the bed is generally mounted closer to the Z axis with short rods so this will maximize bed area usage.

Sat Dec 1, 2018

testing assembly of collar clamp and measuring possible rod lengths. If the clamps & the axis' are asymmetrically mounted the max distance it can mount is 14.4488" or close enough to 14.5" to work as a good cut point. But, there it may be possible to increase the printable volume in another configuration. Hangups may be the position of mounting the bed on the Z carriage as well as stop points for the X axis.

Wed Nov 28, 2018

I helped Marcin figure out his FreeCAD Legacy install. The main issue was my confusing the use of new easier apt with the apt-get commands on the freecad ppa page.

Reading more of the freecad 0.17 links I found because some of the concepts like datums look very promising speed editing files and ease of making constructs that are difficult or many steps in v0.16. I experimented with primitives and sketches in a body and how they move or not before and there are so many options it can be confusing, but from the documentation, I think I see sufficient basic examples to understand it now.

Tues Nov 27, 2018

looking at details on clamp part. bolt lengths? reduce plastic via more varied shapes.

I did some more reading on the newer freecad part work-flow and reviewed some discussion forum links.

https://www.freecadweb.org/wiki/PartDesign_Body

https://forum.freecadweb.org/viewtopic.php?f=9&t=15269

https://forum.freecadweb.org/viewtopic.php?t=15432

https://www.freecadweb.org/wiki/index.php?title=Sandbox:Part_Design_Next

Mon Nov 26, 2018

I drew up a 2 piece collar style clamp and after trying a few variations, it does look like it will print faster in it's simplest form with no hex holes for nut catchers. They seem unnecessary anyway due to the curved side being able to hold any nut and using the nut catcher on the axis part might be easier. Although I see disassembly & reassembly on the motor side depending on how tightly/well aligned the nut is held under the motor.

The only problem I see for assembly is this design changes the mount bolt hole to an offset position and the extra thickness of the bolt holes around the clamp side is more than the PVC corners and will make the Z-axis throw it off level unless some kind of feet are added.

I'm not seeing an easy way around the feet issue for 3d printed corners they could be customized, but for stock PVC some other feet look needed. 3d printed feet would be difficult to attach to the corners. Multiple clamps could be used, but that a lot more parts.

Mon Nov 19, 2018

Measuring distances on axis part assemblies.

Sun Nov 18, 2018

Reading through FreeCAD's automatic python modules looking for calls from my simplify script, but having trouble finding details on function calls. I'm thinking I need a way to load the applicable libraries as a project into an IDE like Atom. Also, the calls used aren't necessarily relevant because I need to find other functions to generalize or automate the selection of visible part feature objects.

Recorded Test Macro:

# -*- coding: utf-8 -*-

# Macro Begin: /home/abe/.FreeCAD/Macros/simplify.FCMacro +++++++++++++++++++++++++++++++++++++++++++++++++

import FreeCAD

import Part

App.activeDocument().addObject("Part::Compound","Compound")

App.activeDocument().Compound.Links = [App.activeDocument().Pocket004001,App.activeDocument().Part__Mirroring,]

App.ActiveDocument.recompute()

App.ActiveDocument.addObject('Part::Feature','Compound').Shape=App.ActiveDocument.Compound.Shape

App.ActiveDocument.ActiveObject.Label=App.ActiveDocument.Compound.Label

#Gui.ActiveDocument.ActiveObject.ShapeColor=Gui.ActiveDocument.Compound.ShapeColor

#Gui.ActiveDocument.ActiveObject.LineColor=Gui.ActiveDocument.Compound.LineColor

#Gui.ActiveDocument.ActiveObject.PointColor=Gui.ActiveDocument.Compound.PointColor

#Gui.ActiveDocument.ActiveObject.DiffuseColor=Gui.ActiveDocument.Compound.DiffuseColor

App.ActiveDocument.recompute()

App.getDocument("Unnamed").removeObject("Compound")

App.getDocument("Unnamed").removeObject("Pocket004001")

App.getDocument("Unnamed").removeObject("Part__Mirroring")

# Macro End: /home/abe/.FreeCAD/Macros/simplify.FCMacro +++++++++++++++++++++++++++++++++++++++++++++++++

For the PVC frame scaling, I found the distance for the motor side + limit switch is ~3.15", which makes the axis parts total length ~4.18".

Fri Nov 16, 2018

Started to assemble clamp to frame and realized some of the pipe part sizes are not 3/4", which I should have remembered earlier. The smaller 1.050" clamp size for 3/4: PVC should be easier in some ways. Inconsistencies appear to need correcting for the separated parts and STL's.

Corrected part sizes and started testing assembly to see how far off alignment will be. https://gitlab.com/Abe_Anderson/d3d-mini-pvc

Thurs Nov 15 2018

I found this WYSIWYG wiki editor extension while looking at text/HTML/code editors MediaWiki WYSIWYG editor extension As common, I find Atom is a popular editor for everything.

Wed Nov 14, 2018

Reviewed lots of 3d printing info. Looking at many clamps 3D printed clamp styles to rethink the design for something printable without supports etc.

Lots of Tweaking on the clamp sketch just to look at different shapes. The 30mm bolt - nut makes a nice snap in shape rather difficult, so I wondering if it can be eliminated completely using PLA. There are all kinds of examples of living hinges etc., but longevity and failure modes aren't ideal. If a C shape clamp with no clamp bolt is designed just right it might be printable with the clamp opening up and the mount bolt hole on the bed. The temperature of the plastic when snapping it on may determine flex and strength. Having to heat the parts before dis/assembly to be sure they didn't break would be annoying.

The only quick way I can think to do this would be to design a bunch fo variations print them screw them to a jig & of course have a fancy robot abuse them with a PVC pipe.

I'm looking for the latest versions of 3d printing software for D3D to update because I remembered I can use slic3r to check STL's for printability. My OSE Linux Install says Silc3r isn't installed, but it has Cura.

After looking at other plastic clamps & not seeing good ways to solve the 30mm clamp bolt length issue I decided a snap on boltless design might be possible. Even more variables for plastic flexibility and strength issues, but may have potential if again lots of testing works out.

Tues Nov 13, 2018

looking at simplification options for short idler and axis, since the short idler is not included in the CNC Mill axis' and those axis' are to simple (missing bolt holes needed to align parts).

meeting prep.

Mon Nov 12, 2018

trying different methods to find an ideal rod length by editing the axis mount part 0.5" thick on the axis mount side. The Z axis can stick up above the top some, but that means the top clamp would be bolted to the inner holes. Also, the max distance between the corners is ~10.5" and the short idler + motor mount = ~3.37" this comes to ~13.87" so it would be nice to make the rods 14" or 13.75".

All this assumes a relatively accurate PVC assembly. The current CAD frame pipe sections are ~10.427". The frame generator appears to fit it perfectly, but as I recall PVC is slightly tapered for creating tight fits and good welds, so pipe sections should be shorter. Good workflow methods (marking jig?) & instructions for marking the pipes to fit with ~10.5" space between the fittings will be critical for creating a square frame. I'm assuming squaring the frame is a major issue for accuracy & quality prints. From build instructions, it looks like care has been made to cut & assemble rods accurately.

I'm leaving the clamp narrow for now because that should be tested first. I'm tempted to speculate it will be a lot more stable if made the full width of the axis blocks with 3 to 4 bolts. If wider it probably has to be printed with low infill for flexibility anyway.

reworked clamp features after changes to the profile to add printable nut catcher notches caused some glitches. Hopefully, it is easier to edit now too, but all the hole sizes are copied from the axis part geometry sketches.

Now it is ready for assembly testing to check the thickness of the mount side and making adjustments until rod length is something sensible.

