Aidan Williamson Log: Difference between revisions

Jump to navigation

Jump to search

(→12/1) |

|||

| (270 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{RightTOC}} | |||

{| | |||

|- | |||

|[[Special:Contributions/Aidan_Williamson|contribs]]<br/> | |||

Old Logs: | |||

*[[Aidan_Williamson_Log_2018-2020]] | |||

*[[Aidan_Williamson_Log_2015-2017]] | |||

*[[Aidan_Williamson_Log_2014]] | |||

*[[Aidan_Williamson_Log_2013]] | |||

*[[Aidan_Williamson_Log_2012]] | |||

[[ | |||

* | |||

== | || <html><iframe width="600" height="500" src="https://osedev.org/wiki/Aidan?start=9/1/2019"></iframe></html> | ||

|} | |||

=December 12, 2022= | |||

All the exterior module [[seh4cad|Cheatsheets]] I've been uploading are looking at the module from the exterior of the building which may be confusing when it's time to install electrical boxes. Probably will just stick with the scheme for the first floor and start drawing the cheatsheets from the interior for the 2nd floor. | |||

=July 20, 2021= | |||

[[Hydraulic DCV Comparison]] | |||

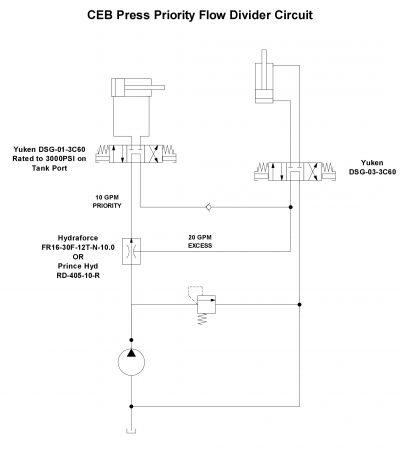

Scalable CEB Circuit. Up to 3 PowerCubes with hydraforce part. GPM numbers assume 30gpm pump. Pump can be replaced with intake manifold. Scale to 3 powercubes input. Quick disconnect one and put it on tractor. Put it back. etc. | |||

[[File:CEB_Prince_400.png|400px]] | |||

[[Category:Logs]] | |||

Latest revision as of 00:58, 3 December 2022

| contribs

|

December 12, 2022

All the exterior module Cheatsheets I've been uploading are looking at the module from the exterior of the building which may be confusing when it's time to install electrical boxes. Probably will just stick with the scheme for the first floor and start drawing the cheatsheets from the interior for the 2nd floor.

July 20, 2021

Scalable CEB Circuit. Up to 3 PowerCubes with hydraforce part. GPM numbers assume 30gpm pump. Pump can be replaced with intake manifold. Scale to 3 powercubes input. Quick disconnect one and put it on tractor. Put it back. etc.