Chris DeAngelis Log

Skills

Quick Links |

|

March 19, 2018

Power Drill idea

March 10, 2018

Collecting current information on Torch Table.

Having trouble finding active users.

Would like to create an instructional video on how to quickly jump into the project. Collaborate with us

Using the 3 following search terms to find all pages on the torch table project:

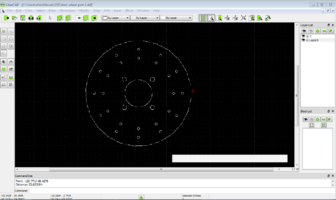

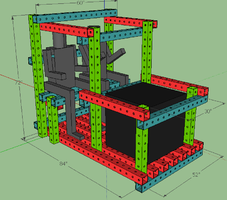

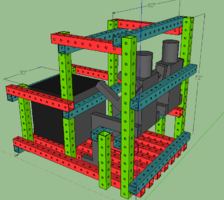

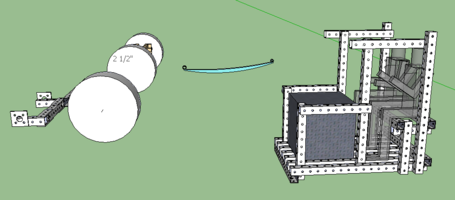

uploaded CAD files here http://opensourceecology.org/wiki/CNC_Torch_Table_2/Manufacturing_Instructions#3D_CAD

2016

March 5, 2016

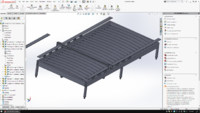

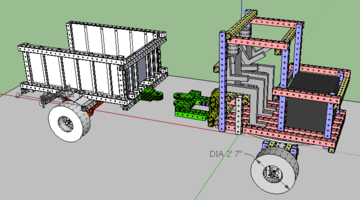

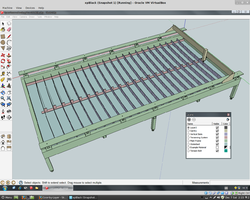

added parts to the CNC Torch Table assembly STP file. Still struggling with FreeCAD, but recent versions of freecad are getting much closer to production class. In my estimation, FreeCAD is currently the most suitable CAD software for Open Source Ecology development, in light of is open source code, and functionality. I am also impressed by openSCAD and SolveSpace, however they seem more useful for small 3D printable objects. Sketchup seems best for architecture.

As for the Torch Table, I will be devoting 100% of my "ample spare time" to it's development. I realize I may have been part of the bottleneck, by not yet finishing the promised exploded assembly drawings. However, I am also trying to comb through all of the documentation on the torch table (reptab) that OSE has accumulated over the years.

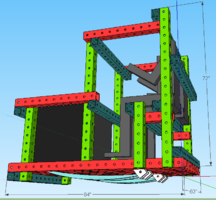

To me the Torch Table development/"design" can be broken down into 4 parts: 1) physical structure (frame, gear rails, gantry), 2) Electronics (arduino, stepper motors), 3) Software (arduino programming, STP file creation, Gcode creation), 4) clear and concise documentation that will encourage replication.

Winter 2013-14

February 5, 2014

- uploaded Liberator pressfoot FEM analysis: File:Liberator-Pressfoot-FEM-analysis-2013.pdf

December 18, 2013

- added video to Inverter

- created and uploaded File:Step wave inverter concept.skp

December 14, 2013

It is my understanding that the .step file format is the most compatible 3D cad format. It is based on ISO (International Standards Organization). when saving a 3d assembly as a step file, dimensions are preserved, and parts are segregated. The main problem with step files, (which is possible to overcome) is that if you design a cylinder by drawing a 2d circle and extruding it (push/pull), you can later adjust the diameter of the circle, which the cylinder diameter is linked to. In a step file, the 2d circle is lost, and it may be impossible to adjust the cylinder diameter.