Sun Nov 11, 2018

I've been experimenting with macros including ones from https://www.freecadweb.org/wiki/Macros_recipes & https://github.com/FreeCAD/FreeCAD-macros Many appear to be outdated & incompatible but reading some of them will give me a better idea of how to make generic code. I think a simplification macro would be useful, but it has to work universally. For some macros, GUI interfaces would enable a lot more functionality & there appear to be a few simple macros that use them. Some of the macro's appear to be to assist with making more macros or writing python scripts so they should contain some useful GUI examples.

Recording macros to see how existing GUI functions work and then reading up on the specific software calls is also likely to be useful.

I figured out git branch checkout better finally and I see how it changes the file system every checkout, but there is the worktree option for multiple working folders. I'm not sure which will be easier yet. When versioning via branches at some point CAD files may have to be manually "merged" by assembly thus requiring access to files in various branches.

Sat Nov 10, 2018

continuing D3D Mini PVC files & assembly.

also looking at making macros and python scripts https://www.freecadweb.org/wiki/Macros_recipes The record macro function often doesn't work for similar cases in different files or after slight changes because it generates scripts with enumerated part names. I think the scripts can be rewritten more general.

found CC licensed arduino ramps model, but it is probably more complex than we want to add to most files. https://www.thingiverse.com/thing:34174/files

Does D3D printer software toolchain (slicer) require STL files to be exported from FreeCAD in a particular way (orientation)? Searches aren't turning up much documentation this, but I did find some likely out of date info about sketchup and fixing STL's. Even if the slicer software can reorient parts without issue, is it still easier to do before exporting?

added D3D Mini PVC files I'm experimenting with to https://gitlab.com/Abe_Anderson/d3d-mini-pvc

Fri Nov 9, 2018

continued research & tweaks on PVC mount clamp.

further review of printer build pages.

added PVC frame STL files D3D Mini PVC

Thurs Nov 8, 2018

Realizing how tight the tolerances are on the PVC frame mount. The rods need to be ~13" so they are not longer than the frame. This makes the clamp as thin as ~0.1" between the axis parts and the PVC pipe.

The rods could be cut precisely to 13.1". Precision will help in assembly since I assume squareness is important for the frame. The rods don't can't be to precise though and if needed the plastic axis parts could be extended to the max length beyond the rods if that is easier for workshop builds.

I need to check the dimensions of the bolts with threads to get the holes more precise, I just hope 0.2" solves the thickness problem. The other part of a solution may be asymmetry in the mounting. The attachment hole may need to be offset anyway. The thicknesses of 0.1" for flexibility were easy for symmetry in CAD, but are guesses.

Tues Nov 6, 2018

found universal tube builder Talk:AbeAnd Log I knew there were other tube designs before and the simpler was selected to be used for file complexity, but this mehtod looks handy and adaptable.

meeting prep.

I'm curious about the priority of the D3D Mini PVC.

I've learned a few things from reviewing the D3D CAD & PVC Mini frame. I also rewatched the Design Sprint for clarity. The rod length being equal might make the size and shape of the mounting parts strange when trying to maximize the X axis length. The end stops and short idlers are needed in the CAD yet. The rods may be some weird length as well if 13.5 - 14" doesn't work easily.

I definitely need to review further the D3D assembly instructions to get a better idea of how to maximize build efficiency. I'm currently wondering if it should be as wide as the existing U-axis blocks with 2 bolts for stability.

Sun Nov 4, 2018

edited D3D Mini PVC parts gallery

Realized I could easily resize axis parts from Circuit Mill roughly by changing rod length then selecting and moving groups of relevant parts. I'm not sure what inaccuracies it has besides needing position alignment & further length adjustments, but it makes an easy starting point.

Fri Nov 2, 2018

Looking at D3D design sprint needs. I've downloaded many of the D3D files, but most are simple and to get the editable parts one has to go back through the history of each file. If I understand most of the components exist and need little correction for size; Mainly the frame needs to be sized to the existing axis' and the new attachment parts designed as modular as possible to hold the axis' to the frame.

added working doc to D3D Mini PVC with queries & ideas for general aproach to design.

Thurs Nov 1, 2018

initialized gitlab repo for LT https://gitlab.com/Abe_Anderson/ose-lifetrac-v17.10

I experimented with modularizing the frame and thinking of structuring only a few components (parts/sub-modules/modules) together at a time to make files that make finding data for construction of each module easier. I think all unique parts should be in individual files first. I may put all the CNC cuts into a separate folder & temporarily on a separate branch.

I added the frame files to a separate folder and then committed to branch frame since these changes will be in progress for a while. I attempted a tag called modularize, but I think I failed to attach/commit it correctly.

https://gitlab.com/Abe_Anderson/ose-lifetrac-v17.10/tree/frame

I also noted the frame tubing needs to be changed to realistic parts for verifying part weld interfaces and to do FEM testing.

Tues Oct 30, 2018

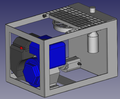

continuing reworking assembly modules for Power Cube. The LT also needs to be broken down into modular assemblies so it is easier to edit because there are many parts still missing from it that will likely be changed repeatedly as options are explored.

meeting prep.

Looking to further clean up files in the repo and each PC version subfolder I'd like to put into separate repo's on gitlab I found a number of misc files to remove and others that need editable versions of subfiles added for completeness.

I improved the messy Xp16HP engine file as well to attempt further assembly tests later.

https://github.com/Witz0/OSE-Power-Cube

During this, I formalized some logic to describe cases where it is faster to use the assembly 2 WB features correctly without later issues due to changes. I added this to the list of tutorials to be done. https://docs.google.com/presentation/d/1ocE8xZnJeRBSup3BfamcUucgjZqCgKWY3sLkm-SRAL0/edit#slide=id.g4582d543c0_0_0

I'm starting to reorganize LT files locally to attempt breaking it into modules.

Sun Oct 28, 2018

reworked PC v18.01 frame and assembled most of it so it will update automatically with any future changes. It looks tight around the 1240 cooler, but after measuring the base cooler CAD it is ~0.5" to wide. Specs online say 18" extent. So the prior CAD needs slight rework.

https://github.com/Witz0/OSE-Power-Cube/tree/master/Power%20Cube%20v18.01

Fri Oct 26, 2018

More ideas on LT back end PC frame changes for bracing; I'm sketching them in my working gdoc so far. When the LT has a stable fit for the PCv18.01 then I'll readjust the size again; Maybe rebuild the part & assembly files more correctly.

I added a global .gitignore file so I can ignore FreeCAD's backup files. More files can be added as well and it well speed up adding files to git comitts since I use the terminal it is easier to do keep a clean working dir then do "git add *", "git comitt *", & "git push".

https://help.github.com/articles/ignoring-files/

Further diagrams and thinking on the LT framing around PC's has me wondering even after widening the area for the PC's if stacking the small ones down to the back is best for the lower center of gravity. The tradeoff is stacking 3 high (over 60") or 2 high with more mass on the back end is better. If there isn't a heavy implement on the front the back may be to heavy, but if there is it may balance it better. stacking 2 in front of the others reduces shelving complexity as well and may make it easier to remove modules because you don't need another tall reaching tractor to remove cubes.

Wed Oct 24, 2018

Still looking at LT and I have a few more ideas about redesign of the back frame around mount PC area. Custom shaped supports below the pivot point for the arms could help widen that space to 40". However, reviewing PC v18.01 it is 20.25" so it needs to be narrowed to less than 20". It's current width is to give plumbing working space around the 1240 cooler. It is 18" fittings add ~1" and side plates ~0.5", so outside could be 19.5"; ~19.875" might be safer. Even if the back frame is CNC cut with a more complex design it will be hard to get more than 40" of space. I updated some files on v18.01 and I see a few more files and details to push. https://github.com/Witz0/OSE-Power-Cube/tree/master/Power%20Cube%20v18.01

Mon Oct 22, 2018

I've been considering ways to redesign the back end supports around the power cubes on LifeTrac v17.10. The tubular framing is definitely strong, but as I recall expensive relative to CNC cutting. The near horizontal beams are also welded to the side of the front uprights, which is likely quite strong, but not as good as the back end post and beam style.

