Molten Salt Flash Pyrolysis Biomass Reactor

Basics

- A Process Using Molten Salt to Heat and Pyrolyse Waste

- More industrial than other methods due to complexity

- Can be used for Bio-Oil / Syngas / Charcoal / Clinker Co-Production , although it is optimised for Bio-Oil production typically

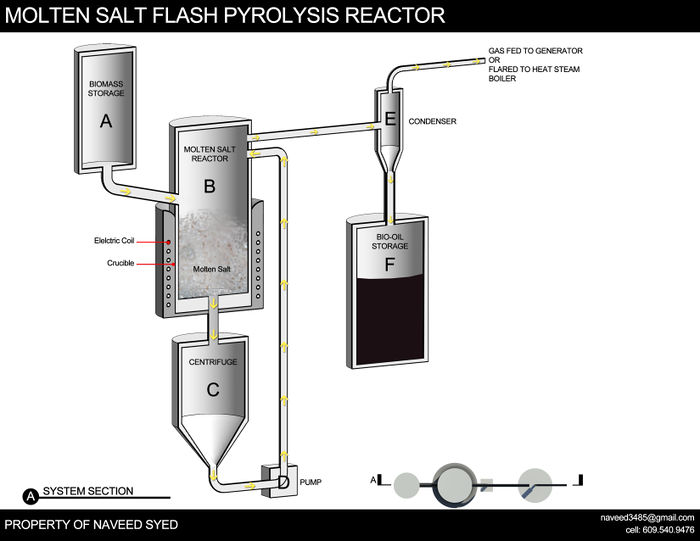

Diagram on the Process

Flash Pyrolysis Biomass Reactor By: Naveed Syed (naveed3485@gmail.com, 609 540 9476)

Flash pyrolysis is used primarily to yield a higher Bio-Oil output and Syngas and Charcoal outputs. The Molten Salt Flash Pyrolysis Reactor will use Molten Salt at a temp of 450-550C to gain optimum bio-oil yields.

A: The biomass will be a closed container and will feed the biomass into the molten salt. Variations in design: The feeding system can use a screw feed or an air feed system. The biomass will have to be very fine, under 1mm in size. If need be, nitrogen can be used to keep the oxygen levels low, but it may not be necessary. Variation in design: The biomass can be fed and injected underneath the molten salt or over top. If the biomass uses a screw feed and it places the biomass on the surface of the salt, then a cyclone effect or blender mechanism must be added. This will ensure that all the biomass is quickly brought underneath the molten salt and ensures the highest possible bio-oil yield due to quick reaction times.

B: Reactor with Electric heating coils- the molten salt will be placed in a sealed, insulated, and coil lined electric heater. This will ensure less heat loss and digital control over temperature.

C: When the biomass is added, the container will begin to fill due to the added volume. Most of this will be small particles of char. At timed intervals, an electronically controlled valve will open and release the molten salt. If the reactor is much larger than this will be done over longer intervals. The released molten salt will run through a high heat, high speed centrifuge. Because the salt is liquid it will separate in the centrifuge with the char. The char solids will collect in the centrifuge while the liquid salt flows down the pipe

D: A high heat pump will pump the salt and inject it back in the reactor.

E: The vapors will rise through the tube at the top of the molten salt reactor. The vapors will condense using either air or water as a cooling agent.

F: After the gas is condensed to oil it will be collected in a storage drum. The remaining gas that could not be condensed can be run in a generator maximizing overall efficiency of the system

Pyrolysis Reactor for Waste Disposal

This same reactor can be used for waste pyrolysis. There are a couple variations. The temperature of the furnace will be much higher, over 1000 degree Celsius. Particle size is not much of an issue because reaction time is not important. The smaller sizes should result in quicker pyrolysis. The main component out of this high heat pyrolysis system will be gas, char, and very little oil. The other components will remain similar. Variations can be made in feeding speed and temperatures to gain desirable output.

Garbage, plastics, papers, tire wastes, animal wastes, sewage waste (reasonably dry), etc. Above are the different items that we can turn into char and also keep the landfills clean. The system should be efficient enough to create surplus electricity once continuously fed with these items.

Flow rates, feed size, temp for optimum oil yields, etc will be determined when a prototype is built.

Possible Workflows

"Dry" workflow

Waste Initial Dehydraation

- Waste is left in an Evaporation Pond or is spread on sheets etc to roughly dry it

Shredding + Grinding

- Depending on size and composition of the material at this point, it is then either shredded, then ground, or ground directly

- This can be done with a Hammermill , a Ball Mill , an Autogenous Mill, or some similar device

Use

- It can be sent into the reactor in this powdered form or be pelletized then used in that form

"Wet" workflow

Shredding/Grinding

- The wet/damp material is either piped into, or directly dumped into, a Wet Waste Grinder Often known as "kitchen garbage disposals" in smaller forms

- This may require a Shredder phase if large materials are present

Drying

- A Conveyor Dryer and a mill of some sort to repowderise the output, or a Spray Dryer are used to produce the final feedstock

- This is then fed by an auger, conveyor, or Pnuematic Conveyor to the main reactor

Internal Links

External Links

- The Wikipedia Page on Molten Salt Oxidation **This seems to be more waste managment based, but same concept