The software I am currently experimenting with is as follows:

- freecad

- sketchup

- solidworks

- hypermesh

- salome

- openSCAD

- catia

December 7, 2013

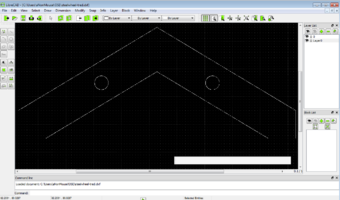

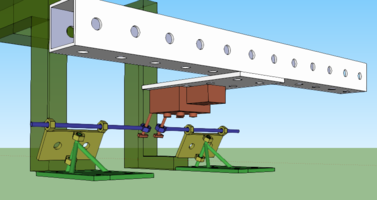

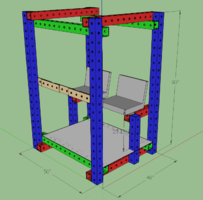

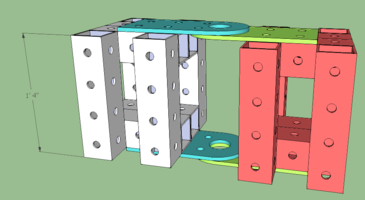

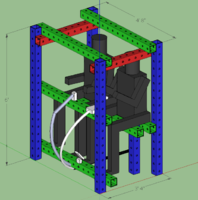

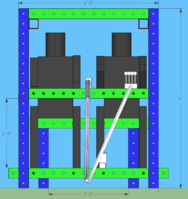

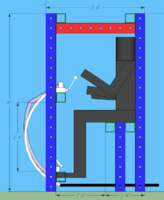

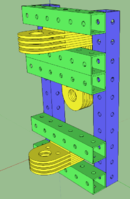

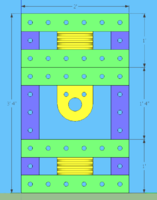

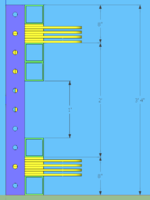

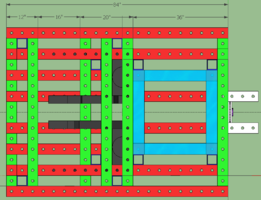

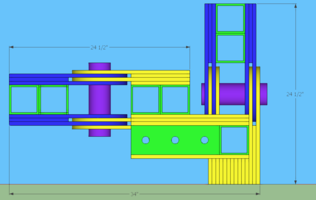

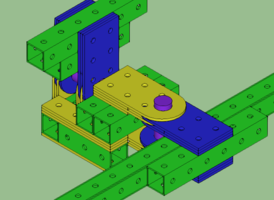

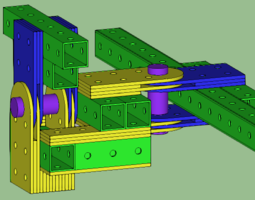

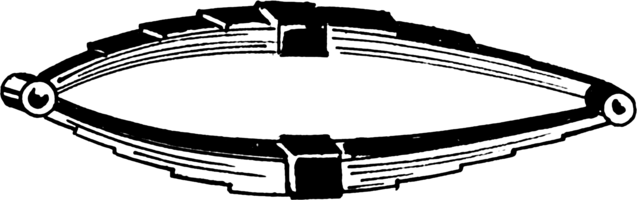

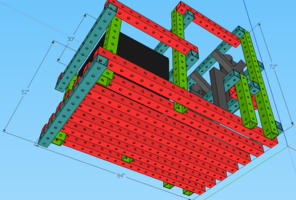

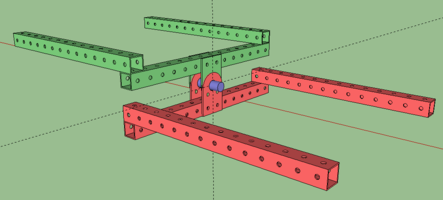

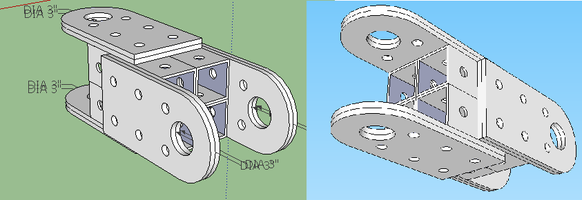

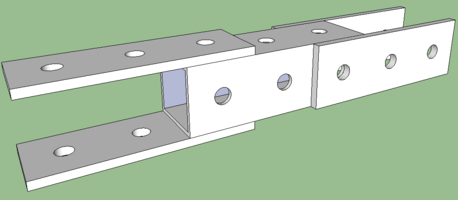

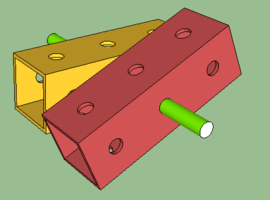

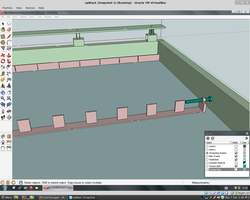

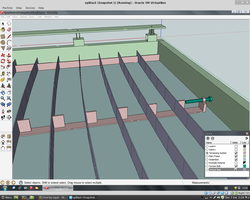

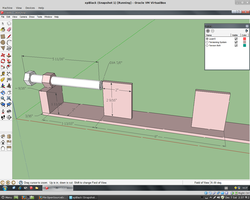

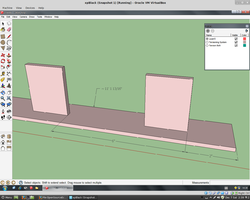

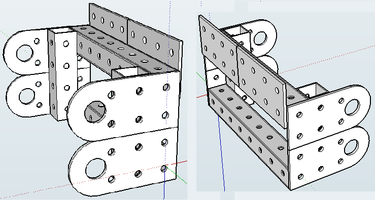