I added some files to the modules for the LT. The way the LT was built there aren't many modular files because that is easier, but it would be ideal to break it down more.

Tues Oct 16, 2018

still catching up, but I watched many recent videos last night. Many interesting topics. Being busy and not getting a lot of hours in has at least given me some time to think larger perspective. Since the PC design seems 90%+ good, the priority is fitting this system on the LT and the hose routing is a sub-component.

cleaning backup files from github & updating [Power Cube Library] links.

https://github.com/Witz0/OSE-Power-Cube

I also checked size of PC v17.08 on the MC & PC v17.11 is 0.5" wider, 0.5" shorter in depth, & 0.25" taller. It looks like it will fit on MC ok.

I merged out the plumbing test branch because of confusion.

Pushing mostly minor changes and restructuring to github via git CL.

If I push to gitlab now I'll have to sync both so simpler to wait on that.

Reviewing LifeTrac v17.10 CAD some changes were never fully clarified and I'm thinking there is more room for changes that use CNC Torch cut parts especially on the top-heavy & expensive tubing parts. I'm not so sure about CNC cutting the whole cab though, 2x2 tubing plus sheet reinforcement still seems ideal. Lots of CNC cutting will require good nesting though. If more CNC cut heavy long tube parts are done FEM analysis would be useful, but doing that on major portions of the tractor could be difficult/ time-consuming.

I'm considering restructuring the LT files and moving them to gitlab, but there are a lot to sort through.

Tues Sep 25, 2018

continuing to examine the draft WB wire & curve tools with more examination of the python console to try to see how it is setting points and the working plane. I'm still struggling with the curves in multiple planes. I think this is partly 0.16, but I've been trying to use B-Spline assuming it will be more flexible for editing, but the Bezier curves may be easier to edit.

I have yet to start rebuilding the PC repos on gitlab, but I'm definitely leaning towards keeping it as close to software dev as possible. Technically it is all software it is just used to describe hardware designs. https://docs.gitlab.com/ee/workflow/releases.html

meeting prep.

Sun Sep 23, 2018

reviewing freecad draft WB from tutorials and experimenting with it on PC CAD. some progress learning to control the working plane, but there may be some differences and controls missing from 0.16 vs 0.17, which many tutorials are using. I'm able to edit the wires and splines, but not able to control direction in all axes as needed yet.

Tues Sep 18, 2018

freecad tutorials review.

Another concept that could be added to my tutorial is the extra settings in pads and pockets. Some are obvious, but the overall types or ways of how pockets are applied through objects hasn't been covered in any OSE tutorials. Maybe some online. There are more functions only in the menus and not in toolbar buttons like reorient sketch and create simple that I have not seen covered anywhere either.

https://docs.google.com/presentation/d/1ocE8xZnJeRBSup3BfamcUucgjZqCgKWY3sLkm-SRAL0/edit#slide=id.p

meeting prep.

created gitlab for power cube. https://gitlab.com/Abe_Anderson/power-cube

I don't have experience with gitlab yet, but from what I've seen I'm leaning towards trying to reorganize the files into folders for parts and assemblies with each versions freecad files comitted in order and set as a release with the existing version names. Rather than trying to modify the usual git workflow for hardware it will be best to stay as close to software so it is easy for everyone to use as is.

Thurs Sep 13, 2018

continued freecad research. reviewing other tutorials.

Also examined git repos more and further info about binary handling. https://stackoverflow.com/questions/52131250/how-does-git-perform-on-compressed-files

created gitlab test sand box for OSH binaries. https://gitlab.com/Abe_Anderson/test_sand_box

Wed Sep 12, 2018

continued work on a general FreeCAD Tutorial. The first tutorials are very thourough on almost all the basic tools and covering every possible interaction and use case between tools would be an nearly impossible. There are a few concepts I wished I'd understood sooner so I will attempt to make those apparent. I have created a gdrive folder for more tutorials and freecad files so they can be interactive.

https://drive.google.com/drive/folders/1nLBRNIryThMA8oqBdGi7ihpbyaxBqRwr

I'm improving the outline, but so far my recordings are to slow and not concise enough to edit easily. Better to keep scripting it out and practicing until it is relatively clear with little need for editing.

I don't expect it to be short with demonstrations of complex UI interactions, but I need to talk faster and more clearly so that a speed up in kdenlive with minimal cuts will sound ok. I think segmenting the recording sessions and then editing the clips together to get fast repeated improvements will speed up the finale. I'd like to get onto the advanced draft WB tutorial because that is what I need to learn now.

Tue Sep 11, 2018

continuing evaluation of freecad, the current status of tutorials, the PC plumbing, draft WB, and Flamingo WB. Looking at current tutorials of freecad on YT I see quality and details are often lacking. I'm thinking of a short sketcher constraint tutorial to start, but want it to be thorough enough without going through every tool in many WB's.

The Draft WB should enable me to do the 3D curved wires I need for hoses, but the exact workflow/ order of operations evades me so far. Using the Flamingo Pipe WB with solid elbows and straight pipe sections seems to cludgy and not useful for visualizing or figuring out hose bend radii. The order of operations of I'm looking for is mainly how to change the working plane in Draft WB to any angle in multiple planes. I think this is possible, but maybe to make it easy there needs to be some macros or maybe eventually a hose WB.

As a test I uploaded my so far useless plumbing file to a branch in github. I think I should have added tags. This created a pull request. I did this mostly to see options related to branching and how the acceptance or in this case rejection of the commit would work since the file is not meaningful to the main branch I think the commit could be overwritten by a future correction or the entire branch rejected and deleted or not.

If I understand correctly Jose suggested even having major versions of the machines in one repo, which would mean each major revision is a branch itself I think. Feature suggestions, updates, and ongoing design would then be in sub-branches as teams and individuals work on getting them to an acceptable state. I guess the latest complete revision could then be merged to the master when finished to make for an easy. Any commits not on a node/branch of the graph get culled/deleted eventually depending on team decisions about what files/features to include. I also see git binary handling git attempts to figure out delta changes for binaries if it is viable (I'm guessing expense check is storage savings? Not CPU? or maybe a ratio or cost-benefit is computed)

I attempted to make a sketcher tutorial a few times and then lots of editing in kdenlive to fix issues, but it seems more time efficient to practice the tutorial until I get closer to the outline. A full script seems overkill though. Kdenlive would also not speed up audio+video as shown in a tutorial on YT I realized the version was 15.x and 16.x supported it. I think it was a version from the much earlier OSE Linux install that had not been updated. Version 17.x is latest and it much better.

Sun Sep 9, 2018

caught up on OSE videos while researching more freecad and thinking about how python might be most useful. In looking for the direction I should focus on learning I'm looking at docs on freecad 0.16 and realated WB's, freecad 0.17, and I even opened freecad daily 0.18 to get an idea of where it's going. The direction is probably more obvious to experienced CAD users; It does appear they are gradually adding features that increase interoperability of the existing framework and features. The learning curve looks less significant overall as many new features are designed to increase usability with better UI and more advanced drawing abilities. There is a need to add some simple and maybe broad overview videos on freecad. I can add some little things I've learned and generalize about what I don't know and the possibilities from those.

This [Microfactory Boot Camp - Every Hardware Build is a Fork] also got me thinking about the optimal use of gitlab for freecad files. The current issue with the powercube where I've uploaded multiple versions to the main branch is not ideal, but I've been indecisive about how to test other options. While storage is an issue for any system that is versioning files (especially binary) cloud storage is both cheaper by the second and likely partly because of data compression and deduplication in many cases. However, structuring branching so that it improves workflow could lead to more file creation at some points. But, the branching of sub/assemblies and discussion prior to any "merges" can reduce excess duplication of mistakes in large files.

