Gary Log - June 2013

Sunday June 30

Goal completion

- Got a good portion of the materials, however we were unable to procure all materials. Some due to inaccurate ordering, other due to machine shops not keeping to time lines and in some cases quitting and not completing the order due to technical difficulties.

- Designs were completed, however due to limited time for the QA session, we have seen a few issues with current designs and had to make adjustments that should have been caught in a proper QA session.

- Hyd complete. We have decided to use some previously build wheel connects due to time constraints. Connects for bulldozer are complete.

Tuesday June 23 - Saturday June 29

Continued to work on 6 in 60 with some great gains and success. Back hoe is coming together, had to modify the design due to some oversight and lack of a full QA session. Modifications are complete with the build process in place. Ironworker has begun. Having problems getting material cut in the time frame that was quoted to us originally, sliding our time table to the right a few days. Adjusting however. Overall good progress.

Monday June 22, 2013

Goals for the Week:

- Finish procuring product for build, metal, hydraulics, plates etc.

- Complete Designs and QA for build out by Monday

- Finish the build on hydraulics by Tuesday, Weld wheel quick connects on Wednesday

Tasks for the week

- Call John About Welders

- Set Welders up

- Welding Classes

- look into cost and renting trucks for material pick up on Friday

- Complete Shop Set Up

Recap

- 90% complete of the designs for builds

- Welders working... more or less

- Shop cleared out of Lifetracs and brick presses

- Began orginization of parts

- Shelf's built

Saturday June 21, 2013

Final design Sprint to complete 6 in 60 designs. Good progess on the Bulldozer and back how today. Still have some hyd cyl issues with the pivot for the back how to iron out. Was able to complete minimal QA review today, will pick this up on Monday.

Friday June 20, 2013

Started a Quality Control page to begin the initial QA process for those that want to help.

Order of importance.

- Need to pick up steel. 15,000 lbs – 10 foot long /40 sections of ¼ 25 sections of ½

plates come with / 150 8x16 plates

- Paragraph on what they should be looking for QA standards.

1. bulldozer – We need to have the complete / issues will be with the design going together with the wheel module. The pivot in the back lining up with the side to side pivot. Weights for bulldozer, passenger module, loader arm module, power cube module, weight module (?)

- 2 people on the Cab**

hydraulics with bulldozer and pedals!

how the wheels will attach to the vehicle? Beefy quick connect? What about the quick connect lateral movement will it be enough?

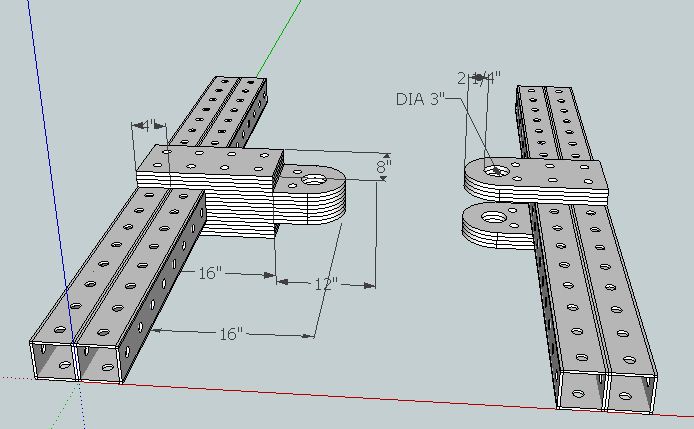

2. 3 inch wheel hub to be usable for the rubber wheel and 40” wheel

3. hyd. on the side to side pivot back hoe

4. hyd for the boom , stick and bucket are finished

5. Legs and feet. (4x4 with a smaller inch pin)

6. Completed backhoe (put it together)

7. Truck suspension parts and rubber mount, leaf spring detail w/bushings

8. check dimensions for the blade (holes etc) QA

9. iron worker cyl mount.

10. James router module

Thursday June 19, 2013

Continued on the workshop today, all tractors and brick press are moved and stored. Welding tables set up as well as extra storage area for shelves. Smaller things are starting to be tackled like small tool organization. Should be functional for the build portion of 6 in 50 tomorrow.