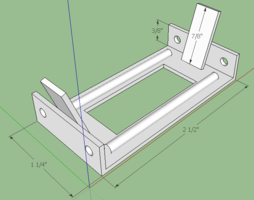

Completed the design for the Torch Table Tensioning System in Sketchup: File:OpenSourceEcologyTorchTable.skp

|

|

|

|

|

December 4, 2013

- Started to draft a new version of the wiki's frontpage: Proposed Main Page

- Starting FEM analysis on the CEB Press Press Foot. Investigating "tamper design" alternative.

Summer 2013

June 23 through June 29

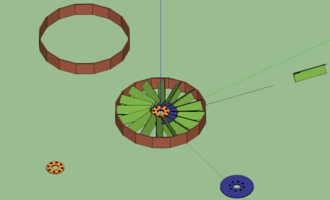

- Reinventing the wheel, OSE Style!

- File:Steel wheel.skp

June 24, 2013

=Fabrication Instructions

=

June 16 through June 22

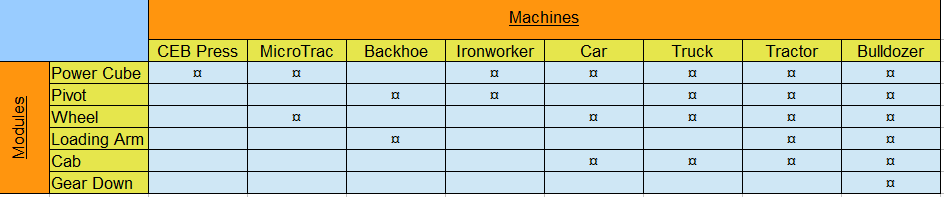

- Major update to GVCS Modules wiki page

June 18, 2013

- converted steel wheel parts to DXF for CNC Machining

- created dual pedal

June 9 through June 15

June 15, 2013

- created June 2013 hydraulic order form (also seen above)

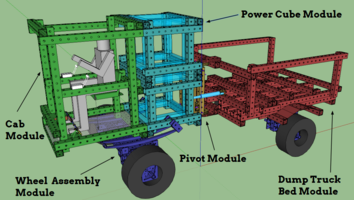

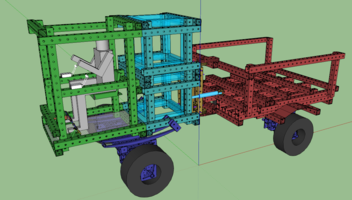

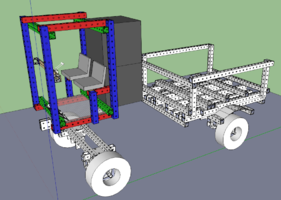

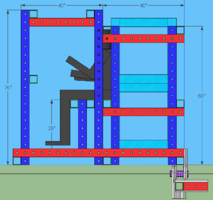

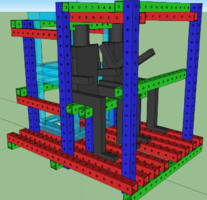

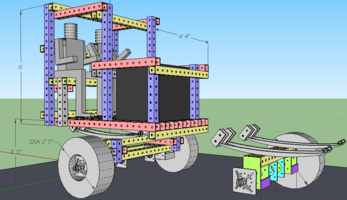

- Major update to File:Truck full.skp using up to date versions of the front and back modules