Sun Aug 26, 2018

Researching FreeCAD methods to make 3d curves for piping.

https://www.youtube.com/results?search_query=freecad+3d+curve+dwire

The flamingo WB is ideal for solid plumbing with simple elbows, but I think positioning circles via the draft WB and using loft and sweep between them can make good piping with complex curves in 3d space.

I'm also catching up on understanding freecad 0.17 from some of these tutorials and how the body and plane functions work in the new Part WB. I see many tools that seem to be working much better in 0.17 that we've been wanting to use that have thus far been to difficult in 0.16. I'm also looking at python scripting since I have been progressing in learning python.

https://www.freecadweb.org/wiki/FreeCAD_Scripting_Basics

I'm also still thinking about how to restructure CAD files & folders for git. I lumped the 3 recent versions together because of common files, but with git hosting services redundant copied files don't matter so much and each version/repo needs to be wholly functional unto itself for users to download only that version. With CAD files in specific folder structures, it is easy to use the A2WB to import parts and subassemblies and the whole package will be easily editable and stay small with minimal redundancies.

Continuing to figure out the bezier or bspline in draft WB is proving difficult in multiple work planes. Adding other draft wires stepping in x, y & z, dirtections as guides seems like it should help, but the curves are still hard to control and unpredictable.

https://www.youtube.com/watch?v=-ivzKZm_W7g

decent tutorial showing abililty to move curves into a 3rd axis, but not with external reference points or draft utils.

Tues Aug 21, 2018

I am starting to understand underlying functions of git and I see files can be managed, but there are limitations and complexity I don't get yet. I wonder given the modular OSS model of gitlab if more development on tools for managing different file types can be easily developed. New features and updates are to be made in separate branches just like software, but binary files can't be merged so there is more potential need for discussion of issues before merging updates. Good labeling is critical. At least it gives a clear history of development as long as someone can interpret the branching. This is one area a GUI may aid over the CLI. I installed gitkraken to look at its interface, but I am using the CLI so far, but I have yet to try making any commits to a branch properly. One issue with learning git is there are many different terms used for the same actions and not just by different platforms.

I created a gitlab account to explore the interface. I suspect moving to gitlab before getting to used to github is ideal. Groups there are equivalent to Organizations on github.

https://gitlab.com/Abe_Anderson

A good next experiment will be reworking the Power Cube freecad repo. The other issue there is my freecad knowledge and workflow needs significant improvements to work well with git.

http://www.sparkleshare.org/ is a git GUI for linux. It's distributed in a flatpack container. I'm installing it now for later testing.

I re-edited the cordless drill photos again less aggressively this time, but it was clearly still to much. It found features, but the exhaustive matching was only [1/1], [1,1] blocks and it finished quickly with results showing only several camera angles along one side. More unique background features for triangulation appear critical in this case.

Sun Aug 19, 2018

The cordless drill COLMAP test finished overnight. rather quickly I think. It ended with only 13 photos on one side being used. Clearly the rather aggressive selection masking of the background I did, caused it to find much fewer common points. There must be some tradeoff point though. I still think controlling the background environment white curtain or green screen would be interesting to test.

I'm looking deeper into gitlab while still learning git.

https://about.gitlab.com/2017/09/11/comparing-confusing-terms-in-github-bitbucket-and-gitlab/

I created a gitlab account to get a better look at the web interface.

I'm nearly through reading Think like (a) git and reviewing some of the git command line as well. I think the CLI is sufficient and there are ways and tools to colorize and improve that interface. Maybe something could be added to freecad too, but there are many other files to add so automating committs could get confusing to some, better to keep is simple.

Sat Aug 18, 2018

Continuing to learn about git since it seems universally valuable to understand for software and potential use for collaborative work.

http://think-like-a-git.net/sections/about-this-site/what-this-site-will-try-to-teach-you.html

I see examples that scientists are using it for data logging and documentation. There has always been a lot of discussion about workflows and software for documentation and changes over the years seem to be the norm, which over the long term is to be expected, but there is a need for some static consistency. Git has been around long enough and is such an integral part of Linux and open source that it may be the ideal tool. It's recent popularity is likely a product of that and that popularity driving creation of easier to use supporting tools.

My current point in the PC freecad requires learning the pipe WB's and I think more of the draft WB will be helpful as well. I did a quick upload of folders to github when I started using it and that is wrong. I see from the example files Jose has setup that I need to learn git and substantially more freecad to be efficient using it, but it definitely looks worth it.

As far as github and MS concerns I see Jose thinks gitlab would not be hard to migrate to and is considering it since it is open source. Github has PR advantages due to it's popualrity, but from an OSS purist perspective it is the oposite. That said, I don't think there is anything that can prevent anyone including MS from using open data for training AI's to help closed development.

https://www.microsoft.com/en-us/research/blog/learning-source-code/

In fact if gitlab could work out a similar, but OSS friendly deal (OpenAI?) it may enable them to eliminate the limits on the free service. I do not yet understand the gitlab limits either or if how they may apply to a larger organization.

Marcin emailed link from Harman to drill photos for testing.

https://drive.google.com/file/d/1lGYj5yPYpYdZUFDlQ8HiWUEHe1q5vL9n/view?usp=sharing

I updated my photo share as well.

https://photos.app.goo.gl/ojZ2UEZt3AQT6muG7

I'm part way through editing ~124 1080p photos from a video using gimp to test, but I haven't been prioritizing that given my experience so far. Mainly my lack of GPU, but I think starting quick CPU tests on different image sets and canceling as soon as I can see how many matches it has found to check may help determine any advantages to editing the images first.

The drill photos are hi-res only 41 and the lighting is fairly soft, but there are some reflections and glass in the background. As I recall from the point cloud Harman generated there was quite a bit of background points so I think I will try masking some parts out and running that as a test next.

I found a gimp script to save all files. It made it much easier to lasso select around the drill and not worry about so many shortcut keys or lack thereof.

https://antumdeluge.wordpress.com/2017/12/20/export-all-open-images-in-gimp/#intro

Wed Aug 15, 2018

I've been reviewing git, github, gitlab and interoperation with freecad workflows more based on yesterdays meeting suggestions. I was a bit surprised by Jose's points, but from what I can see they are reasonable. Although, he is choosing to make more compromises and use less open software in some cases. Looking at git further it has become incredibly popular for many organizations to use in a variety of ways beyond software development. It's distributed data concepts are also the basis of much of the new web 3.0 libraries like IPFS. The FreeCAD workflow definitely needs updates, but I still see the importance of prioritizing existing work and python for future changes. github seems to be the easiest solution and it is more popular for now. I expect most OSE devs well be aware of git to start, but if not it is so widely used in business and industry now it is critical to understand the basics.

Most of the tutorials also say the basics are all that is necessary and the advanced concepts are unnecessary and I think that easily applies to freecad and related data files. Much of the efficiency that can be gained from Jose's suggestions are more related to features technically external to git, but standard inclusions like issue tracking and maybe dev team management. Also freecad can be used more integral since it opens/exports or includes many other types of files related to CAD/CAM with its growing work benches and their increasing quality. I'm seeing there are more advances in freecad 0.17 than I thought. An important concept is using freecad in a way analogous to writing readable code versus comments so documentation ends up being part of the process and less time consuming in other applications.

Tue Aug 14, 2018

Meeting prep. reviewing COLMAP experiments and PC CAD.

Thurs Aug 9, 2018

COLMAP finished overnight not sure how long it took the timestamps in the log are confusing. I think it's waste to because at the end of log it reports canceling dense reconstruction due to lack of CUDA. So I'm not sure at what point it requires it. I know CUDA can be turned off for CPU only and I'd expect the GUI options to do that as shown, but some step must require CUDA. Interestingly at first I though there were more points in the model around the tape areas then I decided it might be the oposite. It is hard to tell. After reading more in COLMAP docs I think close-ups and higher res are useful for smoother objects. Most of the pixels are wasted on background since it is hard to frame shots doing video. I retook some more careful video while it was partly cloudy in case more data for testing is useful. I still think with a pro green screen the object could be scanned in hi res and even moved if needed, but I am uncertain if the software is designed to handle that. I ran the original video back through kdenlive at 1080p 60fps at 1000% speed it gave me 124 images. There must be ways to rapidly mask photos in GIMP so I will look into that.