Wednesday June 18, 2013

Moved the dismantled three brick presses and moved to the outside storage area. Moved the life tracks to the storage area as well. Building shelving units to house the incoming material. Attempting some reorganization of the workshop prior to material delivery.

Tuesday June 17, 2013

Travel Day

Monday June 16, 2013

Meetings.... lots of meetings. Collaborated on the Spark life track to help make the design more simple. Prepare for travel to the FeF

Sunday June 15, 2013

Did a metric ton of research concerning the new VW engine and trying to make a power cube for it. With the Wiki Speed configuration the engine compartment is 3'1" x 1'9" which is REALLY tight... Now I would imagine we can make the engine a little larger than from what its housed in as there should be some room in the "compartment" that would be the engine bay of the car. However..... if we try and make a pre-existing frame and then place that into the car compartment we will have serious fit issues to the point where I dont think it will fit at all.

1. We can place the engine upright as its normal design is at 2'1", which if we utilize the current wiki speed measurements well have a ton of room around the engine... just not above or below

2. we could place it on its side like they engines are used in airplanes, but this isn't fitted for an airplane so the oil pan would be on its side. not to mention we would run into the same issue with the pump being to tall. But if we had one it looks like it would have worked perfectly it looks like (maybe for the future?) 3. oddball thing... is the drive drain is in the back of the engine... if we face the engine with the drive train backwards, the exhaust (which isn't included in the model and will add about 8 inches or so to the girth will be expelled to the front of the car. I know they make different exhausts... Until we know what exhaust is needed its very hard to make a proper cube as the dimensions will be almost a foot off depending upon what we want to use, however the more I look at exhausts and the tighter this gets, we may have to have one specialty made for our purposes.

4. The tanks are also taller than the wiki frame, they are about the same size as the motor, even in the longer wiki frame, with the motor mount and trying to leave room for the Hyd Pump, the hose fittings for the hyd reservoir are getting snug. For now in my VERY rough sketch it fits... but this could change with some exact measurements... We could source wider tanks that would have a lower profile and fit within the frame.

5. in the end... if we want everything to fit into the dimensions of the wiki speed frame... it doesn't... the engine is simply too tall in this configuration. We can fit most everything else... maybe we make a hole in the hood for the engine? :)

File:Engine.skp File:50hpCube.skp

More to come...

Friday June 14, 2013

Monica has started on the large steel tractor wheel File:Wheel.skp

Thursday June 13, 2013

Early meeting at the real estate office 8am PST. Will be available by cell if needed, please continue working on your projects and I'll check in around 1 and 2 PST!

Wednesday June 12, 2013

Great work with the designs today! For the dozer I would try and utilize a much lower arm for the design, the current one places a lot of stress at the joints with the angle its at. Currently in negotiations with the ED regarding the floors in the modules.

Tuesday June 11, 2013

Microtrack - Clean up the newer version.. make it legit. Add the wheels, axles, your new motors etc. Once that's complete work on finding a hyd cylinder for it and attach it and make it move correctly.

Bulldozer Blade - Keep going see notes below, looks good so far.

Front of Truck - Work out the control system, make sure all you design you can order...

Dump Truck - Continue on with the the most viable option get some feedback from the group and well talk in the morning.

Hinge - See comments below. http://opensourceecology.org/wiki/Pivot_Module

Monday June 10, 2013

Microtrack - Helped out and came up with a compressed version of the microtrack File:Micro2.skp. Tracks still need updated, some minor fit issues with the front right quick attach. Tracks etc.

Bulldozer Blade - Looks great keep it up, make sure the hyd cylinders you're utilizing in your sketch are real and you are able to order them from somewhere in order to build your blade.

Front of Truck - Looks good so far.

Dump truck - keep on trucking?

Hinge - look at this, digest it.... then well talk and try and figure it out... http://opensourceecology.org/wiki/Pivot_Module

Sunday June 9, 2013

Completed a new version of the microtrac to assist students with some fit issues. The original microtrac was built without the current 4x4 tubing with the holes in mind, so it made everything off just a enough to not work. Corrected the major fit issues, the Engine will be loose in the frame, however it's an easy fix with some spacers or bolts to keep it in place. Over all design allows for the front quick attach to be raised or lowered as the micro track will not have the full functioning arms like the lifetrack. This will allow you to raise and lower the instruments by 4 inches with the removal of 4 bolts. File:Microtrac version new.skp Tracks are not exact, will need to be modified for proper build. Need to add proper tracks, axles, hubs and a proper hydraulic cylinder.

