Paul Neelands Log

Great work. Latest on Top, please

Sun Feb 21, 2021

Sat Aug 3, 2013

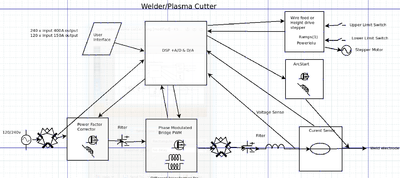

Welder/Plasma Cutter

CNC Torch Table Critical Path

Paul will move forward on Height Controller materials order on Aug 12, Marcin will ship a RAMPS board to Paul for testing.

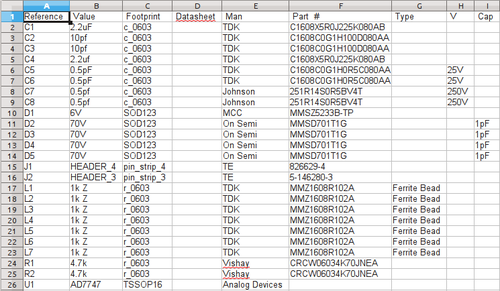

BOM

Order link from Mouser - [1]. Note - zener diode has been replaced with one that is in stock in this order, as the one in the table below was out of stock.

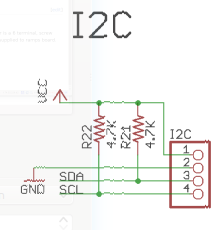

Point: I2C connector is available on RAMPS. Use pullup resistors on it, and we can use it. Found capacitive sensor.

This is an open source version with a simple metal capacitive sensor ring - self-fabricated. The Cypress capacitive sensor is designed for touch keyboards - way too much overkill. AD7747 Capacitive sensor chip - metal plate that we cut needs to be grounded. The sensor sends a 30kHz square wave at 2.5-3V - and senses attenuation of the wave. It has a shielded cable output to negate noise pickup of sense terminal.

To shield Arduino or RAMPS, needs Capacitive Decouplling.

Comment on Analog Devices AD7747 vs Cypress PSoC4: AD7747 has higher-performance (24-bit) capacitance converter, just one channel, costs ~$10 @ 10pcs; PSoC4 has less resolution (16-bit), can scan lots of channels (scan time may slow down system response), includes a full microprocessor, bigger package, ~$3.50 @ 10pcs. PSoC4 requires programming; it could be programmed as I2C slave and approximately emulate AD7747 if backwards compatibility needed. ChuckH (talk) 03:57, 13 August 2013 (CEST)

Circuit Order

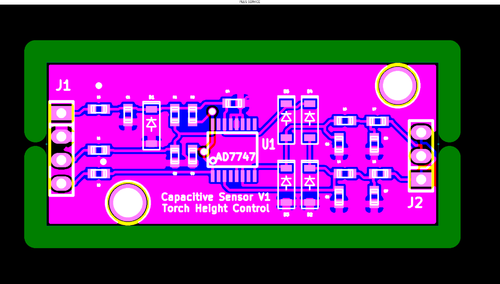

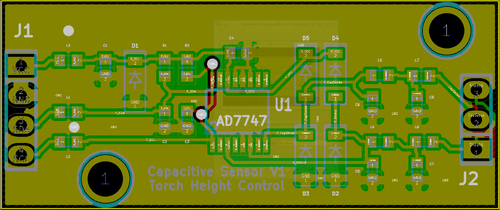

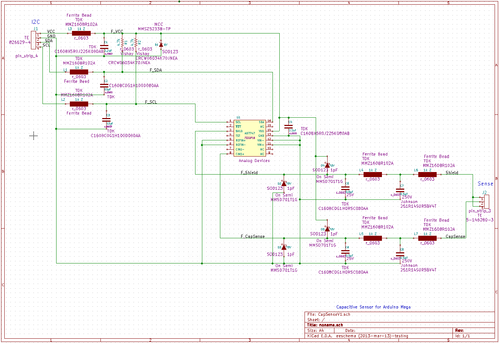

Based on Paul Log - here is height controller, using the Capacitive to Digital Converter chip AD7747

Hello Anthony/Marcin,

Thank you for your order, please confirm you require our Plus Service for "Open Source ecology" as your data included solder masking and a top legend, however you requested our Basic Service which does not include these options. Your two PCB order with out Plus Service as shown in the attached image file is $21.96 US before shipping handling and taxes on a three business day turn. We require your confirmation of Service Type to proceed with manufacturing.

Best Regards, Support

We are holding your order until we will receive authorization to proceed or we receive your layout modifications.

Please review the attached JPG(s) and advise us how to proceed. Red is Top layer, Blue is Bottom layer, and Green is Drill locations. Note: Bright White pad locations indicate plated hole locations.

When regenerating new data please send a complete zip package containing: Gerber files, apertures if necessary, NC drill file, tool list, and an order form to support@apcircuits.com referencing your original order number.

Should you have any additional questions, or require additional data, please contact us, at your earliest convenience.

Thank you.

