Hempcrete

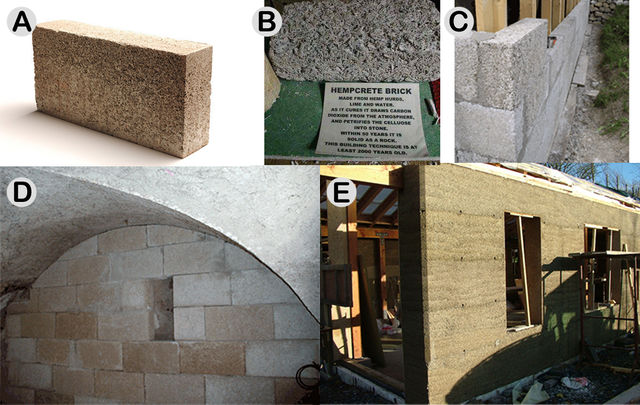

Hempcrete (also marketed under names like anobiote, Canosmose, and Isochanvre) is a construction material made from hemp hurds (shives) and lime.

Hempcrete and acts as an insulator and moisture regulator and usually comes in the form of stackable blocks several times bigger than a normal brick.

Eco-credentials: The hemp plant used as the aggregate in hempcrete absorbs so much carbon during its rapid growth that, even after the energy used in production of the lime binder, transportation and on site construction, more CO2 is locked up in a hempcrete wall than is used to build it.

Pros and Cons

Pros

- Made entirely from natural/sustainable/renewable materials

- Carbon-negative (absorbs CO2 from the atmosphere)

- Regulates moisture (in addition to acting as an insulator)

- Easier to work with than traditional lime mixes

- Does not need expansion joints (since it does not have the brittleness of concrete.)

- Lasts hundreds of years (since it eventually turns in to petrified rock.)

- Mold-resistant

- Fire proof

- Pest-resistant

- Vapor-permeable

- Its density is only 15% that of traditional concrete.

- High strength-to-weight ratio.

- Highly suitable for earthquake-prone areas (does not crack).

- Excellent acoustic (soundproofing) performance. [1]

- In historic buildings hempcrete works in harmony with the original materials.

Cons

- relatively new material, quite different from most conventional building materials; it may take time until some key concepts and techniques are understood.

- Architects who are not used to working with hempcrete and other natural materials may not find it easy to detail buildings correctly when using these materials.

- Its compressive strength, at 1 MPa, is 1/20 of residential grade concrete.

- Only lime-based paints shall be used to maintain hempcrete's breathing abilities.

How hempcrete blocks are made

1. Make a mix of 4 parts hemp shives, 1 part lime binder, 1 part water.

2. Make a form (from fiber board or other hard material) and pour your mix into it.

3. Let the hempcrete cure for 45 days.

4. Remove the hempcrete block from its form.

Wall segments with an exterior made from fibreboard and an interior made from hempcrete can also be made with integrated protected electronics.

Hemp hurd or shives are usually made by using a Hemp decorticator.

Considerations:

- Shield the hempcrete from the rain during the first 10 days of curing.

- If using hydrated lime as a binder, ensure that it has at least 90% calcium content.[2]

Video

Related Pages

- Lime and Hemp

- Biocomposite

- various pages on compressed earth blocks