CEB Press/Manufacturing Instructions/Detroit Fab Lab Solenoid Driver v2: Difference between revisions

No edit summary |

No edit summary |

||

| Line 6: | Line 6: | ||

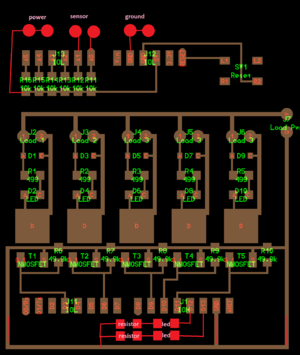

[[Image:Detroit2schematic.png|thumb|Schematic (note: v_in connection missing)]] | [[Image:Detroit2schematic.png|thumb|Schematic (note: v_in connection missing)]] | ||

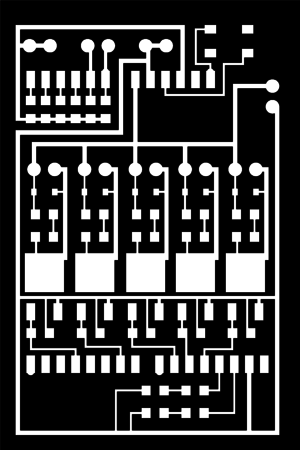

[[Image:Detroit2s.png|thumb|small version 2x3. This was done in MS Paint - a modification of initial Detroit solenoid driver board. (note: v_in connection corrected)]] | [[Image:Detroit2s.png|thumb|small version 2x3. This was done in MS Paint - a modification of initial Detroit solenoid driver board. (note: v_in connection corrected)]] | ||

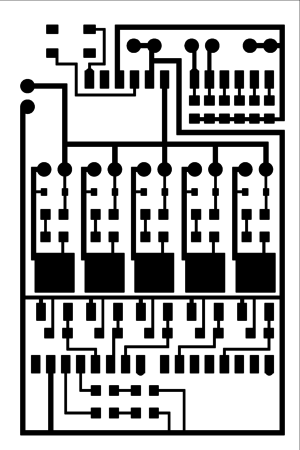

[[Image:Detroit2sprint.png|thumb|image for pcb etching. (note: v_in connection corrected)]] | [[Image:Detroit2sprint.png|thumb|image for pcb etching. This was generated by reversing black and white from the MS Paint drawing by using GIMP. (note: v_in connection corrected)]] | ||

Revision as of 19:15, 5 December 2011

Introduction

put sensor terminals on detroit board

http://opensourceecology.org/wiki/File:Detroit2print.png

http://sketchup.google.com/3dwarehouse/details?mid=10a3722997daf166b38804396e417a9b

General Processes/Circuit Etching

bug

i found a bug today. there needs to be a connection from the 12v line to the VIN pin next to the ground pin the sensors are connected to. will update drawings when i get the chance. --Dorkmo 21:37, 3 November 2011 (CET)

- k updated --Dorkmo 00:49, 12 November 2011 (CET)

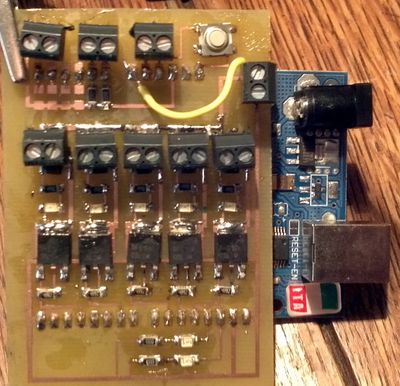

Finished Board

Note: jumper not needed, already corrected in board image for pcb etching.

Upgrades

1

Field testing at Factor e Farm in 2011 has shown that twigs and rocks can jam the soil loading drawer if these are not crushed by the scissor action of the drawer. In the case of a jam, we uploaded the CEB testing code interface to move the drawer and get it unstuck - by computer control via USB cable. This is time consuming, so the next iteration should include manual bypass toggles on the controller board itself, so the user can move the drawer manually as needed. This applies to both the primary and secondary cylinder.

To do this, a simple toggle switch such as the reset switch should be placed between the 5V power and the digital output (d9 or d10) pin corresponding to the left (ejection) motion of the secondary cylinder. This is not necessary for the main cylinder, which has 20 tons of force. This is also not necessary for the right motion of the secondary cylinder, since such motion is already present upon power cycling of the controller.

Implementation

Do we need just a connection to be closed between 5V and the d9 or d10? An?y resistors in between?

- how about a "garage door" button. if its running and you push it it will stop. push it again it goes in reverse. push it again it stops. push it again it continues along again. if we had a button that connected one of the digital channels to the ground would that be sufficient to trigger the software? we could put a button on the board or have a terminal wired to an external box button. --Dorkmo 04:15, 3 December 2011 (CET)

2

For full manual testing of hydraulics without using a control computer, 5 of these manual toggles should be applied, one for each hydraulic channel.