Also found a site with scripts for automating photogrammetry processes. https://pfalkingham.wordpress.com/2017/08/14/automating-free-photogrammetry-scripts-i-use/

This overview of photogrammetry app demos is fairly thorough. https://youtu.be/ELHOjC_V-FE

With good images it seems it should be possible to create models with less processing from sparse reconstruction, but it may require more human hours if it can't be automated via scripts etc.

Wed Aug 8, 2018

Took so more video of the wood handle; First I added some striped masking tape on the handle put it on a white sheet of paper and took video under more artificial light, but it was overhead and shadowy. Finally, had a cloudy day so I realized it should be shadow free outside. I had to tape the paper down and the handle due to a slight breeze, but I didn't notice motion or many shadows, but there was some cloud variation. I took video in slow motion, which I think is 720p (no options), but I saw some interlacing artifacts in the playback. So, I tried smooth motion 60fps, which said it was 1080p again no camera options on res. It copying and uploading now. With the space outside to move around I think I got better angles distance & smoother shots this time. I also think picking a few of the best shots manually and erasing the background in GIMP is the next best test.

After erasing backgrounds of 50 images from the 60fps smooth motion 1080p video in GIMP I ran COLMAP and it went way to fast. It only used several images from a narrow band over the top and the length of the handle. I ran it on low quality and sparse so I try some other settings first. I'm wondering if I over-erased and/or there was to little detail from the white paper background.

I restarted COLMAP to run a dense high quality model on the other 50 unedited images to test those. I now see I technically made a mistake with kdenlive default output to 720p, but I don't see how that matters much. All the other examples say resolution/pixels are only important for detail and we want smooth CAD like textures for most parts not noisy bumpy ones. However, it is another test to run. I think it all comes down to image quality either it can find good matches or not and so far I think all the tests have said no good initial pairs found. It is unfortunate because the 60fps output looks much better. There are still some shadows at points due to cloud variation and maybe between that and a background or erased background it can't find the points it needs. More consistent distances and slighter angles may help. They should be in the video though. I thought maybe my overediting caused the 1/1 matching block issue, but with the other 50 unedited images it is saying the same thing so far.

COLMAP still running for hours now so I put it on low priority just to make sure I could run anything else without issues.

Propagated PC v17.11 frame changes to PC v18.01 frame.

Tues Aug 7, 2018

Reviewing COLMAP progress and some more tutorials that clarify best practices.

https://www.youtube.com/watch?v=bDHJM6nAKtc This video suggests using video then extracting good frames using VLC then deleting the excess background around the object in a image editor (GIMP). This is somewhat the oposite I was thinking with having better background points to reference and it makes sense. I was thinking some background points around the object would triangulate shape, but really thsoe points need to be on the object itself anything else is excess noise and computation. So instead of grids around the object having adding distinct high constrast markings to the object. I have some striped masking tape, which would likely work well or just marking on some plain masking tape to add contrast. If a lot is needed it will make the pixel texture look odd if that is important later, but for most likely objects without distinct points the texture is unimportant. For something like an engine it would likely have enough distinct points adding markings should be unnecessary.

I saved the COLMAP projects and a ply file, but I can not open the files now. COLMAP says the project is invalid and the ply mesh file is recognized as binary. opening it as a txt file shows some basic ply file info then data. From reading COLMAP tutorials I think the sparse operation may not be generating the right data files. From the view I saw in COLMAP the sparse points looked sufficient to generate a low detail mesh object, which is what we want. The dense data may be needed for generating acceptable ply mesh files for meshlab. I'm tempted to think the software could just be tweaked for lower res object estimation.

In the end the question is how much human time does it take to edit the video/images & mesh to a final freecad acceptable mesh part. Is it more than just drawing it in FreeCAD from basic photos with measurements? Then there is the ideal mesh to parametric conversion for editable freecad parts.

Mon Aug 6, 2018

I see Harman is working on COLMAP. Photogrammetry 101 with Harman I just tested it with my photos and the suggested settings, but I have no dGPU since I removed my old nvidia card because it seemed to be failing. COLMAP simply closed and I assume that is why. Several hours of processing is alot. So, myquestions are if quality can be lower for inputs or more or fewer photos will help speed overall. Running COLMAP on my i5-4590 CPU @ 3.30GHz × 4 on medium quality inidividual images. Video frames didn't work, but might be interesting to figure out if there is some benefit. I installed meshlab via ubuntu software center I finally got it to run via terminal. It may be throwing some errors that need to be checked.

COLMAP just finished, which was surprisingly quick. The photo positions are from one side and obviously wrong.

Log file--> https://drive.google.com/file/d/1HvMs_YH2UVrzt19ZwNg4xCWT3MgNkGlx/view?usp=sharing

I made a shared album for Photogrammetry from yesterdays media. https://photos.app.goo.gl/ojZ2UEZt3AQT6muG7 Note my first test used photos from the video extracted with kdenlive as described not my stills.

Reviewing the COLMAP & the log it says 57 images 3056 points, but it did analyze all 191 images. Further review and understanding why/which images are good may help. For more data I'm thinking more images from kdenlive. I think I'll try video input first.

I attempted to make a quick grid for backgrounds, but I don't have a laser printer handy. I wonder if background focus or lack thereof plays more of a role than focus on the part.

https://docs.google.com/drawings/d/1dmYeJFPCqMLOMjk2SEMA-UwylYw5b4wH1S_HwHkZTsM/edit?usp=sharing

I created a crude grid with a paper and marker. I'm hoping the complexity and accuracy of the grid matters little, only that it is high contrast and static. I am shooting a new video of the handle because I think it is the best test case part.

I exported the new video from kdenlive at 500% so I got over 400 images, jpg's this time so size is ~50-175K. Lots of small blurry ones so I may try deleting all those, but COLMAP seems to determine image quality on its own. I immediately noticed the number of features it is seeing per image is much higher, 5-6k. COLMAP pegs all 4 cores at 100%, but the system still seems responsive.

I stopped COLMAP after less than 1 hour because it was taking to long on the matching. It got to 3/9 and in my experience things that take to long processing due to poor inputs aren't worth. Iterate try again. I did get some log data that is different though.

https://drive.google.com/file/d/1EQ_RLhPPJDIT-Ow2YWDQ8QA-VnkSFwwk/view?usp=sharing

I think manually picking a few dozen jpg's will be a good test.

I manually selected 91 images from the ~400 I generated before. I picked out the images with as little blur as possible mainly on the object, but also its surroundings. COLMAP is only working with 2 matching blocks, but it is taking much longer towards the end. I suspect this is due to the blury shiny glare filled backgrounds at the low angles in the final photos. I will let it run overnight.

After reading more about the processes used I think the background is really important and a good identifiable camera model is probably helpful. I grid in the background may be very helpful as well I may try setting up some cardboard around the object and taking carefully focused photos next. Maybe strips of card board with grids taped to the edge of the stool at intervals so I can take shots in between without obscuring the object.

There are other apps like COLMAP to test, but I read comments COLMAP is better with low noise.

test 3 log https://drive.google.com/file/d/1D8LsISdWp0fP7v5WCnuyjaogMD1pFSqH/view?usp=sharing

It finished and has a lot more points in the background surfaces, but I'm not sure if there are enough on the part. Definitely, need to get more consistent photo spacing low-res focused stills with more grid or clear reference points around it should help.

