Steam Engine Design/Boiler

Main > Energy > Steam Engine

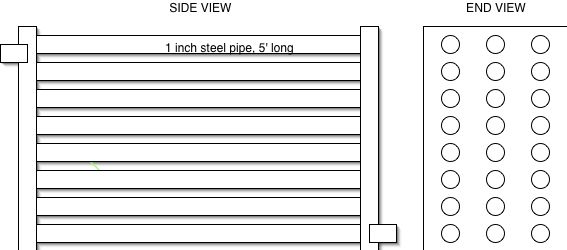

Boiler

A simple boiler implementation involves a Babington_Burner heating the inside of a 6 inch metal pipe of 1/8" wall thickness. A 100 foot long coil of 1/2 inch steel tubing is placed inside this coil, and an electronically-controlled Valve delivery system (note: in steam engine case, the 'solar boiler' in last link is replaced by the above 100-foot coil of steel tubing.

Design Rationale

- Easy to fabricate

- Welds around each tube - 48 welds

- Tubes stick through end plate for welding

- End plates covers are welded on afterwards

- 40 square foot area, sufficient for 8 hp steam engine?

Review

By VK Desai of Tinytechindia.com:

Not perfect idea. Flue gas path not shown. Boiler cover not shown. 40 sq feet enough for 4 hp steam engine.

Materials

- Stainless steel tubing at McMaster Carr, $130 for 100 feet of 1/2" tubing - type 304 stainless - item number 8989K67 at http://mcmaster.com

- 200 psi pressure relief valve http://www.grainger.com/Grainger/wwg/guideBrowse.shtml $60.80.

Boiler Fuel:

For transportation vehicles some biomass fuel energy densification is required. Pyrolisis fuels without elaborate processing look promising here is a brief summary of some methods http://www.ars.usda.gov/sp2UserFiles/Program/307/biomasstoDiesel/RobertBrown&JenniferHolmgrenpresentationslides.pdf

http://www.biomasscombustion.com/horizontal_grate_technology.htm

Stationary applications can probably get by with a simple style grate biomass boiler. http://www.biomasscombustion.com/horizontal_grate_technology.htm

Flash Steam Generator

- Coil bending jig - $400

- Stainless steel coil, 150 feet - $200

- Babington fittings and metal - $100

- Dremel tool - $40

- Dremel micro drill press - $40