Friday June 7, 2013

Some notes for the DPV's...

- I have an early appointment tomorrow and I may have to push the 11am meeting back. I'll call in randomly to check on you all... call me if you have any issues... you know the drill.. I'm here for you! I will be remote though so when you upload things please include a jpg.

- You are all doing amazing.. keep it up! I'm really stoked with the effort you are all putting in, you seem to be working together well and it shows in the product you are all putting out at the end of the day. Except for Jordan... KIDDING Jordan!!!.. your pivot is spot on... well done everyone!

- You can use other pieces when building... it you want to use 1/4 steel plate for something... please do. The point of the warehouse is to try and keep things standardized for design. We will not be taking rounds, explosives or need to armor ourselves against Al Qaeda attacks while farming.. so really there is no need to to use 1/2 inch plate unless it's load bearing in some way. If you can show me something smaller will work and still be plenty to do the job.. I'll buy in... just come prepared to tell me why! the main structure is what we want to use the warehouse for, functional things.... and the like. Things like the side of the bed of the truck, the walls or roof of the truck.. we can use sheet metal for that. We CAN add things to the warehouse if you find multiple uses for it... the warehouse is by no means set in stone... but when it comes to basic frame design... its darn close... most everything else is up for interpretation.

- Again great job, things are starting to look very professional, more and more detailed and soon the minions can start on global domination... or we can just open source everything... whatever you choose... it's collaborative!

Front/Back of truck - upload your latest files. - For both of you complete the front and back with the addition of the suspension. When they are finished collaborate with Jordan and make two models, one with the single pivot hinge, the other with the dual. If you finish this before the end of the day (which I hope you do) I would like you both to work together on the controls, i.e. how are we going to make this thing move. Brainstorm, come up with a couple different ideas dealing with hydraulics on steering. From there, go to controls and tubing, run the lines and make it work! (if you get all this complete in a day and get it right you both should be working for Nasa.... good luck) GO TEAM TRUCK! And for fun... if you choose to accept this mission.... How cool would it be if we made this a dump truck too? Think about it.. What would we need to do to make that work? Again.. just for fun if you want to work on it.

Microtrack - keep working on the controls.

Pivot - Ok you ... now I'm going to throw you a curveball... great work so far. I want you to come up with an alternative pivot... utilize exactly the same idea you have... except make it more... compact if you will... try and make the pivot inline with the cab instead of hanging below...Also the current design the pivot is confined by the frame.. it will only pivot as much as the frame allows before it runs into it.

ALSO ... Where the pivot attaches to the frame, the pivot mounts ,meaning the parts with the big holes... need to be doubled up for support... see this pic you'll understand what I mean... Pivot attached to the frame needs to be attached to TWO 4x4 pieces.  Once you finish that, go back to helping with the microtrack controls.

Once you finish that, go back to helping with the microtrack controls.

Bulldozer blade Few questions to play devils advocate. What will the ball joint attach to? Utilizes the newer lifetrack frame File:3DLifeTrac.skp and attach this to that, then see how you can utilize this design using that mounting surface. (or if you can't, come up with something that you can) What happened when the ball joint inevitably becomes loose? What will keep the weight from pulling the blade down? Will the weight end up pulling down on the hydraulics causing them to bend or to not function properly? Will the end up holding the blade up? At the start of the morning I would like everyone to look at your design and tell you how they think it could fail, and ONE recommendation on how to improve it. Take the good and bad and then move forward....Improve your design, redesign if you have to, make changes how you see fit. Overall so far it is awesome... It is a good idea.

Randoms- Spoke to Wayne with Small engine repair, needs a new hydraulic pump for a powercube. Spoke to John about the welders, all 3 welders now have new guns and are functioning perfectly. John gave us a VERY good deal on some guns... Thank you Mr. Brushwood!!! He will be by on Monday to pick up the other welders and drop the repaired ones off. Had a great conversation with Esther Livingston from Berea College today concerning the Interns. Great conversation, We are VERY happy to have all of the interns at OSE! Berea is a great University and the program itself and what it does to help students is amazing!