Sun Aug 5, 2018

Took video and photos of objects for photogrammetry testing. UHD video seemed to be to slow on my old GS5 phone so I went down to 720p & kept 16Mpx for stills. I'm uncertain how much movement of the phone matters. Obviously movement of the object is not good. I also assume a checkered or grid background would help. I tried a few different odd positions and test objects. The media might finish uploading to google photos in a few hours if not then in the morning. How to process video into stills easily seems harder than it should be. I'm thinking quick edits of video clips in kdenlive for general cleanup and cut out movement mistakes etc. before generating a sequence of stills. I wonder if exporting/extract frames as images in kdenlive has to be done via plugin scripting. I see discussions about it for OSS and GIMP, which doesn't do it either. The only easy app looks like virtualdub, which is OSS, but is a windows app. Not sure about LivES; blender will export all frames as images and it should allow frame dropping too.

https://github.com/GNOME/gimp-gap/blob/master/docs/reference/txt/plug-in-gap-extract-video.txt

https://www.raymond.cc/blog/extract-video-frames-to-images-using-vlc-media-player/

https://forum.kde.org/viewtopic.php?f=272&t=115743#p284361

https://forum.kde.org/viewtopic.php?f=272&t=116323#p286963

I figured out how to get an image sequence out easy in kdenlive.

step 1 add clip and drag to video timeline step 2 select and right click clip and split audio step 3 right click clip again and ungroup step 4 delete audio track step 5 Effects->Motion->Speed (1000% gives ~3fps) step 6 Project->Render Step 7 In rendering dialog window select Images sequence in right file format list (last item in list) step 8 select image file format in right list (PNG?) step 9 deselect Export audio step 10 Make sure the radio button for Full prpoject is selected Render to File

I did this for a wooden handle I put on a stool and walked around taking 720p video while lowering the angle from above it. At 1000% speed I got 191 images from the 00:01:19:13 long clip. Most images are over 1MB and I noticed partly due to my poor camera handling there are some blury pics. I'm not sure how bad the quality of these might have to be to mess up the 3D mesh generation, but they are easy to spot and delete by file size. If more good files are needed then the speed can be reduced and to reduce the number of image files there should be an way on linux to delete odd or even files etc. Or it can be done manually if only a few dozen of the best angles are needed. My current test images are all 720p. I wonder if 1080p will make a difference. Lots of testing to do. I have video and images from 5 different objects wood, metal, plastic, and plant.

Wed Aug 1, 2018

Compile and Installation of COLMAP appears successful. https://colmap.github.io/install.html#linux

I also installed meshlab, but I'm not sure it is working or installed correctly. Searching for more instructions.

I'm trying to figure out how kdenlive can export a sequence of images from video. With kdenlive it shouldn't be difficult to decimate the frame rate down to maybe 2fps? from standard or low frame rate video with a high enough res probably 1080p and up and then export the frames as images for COLMAP. It might require a script to extract the remaining frames. This should make it easy to capture plenty of images by simply walking around a part with a phone camera a few times. If 2fps isn't enough or some needed view points are decimated out they can always be extracted from the original video.

In cases where an editable part(s) may be desired from the final output file, the big issue may be that it is mesh format and not directly editable by freecad; Unless the mesh to freecad conversion can be automated more it may still require alot of work in freecad, but at least detail and accuracy would be available.

Tues Jul 31, 2018

meeting prep.

next steps on PC plumbing, but will prioritize photogrammetry as discussed in meeting. So I need to finish installing COLMAP etc. (not sure where I left off on that before). Also look into the google vrxworks? framework for android I saw somewhere, which may be partly open source, but likely runs on google services.

Sun Jul 29, 2018

updated details on frame module and cleaned up PC assembly and added pump plumbing.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/PC%20v17.11%20Frame.fcstd

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/powercube%20v17.11.fcstd

Tues Jul 24, 2018

I think all changes needed to the engine module and frame are propagated through to the final assembly file. Now it needs cleanup and re-assembly and addition of plumbing.

meeting prep.

Sun Jul 22, 2018

I have to rework some of the pipe fittings assembly to the tank because I simplified to early and can't add parts inside the tank. I started by making a new 3/4" NPT 90 elbow. It is based off components generated by the OSE pipe WB, which doesn't quite work in 0.16 in the mode I need. It may be a little short, but close enough. Thinking about it now, it could be redone with a trajectory from a bigger elbow maybe 1". I keep thinking about changing the way I'm making and uploading files to Github, but it is much easier to work with different files for assemblies and simple versions instead of putting it all in one history to search through. Having uploaded the whole folders with the FreeCAD backup files is a task not to repeat though.

edited the 3/4" down to 1/2"

updating frame assembly with plumbing starting in tank.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/PC%20v17.11%20Frame.fcstd

updated changes to simplified frame into full PC assembly.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/powercube%20v17.11.fcstd

Tues Jul 17, 2018

I re-constrained the tank panels to the tank fixed back.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/PC%20v17.11%20Frame.fcstd

Next examining constraining the plumbing in the tank and fittings welded to the tank into the frame module instead of the assembly to reduce complexity.

adding plumbing parts with constraints to simple version of frame file.

meeting prep.

Sun Jul 15, 2018

added symmetrical top notch to cube sides. edited side lengths to make cube 30" deep, which should give a little (~0.75") room for movement too.

I had some trouble with re-constraining the sides correctly so best to just delete most of the constraints and redo them.

I've also been thinking of constraining at least some of the plumbing parts into the frame; Especially, since the welded parts and the plumbing in the tank is technically part of the frame. It will also simplify plumbing constraints in the editable full assembly.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/PC%20v17.11%20Frame.fcstd

Tues Jul 10, 2018

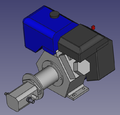

Checking the engine-pump module in the frame shows quite a few needed changes. As expected the frame is to short vertically (~1") and in depth (~2"). The rubber feet in the base are currently 1" this increases the height once installed but at that point, the top being even with the frame isn't cause for concern. It is getting in the side of the frame that is difficult. The bottom mount plate is to small and the holes in the wrong position in general.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/PC%20v17.11%20Frame.fcstd

updated mount pattern to constrain engine module to for visuals of the next changes needed to the frame.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.11/powercube%20v17.11.fcstd

meeting prep.

As discussed in the meeting searching more I found a makerspace local to UCA in Conway. It appears funded by an organization called The Conductor that promotes entrepreneurship and is funded in turn by local businesses. Both could be good contacts for finding students and organizations interested in promoting learning through making hands-on and open source tools.

http://www.arconductor.org/makerspace-2/

I also need to decide where to post a CAD rule about making sure parts are assembled from physical sub-parts such as those that are welded together.

In reviewing FreeCAD_101 and rewatching some of the videos I see some potentially out of date info, but they are all good tutorials. I think the last tutorial by Manolis uses the A2 WB to import all parts, which was later changed to mostly merging all, but a base part as in Roberto's tutorials. I thought Roberto's more recent tutorials on assembly workflow were included, but I don't see them there so I am adding them. I'm thinking of adding a final Tutorial section with guidelines as text and as a placeholder for potential future video update(s).

Mon Jul 9, 2018

reviewing engines module specs to look for flaws before finalizing to update other modules.

I found the mounting base was backward because the elongated holes are supposed to be close to the back not the front. Reconstraining this proved to difficult for the solver and editing the original sketch was to slow. So I simplified the base separate from the rest of the engine and constrained the simple parts and uploaded that and the final version.

I also noticed github doesn't show the descriptions, but an ellipse button in the history. I also wonder how searchable the descriptions are for finding versions of parts.

Started to assemble into pump module, but found the holes for the sleeve coupler is rotated out of alignment. So editing the sleeve is easiest to make sure holes are correct distances.

In editing the sleeve I looked at SAE bolt patterns and went back through logs and parts on the wiki. The engine pattern may be a SAE B 4 bolt, which is 90mm (~3.54331 in sq, I used 3.5") I think while the pump is SAE 2 bolt pattern and the pump CAD should be correct according to previous data found to create that CAD. I made the holes on the engine side 0.3" diameter instead of 0.25", the accuracy of the CNC may be uncertain anyway.

