CNC Torch Table v17.08: Difference between revisions

Jump to navigation

Jump to search

| Line 19: | Line 19: | ||

<gallery perrow=6> | <gallery perrow=6> | ||

File:CNC_Torch_1in_carriage.png|[[File:CNC Torch 1in carriage.fcstd]][[File:check.png]][[File:CNC Torch 1in carriage.stl]] | File:CNC_Torch_1in_carriage.png|[[File:CNC Torch 1in carriage.fcstd]][[File:check.png]][[File:CNC Torch 1in carriage.stl]] | ||

File:CNC_Torch_1in_carriage_metal_plate.png|[[File:CNC Torch 1in carriage metal plate.fcstd]] | File:CNC_Torch_1in_carriage_metal_plate.png|[[File:CNC Torch 1in carriage metal plate.fcstd]] + [[[[File:CNC Torch 1in carriage metal plate.stl]] | ||

File:CNC_Torch_1708_Motor_interface.png|[[File:CNC_Torch_1708_Motor_interface.fcstd]][[File:check.png]]. STL for printing - [[File:CNC_Torch_1708_motorside.stl]] | File:CNC_Torch_1708_Motor_interface.png|[[File:CNC_Torch_1708_Motor_interface.fcstd]][[File:check.png]]. STL for printing - [[File:CNC_Torch_1708_motorside.stl]] | ||

File:CNC_Torch_1708_Motor_interface_module.png|[[File:CNC_Torch_1708_Motor_interface_module.fcstd]] | File:CNC_Torch_1708_Motor_interface_module.png|[[File:CNC_Torch_1708_Motor_interface_module.fcstd]] | ||

Revision as of 04:00, 14 October 2017

- 1"_Universal_Axis deprecated

Version 3 Working Doc

Parts Library / CAD

Master

Modules / Individual Parts

File:CNC Torch 1708 Motor interface.fcstd

. STL for printing - File:CNC Torch 1708 motorside.stl

. STL for printing - File:CNC Torch 1708 motorside.stl

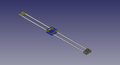

File:CNC Torch 1in carriage module.fcstd For X Axes

- Bolts.png

Frame

- CNC Torch 1708 Table.png

Rail System

Torch

Deprecated

See version history - version of October 9, 2017 and earlier - with the double length metal plates. These are not used to allow for adjustability of X axis spacing by using 2 single carriages.

Electronics

Various Pictures

====Pins from TB6600 to arduino mega for X axis:

- All 3 negatives (ENA-, DIR-, PUL-) from TB6000, bridged and connected to GRN on Arduino

- ENA+ connected to Pin38

- DIR+ to A1

- PUL+ to A0

====Pins from TB6600 to arduino mega for Y axis:

- All 3 negatives (ENA-, DIR-, PUL-) from TB6000, bridged and connected to GRN on Arduino

- ENA+ connected to PinA2

- DIR+ to A7

- PUL+ to A6