Medium-fired CEB: Difference between revisions

(inserted images) |

m (Added an internal link) |

||

| (2 intermediate revisions by one other user not shown) | |||

| Line 3: | Line 3: | ||

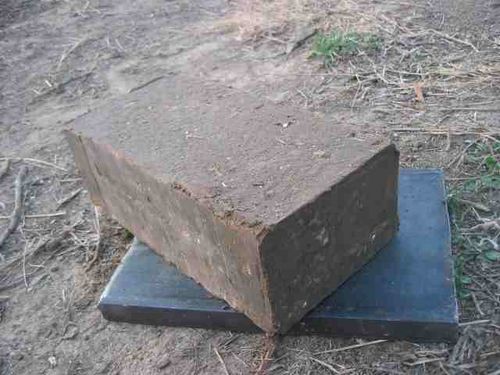

[[Image:44_cebfab.jpg |500px|thumb|Idea: fire the [[Compressed Earth Blocks|CEB]] at low to medium temperatures for (maybe) added strength and durability. ]] | [[Image:44_cebfab.jpg |500px|thumb|Idea: fire the [[Compressed Earth Blocks|CEB]] at low to medium temperatures for (maybe) added strength and durability. ]] | ||

This is a rather speculative idea but if workable, could potentially have very high impact. The idea is to '''fire a [[Compressed Earth Blocks|CEB]]''' | This is a rather speculative idea but if workable, could potentially have very high impact. The idea is to '''fire a [[Compressed Earth Blocks|CEB]]''' but at lower temperatures than a typical fired brick. This could potentially achieve some of the properties of a proper fired brick (water resistance, stability, etc.). | ||

A brief background search did not reveal whether this had been attempted. If possible, a system similar to the [[Vertical Shaft Brick Kiln|VSBK]] could be devised but would only have conduct the heat, and not require active | A conventional fired brick typically requires temperatures of about 900-1000°C and therefore has high [https://en.wikipedia.org/wiki/Embodied_energy embodied energy], even when an efficient system such as the [[Vertical Shaft Brick Kiln|VSBK]] is used. | ||

Now if a '''CEB''' is used instead of an uncompressed (i.e. “green”) brick, how would that affect the properties of the finished brick? And could the lower temperature achieve some of the same properties of a high-fired brick? Temperatures of about 500-600°C are available as “ [[Waste Heat]] ” from some thermal biomass processes, such as from [[biochar]] production. | |||

A brief background search did not reveal whether this had been attempted. If possible, a system similar to the [[Vertical Shaft Brick Kiln|VSBK]] could be devised but would only have to conduct the heat, and not require an active fire inside the kiln. This could really simplify things. Such a system would have lower requirements for the lining of the kiln (firebricks). It would likely be somewhat cheaper. The largest benefit would be that waste heat could be used (co-production). | |||

==Outlines a Research Project== | ==Outlines a Research Project== | ||

* needed: [[Compressed Earth Blocks|CEBs]] (should not contain any organic matter!) | * needed: [[Compressed Earth Blocks|CEBs]] (should not contain any organic matter!) | ||

* “bake” at different temperatures, with different time courses (length of firing). | * “bake” at different temperatures, with different time courses (length of firing). | ||

* evaluate properties of bricks ( | * evaluate properties of bricks (microstructure, strength, durability, etc.) | ||

* publish findings | * publish findings | ||

==Related Pages== | ==Related Pages== | ||

* [[Vertical Shaft Brick Kiln]] | * [[Vertical Shaft Brick Kiln]] | ||

* [[Compressed Earth Blocks]] | * [[Compressed Earth Blocks]] | ||

* [[Kon-Tiki Kiln]] (as a source of waste heat) | |||

* [[The Biochar Economy]] | |||

[[Category:Housing and construction]] | [[Category:Housing and construction]] | ||

[[Category:Materials]] | [[Category:Materials]] | ||

Latest revision as of 01:56, 10 May 2023

This is a rather speculative idea but if workable, could potentially have very high impact. The idea is to fire a CEB but at lower temperatures than a typical fired brick. This could potentially achieve some of the properties of a proper fired brick (water resistance, stability, etc.).

A conventional fired brick typically requires temperatures of about 900-1000°C and therefore has high embodied energy, even when an efficient system such as the VSBK is used.

Now if a CEB is used instead of an uncompressed (i.e. “green”) brick, how would that affect the properties of the finished brick? And could the lower temperature achieve some of the same properties of a high-fired brick? Temperatures of about 500-600°C are available as “ Waste Heat ” from some thermal biomass processes, such as from biochar production.

A brief background search did not reveal whether this had been attempted. If possible, a system similar to the VSBK could be devised but would only have to conduct the heat, and not require an active fire inside the kiln. This could really simplify things. Such a system would have lower requirements for the lining of the kiln (firebricks). It would likely be somewhat cheaper. The largest benefit would be that waste heat could be used (co-production).

Outlines a Research Project

- needed: CEBs (should not contain any organic matter!)

- “bake” at different temperatures, with different time courses (length of firing).

- evaluate properties of bricks (microstructure, strength, durability, etc.)

- publish findings

Related Pages

- Vertical Shaft Brick Kiln

- Compressed Earth Blocks

- Kon-Tiki Kiln (as a source of waste heat)

- The Biochar Economy