The way the CAD is done on the sleeve is simple enough to editable, but isn't done realistic parts as the would be welded together. The method used is probably quicker and simpler though. It will not give correct 2D patterns and measurements for nesting and CNC cutting as is because the inner hole size for the end plates needs to be the outer diameter of the pipe.

I think a CAD rule to add somewhere on a FreeCAD page would be to always draw actual sub-parts and then assemble. This should be discussed in the meeting tomorrow.

http://www.hkhydraulic.com/image/cache/data/bildimport/W3-SAE-B-Flans-700x700.JPG

Tues Jul 3, 2018

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.08/Xp16hp.FCStd

on a trip the last week and can't make the meeting. I didn't get much done on CAD, but I have had a chance to listen to a lot of other educational media. Continued to learn a little python, and related info about tensorflow deep learning software tools. I noticed VRWorks tools for Android that allow measuring surroundings based on image processing (in cloud for mobile). I'm not sure how much of that software is based on open source, but the basic tools are open. I also reviewed info about Ethereum its contracts model and more. All useful open tools to learn to apply.

Tues Jun 26, 2018

checked extents on engine and looking at best way to add bolt pattern for pump. reviewing logs to make sure I'm not missing anything else.

meeting prep.

continued adjusting distances on the engine. The tank and filter/covers are a technically a bit short in depth (front to back), but with the current design, it looks ok to leave it as is. I finally got distances to add up to 14" with the shaft cut short by 2" (pics show 16" total depth), which makes sense given the 5" thick cover, 5.75" base, 1.25" back (with oil ports), and the 2" shaft. I will add a 0.25" bolt pattern next, which makes the total thickness of the back cover 1.5" as measured.

I added a ring with 1/4" bolt holes at 3.5" center to center.

Need to review, but I think it is ready to simplify. Using GitHub even though it versions files I think it will be easier to identify if I just use separate files with simple in the name like I do locally.

Mon Jun 25, 2018

reworking top compound of tank & air filter.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.08/Xp16hp.FCStd

The distance of extents for the top tank and cover look ok they might be a little small now, but I don't see anything that obviously matters. Need to double check extents though. The last thing I can think of is to add a pattern for the bolt holes on the back side for the pump adapter mount. I might add a thin part instead of editing the existing clone if it makes sense distance wise.

Tues Jun 19, 2018

edited engine constraints to get distances more accurate and made measurements to figure out top/tank positioning. The tank+air filter compound needs to be redone since it is to narrow by ~1". Otherwise constraints are good. I also added a breather cap, but haven't got the pull cord handle right so it easy to constrain yet.

Mon Jun 18, 2018

I assembled most of the engine fairly close, but some angles changed so I need to redraw the muffler part or just redo the constraints. I was concerned the tank and cover compound I froze might be to different in size to fit the new larger body, but it looks ok so far.

Need to adjust total height and add the breather cap that sticks up.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.08/Xp16hp.FCStd

Tue Jun 12, 2018

editing engine CAD and meeting prep.

Sun Jun 10, 2018

Figuring out how to do re-assembly on the engine CAD. In order to make some symmetrical constraints I added hidden features just to use as constraint points. Still not quite enough, but getting closer.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.08/Xp16hp.FCStd

Tues Jun 5, 2018

working on engine CAD and updating to github https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.08/Xp16hp.FCStd

meeting prep. copied current meeting doc

Sun Jun 3, 2018

created github repo for power cube https://github.com/Witz0/OSE-Power-Cube

I think I successfully separated some sketches in the engine file from faces by choosing to reorient them (Sketch--> reorient sketch...), but it still breaks most other features.

I'm not sure what best practices are for the github repo's are yet and I think there is a list of preferred licenses in the wiki somewhere, but a quick search didn't find that.

So I uploaded all the power cube folders I have including the engine file and some other files that maybe could be referenced from other repos depending on how they can be setup.

https://github.com/Witz0/OSE-Power-Cube/blob/master/Power%20Cube%20v17.08/Xp16hp.FCStd

Sat Jun 2, 2018

I've been trying to edit the engine with some difficulty in finding the fastest way to make changes to the sub parts without breaking all the sketches and interdependencies. I've mostly given up and decided to break it down into simple components and reassemble them after redrawing the main body parts. This is an example of where I think the new Part WB in 0.17 will make editing easier. Sketches no longer map to faces and parts have more independent coordinate systems I think. Therefore it should make sub part merging and assembly easier.

The file is a mess though and I'm not sure the best way to clean it up perhaps parts will just need to be edited in the old version or redone if needed.

I'm also having trouble uploading it even though it is only ~500K. It is probably best to move it to github anyway.

Upload warning It is recommended that files are no larger than 524288; this file is 540673. A file with this name exists already, please check File:Xp16hp.FCStd if you are not sure if you want to change it. File:Xp16hp.FCStd

Tues May 29, 2018

checking history on the engine model I see Josh_Log#Fri_Aug_18.2C_2017 made a rough model on aug 18 and the photos are dated aug 19. So obviously they were not referenced as I thought. They are close, but not enough for CNC cutting parts.

Sun May 27, 2018

Looking for specs to redraw the quick disconnects to other sizes. 1/4" 1/2" and 3/4" are commonly needed.

The pump situation needs to be verified and BOM's updated.

Also modifying the engine CAD with fluid access points and pull cord.

Looking at OSE Pipe WB more I found I can generate the parts in FreeCAD 0.17 that glitch in 0.16, probably due to the part WB, but the design is still for PVC so I need to learn LibreCAD better. Getting the shapes shoud be possible with existing labels and code functions, but I'm not sure how much code reconfig might be required. I also think adapters like SAE-NPT could be done, but that clearly requires more coding and there are different ways to do it.

Added SAE -12 adapter. It would be nice to just generate these in a WB, but so far editing these is simpler. File:SAE 12 to 0.75in NPT adapter.fcstd

Added starter pull cord handle to engine in engine-pump module. File:PC v17.11 engine pump module.fcstd

A point to consider on the plumbing and BOM's it seems the demarcation point for parts to the PC versus the operating machine for plumbing may need to be the hoses simply because of hose length being dependent on installation to the machinery.

After further searching for an oil fill point besides the drains because I thought I understood there was one I found the stickers and tags show oil is filled through the drains as well. Tip it one way or the other after removing drains then level it and refill. Looks messy to service, but could be done while in the frame I think.

Further measurements in CAD and comparing to the photos shows there are likely some size discrepancies for the engine model. The base mount holes look close on depth (front to back), but short on the overall depth of the base as well as on the width of the mount holes. The whole model may be an ~1"+ short front to back. I thought I checked this before so I should review previous notes. It is disconcerting and makes me think the 3D photogrammetry method is needed to get sufficient accuracy for the CNC cutting.

Further measures and checking old logs show the breather cap still needs to be added and is ~18.75", which will require top notches in the frame as well. The engine is short almost 4" front to back. The mount holes are close at 3.5" from outer edges, but from photos could be 4.75". The width of the base is 10" total, but not quite 9" in photos. Looking closer the mount for the pump coupler look slike the distance between the 4 holes is ~3.5", but somehow I got ~5". I need to review because this looks like a mess of errors.

Fri May 25, 2018

I think I found the right pump https://www.surpluscenter.com/Brands/Dynamic/0-61-cu-in-Dynamic-GPF2010S9C-Hydraulic-Pump-9-7789-A.axd

It has Inlet Port SAE 12 and Outlet Port SAE 10. The size looks a little smaller so it should be ok, but the ports and fittings need to be changed in CAD.

Tues May 22, 2018

simplified File:SAE 10 to NPT 0.5in adapter.fcstd

The SAE 10 file is made is sections that should make it easy to edit it into many adapters including the SAE 16.

Fairly easy just sizes and renaming parts.

