User:Dorkmo/Ideas/Battery

< User:Dorkmo | Ideas

Jump to navigation

Jump to search

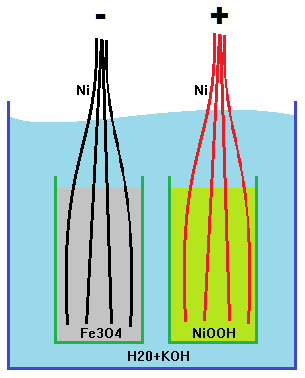

idea is to use powder contained in tubs. the walls will have a perforated mesh whos holes angle up and out so that the powder cannot escape. Nickel wires will be placed in the powder to conduct out of the cell. -Contact area is not optimal - that's why they use liquid electrolyte?-MJ

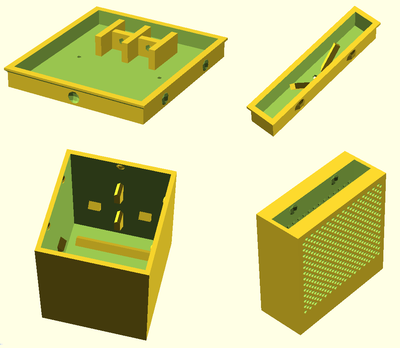

design

principles

- maximize 3d printing

- utilize parametric customization

- avoid complicated chemical processing

- no nickel plating

ideas

- powders are very likely to become airborne

- internet has suggested that "black strap molases" was added to edison batteries

- might try to mix in at different ratios to see what happens to consitency

- add a couple super capacitors to get some cold cranking amps?

- not sure if that would work but just an idea

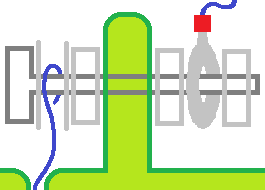

- two tubs with grid on four sides of each or shared center.

- fins for surface area.

- cages that snap in to the bottom of a tub shared by two cages.

- might use a part of a sphere for the snap in idea.

- tub lid

- tub lid will need some sort of two pole terminal block

- from cages below

- to next tub or out for use

- might need some sort of cover for uninsulated wires from cage

- vent for gas?

- tub lid will need some sort of two pole terminal block

- need to make parametric for 10 tub battery

- maybe input number of rows and columns so it can be a single row or two side by side

- might move side spacers onto cages. 3 sphere divots. 1 middle top and 2 side by side bottom, flip on opposite face. 1 or 2 on non mesh sides.

lessons learned

- 3d printing with layers most often leads to leaks

- can sometimes hold but not reliably.

- perhaps in the future print settings could be optimized

- need to use a regular plastic container for tub

- perhaps half gallon milk jug

- can sometimes hold but not reliably.

sketches

single cell separated by a grid.

File:BATTERY-idea-20141012.skp

scad work

parametric code to produce stl files for custom sized 3d prints.

User:Dorkmo/Ideas/Battery/SCAD

chemistry

KOH corrosion

- need to find out if ABS or PLA or other plastics will hold up to corrosion by the electrolyte

calculations

- nickel hydroxide Ni(OH)2

- 4.10 g/cm3

to research later

- would liked to have an info for:

- Ah/gram

- impact surface area has

- calculate AWG output based on dimensions of cage and cells

analysis

Need to find a battery analyzer.

bom

hardware

nickel, aluminum, brass?

- all thread

- bolts

- washers

- nuts

chemicals

wire

Misc

Notes

- internet sometimes suggests having 2:1 nickel hydroxide to iron ratio

- initial charge

- a few places have suggested that a short (30min) small charge happen 1 day before a full charge

- couldnt find any info on why this would be

mixes

- it is suggested to add graphite to nickel hydroxide

- internet says 17% graphite

- will try 85% nickel hydroxide 15% graphite to keep it simple

- one source said graphite is mixed into the iron

- havent seen that suggested anywhere else

- its also suggested that layers of nickel flake were used

- multiple layers were pressed with hydraulic force

- internet suggests 20-30% KOH in electrolyte

- tolerant of different amounts

version 1

- 1 cup dry Ni hydroxide powder

- 1/4 cup dry graphite powder

- then

- 1/4 cup black strap molases

- 3/16 cup water

FDM watertightness

http://www.stratasys.com/solutions/finishing-processes/sealing-fdm-parts

epoxy resin to seal surfaces

- instead use common LDPE containers?