120V Heatbed

![]() Hint: Max continuous temperature of the OSE Insulated Heatbed is 178C, which is the max temperature at which the PEI surface can remain at continuous duty. Without the PEI, the bed can probably go to 400C, with the limit being the temperature limit of the 200C wire junction inside the bed. This heat bed operates at 120V AC, which is dangerous high voltage (shocks occur above 48V). This bed can kill you. Do not use this heat bed unless you understand its design and function, and do not use this without a ground fault interrupter (for eliminating shock hazard) as shown in the BOM for D3D v19.06 - D3D_v19.06#BOM_2.

Hint: Max continuous temperature of the OSE Insulated Heatbed is 178C, which is the max temperature at which the PEI surface can remain at continuous duty. Without the PEI, the bed can probably go to 400C, with the limit being the temperature limit of the 200C wire junction inside the bed. This heat bed operates at 120V AC, which is dangerous high voltage (shocks occur above 48V). This bed can kill you. Do not use this heat bed unless you understand its design and function, and do not use this without a ground fault interrupter (for eliminating shock hazard) as shown in the BOM for D3D v19.06 - D3D_v19.06#BOM_2.

About

- OSE Reasons for using a nichrome 120V bed are scalability and lower cost for large beds.

- Reason for DIY nichrome beds is clear for larger beds on the basis of cost.

- Sound design is required a safe method:

- Do not use parts that melt at low temperature. Thus, use Nichrome C wire and braided fiberglass insulation.

- For connection, use high temp 200C wire, and simply wind them around each other. But wait... How to Connect Wire to Nichrome Heaters.

- Metal, glass, ceramic have been used successfully as heated beds.

Nichrome Heater Design

Heater Element Build November 4, 2019

OSE build Nov 2019

CAD Files

12" 120V Heatbed - For 19.06 and D3D Pro - Sketch included to modify to other sizes - FreeCAD - File:12in120Vheatbed.fcstd.

Fabrication Process

Can use a 8mm bearing and printed cone to pinch the fiberglass sleeve into the bearing. Secure the bearing to workbench, then put other end of fiberglass into drill chuck. Takes 2 people, but can wind a heater coil very quickly!

OSE Build 2

Build during 2019 Open Source Microfactory STEAM Camp:

OSE Build 1

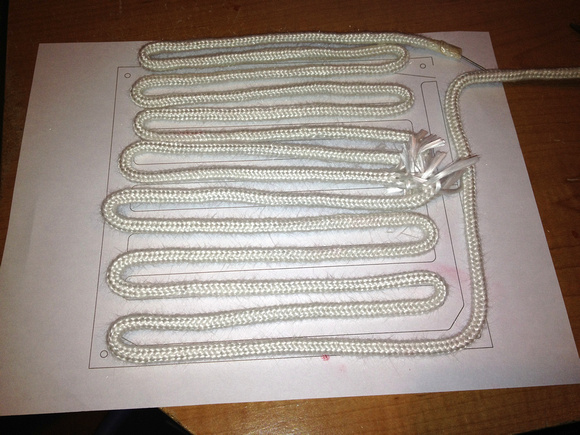

Early 2019: Fast insulated heatbed for the OSE 3D printer. 450W 120AC (compared to former 120W at 12V), so no wait for heating and 30-60% more efficient than industry standards. Efficiency is important for production printing. Insulation is rock wool, 2" thick. Bed base is made from steel house trim. Uses 26 ga nichrome C and 1/4" fiberglass sleeve from McMaster Carr rated for 1000F. 12 feet of wire, 13' of sleeve. Sleeve doubled up on butt ends. Max temperature is up to ~600C, but PEI print surface (to be added) melts at 217C. Metal crimps connect nichrome to 200C high temperature copper wire. DIY 3D printed plug is still needed to fit geometry of 3D printer control panel. See design at https://wiki.opensourceecology.org/wiki/Insulated_Heatbed

Sourcing

Bed Plate

It is interesting to observe the performance of ceramics for heated beds. If heating time is acceptable, this could work.