File:SAE 16 to 0.75in NPT adapter.fcstd

The difference in the way NPT versus SAE/JIC is measured relative to threads makes the sizes confusing and they look a little big and small relative to actual parts. Effectively SAE is including the threads while NPT is close to median because of the conical thread cut.

I have yet to try using the OSE pipe workbench much because these types of parts basically consist of three parts with the hex nut.

I also do not yet understand flamingo WB. There is clearly a learning curve to using to draw pipe between points.

meeting prep.

I'm not finding a 0.61 cu in pump on surplus center; I also see the SAE ports on the lower displacement pumps are smaller despite the main body section looking the same. The other factor is the SAE 2 bolt pattern can vary.

I copied the text and highlighted the BOM issue on 17.10 and 17.11. The source and specs need to be verified and a link found. Also, need to know if parts are in stock or if these parts may change again in the next build. I wonder where in the process this info got lost; It would be good to minimize so inaccuracies don't creep into CAD. When using the CNC torch table to cut parts mistakes could become more difficult to correct manually in some cases.

Sun May 20, 2018

Looking up SAE charts to find pipe thread size for adapters on the pump etc. Most of the tables and charts are not clear or don't contain the specs needed. https://batamniagaperkasa.com/products/3/3-7/3-7-14/par14-8-2.html

https://www.ryco.com.au/technical/thread-connector-identification/sae-threads/

Getting the O.D. and I.D.'s for all plumbing standards will help increase CAD accuracy.

Understanding the SAE JIC standards a little better I think. https://www.surpluscenter.com/images/techhelp/SAE.pdf

For the O-ring standard it looks like -10 is 7/8" O.D. with a no flare design such as here https://www.hydraulicsdirect.com/Fitting-Thread-Chart-s/1934.htm#SAE-STO-R

File:SAE 10 to NPT 0.5in adapter.fcstd

Wed May 16, 2018

corrected ball valve size and added to the PC. It took two tries to get it right, but it isn't too difficult once you recall the patterns to edit and I keep trying to improve labels.

Tues May 15, 2018

fixing dimensions on parts like the ball valve so I can continue assembly on PCv17.11.

Meeting prep.

engine mount points need to be adjusted to the right ~1-2". details on engine for oil drains and fill need to be added. see engine photos from 17.08

I'm wondering if the engine rubber mounts might be too loose and enabling more shaking of the system than they inhibit because of their height or relative softness.

I installed flamingo workbench, but I don't quite see how to use it to make pipe joining parts.

edited frame, suction holes, engine mount and notch.

made more changes to the frame.

At first I thought the import wasn't going to work. It did glitch a bit, but it worked and all the constraints updated good every time. The slow downs with modularity are in the chain of complexity to make edits. Files saves have to be done in order to preserve editable files while updating the editable and simple files. The import function would work locally for more parts, but the simplification step interferes with that and the file links are local as well.

The ball valves are still wrong and the engine needs to be moved back a little for shaking, which means I can reduce & shift the notch again too.

Wed May 9, 2018

I've found the slowness and difficulty editing the PC is based in various issues in the file. Extra constraints not being removed automatically and occasional glitches where the sketches seem to get delinked from their pads. I had to delete and redo the constraints, clones, and pads. Then reproduce them from the sketches to get everything editable again. I've taken the opportunity to separate the frame into its own module. This creates problems of its own but reduces constraints in the full model. I think I'll try importing the frame with the A2 WB like I did the back tank wall then lock it so other constraints don't move the frame. The frame is close to done, but I see the engine mount hole pattern looks backward now. This way takes time to measure and transfer those between files, but at least I'm not sitting waiting for the solver to drive me crazy.

I uploaded a simple frame version though more changes may be needed.

I started adding new constraints between the frame the engine module and plumbing parts. I'm curious to see if using the frame as a locked imported part in the A2 WB will allow changes to it without disrupting constraints. Before this seemed to work only partially without errors.

Tues May 8, 2018

correcting the ball valves on PCv17.11. SAE parts need to be made next, but for simple plumbing parts that can be generated in the pipe workbench I will make spreadsheet CSV lists.

The engine fit through the frame is still a concern as well. Increasing the sides 1/4" and moving the top up will give a little. The question is how much of a puzzle will getting the engine through a side holes be. According to the CAD the engine height is over 16.5" and the holes now are 16". I think reduction of the bottom side widths from 2" to ~1-1.5" will fix the issue and the frame strength should be ok. The only significant weakness is in the monolithic nature of the tank-frame. If it takes a hard hit while on top of the back of the LT and the bending of the frame results in tank leaks that is a major loss or total rebuild.

meeting prep.

I uploaded an update for the meeting, but the ball valves are still wrong.

There are number of changes to make to the frame, so now I'm thinking separating the frame into its own module for simplification will make editing some things faster even if I have to edit the module more.

Sun May 6, 2018

I finally got freecad-legacy 0.16 installed functionally. I expected it to be faster to edit with, but it seems to be running the same. Slower than usual and crashing on basic functions. Maybe its some missed incompatibility with newer libs or the way I'm editing the chain of parts for the grate.

The slowdowns and bugs with the Assembly2 WB seem to be universal across systems so it must be the file itself.

I edited the grate for simplicity, but kept using the same methods then recalled I wanted to consider making the front holes more useful by cutting a pattern of rectangular strips drawn more simply in the sketcher without the multi-transform function, which may be overly complex and causing issues.

I need to move on to fixing the plumbing mistakes now though. I'm thinking about how to finalize the frame as a module, but plumbing parts that get welded to it make sense to include and positions still depend on many other external components so simplifying the frame separate seems problematic for editing. Despite the fact it may speed freecad work up.

I reworked the 1/2" NPT returns and re-constrained them and the 3/4" return. The A2 WB and other operations continue to be slower than before. There is a short period of no apparent activity before the app greys and takes several seconds or more to process the changes even when clicking certain things that without making changes.

Wed May 2, 2018

Finally got the frame grate for PCv17.11 ewdited in FreeCAD 0.16 using virtual box feels a little slower, but mostly the same interface issues and constraints behaving odd again.

Now looking at the hole pattern now it is a little excessive and should be reduced. To much of a CNC Torch table torture test. Instead of hex holes 2 to 4 columns of slots ~4" long several rows high would be less wasteful. In fact 1" square strips would be more useful as scraps.

Tues May 1, 2018

Reading the PartDesign Workbench User Manual is interesting, but not detailed enough. I am experimenting with basic examples in freecad and reviewing the functions individually. I'm also experimenting with the migration and its parameters to see how it affects the existing file.

While the new version of freecad is important to figure out I'm thinking of finishing the PC v17.11 CAD in FreeCAD 0.16 by running OSE Linux 4.3 so it done and it may be easier to start with a fresh project to learn 0.17 better. I still think migrating the old files to 0.17 is important, but the learning curve may take time and dedicating time to developing new tutorials on how to use 0.17 and migrate as needed may be a better use of time.

Meeting prep.

Considering the freecad and Assembly2 WB version situations it is a good time to discuss software dev version compatibility and how to develop most efficiently with the rest of the freecad and open source dev community.

Sun Apr 29, 2018

Testing migrating to the new part design WB is a bit confusing and appears to create chaos with the model most likely in constraints. I'm not sure A2 WB works at all after migration. I can see definite benefits to the new functions and methods, but it is a more significant learning curve than I expected.

Sat Apr 28, 2018

I'm looking into the FreeCAD file migration issue more. I think it is not a problem because a few people were using the 0.17 daily before and I have yet to notice any signifcant problems. For the record freecad daily 0.18 has not executed and loaded for me yet.

Assembly WB development https://forum.freecadweb.org/viewforum.php?f=20

Thurs Apr 26, 2018

more progress on BOM lately and now I'm attempting to update the CAD, but having some more issues with constraints and the way FreeCAD 0.17 is running seems to have changed. editing sketches and constraints feel slower and updates cause application pauses and hangs more. Other than that I find the interface changes ok and see some new functions to explore.