- began research on the truck's steering system

- added link to Google Doc of the Truck Hydraulics

- found a possible hydraulic foot pedal:

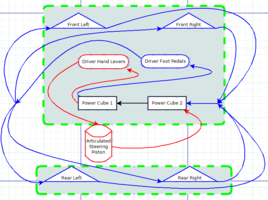

- drew out the Truck hydraulics using Dia software

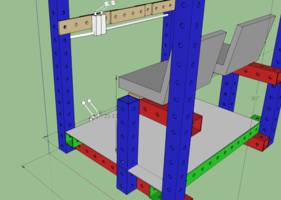

- changed cab module, added floor

- adjusted dimensions

- created a simplified model of the seat sourced bellow.

- Found a seat that we can use for the GVCS.

- http://www.surpluscenter.com/item.asp?item=1-3987

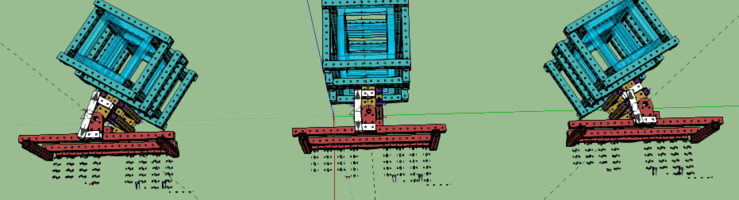

- created youtube video of pivot module

- https://www.youtube.com/watch?v=zb4bAliQHXw&feature=share

- added some hydraulic controls

- enhanced pivot design with dual vertical hinge configuration.

- major changes to the Truck Cab.

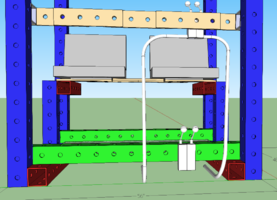

- moved powercubes behind drivers

- modularized driver cab and powercube cab to streamline fabrication

- adjusted width of the front cab to allow for attachment of the trucks central hinge system

- optimized truck pivot File:Truck full.skp

- interlocking hinges increase friction, but distribute axle loads much more evenly

June 2 through June 8

June 7, Friday

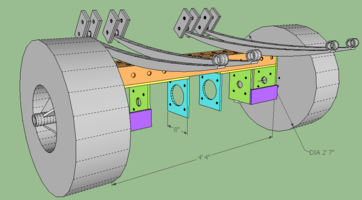

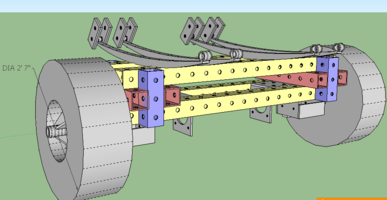

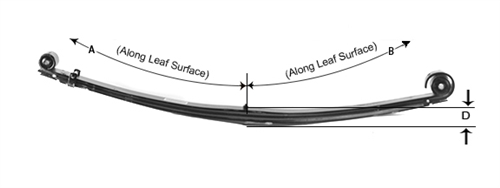

- OSE Truck suspension system with leaf springs

June 6, Thursday

- added leaf springs

- Progress on the front cab

- added leg room, finished roll cage

- File:Truck front.skp

- Pushed forward Truck Cab design

- created models of driver and passenger to help get a feel for the size and space of the Cab.

- Updated Warehouse.skp

- Also found some good images that helped brainstorm ideas

June 4, Tuesday

June 3, Monday

File:Quick attach.skp

File:Quick attach.skp

May 26 through June 1

May 31, 2013

- Created 1:4 scale of microtrac trac for 3d scale model printing purposes

May 30, 2013

Arrived at Factor e Farm today. Got some food and supplies from Dungy's and Dollar General. Purchased 2 boxes of probiotic formula for the HabLab septic tank. Added a full box to the tank. System should get a half box every month. Created a public expense list, with public commenting enabled, here.