Polylactic acid/Manufacturing Instructions

Overview

An overview of the current vision of the process and open questions is File:Materials and protocol rough draft.doc

Lactic acid fermentation

Lactic acid production by microorganism fermentation can be performed by many different organisms and conducted in a variety of anaerobic growth conditions. Optimized production instructions will be produced for microorganisms utilized by collaborators based upon their experience. It is currently proposed to use Bacillus coagulans in a bioreactor for a variety of advantages and high yield.

Inoculation

1. Inoculate 5 ml of LB media with Bacillus coagulans and grow overnight at 55 C.

2. Centrifuge overnight culture at 4000 rpm for 5 minutes and inoculate 50 ml LB with pellet.

3. Grow for 8 hours and inoculate 1 liter for overnight growth. Grow at 55 C overnight.

Fermentation

1. Fill fermentor with desired amount of feedstock material and raise temperature to 55.

2. Inoculate fermentor with 1 l overnight culture.

3. Establish anaerobic conditions and log phase cell growth.

4. Monitor pH, OD, and DO.

Lactic acid purification

1. Start purification pump when the pH drops below 6.5.

2. Collect microfiltered fermentor broth (MFB) in sterile 2 liter flask and maintain at 37 C. Recycle cell dense retentate back to fermentor.

3. When sufficient volume is achieved start nanofiltration. Recycle sugar dense retentate back to fermentor.

4. Analysis of nanofiltered lactic acid for purity.

5. Further purification via electrodialysis.

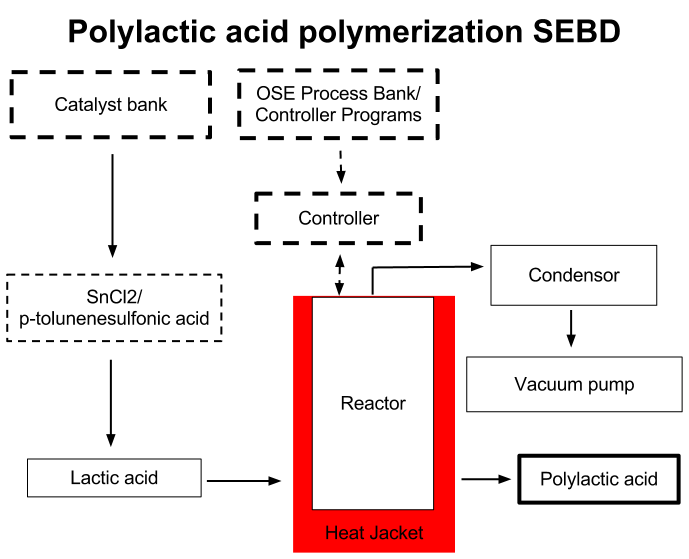

Two-step polymerization

The improved method developed by Zhang and Wang will serve as a model for polylactic acid production due to its ability to produce high weight polymers, use of a limited number of relatively easily acquired materials, and detailed understanding of the physical process underway. The process first uses an protonic acid solvent and tin catalyst under vacuum dehydration to produce moderate weight polylactic acid by melt polycondensation. A finishing step uses the addition of a second small amount of the protonic acid. The process is expected to yield polymers of 100+ kDa. The product will most likely need to be mixed with a plasticizer, such as glycerol, and can then be thermomolded.

Catalyst and reagents preparation

L(+)lactic acid may be filtered through 3-4 A sieves or distilled to remove water in preparation for direct polymerization.

Reactor configuration

1. The reactor is placed in an insulated temperature jacket to control the reaction temperature.

2. The reactor is connected to a reflux condenser and a vacuum pump.

Polymerization reaction protocol

First step melt polycondensation

1. The reactor is filled with 400 g 90% L(+)-lactic acid, and catalysts (wt%) 0.5% SnCl2·2H2O and 0.4% p-toulenesulfonic acid monohydrate (TSA).

2. The reactor is heated to 150°C for 4 h, then 160°C for 4 h and the pressure is stepwise reduced to 500 Pa.

3. Water is removed through the condenser and a medium weight (50 kDa) product is obtained.

Second step solid polycondensation

4. After the 8 hr melt polycondensation reaction is completed the reflux condensor is removed (as only a small amount of water will be produced).

5. To complete the polymerization 0.4% (wt% of starting lactic acid) TSA is added to the reactor. The temperature is further increased to 180 C and the pressure reduced to 300 Pa for 10 hrs.

6. The polymerization product is then dried under nitrogen.

Comments

I believe the reaction would work and it does seem fairly straight forward. For me hardware is the more challenging aspect, and needs a heated vacuum.

I haven't kept up on the latest developments on PLA production, but the condensation reaction relies on removing water, usually by heat and vacuum. The main issue is how L- or D- lactic acid polymerize differently, and then racemerization during the reaction.

The original proposal was to purchase high-grade reagents to tweak the reaction condition and then see what happens with more commodity materials. To experiment I would use pure D- and L- (if they weren't prohibitively expensive), and DL.

The production of lactic acid is separate step, using fermentation and then purification. With a robust polymerization reaction, the hope would be lower tier lactic acid could be used.

How "Hard" of a vacuum is needed, would a simple vacuum pump work, or would something more complex be needed (turbopumps were the next level up i think? (you probably dealt a lot wit this with plasma research at uni) )

Do we have any glassware? It would be small batches, but would a "boiling/round" flask in a water/oil/heating mantle be enough? (quick research says for 15-100 USD you could get a 1-5 liter borosilicate glass round boiling flask)

For the bioreactor, any way to make somthing continous, or will this be a batch bioreactor? Tank with media broth, dripper/small arduino pump, grow tank, then small gradual withdrawl, and returning what doesn't filter?

For low level, the "homebrew" hobby pages etc may be a good place to work, as it is a similar concept. 5gal bucket with 3d printed fittings? should be a good place to start?

Also would be a good excuse to make that data logger, and probes, for monitoring the bioreactor'

--Eric (talk) 19:40, 12 April 2020 (UTC)