Aluminum

- All with hefty shipping - 6" $3- [4]

- 12" $20 with ship for 1 [5], 8x16 $24 [6], 8x8 $13 [7] -

- 24" $43 [8]. $10 per 12" bed, or $5 per 8" bed

- McMaster stock - $13 + SH for 8" - [9]

Steel

- This would be interesting to CNC torch on a waterbed from 8" stock - or just cut with abrasive metal cutoff. Steel is under $1/lb - with a 1 square foot sheet weighing $5. So $5 is the baseline cost for 12" beds.

- If steel is torched, this should be done with water cooling to address warping

- Baseline cost is $5 vs. $10 for aluminum.

Tile

- Tile is a winner in terms of cost at $1/sf. 77 cents at 0.29" thick - [10].

- Granite - $2.50 - [11]

- Polished ceramic tile 69 cents - [12]

- Marble - 0.4" thick - [13]

- Porcelain - $1 - 9/32" thick - [14]

- 8x8 inch quarry tile, 1/2" thick - $1 - [15]

- 1/2" slate - $1.29 [16]

- 12x24 tile exists - [17]

- 36x36" tile exists - [18]. $22 but MOQ of 100.

- 2 3'x3' tiles for $100 - [19]

Pad

- Ultimaker beds are 500W - - [20]

- 8" bed on amazon is $84. [21]

- 8" bed on Aliexpress is $45 - [22]

- Expensive 12" on amazon - [23]

- Silicone rubber sheet - to 450F - [24] - $6/sf

- 10x10" heatbed aliexpress 500W - $10 - [25]

- 200W 8x8, $13 - [26]

Silicone Rubber Sheet

Double Sided Tape

- $3/sf - [29]

Single Sided Tape

- Kapton tape, 4"x100ft - $25 - [30]

- Enough for 300 small beds (4"), or 33 12" beds.

Coated Nichrome Wire

- Need 30 Ohms of wire, about 10' long

- See Nichrome Wire

Uncoated Nichrome Wire

- Need 30 Ohm resistance for the length of wire at 120V to get 480W, for P=IV, V=IR, I=V/R -> P=V^2/R = 120^2/30 according to Electrical Power Calculator.

High Temp Nichrome in Fiberglass

- Claim of 1200C - [31]

Sleeving

- 20 cents/foot, 1/16" ID - [32]. Specifically - 31 cents/foot 12 feet for May 2019 build of 120V hotbed. [33]

- Wire sleeving - [34] - 15 cents/foot for 16 gauge.

Rope Heater

- Up to 500C - [35]. Description: helical winding around core material, then insulating sleeve.

Helical Nichrome Coil

- Can be stretched - [36]

Carbon Fiber

- Carbon fiber is also used as a heating wire - [37]. Interesting. But it appears it can only do 15W/meter? Why is it limited? Limitation appears to be encapsulating materials - [38]

Example of a DIY Nichrome Heater

- Idea is to wind Nichrome around an inner core, as otherwise, the heater element gets too long. That is just a practical consideration for these types of heaters if running high voltage.

- Here is 31 ga and 19 feet - for 90W - at 115V. [39]

- Here is another at 12V, with 16 gauge - 10' long, going up only to 225C. [40]

Derivative for OSE + Calculations

- 31 ga, 19 feet long above

- Power to bring 31 ga up to 2000F is under 4A - so with full 500W, 31 ga wire would probably blow up. [41]. Need to go thicker to handle the power.

- See Electronics Stack Exchange - [42]

Links

- 120V heater pad

- Nichrome Wire Calculator.

- This heat bed is used in D3D v19.04 and later versions of the OSE 3D Printer. See D3D Genealogy.

- Insulated Heatbed

- Hackaday article - [43]