AP Circuits (403)250-3406 (403)250-3465 Fax support@apcircuits.com

Tue Jul 30, 2013

Capacitive Height Sensor 30 July

The Ramps 1.4 board contains an unused I2C connector with pullup resistors. This will interface nicely with the AD7747 capacitive sense chip which also has an I2C interface. Pinout for the I2C connector on the Ramps 1.4 board is: .

.

The capacitive sensor board will need to be mounted on or near the torch with the capacitive sensor pickup ring surrounding the torch tip. A long 4 conductor flat flex cable extends from the I2C connector J1 on the capacitive sensor board to the I2C connector on the Ramps 1.4 board. A short (~6 in.) low capacitance shielded cable (RG6U Cable) extends from the capacitive sense input to the sensor ring. The shield of this cable connects to the Shield terminal of J2 pin 1 or 3, the inner conductor connects to the CapSense terminal of J2 pin 2. This board has been designed to withstand considerable noise. For plasma cutting additional ferrite will have to be added to the cables and to the entrance and exit of the metal board housing. Board dimensions 0.7" x 1.675". Mounting 2 times 4-40 nylon screws. PCB price estimate from AP Circuits $37 for 3 boards, $21 for 1 board (31 July 2013).

Capacitive Sensor board Schematic:

Gerber Package:File:CapSenseV1Gbr.zip

Kicad SCH:File:CapSenseV1.sch

Kicad PCB:File:CapSenseV1.kicad pcb

Kicad Parts:File:CapSenseV1Parts.zip

Sat Jul 27, 2013

MatCAD (closed source calculation) - KiCAD for electronics - of Capacitive Height Sensor. Module - CNC Torch Height Control

Mon Jul 15, 2013

Plasma/Acetylene Cutter

Ramps 1.4 Heater circuit to be used for oxygen solenoid. Connector is a 6 terminal, screw terminal block. Solenoid voltage must be same as stepper voltage supplied to ramps board. Typically 12 or 24 volts DC.

Stepper motors are 425 oz.in 4 volt 2.8 amp. This exceeds the 1-1.5A capability of the ramps Pololu drivers. Decision has been made to use the Powerlolu board at [2] Open source schematic seems ok(Eagle format). Correction: Powerlolu is NC, not open source. Board file seems unfinished. Powerlolu drive capability is 10A. Media:Powerlolu_web_preview_featured.jpg The board is commercially available at [3] This board does not directly attach to the Ramps board, but uses 4 wires to attach to one of the sockets that the Pololu board plugs into on the ramps board also commercially available. Note #1 - This is not very mechanically or electrically stable. Note #2 - The Powerlolu board is current limited but not fused. The power supply to the board should have an inline fuse no greater than 10A. To set the driver current limit see [4]. Stepper motor connects to Powerlolu via two screw terminal blocks.

Use a seperate Arduino Mega for the height control system. Requires a seperate Ramps & Powerlolu board for the z-axis stepper. Requires a custom software sketch in the Arduino to connect Ramps to the capacitive height sensor, or could be prototyped with the $70 eval board. Requires some pushbuttons for jog up/down and engage/disengage height feedback. With some custom g or m codes and a serial line between the two Arduinos the attached pc could jog the z-axis and engage/disengage feedback instead.

Note - Changing from an ultrasonic to a capacitive height sensor relieves the timing constraints considerably. I now think a single Arduino system will work.

Capacitive Height Sensor

A suitable height sensor would be the Omron E2K-C available from Mouser for about $167. Interface is open collector npn transistor. (wire) Alternatively Analog Devices have a suitable capacitive sensor chip AD7747 for $11. This would require a fairly simple pcb to be a height sensor, or could be prototyped with the $70 eval board. A 2x2cm. sensor area at a distance of 0.5cm gives 0.7pF scaling linearly with height. This is well within the range of the AD7747 which has a noise level of less than 100 aF and a maximum sense range of 8 pf. Would require a more complex sketch than the E2K-C but still fairly easy. The interface is I2C which is compatible with the Arduino.

Both of these sensors will require the z-axis controller to back off vertically then go down until the sensor (sees) the metal to establish a calibration point. Since th E2K-C is strictly on/off, the height following is going to be more noisy or oscillatory (hysteris unspecified) than the AD7747 which returns actual capacitance values which enables close tracking. Both of these sensors wiil requre shielding for a plasma cutter and its induced field. Omron also have an electric field based sensor good for iron and aluminum in the $450 range. All sensors require the metal object to be grounded and sense different distances if the ground is removed.

Welder Plasma Cutter Block Diagram

Laser Cutter

Diode electrical power 14*2.5 = 35 watts

ThermoElectricCooler(TEC) Power 6*9.8 = 58.8 watts

Total Power 35+58.8 = 93.8 watts

Diode Max Operating T 30C

TEC Delta T unknown

Recomended heat sink 35 watts

This is confusing. Heat sinks are normally specified in terms of watts per degree C, not watts. 35 watts/degree C is a very large heat sink. If it is really this high, I would recommend water cooling.