Thursday June 6, 2013

Project Truck Day 2

- Front of truck - extend the design as suggested below. Add quick connects along with motors to the axles. Use the EXACT ... I will repeat EXACT type of leaf spring attachment that you found and have a picture of on your log. Also, find leaf springs that will fit (as in source these and make sure we can buy them and have them shipped) and fit them to the front axle. You worked on this before so this should be fairly old hack. Just use the attachments you found as thats exactly what we need! Also for BOTH the front and rear, you will need detailed designs of the shafts, the hyd motors and the mount of the wheel to the shaft (Work with and get some help from Leandra and make it larger to fit the larger tractor wheels.)

- Back of Truck - See above and do the same concerning the axle, quick connect, the leaf springs and attachments. Also for BOTH the front and rear, you will need detailed designs of the shafts, the hyd motors and the mount of the wheel to the shaft (Work with and get some help from Leandra and make it larger to fit the larger tractor wheels.)

- Hinge - Keep going... make it work! If it helps use two micro-tractors and make them articulate. Don't be afraid to ask for ideas from the team if you find yourself stuck.. move things around.. it'll work you have a good start.

- Iron Worker - finish up the bolt count.

- Bulldozer Blade - Continue your research, Look at some pages that we have so far on the wiki Bulldozer Specification and Bulldozer as well as 6-way Blade Make sure as you do your research you post everything you have so far on your log, or even update some of the Dozer pages so that we can follow along with you. This is going to be a fun project... I'm (extra) excited for this one.

DPV Notes Truck Pivot - Awesome job... I'll make some idea changes for you to incorporate.. but overall i think its a sound idea with some tweaking it should work nicely. Dozer Blade - Great start ... very detailed... I'm loving it! Front of truck - Pics look good but I can't find an updated SKP file to check it out... Back of truck- looks good so far.. finish it up and add the suspension! Microtrac - good start on controls, I think the seat location is a good alternative and the best place to put it to keep the tractor compact. Good idea on the cover for the tracks.

Wednesday June 5, 2013

Project Truck Feedback In General - HUGE leap from yesterday as far as workable legit designs... WELL done everyone! Night and day, see... drinking from the firehose isn't so bad! Great job everyone, everything today is usable at the very least at a basic design level, most of it should be utilized almost as you have it with minor corrections... Pure Awesomeness!!! Yes... I said Awesomeness....

Now for some more specific feedback to work on in the morning before our 11am.

- Front of truck - Love the little people... great addition... it actually is the reason I'm going to ask you to extend the space for the people by about a foot. Which is a great thing because this allows us to make this correction now.. not later! Take into account that when the basic design of the truck is finished we are going to need to place controls in the cab along with hoses for hydraulics etc. That extra foot (or so) will need to be taken into account for this very reason. As of now we are going to use articulation to steer the truck. Exactly HOW... will remain to be seen.... regardless, line for the hydraulic motors and hoses will need to be taken into account as well as a control panel... better to have a few inches too much in the cab than the controls in your lap. Also create a "cage" for the passengers meaning make some cross beams above them to protect them incase of a rollover. Overall great job.

- Back of truck - Well done, well have to see what it looks like when added to the front.. hopefully you two of you worked together when designing the separate pieces... if not.. we'll find out soon enough... Collaboration!!!!

- Quick Connect wheels for the truck - Latest review that I saw along with the dimensions is exactly what I was looking for as far as the detail we were discussing... perfect! We'll see how it all fits together soon... great job!

- Pivot - F minus... KIDDING!! you're on the right track.... when you are creating this.. think of what its going to be used for... you are connecting two things together and they need to be able to move fluidly on separate planes. If it helps use the truck cab and the bed and put them together with your design. You are on the right track, but you need to be able to show proof of concept... meaning you need to be able to show that it works.. and how it works... overall very well done for your first day..Plug away and make it work!

- Iron worker - Hopefully your questions were answered. Tomorrow, we'll need to get a bolt count along with links. Good questions and making sure the ironworker is done correctly, these are the type of questions you need to ask of yourself after you have completed a design. Very insightful, nicely done.

- Tracks - Looks good, thats more like it those look feasible. As for the design you used to adjust the tracks... well thought out... the bolts would end up bending due to the weight not being linear with the threads constantly, SO use this (which I should have pointed out in the first place.. MY BAD!) LifeTrac Tracks watch the video "James Slade's Bobcat Tracks" and model the adjustment on your tracks after the tracks in the video... pretty simple... extend the bar and add a hole!

- Divide model into sections or modules, widen rear and front while shortening the cab. Leave the bed at its current length more or less. File:Truck front.skp File:Truck back.skp, Trucktor

- Need to make a 4 way hinge that allows for up and down and side to side movement. File:Example.pivot joint .skp

- Finish up the wheel quick connects for the micro trac to make sure we have a working attachement for the wheels and decent clearance for the tractor. File:QuickCW.skp, Quick Connect Wheels, Microtrac

- Need to have bolts counted for iron worker and where they need to be placed to ensure nothing is going to interfere (along with size and quantity). Also check BOM on page and double check the materials are correct. Scalable Iron Worker

Tuesday June 4, 2013

Progress on the Microtrac

First and foremost... excellent work from everyone so far!!! Thank you for the effort!!...Always some room for improvement, so go forward with the thought in mind of improving your skills!

Frame - Good look to the frame, no issues.

Tracks - Tracks were scaled from a larger model, and after looking at them, the current build we have may be to tiny to utilize on such a small scale. The width of the tracks according to the model is 1 3/4" with a hole in the center. The metal is less than 1/4 inch... With loads of more than 700 lbs of frame and engine... rolling over rocks will bend the tracks pretty easily I think. We may have to revisit this by beefing up the tracks. Lets get a hands on look at this, get some steel against the tires and see what might work and what wont for dimensions.

Quick Connect - Good initial design, however it isn't a working model. Needs more detail as far as what and where the pivot point is in relation to the microtrack itself.

Seat - Have nothing to look at, need to update log everyday with a link to where your work is.

Quick Connect wheels - Look at what we have on Wednesday.

Notes for DPV's

- When you place or use a part on a drawing it needs to be sourced, meaning it has to be a real part. If you are designing something and you don't have the time to recreate a "real" part in sketchup then utilize correct measurements as far as width length etc. even if its a block or cylinder to have a general idea of fit and placement. (something I do a lot until the final product is complete) We need what is utilized in the drawing to be real so that we can procure these parts and build with them. If we design something around a hard to make, or buy part, the design isn't feasible.

- Details, Details, Details. We can build things form scratch without blueprints.... but it sets us up for many headaches and things usually don't fit the first time. Iron out all the details in the drawing.. that's what they are for... the more detailed the drawing is the smoother the build will be!

- When you are designing things make the common sense check, does this look right? what happens to it if encountered a force form this direction? Will it fall over? Does it need legs? Is it big enough? is it small enough?

- It's not enough to be able to design something, you must be able to "prove" your design and show that it can function. Nothing at the beginning stages is perfect, its meant to be a prototype, but I prototype that does not complete its main function is nothing. Ensure what you have completed will work... or at the very least you THINK it will work and this ( ) is why.

- When you design something it needs to be designed to function. When you are complete or at that "90%" solution, you need to step back and utilize the movement applications in Sketchup and see if what you built actually will work!

Does it rotate the way its supposed to?

If it articulates will it have restricted movement anywhere?

Will it FIT!? If not why not? How do I make it fit? Can I widen the design to make it fit? Can I insert or take something out to make it fit?

Will it function? Is what I built capable of withstanding a load? Is it too small? Too large? It may look good in sketch up but remember, its all relative and scaled to a drawing, in real life, we may not be able to use 1/8 rebar for anything. Something utilized to carry a load of 800+ pounds may not work if its only 1" wide with a hole in the middle.

Monday June 3, 2013

Create plan of attack for the week:

- Look through and decide on work handouts for those at FeF.

- Update worklogs.

- Have an idea using backwards planning where we want to be by the end of the week, plan accordingly.

- Keep track of metal order.

- Touch Base with Tom and crew concerning the powercube and tractor design.